METIEC MT300MIX Specification sheet

HCLH/SOP-YF-072-108

Gas Monitoring Series

MT300MIX

Operation and Installation Manual

B1-MT300MIX

1

[Manufacturer]: Wuhan Huchuang Union Technology Co., Ltd.

[Production Address]: No.1 Workshop, 1F, Building B10, Wuhan Hi-Tech Medical Device Park, No. 818 Gaoxin

Avenue, East Lake Hi-Tech Development Zone, Wuhan, Hubei, China

[After-Sales Service Unit]: Wuhan Huchuang Union Technology Co., Ltd.

Date of Approval and Revision: March 1, 2021

B1-MT300MIX

2

Contents

1 Overview .................................................................................................................................................................3

1.1 Operation Instructions of Manual.................................................................................................................3

1.2 Overview ......................................................................................................................................................3

1.3 Environmental Requirements .......................................................................................................................3

1.4 Environmental Protection Instructions .........................................................................................................3

2 Structure Features and Equipment Parameters........................................................................................................4

2.1 Structure Features.........................................................................................................................................4

2.2 Equipment Parameters..................................................................................................................................6

3 Basic Operation Instructions....................................................................................................................................7

3.1 Power-On for Use.........................................................................................................................................7

3.2 Operation Instructions of Buttons.................................................................................................................8

4 Installation Instructions ........................................................................................................................................ 16

4.1 Installation Method 1................................................................................................................................. 16

4.2 Installation Method 2................................................................................................................................. 17

5 Precautions............................................................................................................................................................ 18

6 FCC Warning..................................................................................................................................................... 18

B1-MT300MIX

3

1Overview

1.1 Operation Instructions of Manual

1.1.1 It is not allowed to print or disclose any content of this Manual, including pictures and audio

products, under any name without the consent of Huchuang Union;

1.1.2 The equipment operator may copy some sections of this Operation Manual for internal use only,

such as for instructing the user how to deal with emergencies. These sections are clearly listed in

the catalogue of this manual;

1.1.3 Wuhan Huchuang Union Technology Co., Ltd. reserves the copyright of the Manual. The manual

contains the information protected by copyright laws. No part of the Manual is allowed to be

copied and sent to the users without the prior written permission of the copyright holder;

1.1.4 The contents of the Manual are subject to change without prior notice.

1.2 Overview

MT300MIX device is used to detect the concentrations of CO2and O2in premixed gas. It is generally

connected to the end of the gas path to detect the gas regularly, display the detected concentration data on the

display screen of the local machine, and upload it to the cloud server through wireless technology at the same

time.

The equipment has the function of leakage detection: When the equipment leaks, the audio and video

alarm system of the equipment can send out alarm sound and automatically close the intake valve. In order to

further ensure that the equipment does not leak, a manual valve is installed outside the equipment. If there is a

leak alarm, the user can manually close the intake valve.

The device has the low gas pressure detection function: When the gas pressure in the device is less than a

certain value, it will trigger the sound and light alarm of low pressure, reminding the user the low gas pressure.

The device is powered through the power adapter. The 1000mAh lithium battery built in the device can

only provide the power supply to the device for a short time when being disconnected from the adapter, so the

device cannot work under the condition of disconnection from the adapter for a long time; in addition, the

equipment has power failure alarm function.

When MT300MIX is installed and used for the first time, it is necessary to add the sampling frequency

(operated by professional engineers) in order to empty the excess air inside the device in a short time and

ensure the accuracy of premixed gas concentration detection.

Note:

1) The higher the sampling frequency (55 minutes by default) is, the longer the intake time will be (10 seconds

by default), and the larger the gas consumption will be.

2) The wireless transmission distance should not exceed 3 rooms.

1.3 Environmental Requirements

1.3.1 Only for indoor use, no high temperature, moisture, water or dust;

1.3.2 Atmospheric pressure: 70kPa~105kPa; Working ambient temperature: 0℃~+50℃;

1.3.3 Storage ambient temperature: 0℃~+50℃; relative humidity in the working environment: ≤80%

(non-condensing);

1.3.4 Power adapter (input: AC100V ~ 240V, 50/60Hz; output: 5V, 2.1A, 10.5W);

1.4 Environmental Protection Instructions

B1-MT300MIX

4

1.4.1 MT300MIX device contains reusable materials, and its components can be recycled after being

cleaned and sterilized.

1.4.2 During recycling and handling MT300MIX, it is recommended that the company's technical

personnel dismantle it and recycle it according to different waste groups.

1.4.3 According to national regulations, the compositions of the main raw materials of MT300MIX shall

be are shown in (Table 1).

