4

TROUBLESHOOTING COMPONENTS

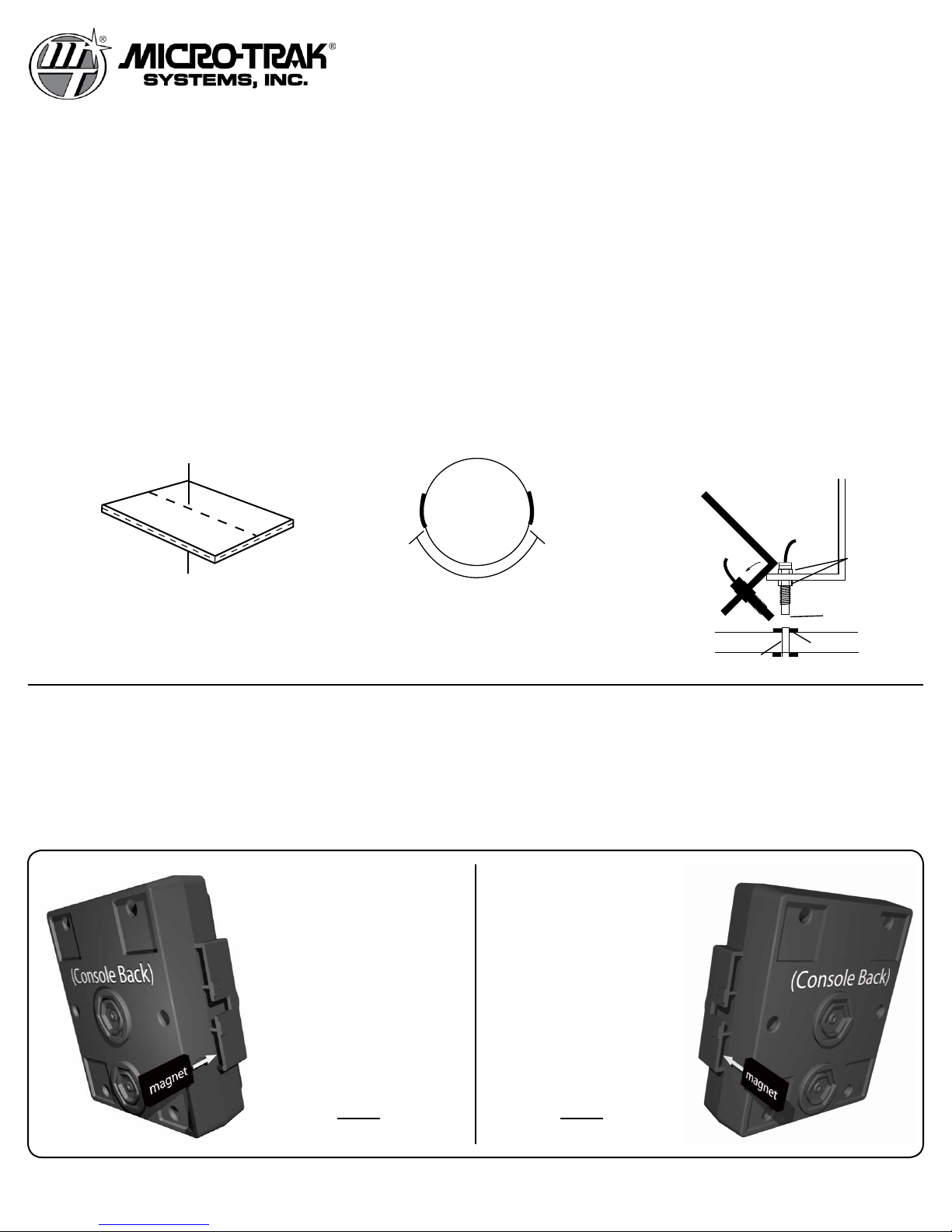

CONSOLE: Make sure the console is in the desired mode (Shaft

or Bin). Either set of 3 inputs (1-3 or 4-6) can be operated in either

SHAFT mode or BIN mode by inserting or removing magnets as

shown on page 2.

It is easy to tell which mode each set of inputs is operating in

when the console is turned on: if a set of inputs is set up for BIN

mode and all sensors are disconnected, all of the GREEN lights will

light. If set up for SHAFT mode, and all sensors are disconnected,

all of the RED lights will flash.

