Metasys 5451 User manual

Fire Initiating Devices and Notification Appliances Technical Manual 408

Conventional Products Section

Technical Bulletin

Issue Date 1095

© 1995 Johnson Controls, Inc. 1

Code No. LIT-408134

Introduction Page 3

●

General Description 3

Installation Procedures 5

●

General Information 5

●

Base Selection and Wiring Installation Guidelines 5

●

Installation 7

●

Tamper-Proof Feature 8

Testing and Maintenance Procedures 9

●

Testing 9

●

Maintenance 11

●

Limitations 12

5451 Conventional Plug-In Rate-of-Rise Heat Detector

2 Conventional Products—5451 Conventional Plug-In Rate-of-Rise Heat Detector

Conventional Products—5451 Conventional Plug-In Rate-of-Rise Heat Detector 3

Introduction

This document contains important information about installing and

operating the 5451 conventional, contact-type, rate-of-rise, heat detectors.

These conventional, contact-type detectors are manufactured by System

Sensor for use with Johnson Controls systems. If you install this detector

for someone else to use, leave a copy of this document with the user.

This detector must be installed in compliance with the control panel

installation manual and meet the requirements of the authority having

jurisdiction. The National Fire Protection Association (NFPA) has

published codes, standards, and recommended practices for the installation

and use of detectors.

Before you install any rate-of-rise heat detectors, read and be familiar

with:

●the control panel system installation manual

●the requirements of the authority having jurisdiction

●NFPA-72-National Fire Alarm Code, national codes, local codes, and

any special requirements of the authority having jurisdiction

●or, for non-United States installations, applicable codes and standards

specific to country and locality of installation

●System Sensor

in the Fire Initiating Devices and Notification Appliances Technical

Manual (FAN 408), which provides detailed information on detector

spacing, placement, zoning, wiring, and special applications

!

CAUTION: Equipment hazard. Do not use in potentially

explosive atmospheres. Do not leave unused wires

exposed.

Model 5451 is a conventional, contact-type, rate-of-rise with fixed

temperature alarm heat detector utilizing a state-of-the-art dual thermistor

sensing circuit. These detectors are designed to provide open area

protection with 50 foot (1,5240 mm) spacing capability and are to be used

with compatible control panels only.

Two Light Emitting Diodes (LEDs) on each detector provide 360°

visibility of the detector indication when the detector is powered and when

it is in alarm (Figure 3).

General

Description

4 Conventional Products—5451 Conventional Plug-In Rate-of-Rise Heat Detector

The detector also has provision for the connection of an optional model

RA400Z remote annunciator. The RA400Z provides a visual indication of

an alarm in the connected detector, and mounts to a single gang box.

Table 1: Specifications Summary

Specifications

Diameter 4.1 inches (104 mm)

Height 2.1 inches (53 mm)

Weight 5 ounces (150 gm)

Installation Temperatures 32 to 100°F (0 to 38°C)

Operating Humidity Range 10 to 93%, Relative Humidity

Latching Alarm Reset by momentary power interruption

Sensitivity 135°F (57°C) Fixed or 15°F/min rate-of-rise

Standby Current 100 µA maximum

Electrical Ratings

Minimum Standby Voltage 8.5 VDC

Maximum Standby Voltage 35 VDC

Minimum Voltage Required to Operate an

Accessory 4.20 VDC

Maximum Standby Current 0.12 mA

Maximum Equivalent Capacitance 0.00002 mF

Maximum Ripple 4000 m VAC

Maximum Startup Time 34 Seconds

Minimum Alarm Current 10 mA

Maximum Alarm Current 100 mA

Minimum Reset Voltage 2.50

Maximum Reset Time 0.30 Seconds

Accessories

Flanged Base B401B

Additional Bases B402B, B404B, B406B

Remote Annunciator RA400Z

Field Sensitivity Test MOD400R

Replacement Test Magnet M02-04-00

Retrofit Replacement Flange F110

Replacement Dust Cover Dust 12

Recess Mounting Kit

(for use with B401, B401R) RMK400

Surface Mounting Kit

(for use with B401, B401R) SMK400

End-of-Line Relay for Power Supervision A77-716B

Conventional Products—5451 Conventional Plug-In Rate-of-Rise Heat Detector 5

Installation Procedures

This section contains installation information for the 5451 plug-in

rate-of-rise heat detector. Instructions are given for wiring and installing

the detector.

Refer to the plug-in detector bases technical bulletins in the Fire Initiating

Devices and Notification Appliances Technical Manual (FAN 408) for

base selection and wiring instructions.