Table 1 Compositions of Main Raw Materials of MT300MIX

Name

Composition

Casing

ABS+PC

Cover plate

Cold-rolled sheet

Side plate

Aluminum alloy

Battery

Polymer lithium battery

PCB

Including electrical components

2Structure Features and Equipment Parameters

2.1 Structure Features

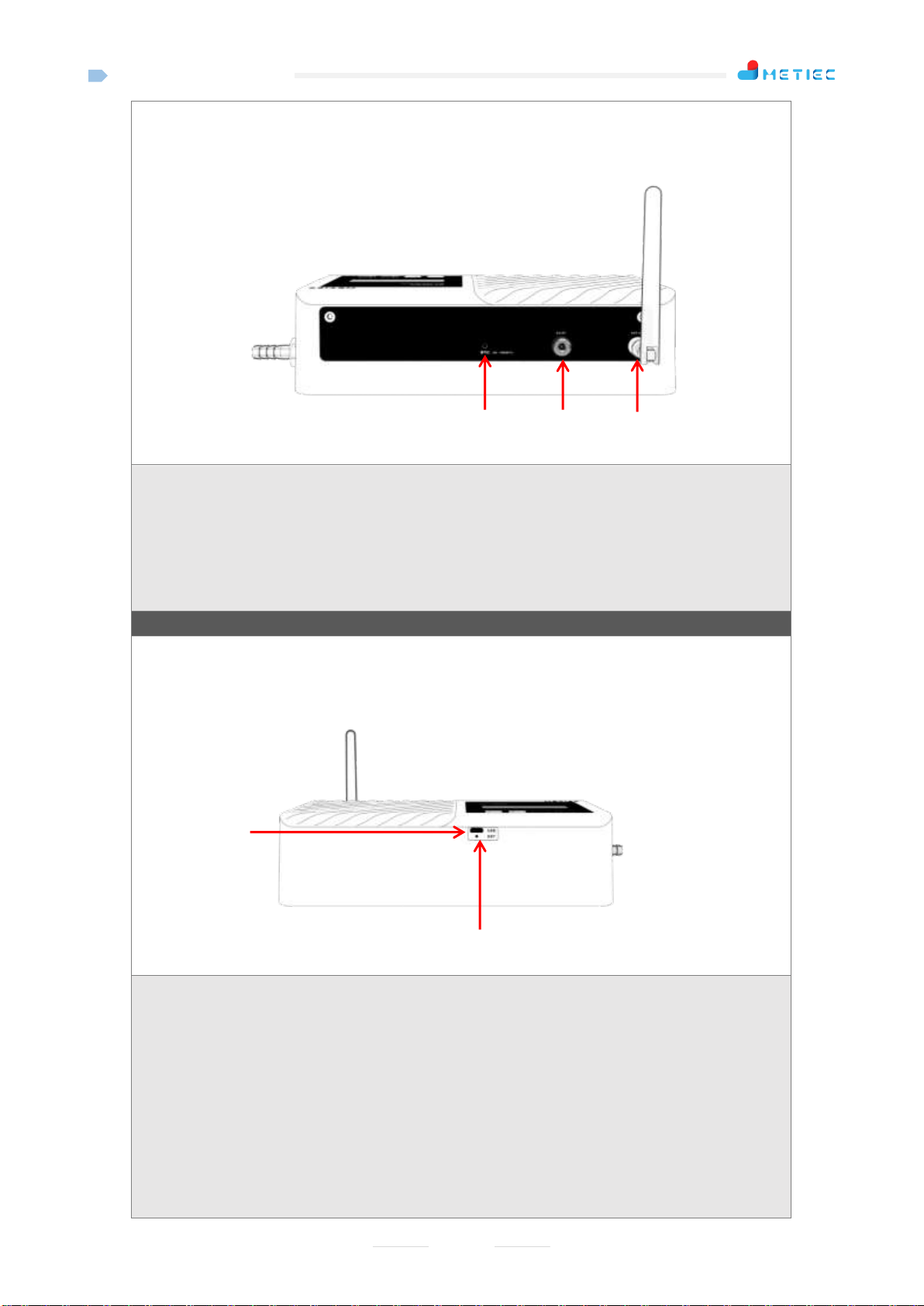

a) Data Display Screen

It displays the concentrations monitored of CO2and O2; the heartbeat state of the device

running (the flash rate) is displayed on the upper left corner; the internal pressure, the air inlet

flow and the CO2concentration of the device are displayed on the upper right corner.

b) Buttons

Pressing buttons; each button has a corresponding function, you can carry out related operations

through buttons; buttons are generally operated by engineers.

a

b

B1-MT300MIX

5

c) Power Interface

Equipped with a 5V/2Apower adapter.

d) Antenna

e) Gas Outlet

Refers to the gas outlet of the device. After the solenoid valve of the device is opened for the intake

detection, excess gas will be discharged through the outlet. Do not block the gas outlet.

f) Upgrade Debugging Port

Micro USB interface; it has 2 functions: Firstly, it can be used for program upgrade: The

special serial cable customized by the company is used for upgrading program instead of

Micro USB cable; secondly, it is used to modify parameters: The special serial cable

customized by the company shall be used for modifying parameters instead of Micro USB

cable; it needs to work with the modification software of " Huchuang Union Wireless Slaver

Debugging Platform.exe".

g) Reset Button (Pin-socket type)

Refers to the emergency reset hole of the device; the whole system can be reset through the

ejector pin here when the equipment breaks down.

e

c

d

g

f

B1-MT300MIX

6

h) Gas Inlet

i) Power Switch

j) Manual Ball Valve

Refers to the manual valve of the gas inlet pipe; in case of equipment leakage alarm, the user

can manually close this valve to ensure that the equipment will not leak.

