Metasys META Air 24 Installation instructions

Kompressoren

META Air |META CAM

Gerätedokument

Einbau, Betrieb und Wartung

Compressors

META Air |META CAM

Equipment Logbook

Assembly, operation and maintenance

Compresseurs

META Air |META CAM

Livret d’appareil

Installation, fonctionnement et entretien

Compressori

META Air |META CAM

Verbale d’installazione

Montaggio, funzionamento e manutenzione

META

AIR |CAM

EN

EN

2

3. General information

The safety, reliability and performance of the appliance is

only guaranteed by METASYS if the following instructions are

observed:

Assembly, alterations or repairs may exclusively be carried out

by authorized service personnel in compliance with EN Standard

60601-1 (International Standard for Medical Electrical Apparatus, in

particular Part 1: General Rules for Safety).

The electrical installation must comply with the regulations of the IEC

(International Commission for Electrical Engineering).

The apparatus must exclusively be used in conformity with the

instructions for installation, operation and maintenance.

Only original parts may be used for repairs or replacements.

After commissioning, complete the proof of installation at the front

page of this manual and send this to METASYS in order to de ne the

warranty period.

All inspection and service work must be entered into the device

documentation at the rst pages of this manual

When requested by an authorized engineer, METASYS agrees to make

all documents available for the use of technically quali ed service

personnel.

METASYSaccepts noresponsibilityfor damages caused dueto external

factors, such as wrong installation, improper use of the apparatus or

unauthorized technical intervention.

Users must study equipment and assure themselves of its good

condition before every use.

When the complete compressor is dismantled at the end of its service

life, it must be returned to the manufacturer for orderly disposal.

1. Index

The header on each page defines the user group particular information is

aimed at.

Chapter Page

1. Index 2

2. Key to symbols 2

3. General Information 2

4. Use 3

5. Scope of delivery 3

6. Explanation of the type plate 3

7. Technical data 4

8. Functional description of the compressor 8

9. Functional description of the membrane dryer 8

10. Storage and transportation conditions 9

11. Installation guidelines 9

12. Instrument unit 10

13. Electrical connections 10

14. Preparations before rst use 11

15. Commissioning and usage 13

16. Wiring diagrams 14

17. Guarantee, service and maintenance 17

18. Decommissioning and disposal 18

19. Troubleshooting 19

2. Explanation of the pictograms

iInformation

Caution!

General warning sign

Follow instructions for use

Index Explanation of the pictograms General information

Practice personnel, technicians

1

2

3

3.1

3.3

3.5 3.63.4

3.2

3

EN

Use Scope of delivery Explanation of the type plate

Practice personnel, technicians

4. Use - intended purpose

METASYS META Air / META CAM compressors produce compressed air for

the dental treatment of patients, which complies with the high dental

standard requirements for air pressure, air ow rate, humidity, oil content

and particle contamination.

Picture 1 : META Air 150

Picture 2 : META Air 150 Light

The compressors are designed for operation in dry ventila-

ted rooms and may therefore not be operated in a damp or

wet environment.

Use of the compressors in the vicinity of gases or inamma-

ble liquids is also prohibited.

5. Scope of delivery

All META Air / META CAM compressors are shipped in a single

package consisting of a pallet plus carton. A booklet containing the

installation proof, equipment logbook and manual for installation,

operation and maintenance is included in each shipment.

6. Explanation of the type plate

Picture 3 : The type plate is located on the tting panel.

3.1 Equipment type

3.2 Mains supply data

3.3 Serial number

3.4 Address of the manufacturer

3.5 CE marking

3.6 Protection Class I

4

5

6

7

EN

4

Technical data

Practice personnel, technicians

7. Technical data

4 META Air 24

Tank capacity 24 l

Electric motor power 1,1 kW

Delivery rate 135 l/min

Dimensions (H x W x D) 600 x 430 x 400 mm

Power supply 230 V

Frequency* 50 Hz

Pressure range 5 -7 bar

Sound level 65 dB(A)

