Meters UK EM606 M-Bus User manual

EM606 M-Bus

METERSUK

L

T

D

User Manual

KEY FEATURES

The EM606 is three phase kWh M-bus meter with a LCD display in a

4 module (60mm) casing, ensuring a high accuracy class (Class1)

Excellent long term stability which is designed for DIN, IEN and

EN standards and 1 year warranty.

MID B approval which ensures the meter is produced to European

and International standards and the meter is legally suited for both

business and invoicing purposes.

For connection rate of up to 950A.

s a l e s @ m e t e r s . c o . u k 0 1 5 2 4 5 5 5 9 2 9

Three Phase 4 module energy meter

METER SPECIFICATION

-25°C to +55°C

-30°C to +70°C

Performance Criteria

Operating Humidity ≤ 75%

Storage Humidity ≤ 95%

Operating Temperature

Storage Temperature

International Standard

Active Energy Meters Class 1/B IEC62053-23| EN50470-1/3

Reactive Energy Meters Class 2 IEC62053-23

Voltage, LN & LL (Phase 1,2,3) ± 0.5%

Amps (Phase 1,2,3) ± 0.5%

PF (Phase 1,2,3 & ∑) ± 0.2%

Active Power (Phase 1,2,3 & ∑) ± 0.5%

Reactive Power (Phase 1,2,3 & ∑) ± 0.5%

Apparent Power (Phase 1,2,3 & ∑) ± 0.5%

Frequency ± 0.2%

Active Energy ± 1%

Reactive Energy ± 1%

Accuracy Class 1/B

Protection against penetration of dust and water IP51

Insulating encased meter of protective class II

The mecha nica l a nd el ectroma gnetic environmenta l cla s s es B

EM606

User Manual

Specifications

Nominal Voltage (Un)

230/400V AC (3~)

Operational Voltage

161/279 - 300/520V AC (3~)

AC voltage withstand 4KV for 1 minute

Impulse voltage withstand

6KV - 1.2 µ S waveform

Basic Current (Ib) 1.5/10A

Max. (Imax) 6/100A

Starting current (Ist)

0.4% of Ib

Imin | Itr

5%Ib | 10% Ib

Over current withstand

30Imax for 0.01s

Operational frequency range

50Hz ±10% | 60Hz ±10%

Internal power consumption

≤2W /10VA per phase

Power consumption on current circuit ≤ 4VA

Test output flash rate (PULSE LED)

400, 800, 1600 or 3200imp/kWh

Test pulse output rate (pins 8 & 9)

400, 800, 1600 or 3200imp/kWh

CT Changing Ratio

27 ratios to choose

Power supply indicator (Phase A, B & C) Meter is connected. A/B/C voltage power on

Consumption indicator (Pulse & SO LED) Flashing

Communication indicator Communication symbol flashes

Data Communication port Mbus

Data Save 20 years + when power off

Dimensions

Width x Height x Depth (mm) 17.5 x 112 x 60

Weight 0.4kg (net)

M-Bus communication specifications:

Bus type

baud rate

Range

Downlink signal

Uplink signal

Cable

Protocol

Max. Number of meters

*Note that the maximum number of meters is dependent on the converter, baud rate (the higher the baud rate the smaller

the number of meters which can be used) and the circumstances under which the meters are installed.

M-bus

2400 (default)、4800, 9600

≤1000m 64PCS*

Master to slave,Voltage modulation

Slave to master,Current modulation

JYSTY (n×2×0.8)

l EN13757-3

64*

0.05Ib≤I<0.1Ib 1.0 ±1.5 1.0 ±2.5

0.1Ib≤I<Imax 1.0 ±1.0 0.5L or 0.8C ±2.0

0.1Ib≤I<0.2Ib 0.5L or 0.8C ±1.5 1.0 ±2.5

0.2Ib≤I<Imax 0.5L or 0.8C ±1.0 0.5L or 0.8C ±2.0

Current value

Power fac tor COSΦ

Error%

Power fac tor SINФ

Error %

Ac tive Class 1.0

Reac tive 2.0

BASIC ERRORS (with balanced loads)

EM606

User Manual

Register material: PC inflammable retarding

Case/Terminal Block/Cover: ABS inflammable retarding

DIMENSIONS AND INSTALLATION

110

110

90

44.86

70 70

4.5

Installation

Energy Use indicator

We recommend that the connecting wire which is used to connect the meter to the outside circuit should be sized according

to local codes and regulations for the capacity of the circuit breaker or over current device used in the circuit.