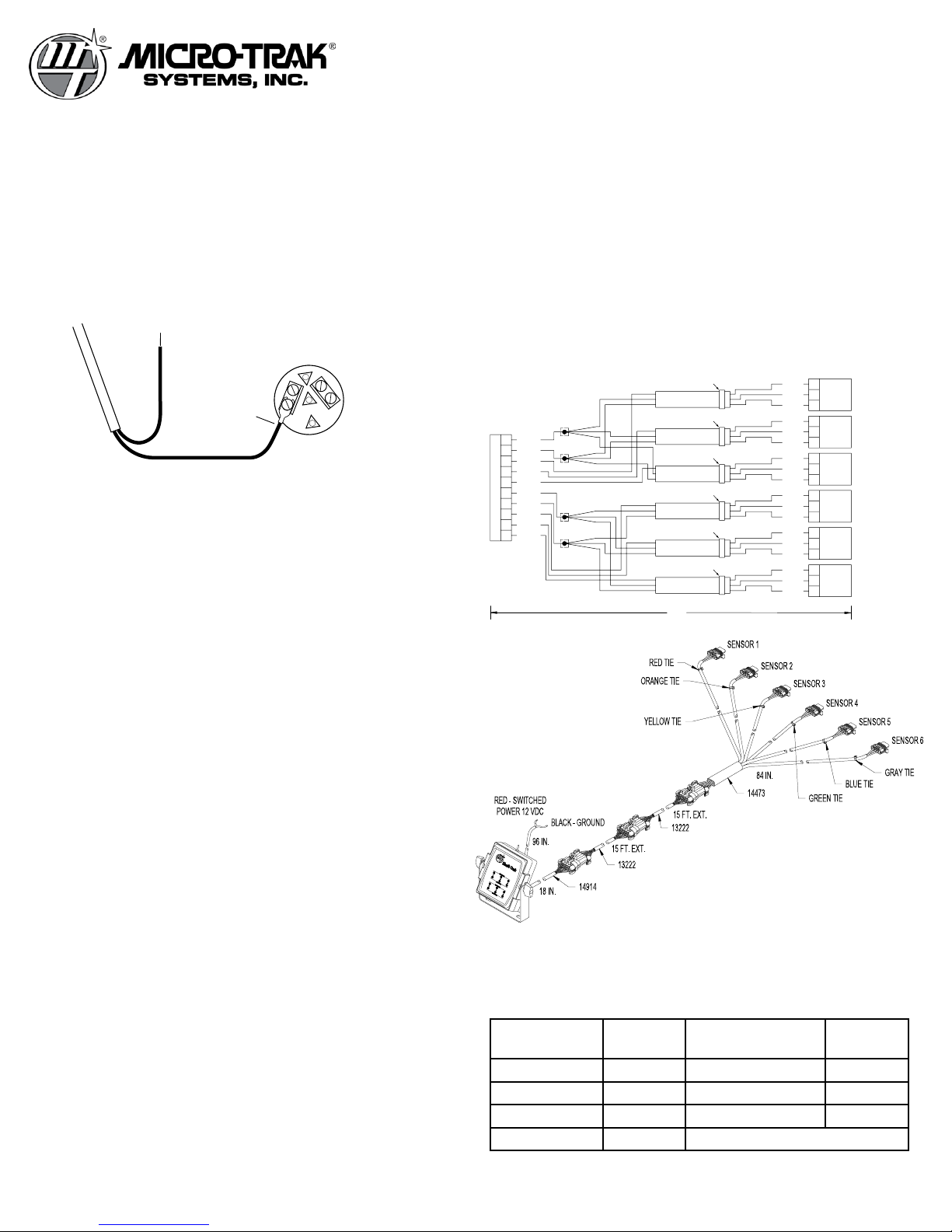

HARNESS: The harness can be checked using an ohmmeter or

continuity tester. The main wiring diagram shows the pin out of all

connectors.

ELECTRICAL INTERFERENCE: Erratic operation of the system

may be the result of electrical interference from ignition wires or

inductive loads (electrical clutch, fan solenoid, etc.) Always try to

route wires as far away from suspect areas as possible. If problems

occur, you may need to relocate the console and/or wiring harness,

or install a noise suppressor.