2 META Air 24 Light META Air 24s Light

Tank capacity 24 l 24 l

Electric motor power 1,1 kW 0,55 kW

Delivery rate 135 l/min 135 l/min

Dimensions (H x W x D) 600x430 x400 mm 550x400x400 mm

Power supply 230 V 230 V

Frequency* 50 Hz 50 Hz

Pressure range 5 -7 bar 5 -7 bar

Sound level 65 dB(A) 65 dB(A)

6 META Air 30

Tank capacity 40 l

Electric motor power 1,1 kW

Delivery rate 120 l/min

Dimensions (H x W x D) 770 x 710 x 410 mm

Power supply 230 V

Frequency* 50 Hz

Pressure range 5 -7 bar

Sound level 64 dB(A)

7 META Air 30 Light

Tank capacity 40 l

Electric motor power 1,1 kW

Delivery rate 135 l/min

Dimensions (H x W x D) 770 x 600 x 410 mm

Power supply 230 V

Frequency* 50 Hz

Pressure range 5 -7 bar

Sound level 64 dB(A)

* also available with 60 Hz

1

2

3

4

5

EN

Technical data

Practice personnel, technicians

7. Technical data

1 META Air 150 META CAM 150

Tank capacity 40 l 40 l

Electric motor power 1,5 kW 1,5 kW

Delivery rate 152 l/min 152 l/min

Dimensions (H x W x D) 770 x 710 x 410mm 770 x 710 x 410mm

Power supply 230 V 230 V

Frequency* 50 Hz 50 Hz

Pressure range 5-7 bar 8-10 bar

Sound level 66 dB(A) 66 dB(A)

2 META Air 250 META CAM 250

Tank capacity 40 l 40 l

Electric motor power 2,2 kW 2,2 kW

Delivery rate 225 l/min 225 l/min

Dimensions (H x W x D) 810 x 710 x 410mm 810 x 710 x 410mm

Power supply 230 V 230 V

Frequency* 50 Hz 50 Hz

Pressure range 5-7 bar 8-10 bar

Sound level 66 dB(A) 66 dB(A)

3 META Air 450 META CAM 450

Tank capacity 90 l 90 l

Electric motor power 4,4 kW 4,4 kW

Delivery rate 450 l/min 450 l/min

Dimensions (H x W x D) 820x1100x630 mm 820x1100x630 mm

Power supply 400 V 400 V

Frequency* 50 Hz 50 Hz

Pressure range 5-7 bar 8-10 bar

Sound level 68 dB(A) 6970 dB(A)

4 META Air 650 META CAM 650

Tank capacity 200 l 200 l

Electric motor power 6,6 kW 6,6 kW

Delivery rate 660 l/min 660 l/min

Dimensions (H x W x D) 900x1450x820 mm 900x1450x820 mm

Power supply 400 V 400 V

Frequency* 50 Hz 50 Hz

Pressure range 5-7 bar 8-10 bar

Sound level 72 dB(A) 72 dB(A)

* also available with 60 Hz

5

6

7

8

EN

6

Technical data

Practice personnel, technicians

7. Technical data

5 META Air 150 Light

Tank capacity 40 l

Electric motor power 1,5 kW

Delivery rate 170 l/min

Dimensions (H x W x D) 770 x 600 x 410 mm

Power supply 230 V

Frequency* 50 Hz

Pressure range 5-7 bar

Sound level 66 dB(A)

6 META Air 250 Light

Tank capacity 40 l

Electric motor power 2,2 kW

Delivery rate 250 l/min

Dimensions (H x W x D) 810 x 600 x 410 mm

Power supply 230 V

Frequency* 50 Hz

Pressure range 5-7 bar

Sound level 66 dB(A)

7 META Air 450 Light

Tank capacity 90 l

Electric motor power 4,4 kW

Delivery rate 500 l/min

Dimensions (H x W x D) 820 x 1100 x 600 mm

Power supply 400 V

Frequency* 50 Hz

Pressure range 5-7 bar

Sound level 68 dB(A)

8 META Air 650 Light

Tank capacity 90 l

Electric motor power 4,4 kW

Delivery rate 500 l/min

Dimensions (H x W x D) 820 x 1100 x 600 mm

Power supply 400 V

Frequency* 50 Hz

Pressure range 5-7 bar

Sound level 69 dB(A)