An external switch or a circuit-breaker should be installed on the inlet wire, which will be used as a disconnection device for

the meter. And there it is recommended that the switch or circuit-breaker is near the meter so that it is more convenience for

the operator. The switch or circuit-breaker should comply with the specifications of the building electrical design and all local

regulations

An external fuse or thermal cut-off which will be used as a over-current protection device for the meter must be installed on the

supply side wire, and it is recommended that the over-current protection device is near the meter so that it is more convenience

for the operator. The over-current protection device should comply with the specifications of the buildings electrical design and

all local regulations.

This meter can be installed indoor directly, or in a meter box which is waterproof outdoor, subject to local codes and regulations.

To prevent tampering, secure the meter with a padlock or a similar device.

The meter has to be installed against a wall which is fire resistant.

The meter has to be installed in a good ventilated and dry place.

The meter has to be installed in a protection box when placed in dangerous or dusty environment.

The meter can be installed and used after being tested and sealed with a letter press printing.

The meter can be installed on a 35mm DIN rail.

The meter should be installed in an available height so that it is easy to read.

When the meter is installed in an area with frequent surges due to e.q. thunderstorms, welding machines, inverters etc,

protect the meter with Surge Protection Devices.

After finishing installation, the meter must be sealed to prevent tampering.

Connection of the wires should be done as below:-

30

32

34

L1

L3

31

33

35

L2

N

Reactive pulse output contact active (-) “-”

Active pulse output contact “-”

BUS2 (Mbus)

L1 phase wire

L3 phase wire

Reactive pulse output contact active (+) “+”

Active pulse output contact “+”

BUS1 (Mbus)