Note: All wiring must conform to the National Electrical Code, all

applicable local codes, ordinances, and regulations, using the

proper wire size. Verify all detector bases are installed, the

initiating device circuits have been tested, and the wiring

is correct.

System Sensor has a variety of plug-in detector bases:

●2-wire applications with and without relays and/or current limiting

resistors

●4-wire 24 VDC or 120 VAC applications

All bases are provided with screw terminals for power, ground, remote

annunciator connections, and relay contact connections. The electrical

ratings for each detector-base combination are included in the base

technical bulletins.

Table 2: Bases Used with the 5451

Model

Number Version Loop

Type Current

Limit

Resistor

Alarm

Contact

Type

Nominal

Voltage Current

Draw on

Alarm

(mA)

B401B UL/ULC 2-wire* No — 12/24

VDC 10-100**

B402B UL/ULC 4-wire Yes Form-A and

Form-C 24 VDC 14-39

B404B UL/ULC 4-wire Yes Form-A,

Form-C,

and Form-A

Supervisory

120 VAC 75 mA AC

Max.

B406B UL/ULC/

EN-54 2-wire* No Form-C 24 VDC 12-100**

* Functionality contingent on panel compatibility.

** Must be limited by control panel.

General

Information

Base Selection

and Wiring

Installation

Guidelines

6 Conventional Products—5451 Conventional Plug-In Rate-of-Rise Heat Detector

The conductors used to connect smoke detectors to control panels and

accessory devices should be color-coded to reduce the likelihood of wiring

errors, and should comply with the type of wiring recommended in the

control panel’s technical manual. Incorrect connections can prevent a

system from responding properly in the event of a fire.

Note: Refer to the releasing device manufacturer’s installation instruction

for proper connections.

For Initiating Device Circuit (IDC) wiring (the wiring between

interconnected detectors), it is recommended that the wire be no smaller

than 18 American Wire Gauge (AWG) (1.0 square mm). However, the

screws and clamping plate can accommodate wire sizes up to 12 AWG

(3.3 square mm). For best system performance, the power (+) and (–)

wires should be twisted pair and installed in separate grounded conduit to

protect the IDC from other types of circuits in the system.

Smoke detectors and alarm system control panels have specifications for

allowable IDC resistance. Consult the control panel manufacturer’s

specifications for the total IDC resistance allowed for the control panel

being used before wiring the detector IDCs.

Begin electrical connections by stripping about 3/8 inch insulation from

the end of the wire (use strip gauge molded in detector base). Then, slide

the bare end of the wire under the clamping plate and tighten the clamping

plate screw.

Note: Break the wire at each terminal to ensure that the connections are

supervised--do not loop the wire under the terminals.