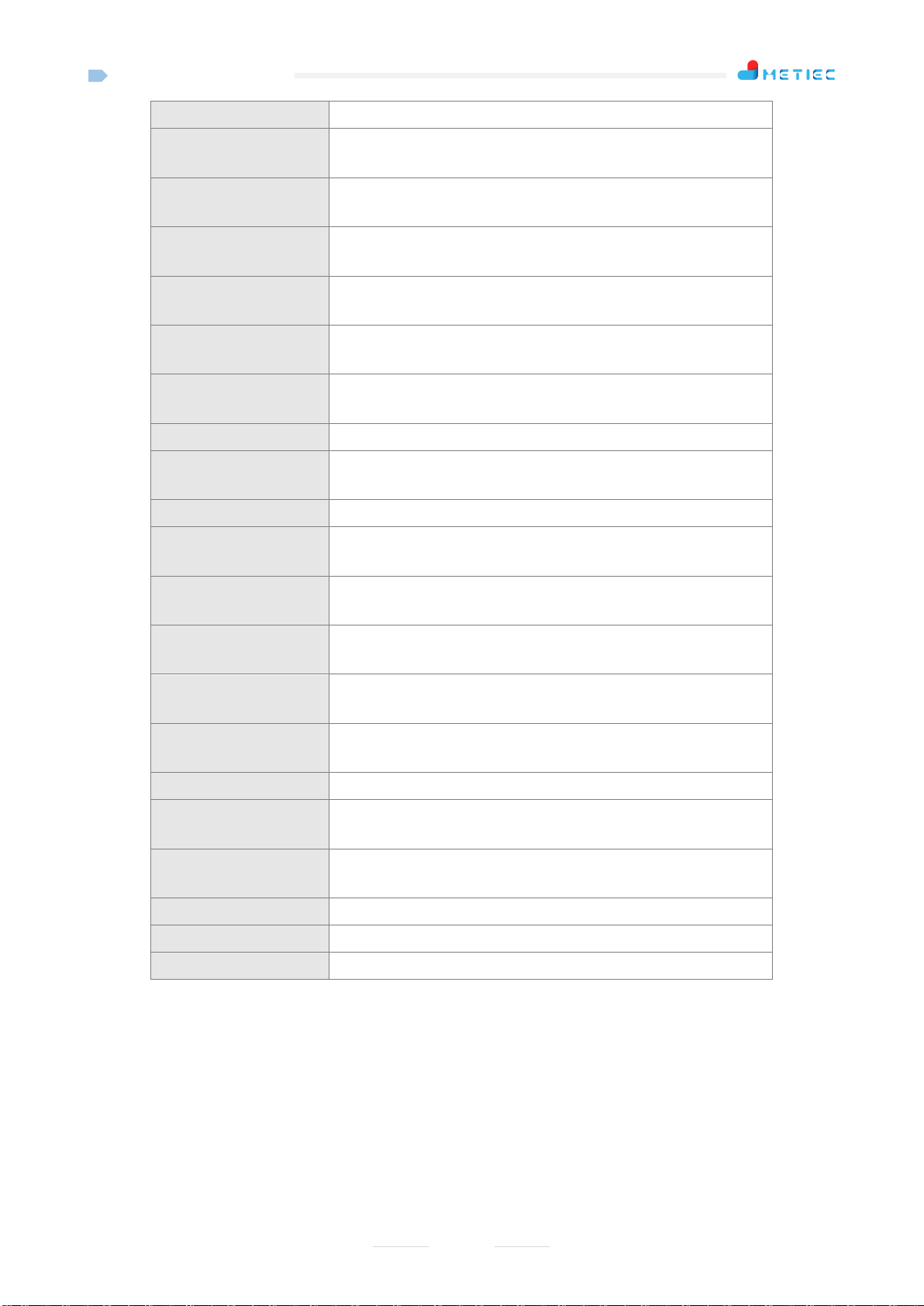

2.2 Equipment Parameters

Table 2 MT300MIX Parameters

Item

Parameter

Overall dimensions

230mm*126mm*56mm

Weight

1367g

Transmission method

Wireless

Working frequency band

425-445MHz

Transmission distance

1200 m in open area, 1000 m in streets, about 300 m inside

buildings (not shielded by metal objects) under the transmission

rate of 10Kbps

h

i

j

B1-MT300MIX

7

Sensor

O2sensor, CO2 sensor

Detection resolution of

O2concentration

0.01%

Detection accuracy of

O2concentration

±0.2%

Detection range of O2

concentration

0%~30%

Detection resolution of

CO2concentration

0.01%

Detection accuracy of

CO2concentration

±0.2%

Detection range of CO2

concentration

0%~10%

Power failure alarm

Audible and visual alarm

Battery

1000mAh, providing the power supply for more than 2 hours after

power failure in fully charged state

Display screen

2.23 inches

Data refresh frequency

of display screen

1 second/ time

Equipment status upload

frequency

3 min/time (modifiable) by default

Concentration sampling

frequency

55 min/time (modifiable) by default

Intake time of single

sampling

10 seconds (modifiable) by default

Range of external input

gas pressure

0.08MPa - 0.2MPa

Power supply mode

DC5V/2A power adapter

Maximum power

consumption

0.4A @DC5V

Average power

consumption

0.15A @DC5V

Storage temperature

-20℃~+50℃

Operating temperature

+15℃~+30℃

Humidity

≤80% (Non-condensing)

3Basic Operation Instructions

3.1 Power-On for Use

Connect the external 5V adapter and turn the power toggle switch to "ON" position, at the moment, the

display screen will be on, and the buzzer will give a short beep, indicating that the system starts normally.

After MT300MIX and MT500 devices are installed normally, users can download the "Laboratory

Monitoring System" APP to view the monitored temperature data; or view the temperature data through the

computer web version.