L2 phase wire

Neutral wire

EM606

User ManualUser Manual

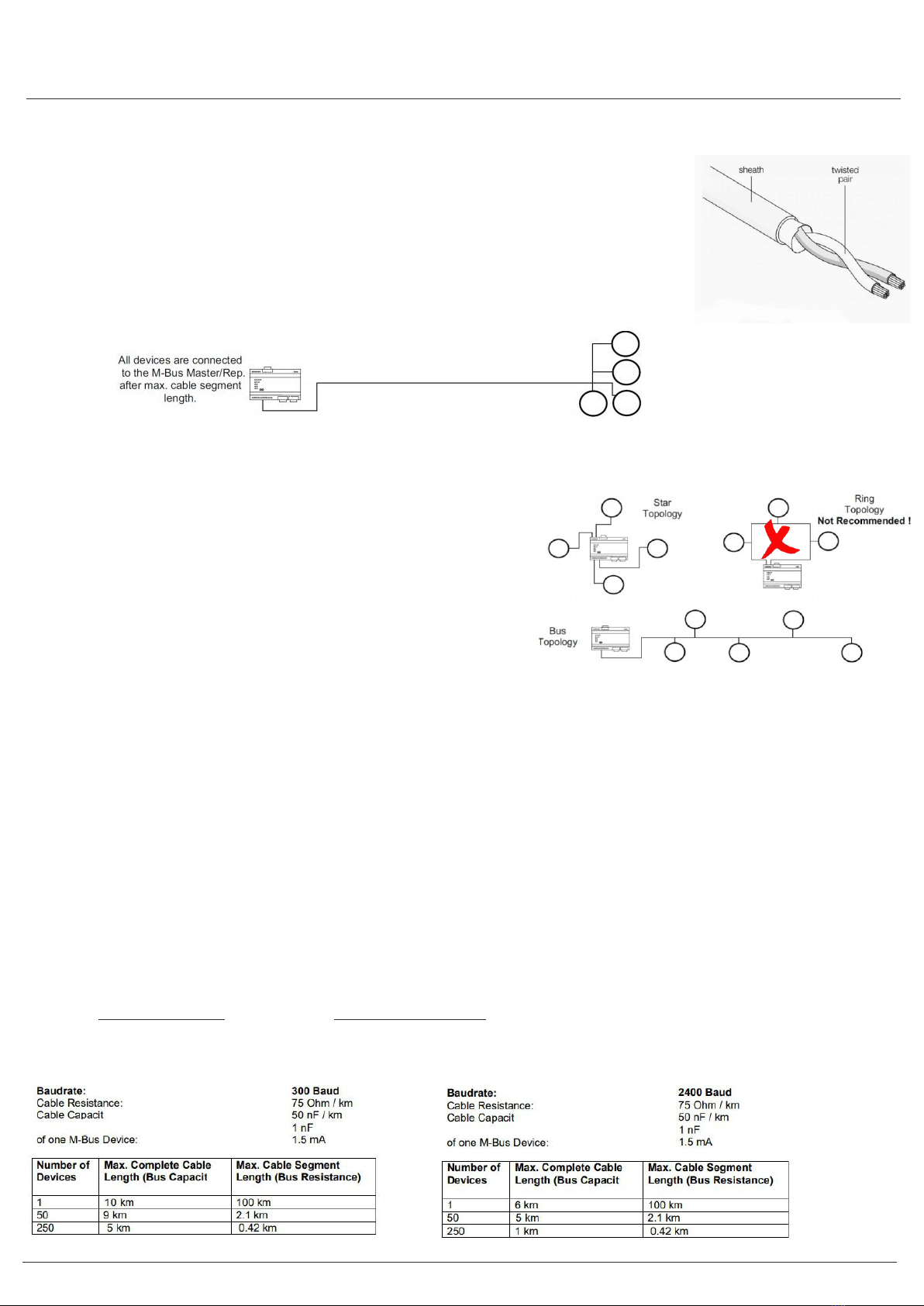

5A. TYPE OF CABLE TO USE

The M-Bus uses two wire cables which are going from the M-Bus Master / Repeater to each

M-Bus device (bus structure).

The M-Bus is polarity independent and needs no line termination resistors at the end of the cables.

Any cable type may be used as long as the cable is suitable for 36 V / 500 mA.

Shielding is not necessary and not recommended since the capacitance of the cable should be minimized.

In most cases a standard telephone cable is used which is a twisted pair wire with a diameter of 0.5 mm

each (2 x 0.8 mm is also suitable). This type of cable should be used for the main wiring.

For the wiring to the meters from the main wiring (last 1 .. 5m to the meter) a cable with smaller diameter may be used.

5B. M-BUS BASICS

The topology of the M-Bus network is (almost) arbitrary. Only the ring

topology as shown should be avoided. In general the length of the

cables should be minimized and a mixture between star and bus

topology should be used.

The limiting parameters in M-Bus networks are mainly the cable

resistance and the cable capacitance plus the capacitance of the devices

(= bus capacitance). Cable resistance will cause, a bus voltage drop.

The maximum drop may not be more than 11 V .. 12 V, as the

minimum bus voltage at any device must not be lower than

24 V (36 V – 24 V = 12 V).

The cable resistance, therefore, limits the maximum possible cable length from the MBus Master / Repeater to the device with

the largest distance away from it (largest cable segment). The cable segment length is the distance from the M-Bus Master to

the M-Bus device furthest away.

NOTE: The given maximum cable segment length takes into account only the bus resistance and not the bus capacitance.

Therefore, some of the cable lengths in the table may not be possible in reality.

The cable capacitance plus the capacitance of the M-Bus devices (= bus capacitance) is responsible for sloppy signal edges.

Therefore, the bus capacitance limits the maximum data transfer rate of the M-Bus. The M-Bus Master is able to drive approx.

0,8 µF at a baud rate of 300 baud.

5C. BAUD RATE & BIT RATES

Bit rate is a measurement of the number of data bits (that's 0's and 1's) transmitted in one second. A figure of 2400 bits per sec

means 2400 zeros or ones can be transmitted in one second, hence the abbreviation 'bps'. Baud rate by definition means the

number of times a signal in a communications channel changes state.

Common Settings for M-bus - 300 or 2400. Parity (Error Checking) is EVEN or NONE.

ALL items MUST have the same settings otherwise they CANNOT communicate.

ance:

ance:

Current capacitance of one M-Bus device:

Current capacitance of one M-Bus device:

ance)

ance)