* also available with 60 Hz

1

2

3

7

EN

Technical data

Practice personnel, technicians

7. Technical data

1 META Air 900

Tank capacity 270 l

Electric motor power 11 kW

Delivery rate 780 l/min

Dimensions (H x W x D) 1030 x 1560 x 1000 mm

Power supply 400 V

Frequency* 50 Hz

Pressure range 5 - 7 bar

Sound level 75 dB(A)

2 META Air 900 Light

Tank capacity 270 l

Electric motor power 11 kW

Delivery rate 900 l/min

Dimensions (H x W x D) 1030 x 1560 x 1000 mm

Power supply 400 V

Frequency* 50 Hz

Pressure range 5 - 7 bar

Sound level 75 dB(A)

3 META Air 1300 Light

Tank capacity 500 l

Electric motor power 16,3 kW

Delivery rate 1350 l/min

Dimensions (H x W x D) 1050 x 1980 x 780 mm

Power supply 400 V

Frequency* 50 Hz

Pressure range 5 - 7 bar

Sound level 78 dB(A)

Operating time

META Air:

An operating time of 70% is possible at the specied delivery rate.

META Air Light:

An operating time of 80 % is possible at the specied delivery rate.

META CAM:

An operating time of ˂ 50% is possible at the specied delivery rate.

2

1

8

7

6

9

3

2

1

10

5

4

EN

8

8. Functional description of the compressor

See picture 1

Compressors without a membrane dryer (Light models):

The compressor power unit sucks in air from the outside through the

air intake lter 1. The air is compressed in an oil-free compression

chamber 2, then passes through a delivery hose 3and is forced

through the non-return valve 4into the pressure tank 5. The air

ow is regulated by a valve plate that allows air ow in one direction only.

Compressors with a membrane dryer:

The compressor power unit sucks in air through the air intake lter 1.

The air is compressed in an oil-free compression chamber 2, then is

forced through the cooler 6which cools down the compressed air and

thus forms condensate water.

The condensate is trapped by a 5 mµ lter 7located below the cooler.

A second 0,01 mµ lter 8blocks further water droplets to ensure high

quality, clean air. This double ltration system has a semi-automatic

drain system that empties the small lters receivers everytime pressure

is discharged.

The clean compressed air then passes through the membrane dryer 9

where residual humidity is removed and the compressed air reaches an

average dew point value of -35°C. Dry, compressed air is delivered to

the air receiver through a hose that connects the dryer to the non-return

valve 5.

The entire system is controlled by the pressure switch 10 that regulates

the ON/OFF mode of the unit. Every time the compressors reaches the cut

out pressure, it switches off and residual compressed air in the delivery

pipe system is vented out by a solenoid valve (for compressors without air

dryer) or by the membrane dryer 9- for compressors with air dryer.

9. Functional description of the membrane dryer

See picture 2

Filtered air enters the membrane dryer and water droplets are collected

on the membrane bres. While the dried air is delivered to the receiver,

a small amount of this dried air is purged back through the membrane to

sweep away the water droplets around the bers. The moisture is then

delivered to the outside through the rinsing nozzles of the membrane

dryer. Since this purge cycle is continuous, the membrane dryer can

operate without interruptions or efciency reduction.

Membrane dryers do not require any maintenance because there is no

water adsorption or adsorbing material.

Periodical maintenance needs to be performed on the double ltration

system (0,5 µm, 0,01 µm) before the membrane dryer. Filter cartridges

must be replaced once a year. Maintenance kits are available at METASYS.

Functional description: Compressor Membrane dryer

Practice personnel, technicians

3

4

9

EN

10. Storage and transportation conditions

The compressor is dispatched by the manufacturer in a carton on a

non-returnable pallet to protect the appliance from damage during

transportation. Wherever possible, the original packaging should always

be used for transportation. Therefore it is advised to keep the original

packaging.

During transportation the compressor must be protected from moisture,

dirt and extreme temperatures. The packaged compressors must be stored

in a dry place to protect it from humidity (max. relative air humidity:

70%). Storage temperature must be between -10°C and +40°C.

The compressor may only be transported unpressurised.

Before it is transported, it is essential that the compressed

air from the pressure tank and pressure hoses is released

and any condensate water is drained off.