B1-MT300MIX

8

3.2 Operation Instructions of Buttons

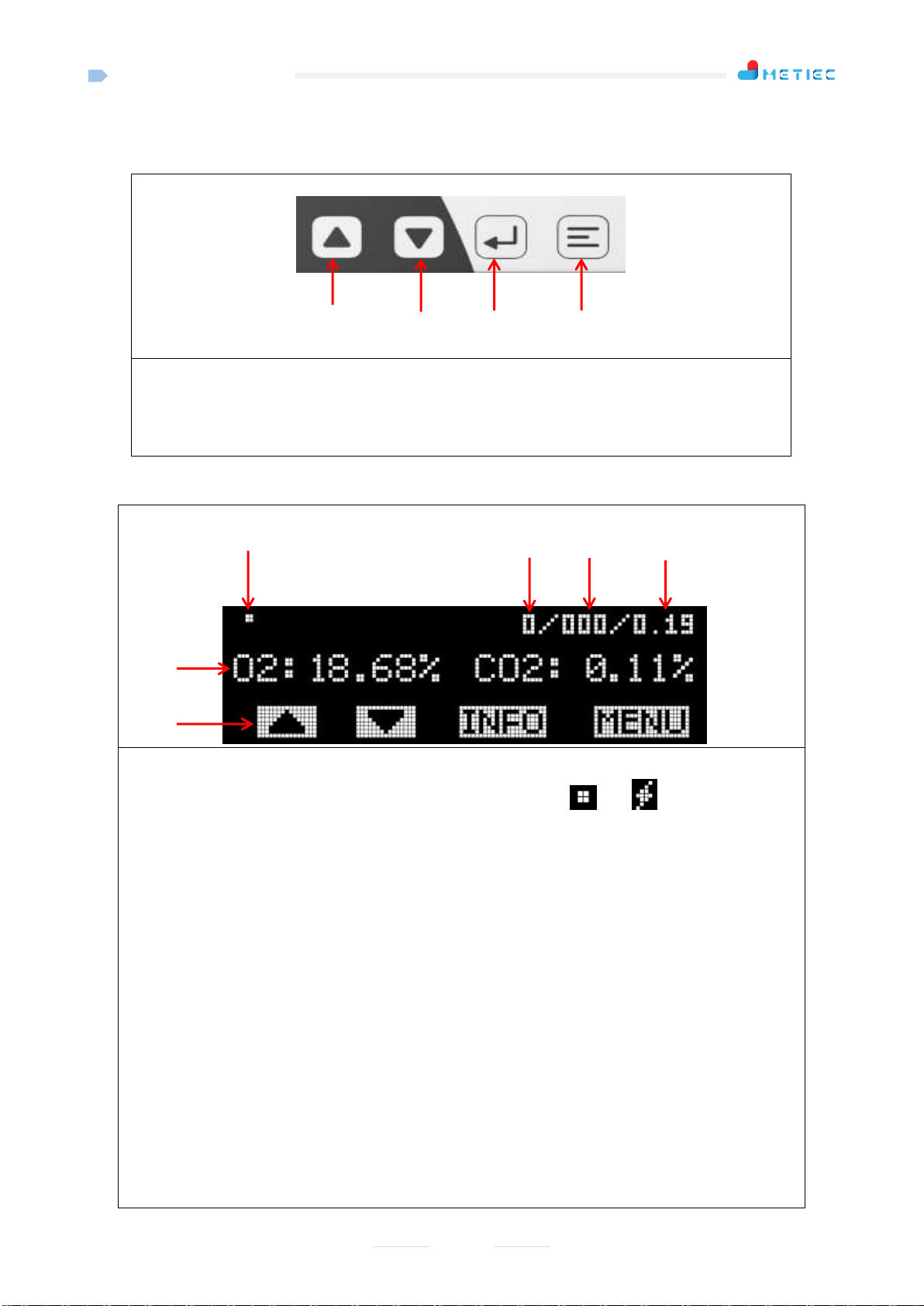

3.2.1 Button Description

a) UP key

b) DOWN key

c) OK key

d) Menu key

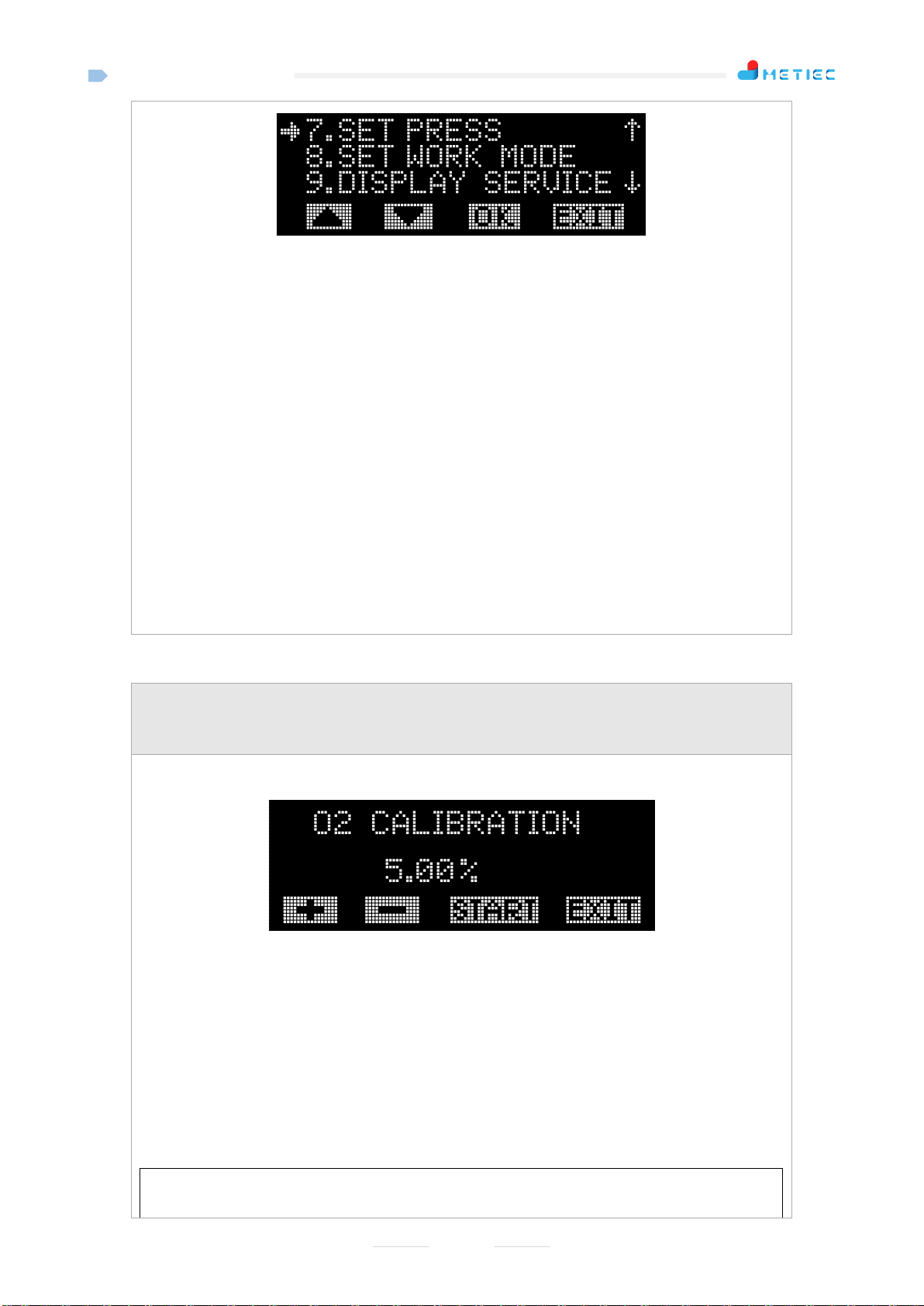

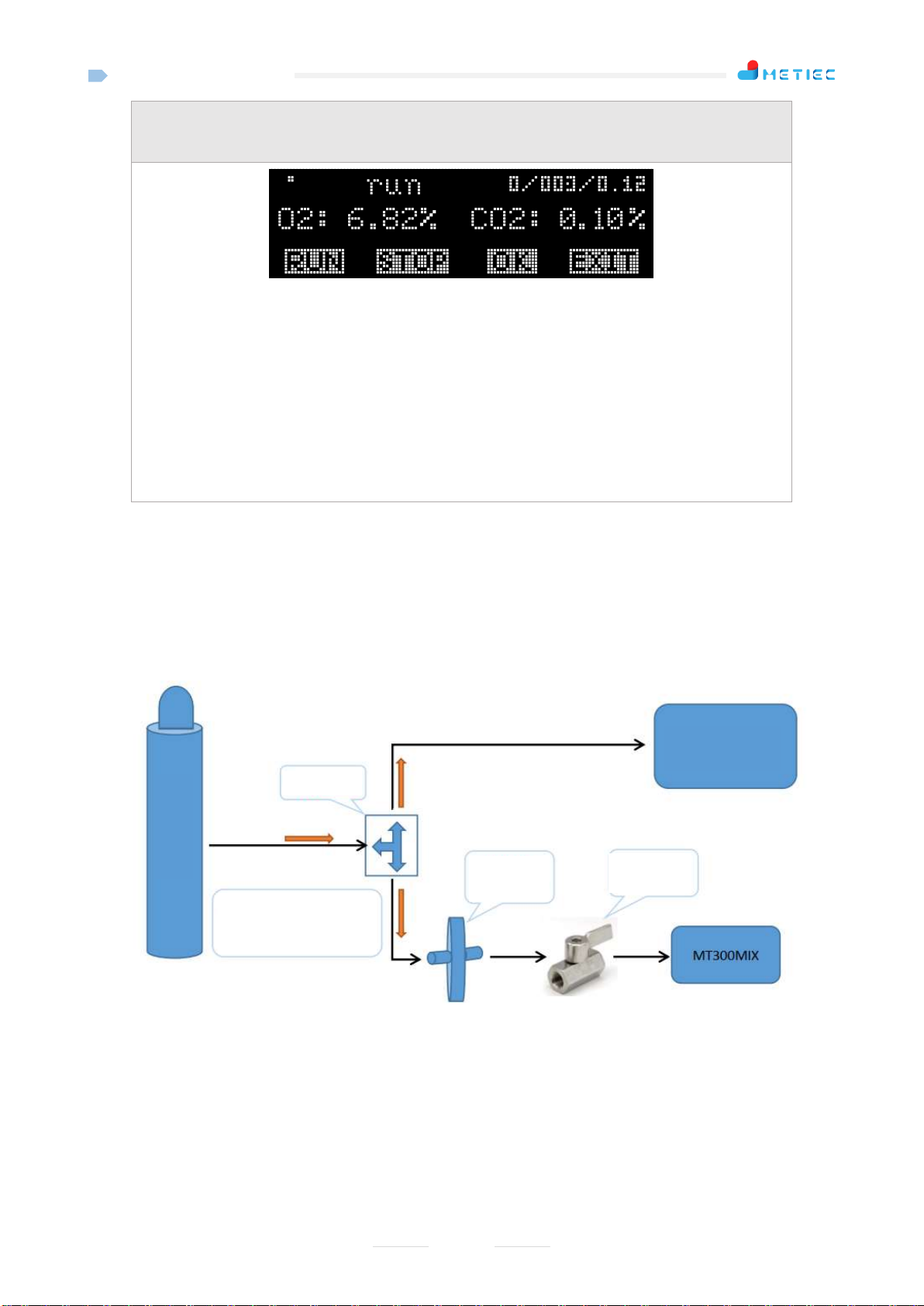

3.2.2 Main Interface Instructions

e) Breathing point of system operating state: It will flash when the system runs normally; it will be

normally on or off when the system breaks down; it will turn from " " to " " upon power failure,

prompting the power failure alarm;

f) Current flow value in the device mL/min (to test whether there is gas leakage inside the device): It is

generally displayed as "0" when there is no gas intake, indicating that the equipment is normal;

g) Pressure value input externally and processed by the pressure reducing valve (to test whether the gas

source has low pressure);

h) Current CO2concentration in the equipment (to detect whether there is gas leakage in the equipment):

When the value exceeds 0.5%, an alarm will be triggered;

i) Current concentrations of O2and CO2in the gas in the external gas pipe monitored by the equipment;

j) Function prompt icon of operation button: The button function will be different with the different

interfaces on the display.