User Manual

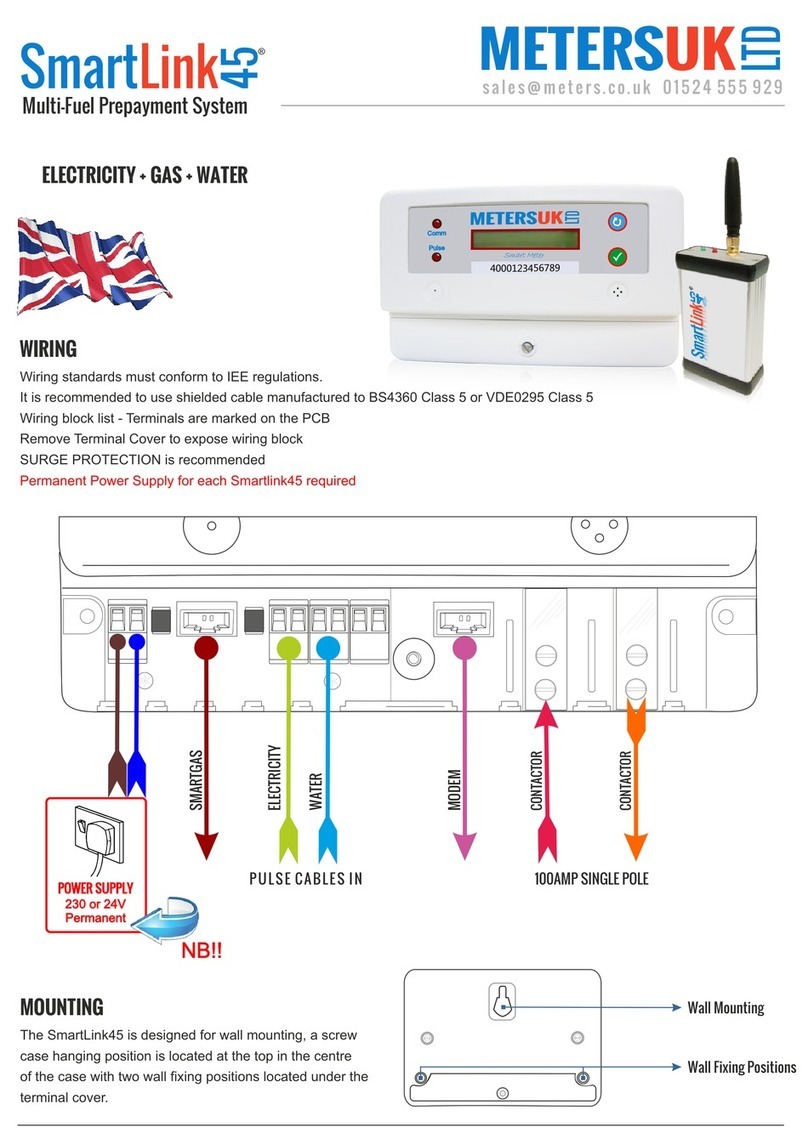

INSTALLATION DIAGRAM

EM606

LINE 1

LINE 2

LINE 3

NEUTRAL

NEUTRAL IN

28 29

27 26

30 31

25 24

32 33

23 22

34 35

21 20

L1

L1

L2

L2

L3

L3

N

N

BUS2

BUS1

SO

+

-

K

SUPPLY

L

LOAD

METER

S2 S1

Fused

3x230/400V 0,015-1,5(6)A

EN50470-3 50-60Hz 3K6

RI=3200

imp/kWh

!B

SEL

PRG M20 0122

EM-606

M-BUS

S m a r t L i n k

123456.0.0

888888.8.8

L1 230

88 88.8.8

:

User Manual

EM606

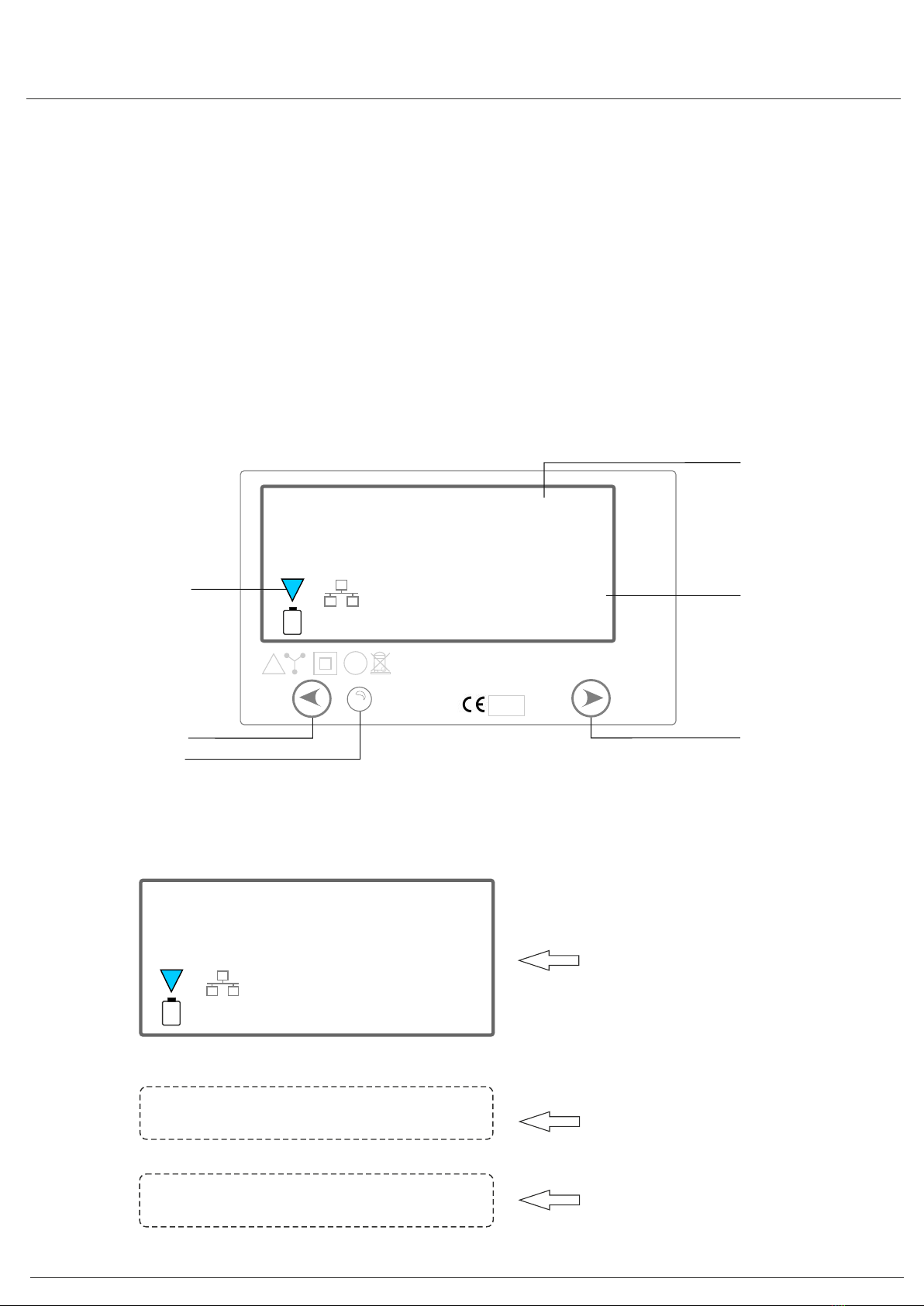

OPERATING

Energy Usage

The LCD will display L1,L2,L3,the voltage and current bearing

The other indicator is for pulse output. When electricity is used; the LED will flash red. The more quickly LED flashes, the more

energy is being used.

Reading the Meter

LCD numerical display : 8 (6 + 2). 6 digits for the sub-display items.

LCD Display

MP

EXP

Kvarh

kWh

MP

EXP

Kvarh

kWh

Hz

Kvar

KWA

MD

Hz

Kvar

KWA

Accumulated Energy

(Auto-scroll only)

V / I / P / PF / Hz /Comms

(Auto or Manual scroll)

Scroll / Select Button

Pulse Output Indicator

Phase Failure Indicator

(Negative or OV)

Config / Change Button

C 400

7fd6

The constant

The software version

Full Screen

will last for 3 sec.

