Electronic Lock RFID ISO MT Technical Manual

FCC Label location is on the “Door RFID Antenna”

because Electronic Lock RFID ISO MT is an OEM product

for locker manufacturers and not for the final customer.

At the time of delivery the label is clearly visible.

Locker manufacturers integrate this product (Electronic

Lock RFID ISO MT) into a final product (locker) and are

responsible for proper labelling of the final product

Therefore final product’s label must include also a

statement “Contains FCC ID: 2ABT8003P1143”.

Metra Electronic Lock RFID ISO MT combines a standard proven Metra Electronic Lock with RFID Lock

Driver and Metal Door RFID Antenna while MEW Controller is used to drive it.

Electronic lock is a reliable electro-motor driven lock. It is not a self-latch and electro unlatch model,

but controls both, locking and unlocking. Electronically controlled locking means that there are no

uncertain situations and that lock performs a self-test for unlocking on each cycle. Only hi-tech, non-

corrosive, minimum maintenance parts are used. Patented ball-shape bolt and adjustable door strike

ensure unlocking also under considerable pressure in any direction, thus compensating for shabby

cabinets and hinge wear. RFID lock driver drives and monitors electronic lock connected to it while it

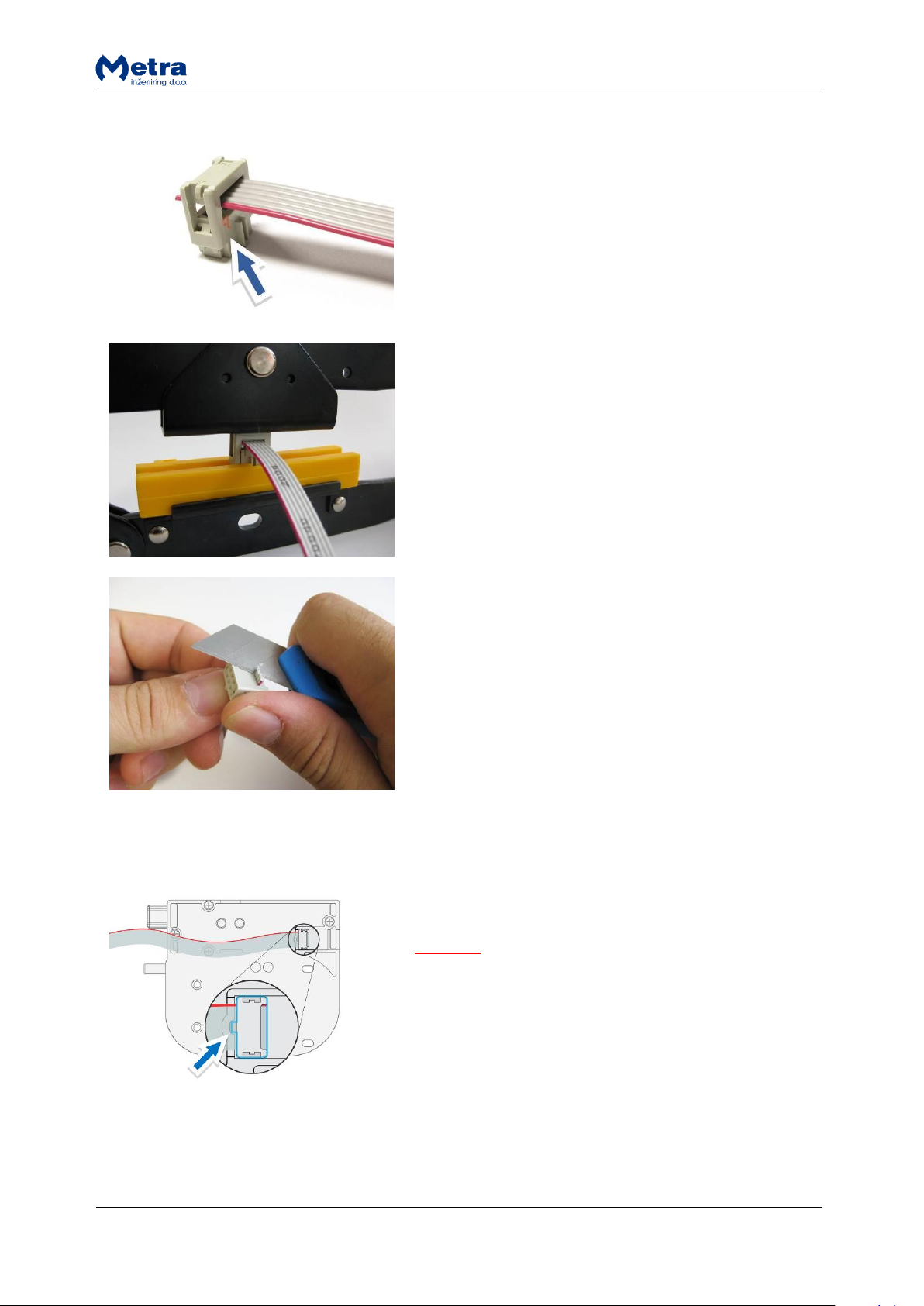

is also a user interface. Build in ISO RFID media reader in combination with Metal Door RFID Antenna

reads ISO 15693, ISO 1443A, ISO 14443 B and Mifare RFID media and it is suitable for metal door and

non-metal door from thickness of 18 millimetres up to 30 millimetres.

Metal Door RFID Antenna boosts and focuses the RFID media reader’s antenna field and can be

installed into a plastic housing such as Metra Metal Door Strike or it is integrated directly into the

door.

Electronic Lock is highly secure, with lock’s holding force over 1000 N (depends also on cabinet

structure) and designed to give an alarm signal even before* a break-in occurs (*depends also on the

cabinet, usually when force exceeds 800 N) giving extra time to react. Alarm notification is triggered

even if the strike has been pulled out from the door and remains in the lock. When unlocked the

built-in ejector pushes the door to open.

Multiple Electronic Locks RFID are connected to the MEW Controller which supports emergency and

security features: a pushbutton for emergency opening of all Electronic Locks RFID connected to it; in

case of attempt of break-in an alarm message is distributed over Metra Network Controller to LAN /

WAN and Metra software.