Function Description of Buttons on the Current Interface:

UP key: No function (disabled);

DOWN key: No function (disabled);

OK key: Press it to enter "System information interface";

Menu key: Press it to enter "Parameter setting interface";

a)

b)

c)

d)

e)

f)

g)

h)

i

)

j

)

B1-MT300MIX

9

Main Interface and Operation Instructions During Intake

UP key: No function (disabled)

DOWN key: No function (disabled)

OK key: No function (disabled)

Menu key: No function (disabled)

Main Interface and Operation Instructions During Sampling after Intake

UP key: No function (disabled)

DOWN key: No function (disabled)

OK key: No function (disabled)

Menu key: No function (disabled)

Note:

1. When the device is in the state of intake sampling, the control operation will be shielded;

3.2.3 Instructions of System Information Interface

Press the "INFO" button on the main interface to enter the "System information interface", as

shown in the picture below:

First row: Displays equipment model;

Second row: Displays equipment SN;

Third row and fourth row: Displays the equipment software/ hardware version.

Instructions for key functions:

After the user presses any key, the system will return to the "Main interface" automatically.

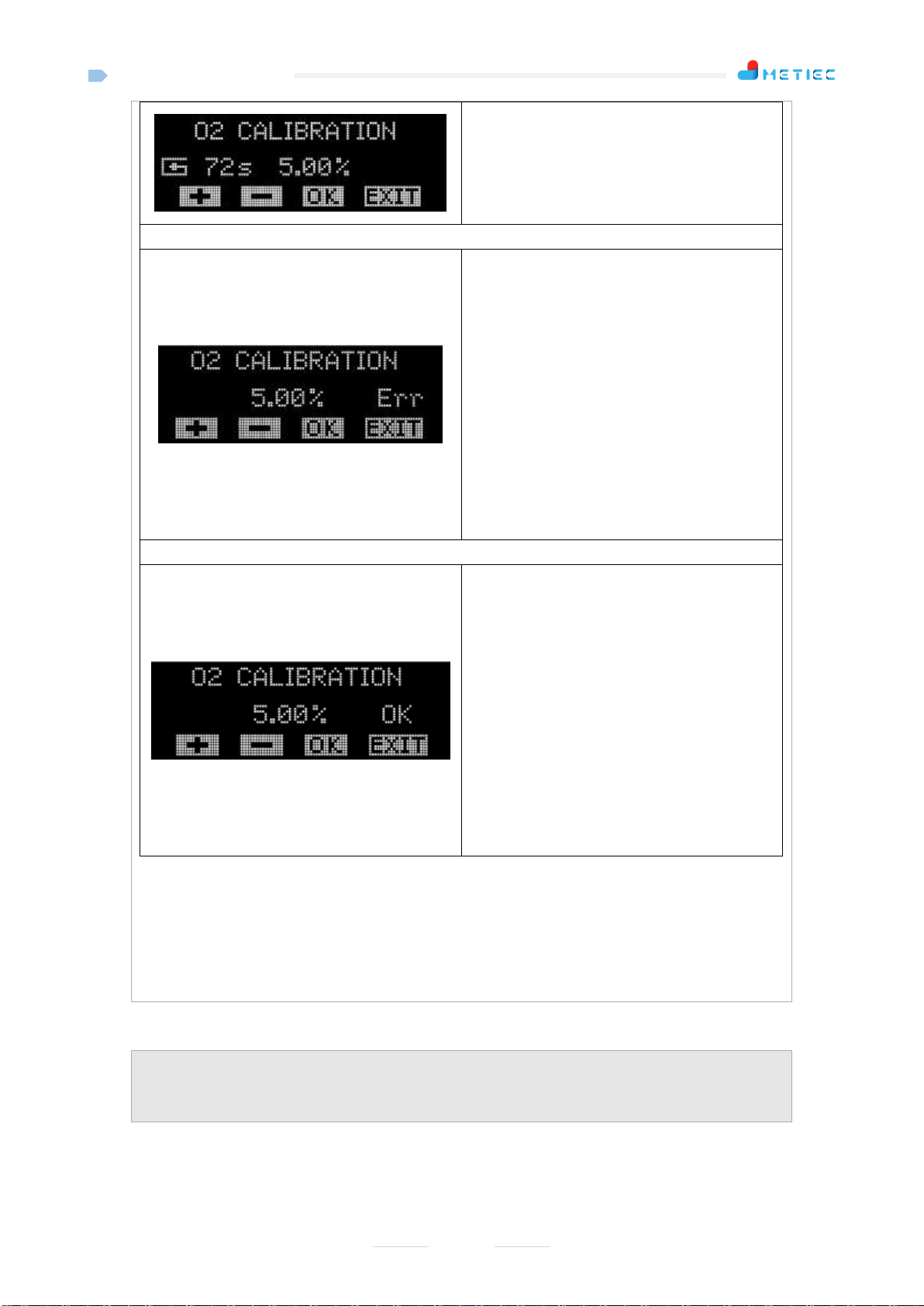

3.2.4 Instructions of Setting Interface

Press the "MENU" button on the main interface to enter the "Setting interface" which includes

three pages and can flip, as shown in the picture below:

B1-MT300MIX

10

Menu Function Description:

"1. SET O2": O2 concentration calibration function;

"2. SET CO2": CO2concentration calibration function;

"3. SET DATA FREQ": Setting function of data upload frequency;

"4. SET SAMPLE FREQ": Setting function of sampling frequency;

"5. SET VALVER TIME": Setting function of intake time of single sampling;

"6.SET FLOW": Flow sensor calibration function;

"7.SET PRESS": Calibration function of pressure sensor in rear of internal pressure reducing valve;

"8. SET WORK MODE": Work mode setting function of equipment;

"9. DISPLAY SERVICE": Real-time data display function.

