Metrix HI-913 User manual

HI-913 HARDY SHAKER

Installaon Manual

DOC# 100929 • REV D (Jan 2018)

1. OVERVIEW

The Metrix Model HI-913 Portable Shaker

Table provides a eld-tested method

for on-the-spot dynamic vericaon of

accelerometers, velocity pickups and non-

contact displacement transducers. Oponal

mounng xtures and hardware needed to

connect transducers to the HI-913 mounng

plaorm are available upon request. A closed-

loop control algorithm provides enhanced

stability and accuracy of frequency and

amplitude levels.

The HI-913 incorporates a built-in sine wave

oscillator, power amplier, electrodynamic

shaker, NIST-traceable reference

accelerometer and digital display. The HI-913

is completely self-contained and operates on

baery or AC power.

The built-in reference accelerometer

is aached permanently to the shaker

armature, maximizing the accuracy between

the reference accelerometer and the test

transducer. The HI-913 is designed to provide

long-term reliable performance over the

frequency range of 7 Hz to 10 kHz. The HI-

913 can be used for a variety of applicaons

that include:

•Vericaon and calibraon of vibraon

transducers and related test systems

•Vericaon of connector and cabling

integrity

•Conrm machine vibraon alarm trip points

are set properly and ensure end-to-end

funconality of vibraon monitoring systems

Notes

•Loads of up to 800 grams (28.3 ounces) can

be mounted directly to the HI-913 mounng

plaorm. Larger loads may be applied to the

plaorm, however, if prolonged tesng of a

heavy load is planned, we recommend using

an external transducer suspension system.

Under these condions the vibraon wave-

form should be viewed on the oscilloscope

to aid in posioning the test transducer and

plaorm to reduce distoron that can occur

with very heavy weights.

Doc# 100929 • HI-913-Shaker • January 2018 - RevD Page 2 of 21

•The HI-913 should always be operated on a stable, at surface.

•The HI-913 is designed for eld test applicaons but care must be taken to maintain the

integrity of the mounng plaorm assembly.

•Hearing protecon recommended when operang the HI-913 for an extended amount of

me.