11. Installation guidelines

Unpack the compressor and check carefully to ensure that it is in perfect

condition. Assemble the support legs as supplied 3 . The compressor

may only be installed and operated in a dry, well-ventilated and low-dust

location. If there is insufcient air ow, a suction device or ventilator of

the correct dimensions must be installed. The ambient temperature must

be between +5°C and +40°C.

The motor fan ensures that the power unit is force-cooled effectively.

However, for this to happen, the air must be able to ow in and out without

obstructions. If this is not the case, a separate ventilation system must be

installed 4 .

The compressor must be installed in such a way that it is easily accessible

for operation and maintenance. The compressor must be placed on a

level oor which is sufciently robust. The compressor must not touch

any other objects due to heat development. It is not necessary to provide

a special foundation or base. The compressor may simply be placed on

a level oor. If the compressor is tted in a mounting bracket, then the

mounting bracket should not be secured to the ground. It is recommended

to attach four vibration dampers.

Storage and transportation conditions Installation guidelines

Practice personnel, technicians

1

2

3

2.3

2.2

2.4

2.1

3.1

EN

10

12. Instrument unit

The compressor is tted with an instrument unit as standard (pictures

1 and 2 . This consists of:

2.1 pressure switch

2.2 safety valve

2.3 compressed air supply

2.4 manometer

The exible delivery hose must be pushed onto a pipe connection and

secured against slippage using hose clips.

iThe exible delivery hose connecting the permanently ins-

talled compressed air pipe and the compressor prevents the

transfer of vibrations and noise.

13. Electrical connections

Connections to the mains supply may only be made by a quali ed

electrician. It must be ensured that the electrical wiring and the mains

voltage is conform with the data indicated on the type plate. A tolerance of

+/- 5% is permissible. Earthing must always be used for safety purposes.

3 The compressors must be connected to a socket which is protected

by a suitable magnetothermal switch. The socket must be easily accessible

so that the appliance can be unplugged easily from the mains supply in

the event of danger. When a compressor which is operated by three-

phase alternating current is switched on for the rst time, it is necessary

to ensure that the direction of rotation of the ventilation rotor is correct

(see arrow on housing 3.1 ).

If any electrical wires or air hoses are damaged, they must

be immediately replaced! The electrical wiring may not

touch the surfaces of the apparatus since the outer surfaces

of the compressor become hot during operation and may

thereby damage the cable insulation!

Instrument unit Electrical connections

Practice personnel, technicians

4

5

6

A

B

A

B

11

EN

14. Preparations before rst use

Before using the compressor for the rst time, it must be ensured that

all the fastenings securing the compressor for transportation have been

removed. Ensure that the compressed air lines are connected correctly.

The compressor must be connected to the mains supply in the proper

manner. Switch on the compressor at the pressure switch by rotating the

switch to position “1”.

Safety valve

The safety valve is set at 10 bar. When the compressor is ope-

rated for the rst time, the safety valve must be checked.

The safety valve may not be used to vent the pressure tank, as

this may impair the function of the safety valve.

Adjusting the pressure switch

4 / 5 / 6 The pressure switch is factory-set. If necessary,

the working pressure of the compressor may be altered at the pressure

switch.

These tasks may only be carried out by authorised technicians.

During this work the protective cover of the pressure switch

must be removed.

The adjustment can only be carried out while the unit is in use.

If problems develop with the cut-in and cut-out pressure, refer to the

following:

Screws A: Minimum pressure adjustment (cut-in) – both of them have

to be regulated at the same level. Note to regulate Max pressure, only

regulate screws A (min. pressure) because the differential pressure

is xed.

Screw B: Differential min-max pressure adjustment (cut-out) –

actually regulated at 2 bar.

The cut-in pressure is set by even adjustment of the two screws A.

Turn clockwise to increase the switch-on and anticlockwise to reduce

it.

The cut-out pressure is set by means of differential screw B (cut-in

pressure + differential = cut-out pressure). Turn clockwise to increase

the differential.