User Manual

EM606

0000000.8

000000.00

0000000.8

l3 229

l1 230

l3 229

IMP

EXP

Kvarh

kWh

IMP

EXP

Kvarh

kWh

IMP

EXP

Kvarh

kWh

0000001.3

l2 230

IMP

EXP

Kvarh

kWh

Hz

Kvar

VK A

000000.00

l1 0.4

IMP

EXP

Kvarh

kWh

Hz

Kvar

KWA

000000.00

l2 230

IMP

EXP

Kvarh

kWh

Hz

Kvar

K AV

Hz

Kvar

K AW

Hz

Kvar

K AV

Hz

Kvar

KWA

Forward

Total Active kWh

Total Reactive kWh

Export

Total Active kWh

L1 Voltage

L2 Voltage L3 Voltage

000000.40

0000000.8

l2 59.6

p 6.89

000000.40

pf 1.00

MP

EXP

Kvarh

kWh

MP

EXP

Kvarh

kWh

MP

EXP

Kvarh

kWh

000000.00

l1 59.6

MP

EXP

Kvarh

kWh

Hz

Kvar

KWA

000000.40

l3 59.6

MP

EXP

Kvarh

kWh

Hz

Kvar

KWA

Hz

Kvar

KWA

Hz

Kvar

KWA

L1 Current L2 Current

L3 Current Active Power

Power Factor

000000.40

f 50

MP

EXP

Kvarh

kWh

Hz

Kvar

KWA

Frequency

000000.40

bd 2400

IMP

EXP

Kvarh

kWh

000000.40

9 0.00

IMP

EXP

Kvarh

kWh

Hz

Kvar

KVA

Hz

Kvar

KWA

Reactive Power Baud Rate

User Manual

EM606

000000.40

000000.40

000000.40

id 01

sl 0000

sH 0000

IMP

EXP

Kvarh

kWh

IMP

EXP

Kvarh

kWh

IMP

EXP

Kvarh

kWh

Hz

Kvar

KWA

Hz

Kvar

KVA

Hz

Kvar

KVA

ID Address Serial number

(high digit)

Serial number

(low digit)

Communication

Display (flashing)

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

888888.8.8

L1 59.6

MP

EXP

Kvarh

kWh

Hz

Kvar

KWA

will flash to indicate that the value of

current is negative

888888.40

L3 0

MP

EXP

Kvarh

kWh

Hz

Kvar

K AV

will flash to indicate that the value of

display is zero

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

It is used as recording consumption and can’t be reset to zero. The reading accuracy is 1/100 kWh.

Button operation:

Right button is selection , left button is program .

Button selection : one short press, lighting the backlight, then press one time show one parameter,

the order is as following: voltage of one phase, current of one phase, active power, reactive power, frequency, baud rate,

ID address, serial number, in total 13 parameters, after one minute the backlight will close automatically.

Press left button more than 3 seconds enter in code confirmation process, use right button choose the

code number then use left button change the digit place, when finish code entering use left button press more than 3 seconds

for confirmation then display show ID 01, use left button to change the display item, use right button to change the information.

The items can be settled is : 1: ID; 2: baud rate, 3: number of display item (The number of Phase voltage, phase current,

active power, reactive power, frequency, communication baud rate, ID address, serial number), 4 CT ratio setting for CT

connection meter.

Pulse output

The EM606 Series DIN rail energy meter is equipped with a pulse output which is fully separated from the inside circuit.

That generates pulses in proportion to the measured energy for accuracy testing.