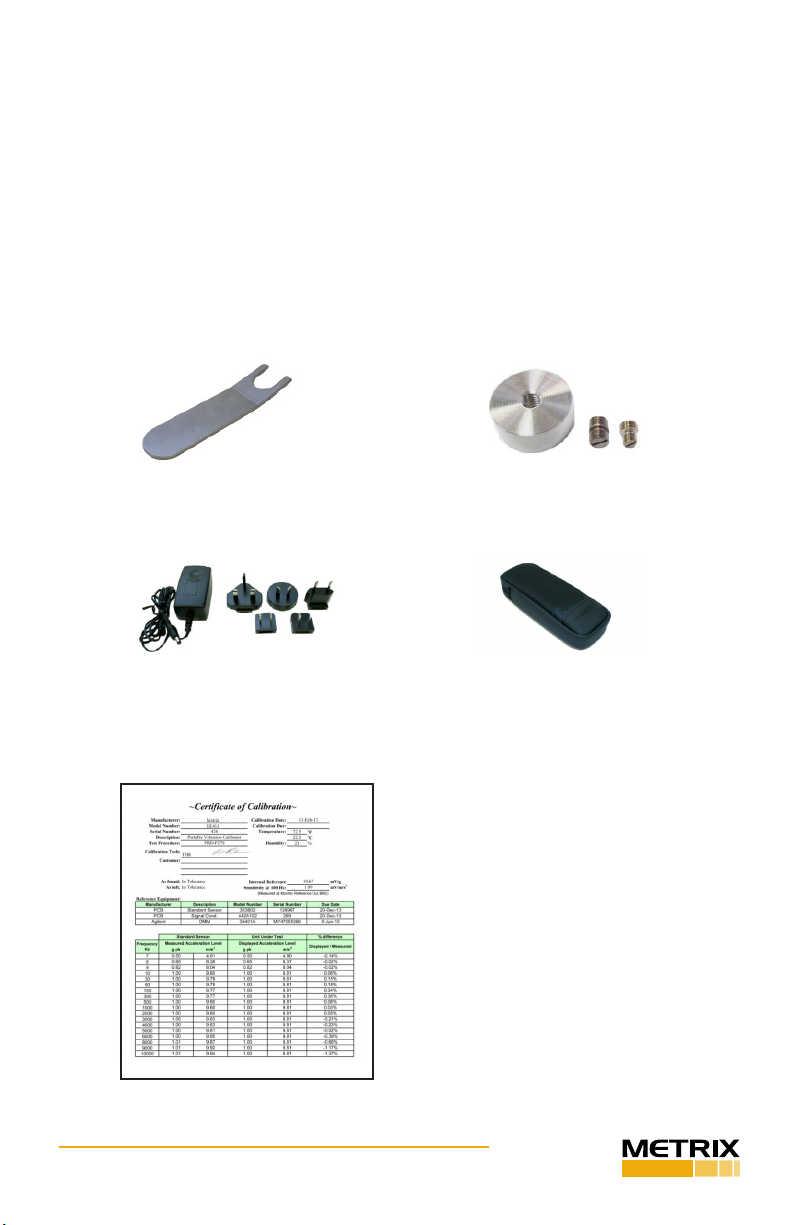

Accessories

Accessories pictured below are included with each HI-913 Portable Shaker Table.

Mounng Wrench 1-Mounng Pad

2-1/4-28 to 1/4-28 Adapter

3-10-32 to 1/4-28 Adapter

Power Supply and Plug Adaptors Acessory Pouch

A Cercate of Calibraon is also included

with every new unit. Metrix recommends

annual recalibraon of the HI-913 unit. The

factory service code for the recalibraon is

HI-913 CAL01.

Doc# 100929 • HI-913-Shaker • January 2018 - RevD Page 3 of 21

2. BASIC OPERATION

Test Set-Up

1. Mount your sensor to the HI-913 mounng plaorm.

• The HI-913 sensor mounng plaorm is threaded for a ¼-28 stud.

Select an appropriate adaptor for mounng the sensor.

• While ghtening the sensor, secure the HI-913 mounng plaorm

with the supplied wrench to prevent damage to the shaker from

torque.

2. Connect sensor signal condioner and readout device as necessary. Make sure

that connecons are secure.

3. Power the unit ON by pressing and holding the FREQUENCY dial for 3 seconds.

NOTE: It is good pracce to perform calibraons on baery power. Disconnecng

from line power ensures a power surge will not cause the calibrator to power down

during test. If excess current is detected during use, the portable calibrator shuts

down to prevent damage.

Seng the Frequency and Amplitude Units

1. Select the correct Frequency Units for your test by pressing the FREQUENCY dial

to enter into the CALIBRATION OPTIONS menu:

• Use the FREQUENCY dial to highlight TEST SETTINGS then press.

• Within the Test Sengs Menu rotate the FREQUENCY dial to highlight

FREQUENCY UNIT then press to toggle between Hertz and CPM.

2. Select the correct Amplitude Units for your test by pressing and releasing the

AMPLITUDE dial. The following opons are available:

Acceleraon Velocity Displacement

g’s pk

g’s RMS

m/s2 pk

m/s2 RMS

in/s pk

in/s RMS

mm/s pk

mm/s RMS

mils p-p

µm p-p

3. Select the desired vibraon amplitude and frequency for tesng by turning the

AMPLITUDE and FREQUENCY dials clockwise to increase or counter clockwise to

decrease the seng.

•Slow Turns – sengs will increase or decrease by single steps

•Fast Turns – sengs will increase or decrease by larger increments

Doc# 100929 • HI-913-Shaker • January 2018 - RevD Page 4 of 21

Compleng the Test

4. Verify that the level indicated on the HI-913 is the same as the level being shown

on the readout of the sensor under test.

5. Before powering the unit OFF, reduce the vibraon amplitude. The HI-913 retains

the sengs used prior to shutdown when it is powered back ON. Reducing the

amplitude prior to shutdown ensures the sensor under test will not be jarred when

the HI-913 is powered ON.

6. Power the unit OFF by pressing and holding the FREQUENCY dial for 3 seconds.

• To preserve baery charge, the HI-913 will automacally power o

aer 20 minutes of inacvity when not plugged into the charger.

Aer Tesng

7. Plug the HI-913 into an AC power source when not in use. This will ensure the

baeries are fully charged for your next test and will also help to maximize the

lifespan of the baeries.

8. Periodic calibraon checks are recommended.

• A dedicated “vericaon sensor” can be used to check the system

readings and results. By using a dedicated sensor, you can ensure that

the system is providing the same result during each test.