Preparations before first use

Technicians

2

1

EN

12

14. Preparations before rst use

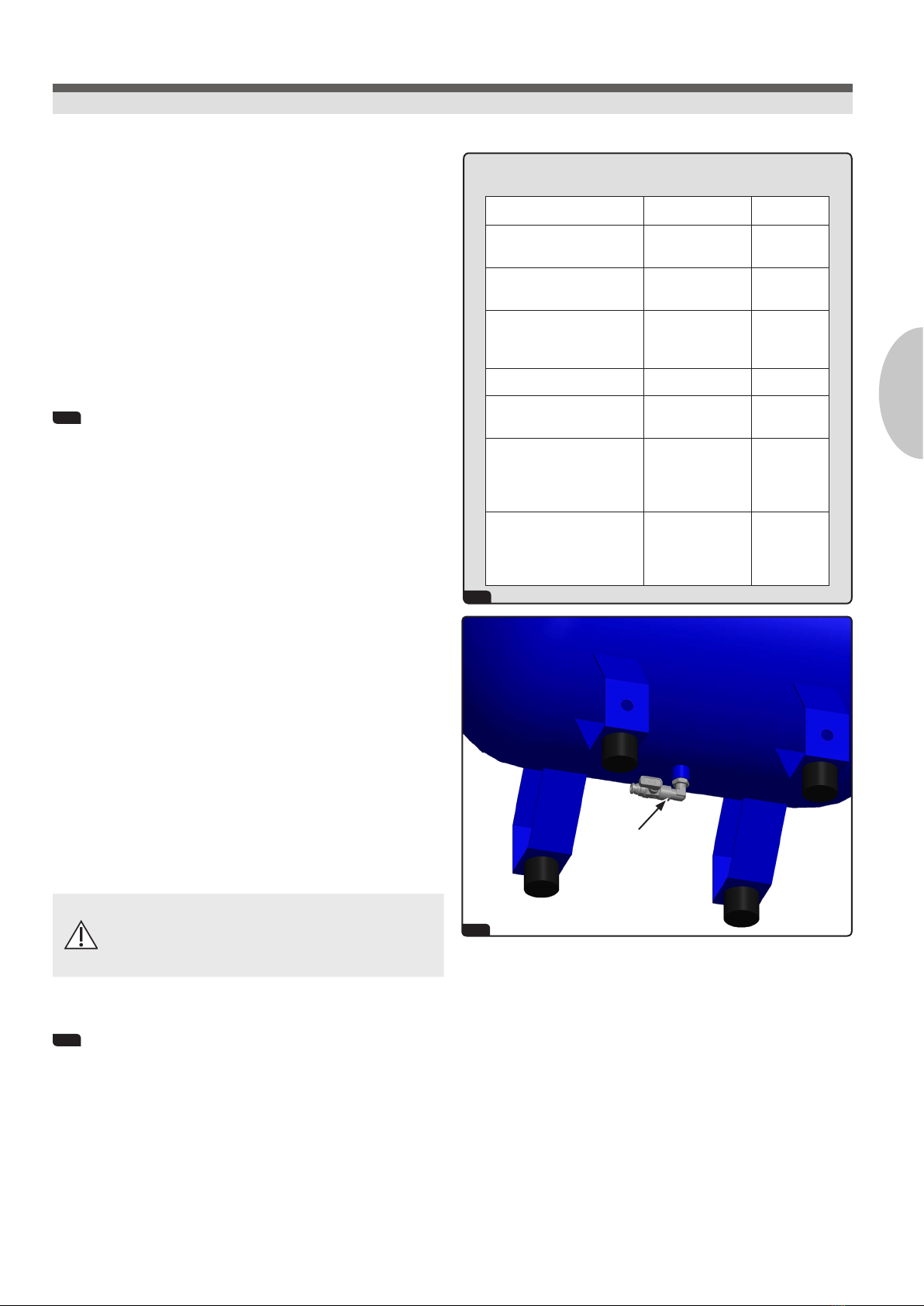

1 Draining off condensate water

During transportation, condensate may form inside the air tank because

of temperature uctuation. Each time a compressor is installed, the

condensation water must rst be drained off – also in compressors with a

membrane dryer.

Procedure:

Check for condensate in the air receiver.

Switch off the compressor and reduce pressure to 1 bar

Place a collection container under the air receiver

Open the drain valve until there is no more condensate inside the air

receiver.