User Manual

EM606

000000.0.0

L1 230

MP

EXP

Kvarh

kWh

Hz

Kvar

K AV

Display once kWh screen shown

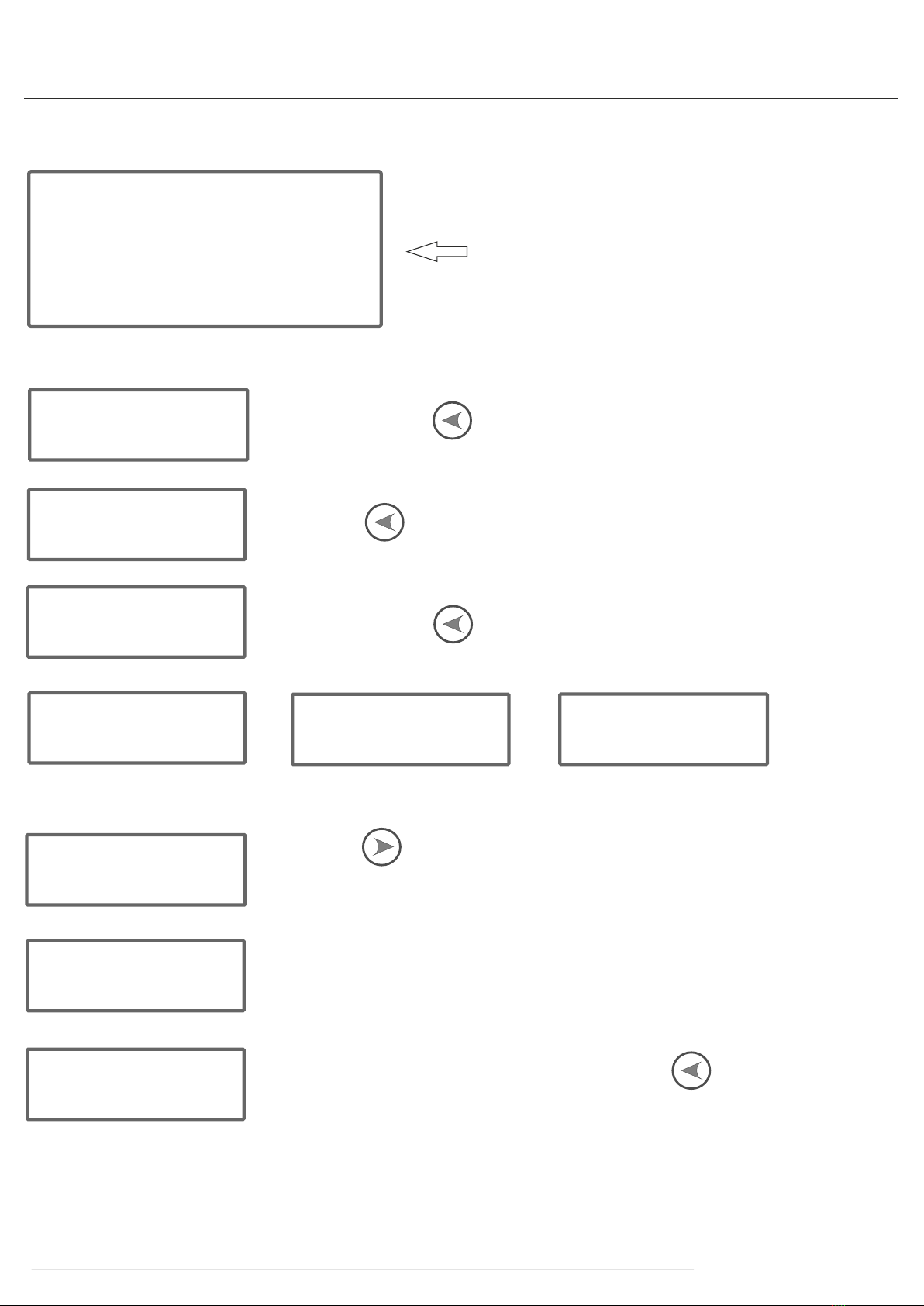

CT RATIO SETTING INSTRUCTIONS

P5 0000

Press and hold the PRG button for 5 seconds.

P5 0001

Press the SEL button once and select “1”. The password selected is 0001

Id 01

Press and hold the PRG button for 5 seconds. The ID button will display.

bd 2400 Sn oe CR 1

Cr 100

Press the SEL button for to set the CT ratios. They can be set at 27 different ratios.

(1,2,5,8,10,12,15, 16,20,24,30,40,50,60,70,80,90,100, 110,120,130,140,150,160,170,180,190)

S--500

ie. If you select CT ratio 100, it will display Ct100.

To check it, turn the meter off and then on again. The 4th screen will display 5--500.

yes

Once you have set the CT ratios, press and hold the PRG button for 5 seconds,

YES will display showing that the settings are now programmed.

Notes

1. Press and hold the SEL button to switch on the screen. The screen will automatically turned off after 1 minute.

The SEL button, when pressed, will display 14 screens: Phase Voltage (L1, L2, L3), Phase Current (L1, L2, L3), Active Power,

Power Factor, Reactive Power, Frequency, Baud Rate, ID, Serial number (high position, low position).

User Manual

EM606

2. Press on hold the PRG button for 5 seconds, the sub display to display P50000; (Press the left PRG button to select the

digit position (digit is flashing), right button to select the corresponding digit. Modify the flashing password number--long press

left PRG button 5 seconds to confirm (factory password 0001).

3. Long Press left PRG button 5 seconds to enter the settable item: 1-ID; 2-baud rate; 3-set the number of cycle display screens

(14 sub-screens); 4- CT ratio, there are 27 ratio settings (CT type default 5:5).

4. Left PRG button to select the corresponding setting item, press the right SEL button to select the sub-item under the setting

item. After all the settings are completed, long press the left PRG button 5 seconds to save the setting. The screen displays

“YES” to indicate that the setting is successful.

If the setting is in the state of automatic setting, the system defaults to the setting in this state.