• The HI-913 should be returned to Metrix for regular recalibraon

(recommended annually) or for any maintenance or repair. The most

current factory recalibraon date is displayed on the LCD screen during

the HI-913 boot-up sequence.

Addional Features

Test Sengs

The “Test Sengs” menu can be found by pressing FREQUENCY dial > “Test

Sengs.” A screen with the following will appear, use the FREQUENCY dial to

highlight and toggle all sengs:

• Back – returns user to “Calibraon Opons” menu

• Cal Route: N/A, Acve or o

o N/A indicates the Calibraon Route rmware opon has

not been purchased. Calibraon Route allows users to

program semi-automated test points. See “Calibraon

Route” secon for more informaon. Contact Metrix to

unlock this feature.

• Source: Internal or External

o If external is selected the shaker can be controlled

with an external source. See “Input/Output” for more

informaon.

Doc# 100929 • HI-913-Shaker • January 2018 - RevD Page 5 of 21

• Frequency Unit: Hertz or CPM (cycles per minute)

Amplitude Units

• Amplitude units that are seldom or never used can be turned

o by using the “Amplitude Units” feature, found by pressing

FREQUENCY dial > “Amplitude Units.”

• The “Amplitude Unit Screen” shows all 10 available amplitude

scales on model HI-913 Portable Vibraon Calibrator. Use the

FREQUENCY dial to highlight each scale and press the dial

to toggle the scale on or o. A lled circle next to the scale

indicates it is acve. An empty circle next to the scale indicates

it is inacve. Inacve scales do not appear when cycling through

scales using the AMPLITUDE dial during normal operaon.

• To go back to the “Calibraon Opons” menu use the

FREQUENCY dial to highlight “Back” then press.

Extending Low Frequency Operaon to 5 Hz

Firmware Opon: HI-913-LF5

Model HI-913 must be ordered with rmware oponHI-913-LF5 for the low

frequency response to be extended from 7 Hz to 5 Hz (420 CPM to 300 CPM). This

rmware can be added at any me. Contact Metrix for ordering and installaon

informaon.

The operaon of model HI-913 does not change if the HI-913-LF5 opon is

ordered. The minimum low frequency response will be 5 Hz instead of 7 Hz. Allow

for extra me for the shaker and sensor under test to sele when tesng at slow

speeds. The HI-913 has a pre-compensaon algorithm to reduce distoron. At

speeds below 10 Hz this algorithm takes 1-5 seconds to center vibraon on the

fundamental frequency and reach the desired amplitude.

Denion of Frequency Units

• Hertz (Hz) is dened as the number of periodic cycles per second and

it is a standard unit for measuring signal frequency.