Close the drain valve again.

2 Installation of the manometer

The manometers must be installed and checked for leakage.

Preparations before rst use

Technicians

3

3

META Air Light models

META Air /CAM

models

2

1

4

13

EN

15. Commissioning and usage

See picture 3

iAutomatic start-up: If the pressure in the air receiver drops,

the compressor will switch on automatically until the maxi-

mum operational pressure is reached again.

If the maximum operational pressure is exceeded,

the compressor power unit must be switched off and

disconnected from the mains (remove the power plug.)

Inform an authorised technician.

In the event of danger, disconnect the compressor from the

mains (remove the power plug). The compressor has hot

surfaces and may cause burns upon contact.

Plug in the power cable and connect the air hose (1). Turn the pressure

switch (2) to position “1”. The compressor operates fully automatic and

is controlled by the pressure switch which stops when pressure in the tank

(3) reaches the cut out pressure, allowing compressor to start again when

it reaches the cut in pressure.

The current pressure can be read on the pressure gauge (4).

Commissioning and usage

Technicians

META Air

META Air

Light META Air

Light

META Air/

META CAM

META Air

Light

*

*

META Air

META Air/

META CAM

META Air

Light

*

*

EN

14

Wiring diagrams

Technicians

* only META Air Light versions

16. Wiring diagrams

1 META Air 24 / 24 Light / 30 / 30 Light 2 META Air 24 / 24 Light / 30 / 30 Light with cover

3 META Air 150 / 150 Light / 250 / 250 Light

META CAM 150 / 250

4 META Air 150 / 150 Light / 250 / 250 Light with cover

META CAM 150 / 250 with cover

META Air

Light

META Air Light

META Air

Light META Air/META CAM

*

META Air/

META CAM

META Air/

META CAM

*

*

15

EN

Wiring diagrams

Technicians

* only META Air Light versions

16. Wiring diagrams

Legend

F fuse

P pressure switch

M1 - M2 compressor motor 1-3

W1 - W3 ventilator 1-3

EV pressure relief valve

H hour meter

KS1 - KS3 motor contactor 1

t1 - t2 timing relay 1-2

7 META Air 450 / 450 Light / META CAM 450 - 3 phases

5 META Air 150 / 150 Light / 250 / 250 Light - 3 phases

META CAM 150 / 250 - 3 phases

6 META Air 150 / 150 Light / 250 / 250 Light with cover - 3

phases META CAM 150 / 250 with cover - 3 phases

Version with

cover

*

META Air / META CAM

META Air / META CAM

META Air Light

*

EN

16

Wiring diagrams

Practice personnel, technicians

2 META Air 650 / 650 Light / META CAM 650

* only META Air Light versions

16. Wiring diagrams

1 META Air 450 / 450 Light with cover / META CAM 450 with cover

4

17

EN

17. Guarantee, Service and maintenance

Guarantee period

The guarantee terms and conditions, which you can review in the rst

pages of this manual, apply.

Guarantee claims for compressors are valid for 12 months. If required

yearly and possible 3000 or 1500 hours maintenances are done, the

guarantee period may be extended for an additional year, however

not more than 2 years. Therefore max. possible guarantee period is 36

months.