This Not This

wirguide

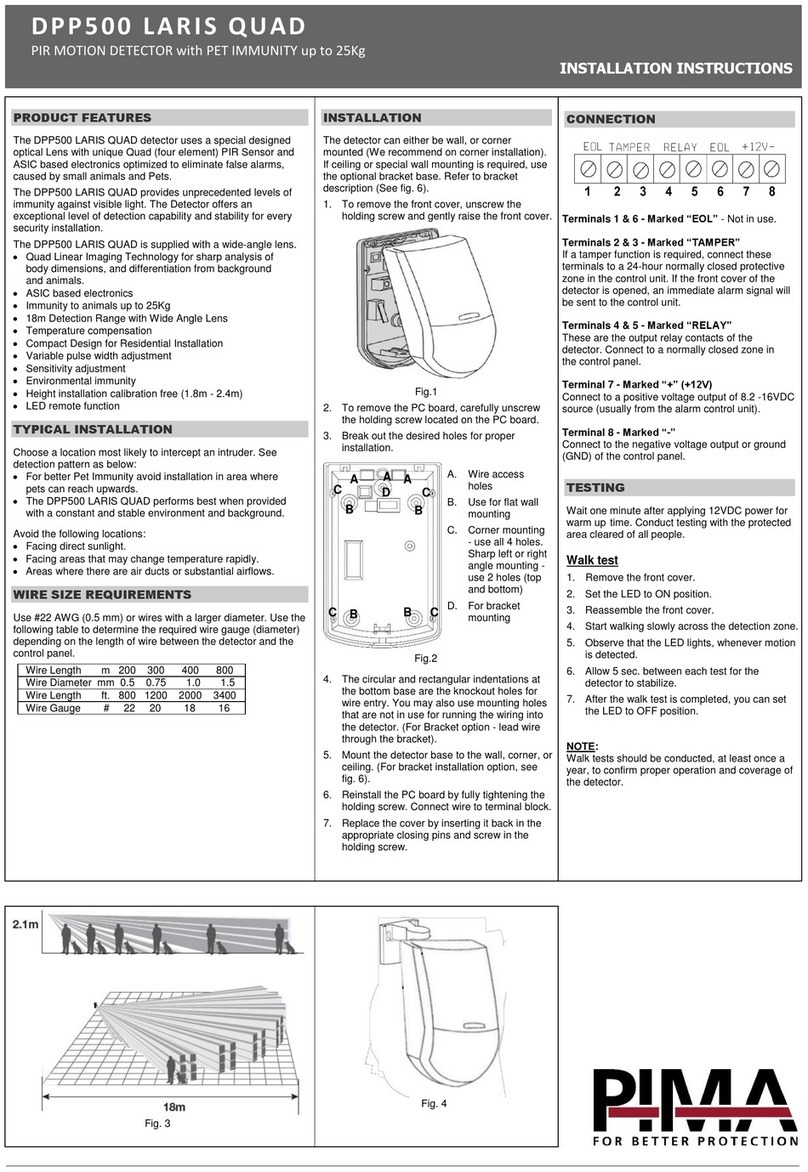

Figure 1: Electrical Connections

Contacts are shown in standby mode and will transfer in alarm condition.

The detectors are marked with a compatibility identifier located as the last

digit of a five digit code stamped on the back of the product. Connect

detectors only to compatible control units as indicated in the Device

Compatibility Technical Bulletin in the Fire Management Accessories

Manual (FAN 445).

Conventional Products—5451 Conventional Plug-In Rate-of-Rise Heat Detector 7

!

WARNING: Shock hazard. Disconnect power from the

Initiating Device Circuits (IDC) before installing

detectors.

1. Insert the detector into the detector base.

2. Turn the detector clockwise until the detector drops into place.

3. Continue turning detector clockwise to lock it in place.

4. Enable the tamper-proof feature, if used. For instructions see the

Tamper-Proof Feature section of this technical bulletin.

5. After all detectors have been installed, apply power to the control unit.

6. Test the detector using the magnet as described in the Testing section

of this technical bulletin.

7. Reset the detector at the system control panel.

8. Notify the proper authorities that the system is in operation.

Installation

Installing the

5451

8 Conventional Products—5451 Conventional Plug-In Rate-of-Rise Heat Detector

This detector includes a tamper-proof feature that prevents removal of the

detector without the use of a tool.

To make the detector tamper-proof:

1. Break off the smaller tab at the scribed line on the tamper-proof tab on

the detector mounting bracket.

2. Install the detector.

tm prprf

Plastic Lever

Break tab at

dotted line b

y

twistin

g

toward

center of base.

Figure 2: Activating the Tamper-Proof Feature

To remove the detector from the bracket once it has been made

tamper-proof:

1. Use a pocket screwdriver, or similar tool, and depress the

tamper-proof tab located in the slot on the mounting bracket.

2. Turn the detector counterclockwise until it separates from the base.

See the applicable detector base data for the location of the tamper-proof

break-off tab and the location of the tool insertion point.

After the detector has been made tamper-proof, head removal first requires

removal of the decorative ring.

remdetct

Use sm all-bladed

screwdriver to

push plastic lever

in direction of arrow.

Figure 3: Removing the Detector Head from the Base

The tamper-proof feature may be defeated by breaking and removing

the plastic lever from the base. However, this prevents using the

feature again.

Tamper-Proof

Feature

Conventional Products—5451 Conventional Plug-In Rate-of-Rise Heat Detector 9

Testing and Maintenance

Procedures

Before testing, notify the proper authorities that the smoke detection

system will be temporarily out of service while undergoing testing and

maintenance. Disable the zone, IDC, or system undergoing maintenance

to prevent unwanted alarms.

After a detector is set into alarm by one of the following test methods and

the alarm activating device is removed from the detector, the system

should be reset at the control panel before testing any additional detectors.

After testing is complete and the system is returned to its normal

configuration, notify the proper authorities that the system is again in

service.

All detectors must be tested after installation and following periodic

maintenance. Testing methods must satisfy the authority having

jurisdiction. Detectors offer maximum performance when they are tested

and maintained in compliance with National Fire Protection Association

(NFPA) 72-National Fire Alarm Code.

Before testing the detector, check to ensure that the LEDs are blinking. If

they are not, the detector has lost power (check the wiring) or it is

defective (replace or return for repair).