QUICK PROGRAMMING GUIDE

Connect mains power to the meter –

Live to the small terminal labelled 27 at the lower left

Neutral to the large terminal labelled N at the upper right

Switch the power on and wait until the meter completes startup (after it shows the CT ratio)

Press and hold the “PRG” button for 3 seconds – the display will show “PS 0000”

Press the “SEL” button once so that the display changes to “PS 0001”

Press and hold the “PRG” button for 3 seconds to enter the password

If the password was correct (default = 0001) the meter is now in programming mode

The first item is “Id” which is the Mbus address and is in 2 digit hexadecimal format

Use “SEL” to increment the address and “PRG” to move to the next item

The next item is “bd” which is the Mbus baud rate. There are 5 possible values –

0600, 1200, 2400, 4800 & 9600

Use “SEL” to increment the baud rate and “PRG” to move to the next item

The next item is “Sn” which is the number of parameters to show on the scrolling display and is in 2 digit

hexadecimal format. The default value is “0E” but due to a software bug the maximum value that can be set when

it is altered is “0d”.

Use “SEL” to increment the value and “PRG” to move to the next item

The final item is “Cr” which is the CT ratio. This value is multiplied by 5 to give the CT current rating.

There are 27 possible values –

1, 2, 5, 8, 10, 12, 15, 16, 20, 24, 30, 40, 50, 60, 70, 80, 90,

100, 110, 120, 130, 140, 150, 160, 170, 180 & 190

Use “SEL” to increment the value

Press and hold the “PRG” button for 3 seconds to save the settings – the display will show “YES” to confirm that they

have been saved.

User Manual

EM606

s a l e s @ m e t e r s . c o . u k | W h i t e L u n d I n d u s t r i a l E s t a t e L a n c a s t e r L A 3 3 B T | 0 1 5 2 4 5 5 5 9 2 9

TROUBLE SHOOTING

The power supply

indicators are off.

(L1, L2 & L3 LED)

The register

doesn’t count.

No pulse outputs.

The pulse output rate is

incorrect Please contact technical support.

Are the fuses or/and surge protection

defect?

Make sure the wires are connected properly

and tighten the screws if possible.

Check if there is 230V AC voltage between N

and one of the L connections with a voltage

meter.

Check if there is 400V AC volt between N and

one of the L connections with a voltage meter.

If the checks above don’t solve the problem,

please contact technical support.

The meter is not connected to a

power source

L1, L2, L3 and N are not connected

correctly

There is no 230V AC between the N

and one of the L connections when

power is supplied to the meter.

There is no 400V AC between the L

connections when power is

supplied to the meter.

There is almost no load connected to

the meter.

The pulse output is not supplied with

DC power.

The pulse output is not connected

correctly.

Still no response.

Check if the (P-: red or P+: green) consumption

led is flashing. 40 flashes of the LED at 400

pulses per kWh equals 0.1kWh.

Check the external voltage source (Ui) is 5-27V

DC with a voltage meter

Check if the connection is correct: the 5-27V DC

should be connected to the collector connection

(pin 28+ or pin 30+) and the signal wire (S) to

the emitter connection (pin 29- or 31-)

Please contact technical support.

The consumption LED

is not flashing.

The pulse cable is not connected.

The load on the line is very low.

Connect the pulse cable.

Check the Ohm meter readings

No data received by the

M-Bus communication

port.

The ID is not correct.

The communication distance

is too long.

Too many meters connected.

The M-Bus terminals are not

connected correctly.

Check the Meter ID by looking for the A in the

display. The number in front of the A, for

example 15A gives the actual address the

meter uses. The default for this meter is 0A.

Make the distance between the meter and the

reading device shorter. Make sure it is no more

than ≤1000m

The number of M bus devices connected to the

meter should not exceed 64.

Make sure that the M-bus wires are connected

to terminals 34and 35. If the checks above

don’t solve the problem, please contact

technical support for a meter replacement.

Table of contents

Other Meters UK Measuring Instrument manuals

Meters UK

Meters UK SmartLink45 4000123456789 User manual

Meters UK

Meters UK SmartLink 45 User manual

Meters UK

Meters UK SmartLink 45 User manual

Meters UK

Meters UK SmartLink45 User manual

Meters UK

Meters UK 3MB100 User manual

Meters UK

Meters UK MOD3CT User manual

Meters UK

Meters UK SmartLink45 4000123456789 User manual

Popular Measuring Instrument manuals by other brands

Hach Ultra

Hach Ultra ORBISPHERE 29981 Operator's quick guide

Hantek

Hantek HT8000 Series instruction manual

Thyracont

Thyracont VD8 Series operating instructions

LOVATO ELECTRIC

LOVATO ELECTRIC DMECD installation manual

Hitachi

Hitachi EUP-L54MA instruction manual

Agilent Technologies

Agilent Technologies ESA Series Getting started guide