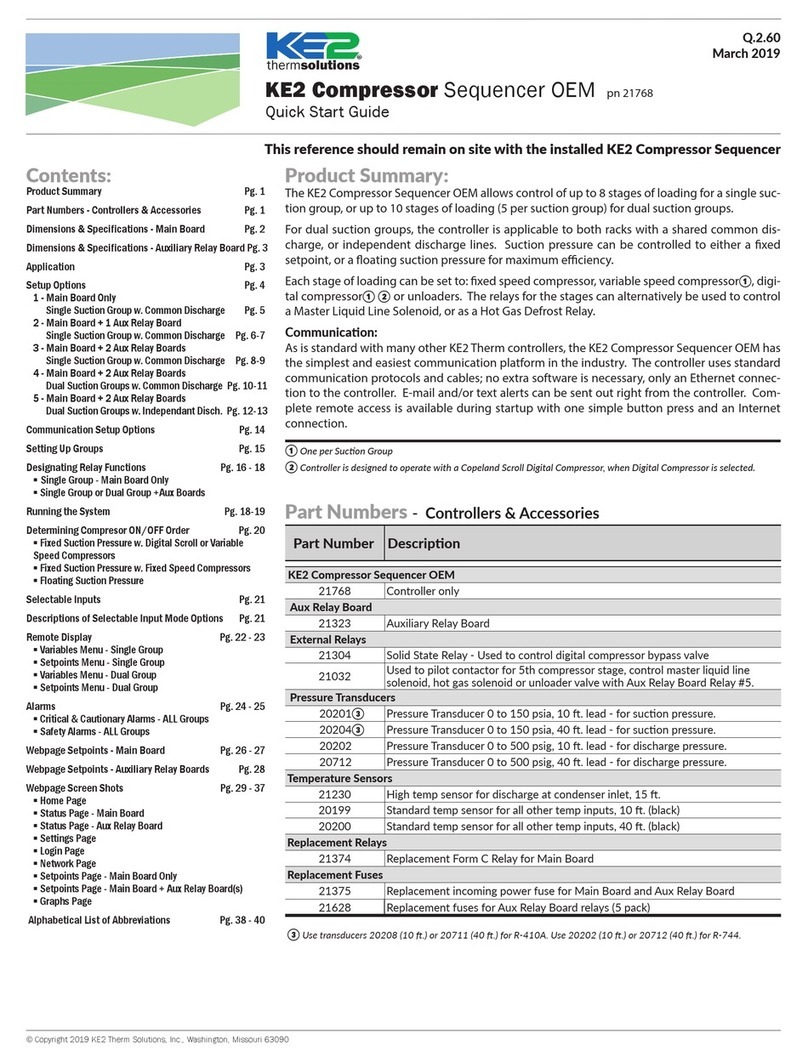

3 Service intervals

Compulsory maintenance rates have to be met precisely. The following

maintenance and inspections have to be done: yearly lter cartridge -

exchange („Filter cartridge - exchange kit“), the 3000 or 1500 hours

maintenance, depending on compressor versions, with the „3000 hours

kit + valve block (complete)“ or the „1500 hours kit 24/30 + valve block

(complete)“. The required inspections have to be registered inside this

METASYS manual on page 11. METASYS reserves to himself the right to

request those registrations to ascertain maintenance and inspection

rates.

Repair works that go beyond the normal maintenance may only be carried

out by a qualied technician or by the METSYS Technical Customer Service.

Use only the replacement parts permitted by the manufacturer and the

accessories intended for this purpose.

for the „Filter cartridge - exchange kit“, the „3000 hours kit + valve block

(complete)“ or the „1500 hours kit 24/30 + valve block (complete)“. Please

provide the module number of the aggregate and the serial number of the

compressor, which have to be maintained.

Before any maintenance or repair work is carried out, the

compressor must be switched off and unplugged from the

mains supply, and that the air tank is unpressurised (check

the pressure gauge).

4 Draining off condensate water

Condensate must be drained off every day.

Check for condensate in the air receiver

Switch off the compressor and reduce pressure to 1 bar

Place a collection container under the air receiver

Open the drain valve until there is no more condensate water inside

the air receiver

Close the drain valve again

Guarantee, Service and maintenance

Practice personnel, technicians

Service intervals

WHAT WHEN WHO

Switch off the compressor

at the end of the use

daily Practice

personnel

Drain off condensate water daily Practice

personnel

Exchange of the lters

with the „Filter cart-

ridge - exchange kit“

yearly Technician

Safety valve check yearly Technician

Check tightness of joints

Overall device examination

yearly Technician

META Air 24 / 30

(including Light versions):

„1500 hours kit 24/30 +

valve block (complete)“

after 1500 working

hours / or at least

every 2 years

Technician

META Air 150 - 1300

(including Light versions):

„3.000 h kit + valve

block (complete)“

after 3000 working

hours / or at least

every 3 years

Technician

3

4

3

2

1

4.1

EN

18

17. Service and maintenance

1 Safety valve check

Check if the safety valve functions properly during rst use of the

compressor.

Pull the ring at the top of the safety valve to check if air is vented

properly.