Operation Instructions of Buttons:

UP key: Press this key to move to the previous option;

DOWN key: Press this key to move to the next option;

"OK": Confirm the selection;

"EXIT": The system exits and returns to the main screen (or the system automatically returns to the

main screen after 30 seconds) when the button is pressed;

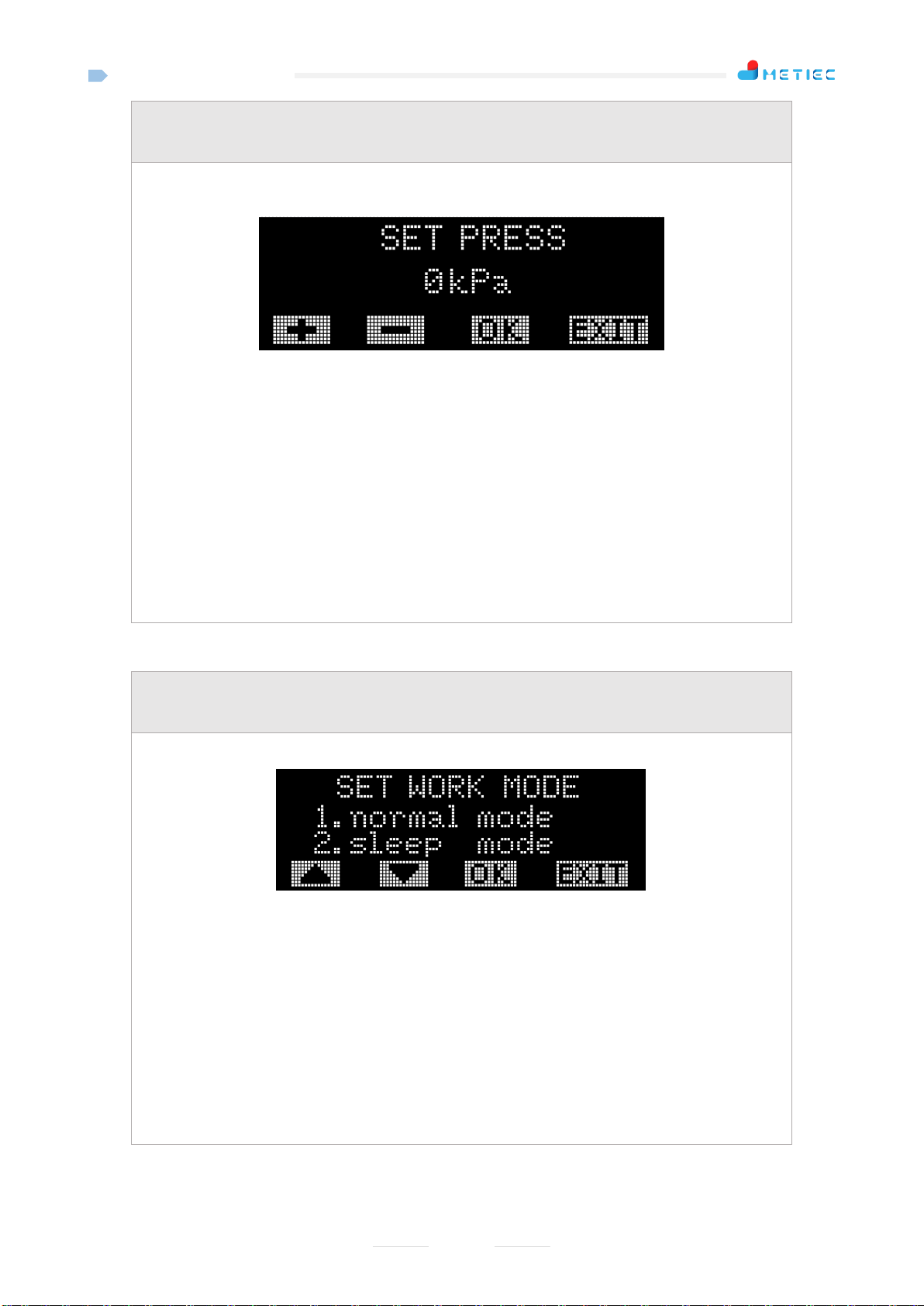

3.2.5 "1.SET O2"

Select "1.SET O2" on the setting interface, and then press the "OK" button to enter the O2

concentration calibration setting interface, as shown in the picture below:

O2Concentration Calibration Interface:

Operation Instructions of Buttons:

"+" key: Press this button to add the value by 0.1%and press and hold this button to add the value by

0.1% continuously;

"-" key: Press this button to reduce the value by 0.1% and press and hold this button to reduce the

value by 0.1% continuously;

"START" key : Press this button to start the intake calibration;

"EXIT" key: The system exits and returns to the main screen (or the system automatically returns to

the main screen after 30 seconds) when the button is pressed; press and hold this button for more

than 5 seconds to enter 21% (air calibration) concentration calibration interface;

Interface and Operation Instructions When Starting to Intake (Intake for 72 seconds by

default)

B1-MT300MIX

11

UP key: No function

DOWN key: No function

OK key: No function

Menu key: The system returns to the setting

interface when this key is pressed

Interface and Operation Instructions Upon O2Concentration Calibration Failure

UP key: Press this button to add the value by

0.1% and press and hold this button to add the

value by 0.1% continuously

DOWN key: Press this button to reduce the

value by 0.1% and press and hold this button to

reduce the value by 0.1% continuously

OK key: The system does not save the

calibration value and directly returns to the

setting interface when this key is pressed

Menu key: The system does not save the

calibration value and directly returns to the

setting interface when this key is pressed

Interface and Operation Instructions Upon Successful O2Concentration Calibration

UP key: Press this button to add the value by

0.1% and press and hold this button to add the

value by 0.1% continuously

DOWN key: Press this button to reduce the

value by 0.1% and press and hold this button to

reduce the value by 0.1% continuously

OK key: The system saves the calibration

value and returns to the setting interface when

this key is pressed

Menu key: The system does not save the

calibration value and directly returns to the

setting interface when this key is pressed

Note:

1. O2concentration calibration setting range: From 0% to 21%;

2. Calibrate two points: 5% concentration and 21% concentration (air calibration);

3. 21% concentration has been calibrated before delivery and does not need to recalibrate. If

calibration is required, press and hold the Menu key for more than 5 seconds to enter the calibration

interface.

3.2.6 "2.SET CO2"

Select "2.SET CO2" on the setting interface, and then press the "OK" button to enter the CO2

concentration calibration setting interface, as shown in the picture below:

B1-MT300MIX

12

CO2Concentration Calibration Interface:

Operation Instructions of Buttons:

"+" key: Press this button to add the value by 0.1%and press and hold this button to add the value by

0.1% continuously;

"-" key: Press this button to reduce the value by 0.1% and press and hold this button to reduce the

value by 0.1% continuously;

"START" key : Press this button to start the intake calibration;

"EXIT": The system exits and returns to the main screen (or the system automatically returns to the

main screen after 30 seconds) when the button is pressed;

Interface and Operation Instructions When Starting to Intake (Intake for 72 seconds by

default)

UP key: No function

DOWN key: No function

OK key: No function

Menu key: The system returns to the setting

interface when this key is pressed

Interface and Operation Instructions Upon CO2Concentration Calibration Failure

UP key: Press this button to add the value by

0.1% and press and hold this button to add the

value by 0.1% continuously

DOWN key: Press this button to reduce the

value by 0.1% and press and hold this button to

reduce the value by 0.1% continuously

OK key: The system does not save the

calibration value and directly returns to the

setting interface when this key is pressed

Menu key: The system does not save the

calibration value and directly returns to the

setting interface when this key is pressed

Interface and Operation Instructions Upon Successful CO2Concentration Calibration

UP key: Press this button to add the value by

0.1% and press and hold this button to add the

value by 0.1% continuously

DOWN key: Press this button to reduce the

value by 0.1% and press and hold this button to

reduce the value by 0.1% continuously

OK key: The system saves the calibration

value and returns to the setting interface when

this key is pressed

B1-MT300MIX

13

Menu key: The system does not save the

calibration value and directly returns to the

setting interface when this key is pressed

Note: CO2concentration calibration setting range: From 0% to 10%.