Test Magnet (M02-04-00)

1. Position the magnet against the cover opposite the test module socket

(Figure 2).

2. The LEDs on the detector should light within 30 seconds, and the

alarm should be reported at the control panel. If the LEDs fail to

light, check the power to the detector and the wiring in the detector

base.

3. Reset the detector at the system control panel.

Testing

Testing the 5451

10 Conventional Products—5451 Conventional Plug-In Rate-of-Rise Heat Detector

testswc6

LED

Test Module

Socket

TestMa

g

net.....

Painted

Surface

LED

Test

Magnet

Figure 4: Bottom and Side Views Showing

Position of Test Magnet

Calibrated Sensitivity Test (MOD400 or MOD400R)

The MOD400 or MOD400R is used with a Digital Multimeter (DMM) or

voltmeter to check the detector sensitivity as described in the module’s

manual.

If the detector’s sensitivity limits or the MOD400R limits do not appear on

the back of the detector, the MOD400R is not suitable for field sensitivity

testing of that unit.

Direct Heat Method (Hair Dryer of 1000 - 1500 watts)

1. From the side of the detector, direct the heat toward the detector.

Hold the heat source about 12 inches away to prevent damage to the

cover during testing.

If a detector goes into alarm, it will reset only if the detector has

cooled and if its power is momentarily interrupted.

2. Check the control panel being used to determine whether the RESET

switch (or some other auxiliary device or control) momentarily cuts

off power to the detector circuit.

Detectors that fail these tests should be cleaned as described in the

Maintenance section of this technical bulletin and retested. If the detectors

still fail these tests, they should be replaced or returned for repair.

Conventional Products—5451 Conventional Plug-In Rate-of-Rise Heat Detector 11

Before cleaning, notify the proper authorities that the system is undergoing

maintenance and will be temporarily out of service. Disable the IDC zone

or system undergoing maintenance to prevent unwanted alarms.

After maintenance and testing is complete and the system is returned to its

normal configuration, notify the proper authorities that the system is again

in service.

The 5451 detector has been designed to be as maintenance-free as

possible. Normal air-borne dust, however, can accumulate on the

detector’s sensing elements and cause them to become less sensitive. All

detectors should be tested and cleaned at least once a year, and those in

dustier areas should be tested and cleaned more often. Detectors must also

be cleaned and tested immediately after a fire.

1. Remove detector from mounting base.

2. Use a vacuum cleaner to remove dust from the sensing chamber.

3. Reinstall the detector.

4. Test the detector as described in the Testing section of this technical

bulletin.

Maintenance

Cleaning the 5451

12 Conventional Products—5451 Conventional Plug-In Rate-of-Rise Heat Detector

●Heat detectors are designed to protect property, not life. They do not

provide early warning of fire and cannot detect smoke, gas,

combustion particles, or flame. They alarm when temperatures at the

heat detector reach 135°F (57°C). The detector can also alarm on a

rate-of-rise. Given the rapid growth of certain types of fires, heat

detectors cannot be expected to provide adequate warning of fires

resulting from smoking in bed, inadequate fire protection practices,

violent explosions, escaping gas, improper storage of flammable

liquids like cleaning solvents, other safety hazards, or arson.

●Heat detectors do not always detect fires because the fire may be a

slow, smoldering low heat type (producing smoke), because they may

not be near where the fire occurs, or the heat of the fire may bypass

them. Heat detectors will not detect smoke, gas, flames, or

combustion particles.

●Heat detectors are components in professionally installed fire alarm

systems. They will not function if they have been improperly wired

into the fire alarm system or if power to them is cut off for any reason.

●Heat detectors cannot last forever. They should be tested and

maintained following the instructions in this manual. To be safe, they

should be replaced after they have been installed for 15 years.

●Refer to the NFPA 72-National Fire Alarm Code for application, or,

for non-United States installations, applicable codes and standards

specific to country and locality of installation.

Limitations

Controls Group FAN 408

507 E. Michigan Street Fire Initiating Devices and Notification Appliances Technical Manual

P.O. Box 423 Printed in U.S.A.

Milwaukee, WI 53201

Table of contents

Other Metasys Security Sensor manuals

Popular Security Sensor manuals by other brands

PCB Piezotronics

PCB Piezotronics ICP M260A01 Installation and operating manual

ADEMCO

ADEMCO 1875EX installation instructions

DMP Electronics

DMP Electronics 1166 installation guide

Robertshaw

Robertshaw 365A instruction manual

AVS Electronics

AVS Electronics WIC 4 manual

SUREN

SUREN CPL-1312 Installation, operation and specification manual