Safety valve must not be used to relieve air from the air

receiver! Always protect eyes from compressed air using

safety glasses!

2 Air line lter and dryer prelter cartridge replacement

Prelter and dryer prelter cartridges (0,5 µm and 0,01 µm) must be re-

placed every year.

Disconnect the compressor from the main supply

Open the air drain cock or the condensate relief from the air receiver

and relief residual pressure contained in the air receiver

Manually unscrew the lter receiver

Unscrew the cartridge as shown in the picture above and replace it with

the new cartridge

Fix again the lter receiver

iCarefully place the o-ring on the lip of the lter receiver.

Replace the o-ring as necessary.

3 Replacement and cleaning of the air intake lter

Clean the air intake lters every year with compressed air or water, or re-

place if necessary.

18. Decommissioning and disposal

Decommissioning

If the compressor is not to be used for a longer period of time, it is re-

commended to drain the condensate from the pressure tank. Then the

compressor must be operated for approx. 10 minutes with the condensate

drainage tap open. Afterwards, switch off the compressor at the pressure

switch, close the condensate drainage tap and remove the mains plug.

Disposal

After disconnecting the appliance from the mains electricity supply by

removing the mains plug, the air pressure in the pressure tank must be

released by opening the condensate drainage tap 4.1 .

When disposing of the compressor, all necessary safety precautions must

be taken in order to avoid harm to persons or objects.

Service and maintenance Decommissioning and disposal

Practice personnel, technicians

19

EN

Troubleshooting

Technicians

Problem Possible Cause Remedial action

Compressor does not start, or stops

and does not start again.

Bad connections

Blown fuse

Overload cut-out switch has tripped

Check all electrical connections. Clean and

tighten as necessary.

No tension or tension too low Check connections, verify standard line

tension.

Air receiver charged Open drain valve to expel air. Compressor

should start again when pressure reduces to 5

bar (72 psi).

Solenoid valve does not empty the delivery

pipe

Control the solenoid valve, clean or replace it.

Electric motor capacitor damaged or not

properly tted

Check the tension at the capacitor, in case of

damage replace it.

Compressor does not reach set

pressure and overheats easily.

Inlet air lter is blocked

NOTE: It is also possible that more air is

being required than compressor is capable of

delivering

Replace air intake lter.

Compressor does not build pressure or

very low performance.

Compressor valve damaged Replace the complete valve block including

gaskets.

Compressor piston ring consumed Verify compressor performance and replace

the piston rings.

Air leaking from pressure switch valve

when compressor is not running.

Faulty non-return valve First drain all air completely from receiver.

Clean or replace the non-return valve.

Air leaking from rinsing nozzle when

compressor is running (compressors

with membrane dryers).

Faulty rinsing nozzle Clean or replace the rinsing nozzle.

Air pressure from regulator does not

adjust.

Diaphragm inside regulator body is broken. Replace regulator.

Compressor operating, but no air from

outlet.

Inlet air lter blocked

Pressure regulator closed

Drain valve open

Replace oil ller/air lter plug.

Turn regulator clockwise to set required

pressure.

Close drain valve.

Electric motor cuts off during normal

operation.

Electric motor temperature probe switches off

the compressor to protect the motor

Too high temperature: Verify general

conditions.

Thermal switch stops the compressor

in standard conditions.

Thermal switch is damaged

Problem with piston rings

Electric motor damaged

Replace the thermal switch.

Check rings conditions.

Check if compressor starting is regular,

replace the motor.

19. Troubleshooting

The following descriptions for use in diagnosing faults are only intended for the use of technicians. Repairs may only be carried out by technicians!

METASYS Medizintechnik GmbH

Florianistraße 3, 6063 Rum bei Innsbruck, Austria

1 +43 512 205420 | 5 +43 512 205420 7

METASYS ... makes the difference!

2018-02 ZK-55.070/03 70100035 Druck- und Satzfehler vorbehalten! / Subject to printing and setting errors!

Visit us at:

GERMANY

+49 8823 938 44 33

FRANCE

+33 4 37 90 22 15

ITALY

+39 045 981 4477

This manual suits for next models

16

Table of contents

Other Metasys Air Compressor manuals