3.2.7 "3. SET DATA FREQ"

Select "3. SET DATA FREQ" on the setting interface, and then press the "OK" button to enter the

data upload frequency setting interface, as shown in the picture below:

Operation Instructions of Buttons:

"+" key: Press this button to add the value by 1 and press and hold this button to add the value by 1

continuously (in the range from 1~3600 seconds);

"-" key: Press this button to reduce the value by 1 and press and hold this button to reduce the value

by 1 continuously (in the range from 1~3600 seconds);

"OK" key: The system saves the parameter and returns to the main interface when this key is

pressed;

"EXIT" key: The system does save the parameter and directly returns to the main screen (or the

system automatically returns to the main screen after 30 seconds) when the button is pressed;

Note: The upload frequency is 180 seconds by default.

3.2.8 "4.SET SAMPLE FREQ"

Select "4.SET SAMPLE FREQ" on the setting interface, and then press the "OK" button to enter

the sampling frequency setting interface, as shown in the picture below:

Operation Instructions of Buttons:

"+" key: Press this button to add the value by 1 and press and hold this button to add the value by 1

continuously (in the range from 5~1440 seconds);

"-" key: Press this button to reduce the value by 1 and press and hold this button to reduce the value

by 1 continuously (in the range from 5~1440 seconds);

"OK" key: The system saves the parameter and returns to the main interface when this key is

pressed;

"EXIT" key: The system does save the parameter and directly returns to the main screen (or the

system automatically returns to the main screen after 30 seconds) when the button is pressed;

Note: The sampling frequency is 55 seconds by default.

B1-MT300MIX

14

3.2.9 "5. SET VALVE TIME"

Select "5. SET VALVE TIME" on the setting interface, and then press the "OK" button to enter the

intake time setting interface for single sampling, as shown in the picture below:

Operation Instructions of Buttons:

"+" key: Press this button to add the value by 1 and press and hold this button to add the value by 1

continuously (in the range from 1~3600 seconds);

"-" key: Press this button to reduce the value by 1 and press and hold this button to reduce the value

by 1 continuously (in the range from 1~3600 seconds);

"OK" key: The system saves the parameter and returns to the main interface when this key is

pressed;

"EXIT" key: The system does save the parameter and directly returns to the main screen (or the

system automatically returns to the main screen after 30 seconds) when the button is pressed;

Note: The intake time is 10 seconds by default.

3.2.10"6.SET FLOW"

Select "6.SET FLOW" on the setting interface, and then press the "OK" button to enter the flow

sensor calibration interface, as shown in the picture below:

Operation Instructions of Buttons:

"+" key: Press this button to add the value by 1 and press and hold this button to add the value by 1

continuously (in the range from 1~1000 mL/min);

"-" key: Press this button to reduce the value by 1 and press and hold this button to reduce the value

by 1 continuously (in the range from 1~1000 mL/min);

"OK" key: The system saves the parameter and returns to the main interface when this key is

pressed;

"EXIT" key: The system does save the parameter and directly returns to the main screen (or the

system automatically returns to the main screen after 30 seconds) when the button is pressed;

Note: The flow sensor is used to detect leakage of the device. The factory has calibrated the zero, so

it is does not need to be calibrated by default; if the calibration is required, plug the gas inlet and

outlet and then calibrate the zero.

3.2.11"7.SET PRESS"

B1-MT300MIX

15

Select "7.SET PRESS" on the setting interface, and then press the "OK" button to enter the work

mode setting interface of the equipment, as shown in the picture below:

Operation Instructions of Buttons:

"+" key: Press this button to add the value by 1 and press and hold this button to add the value by 1

continuously (in the range from 1~200 kPa);

"-" key: Press this button to reduce the value by 1 and press and hold this button to reduce the value

by 1 continuously (in the range from 1~200 kPa);

"OK" key: The system returns to the main interface when this key is pressed;

"EXIT" key: The system does save the parameter and directly returns to the main screen (or the

system automatically returns to the main screen after 30 seconds) when the button is pressed;

Note: The pressure sensor is used to test whether the input pressure is too low. The factory has

calibrated the zero, so it is does not need to be calibrated by default; if the calibration is required, do

not input the gas into the pipeline but directly calibrate the zero under the atmospheric pressure.

3.2.12"8.SET WORK MODE"

Select "8.SETWORK MODE" on the setting interface, and then press the "OK"button to enter the

work mode setting interface of the equipment, as shown in the picture below:

Operation Instructions of Buttons:

"+" key: Press this key to switch over to the previous option;

"-" key: Press this key to switch over to the next option;

"OK" key: The system saves the parameter and returns to the main interface when this key is

pressed;

"EXIT" key: The system does save the parameter and directly returns to the main screen (or the

system automatically returns to the main screen after 30 seconds) when the button is pressed;

Note: The default working mode is "Normal Mode". "Sleep Mode" is generally applicable to

MT300MIX with battery function: In this mode, all detection functions are disabled and the device

enters the sleep state.

3.2.13"9. DISPLAY SERVICE"

B1-MT300MIX

16

Select "9. DISPLAY SERVICE" on the setting interface, and then press the "OK" button to enter

the real-time display interface of sampled data, as shown in the picture below:

Operation Instructions of Buttons:

"RUN" key: Used to update the concentration data of O2and CO2in real time;

"STOP" key: Used to pause update the concentration data of O2and CO2in real time;

"OK" key: The system returns to the main interface when this key is pressed;

"EXIT" key: The system returns to the main screen (or the system automatically returns to the main

screen after 5 minutes) when the button is pressed;

Note: This function can view the current sampled data in real time and be convenient for engineers

to debug the device. The sampled data on the main interface will be updated only when the intake is

sampled, and will be automatically locked until the next sampling.