POWER: Check power source with a test light. If there is no power,

trace cable toward battery looking for breaks. Also check any fuses

or circuit breakers that supply power to the console.

ACCESSORY POWER: The shaft/bin cables have an accessory

power wire. Check for 12 volts between B (white) and C (black) of

the 3 pin connectors. If power is not present, make sure the ac-

cessory power wire is not open or shorted to ground or to another

wire. If this wire has a problem the console may exhibit erratic

behavior or not function at all.

SHAFT SENSORS: Improper connection or voltage could dam-

age sensors. The Micro-Trak standard sensor (black housing)

works similar to a reed switch, but requires power in order to

function. The internal circuit “closes” when near the south pole

(dashed side) of a magnet and is otherwise “open”.

Ground pin C (black) and connect 12 volts to pin B (white) of the

sensor cable. Connect the positive lead (red) of an ohmmeter or

continuity tester to pin A (red) and the negative lead (black) of the

ohmmeter or continuity tester to pin C (black) of the sensor cable.

Holding the tip of the sensor up to the south pole (dashed side) of

a magnet should result in a very low resistance (around 300 ohms).

Taking the sensor away from the magnet should result in a very

high resistance (infinite).

This troubleshooting procedure can also be used for the Micro-

Trak gear tooth sensor (red housing) with the following change;

use a piece of ferrous metal, like a screwdriver tip, to test the sen-

sor. It has an internal magnet to activate the sensing circuit.

Installation and Operation Instructions

Shaft-Trak TM -P/N 50209 (cont)

Copyright © 2019 Micro-Trak Systems • P/N 50209 • 021519

BIN LEVEL SENSORS: Ground pin C (black) and connect clean

12 volts to pin B (green) of the sensor cable. Connect the positive

lead (red) of an ohmmeter or continuity tester to pin A (red) and the

negative lead (black) of the ohmmeter or continuity tester to pin C of

the bin level sensor cable.

If the Bin Level Sensor is “blocked”, the output will show high

(infinite) resistance, and if the sensor is “unblocked” the result will

be low (300-500 ohm) resistance. Make sure the back of the sensor

is covered by the black foam pad; if light enters from the back of

the sensor, it will not “see” blockage. Use your hand or other solid

object to block both “eyes” on the sensor and the resistance should

go high.

CONSOLE INPUTS: If there is no response from any of the follow-

ing tests, refer to the main wiring diagram on the previous page to

locate the next connector in line toward the console and repeat the

test at that connector. If there is a response at that connector, the

problem may be in the cable between the two connectors (or the

connectors themselves).

SHAFT INPUT: Disconnect the shaft sensor from the extension

harness. Check for 12 volts between pins B (white) and C (black) of

the extension harness. Using a clip lead or other jumper wire (such

as a per clip bent in a “U”), rapidly short together pins A (red) and C

(black) of the 3-pin connector. The corresponding green light on the

console should light.

BIN INPUT: Disconnect the bin sensor from the main harness. The

corresponding green light on the console will light. Check for 12

volts between pins B (white) and C (black) of the sensor cable being

tested. Using a clip lead or other jumper wire (paper clip bent in a

“U”), short together pins A (red) and C (black) of the 3- pin connector.

The green light will turn off and the corresponding red light will flash

for one minute or until the short is removed.

REPLACEMENT PARTS LIST FOR SHAFTTRAK

Part Number Description

01544 Bin Level Sensor Kit

13181 Console Mount Kit, Base

13221 Cable, 10’ 10-pin M/P (optional)

13222 Cable, 15’ 10-pin M/P (2)

13223 Cable, 20’ 10-Pin M/P (optional)

13224 Cable, 25’ 10-pin M/P (optional)

13205 Cable, 5’ 3-pin M/P Extension (optional)

13206 Cable, 10’ 3-pin M/P Extension (optional)

13207 Cable, 15’ 3-pin M/P Extension (optional)

13208 Cable, 20’ 3-pin M/P Extension (optional)

14381 Console, Shaft-Trak Standard

14471 Molded Shaft Sensor w/ 5’ cable

14473 Shaft-Trak 6-sensor Branch Cable, 7’