4Installation Instructions

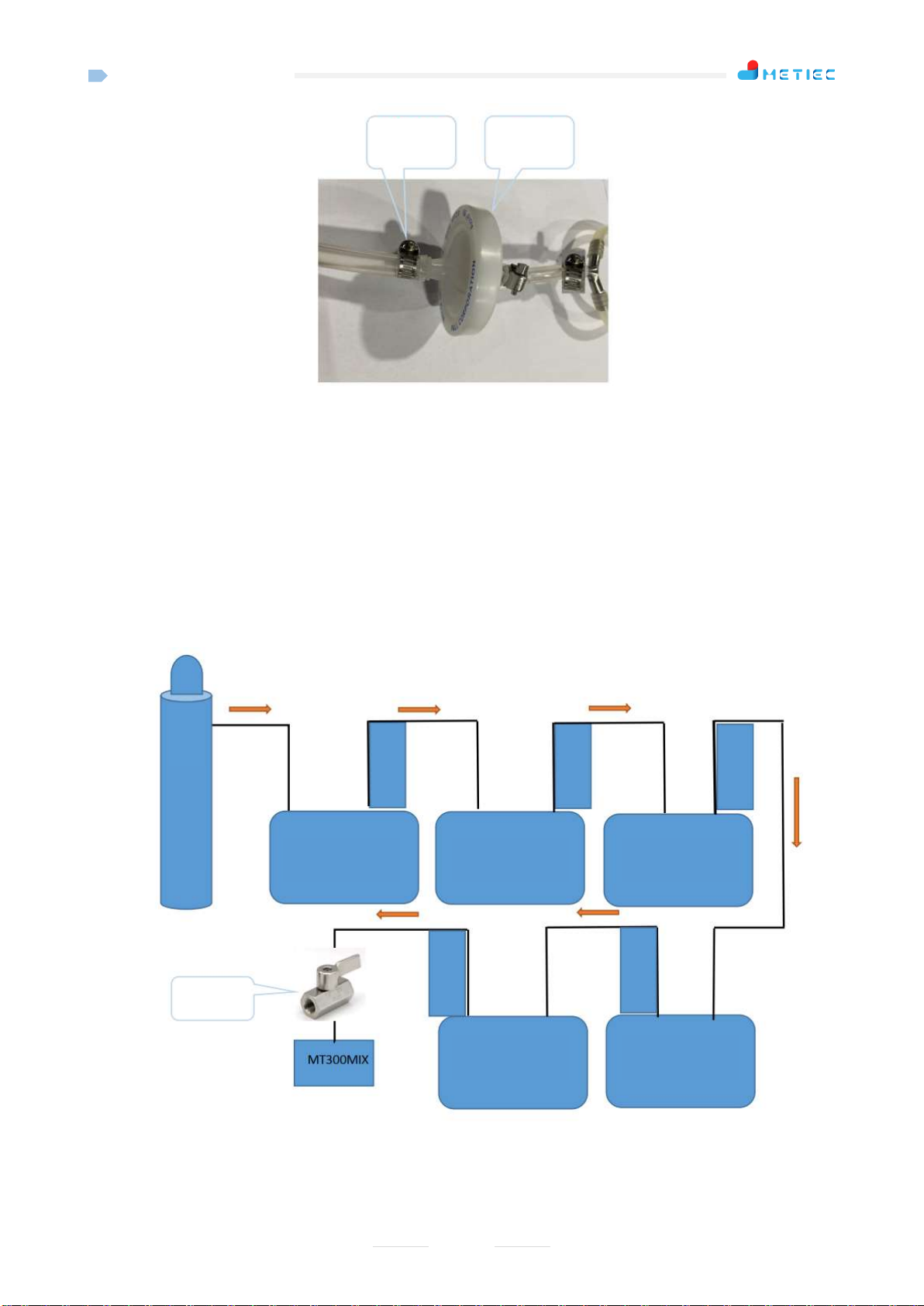

4.1 Installation Method 1

Connect the pre-mixing gas pipe to MT300MIX through a gas tee;

Gas tee

Manual

ball valve

HEPAgas

filter

Pre-mix gas

COOK

incubator

Note: The gas pipe joint

shall be fastened with the

mini M-type hose clamp.

B1-MT300MIX

17

Note: 1) In this installation mode, a disc filter should be added at the front end of the gas intake of MT300MIX to

prevent impurities from entering the equipment;

2) Hoops shall be installed at hose joints and tightened;

3) Pay attention to the pressure range of MT300MIX: 0.08MPA-0.2MPa;

4) Note that the total length of the pipe from tee to MT300MIX should not exceed 2 meters.

4.2 Installation Method 2

Connect MT300MIX to the final end of the pre-mixing gas pipe through the coupler of the

corresponding incubator;

Note:

1) Hoops shall be installed at hose joints and tightened;

2) Pay attention to the pressure range of MT300MIX: 0.08MPA-0.2MPa;

Manual

ball valve

Pre-mix gas

COOK

incubator

COOK

incubator

COOK

incubator

COOK

incubator

COOK

incubator

Union-assembly

HEPAgas

filter

Mini M-type

hose clamp

Union-assembly

Union-assembly

Union-assembly

Union-assembly

B1-MT300MIX

18

3) Note that the total length of the pipe from the last incubator to MT300MIX should not exceed 2 meters.

5Precautions

When MT300MIX is installed and used for the first time, because there is air inside the device, the air

cannot be guaranteed to be emptied at one time, therefore, the concentrations tested first few times after

the installation of the device will be inaccurate;

The wireless transmission distance of MT300MIX is limited and should generally not exceed 3 rooms. If

the walls of the rooms are made of metal materials, it is better to install a MT500 or MT1100 receiver in

each room;

MT300MIX is not waterproof, so the equipment shall not directly contact with liquid water;

MT300MIX is equipped with polymeric battery and shall be not allowed to contact the high temperature

environment to prevent battery damage.

The total length of the pipe fromthe last gas outlet (tee or last incubator) to MT300MIX should not exceed

2 meters.

6FCC Warning

15.19 Labeling requirements.

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1)

This device may not cause harmful interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

15.21 Information to user.

Any Changes or modifications not expressly approved by the party responsible for compliance could void the

user's authority to operate the equipment.

15.105 Information to the user.

Note: This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against

harmful interference in a residential installation. This equipment generates uses and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions, may cause harmful

interference to radio communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or television reception,

B1-MT300MIX

19

which can be determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

-Reorient or relocate the receiving antenna.

-Increase the separation between the equipment and receiver.

-Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

-Consult the dealer or an experienced radio/TV technician for help.

Table of contents

Popular Measuring Instrument manuals by other brands

Keysight

Keysight N2780B user guide

WATANABE ELECTRIC INDUSTRY

WATANABE ELECTRIC INDUSTRY A2200 Series Operation manual

Michell Instruments

Michell Instruments Pura user manual

PCE Instruments

PCE Instruments PCE-PFG Series user manual

Hach

Hach IntelliCAL ISENH3181 Series user manual

CyberVisuell

CyberVisuell LDW-6093K Operation manual

Tera

Tera TOM 600 ME manual

National Instruments

National Instruments NI Vision PCI-1409 user manual

Critical Environment Technologies

Critical Environment Technologies YES IMS Operation manual

Larson Davis

Larson Davis Spartan 730 Reference manual

Aichi

Aichi SD Series instruction manual

Fortis

Fortis 4063726007728 manual