Doc# 100929 • HI-913-Shaker • January 2018 - RevD Page 6 of 21

• CPM stands for Cycles Per Minute. CPM is commonly used for tesng

industrial sensors that monitor rotaonal vibraon. 1 Hz=60 CPM

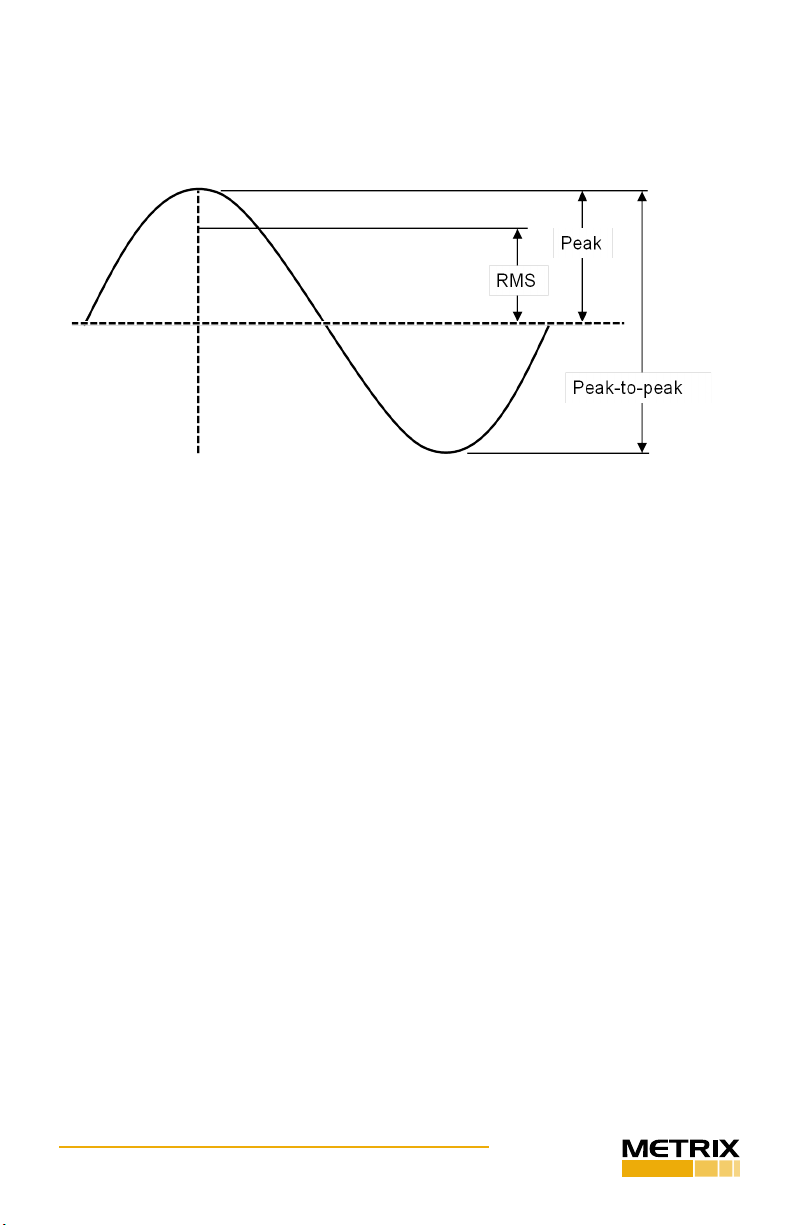

Amplitude Basics

• Root Mean Square (RMS) is a calculaon that takes the square root of

the average of the squared amplitudes from a set of data. This type of

measurement takes all amplitudes of a signal into account rather than

just one, making it an accurate tool for an overall calculaon.

• Peak (pk) bases calculaons on the highest value of the signal

generated during tesng. For a sinusoidal wave (as is produced by

the HI-913), the peak value is calculated by RMS*√2. The HI-913

does not measure a true peak value, but instead esmates the value

mathemacally based upon the RMS value.

• Peak-to-Peak (p-p) is a calculaon of the dierence between the

highest posive peak and the lowest negave peak of a recorded sine

wave. The

p-p value is calculated as two mes the peak value.

• Gravitaonal acceleraon (g) is the acceleraon experienced naturally

by objects in earth’s gravitaonal eld. It is approximately equal to

9.80665 m/s2.

Mounng Basics

Connecng Sensor to HI-913 Plaorm

1. Mang surfaces of the mounng plaorm and sensor should be at,

parallel and free of dirt, paint, epoxy, scratches, etc.

2. Threads in plaorm, sensor and adaptor (if needed) must match to

ensure a proper t and that tesng is free of errors. Clean any worn

threads with a tap or die and coat them in a silicone grease for best

results.

3. An adaptor may be needed to connect the sensor to the armature.

The HI-913 plaorm requires a ¼-28 thread.

Figure: Sinusoidal Wave

Doc# 100929 • HI-913-Shaker • January 2018 - RevD Page 7 of 21

4. Silicone grease can be applied to the mang surfaces and threads to

ensure good mechanical coupling. This is parcularly important when

tesng at high frequencies.

5. For threaded sensors, please follow the sensor manufacturer’s torque

recommendaon.

Tightening and Loosening Connecons

1. When ghtening or loosening the connecon between the sensor

and the HI-913 mounng plaorm, secure the mounng plaorm

with the supplied wrench.

2. It is important to keep sensors and xtures centered and straight

when aaching them to the HI-913 mounng plaorm. This will

ensure a stable, even connecon and eliminate potenal alignment

issues.

External Source Input

As an opon, it is possible to drive the HI-913 by using an external signal source

or a funcon generator. First, connect a signal source to the External Source

BNC Input located on the top right corner of the unit. To enable the EXTERNAL

SOURCE IN input, press the FREQUENCY dial to enter the “Calibraon Opons”

menu then rotate FREQUENCY dial to highlight and click on TEST SETTINGS. Next,

use FREQUENCY dial to highlight selecon next to “Source:” and toggle between

“Internal” and “External” by pressing the dial, select “External”.

1.When in external signal mode, the vibraon amplitude is

measured and displayed on the screen, however, the frequency

and amplitude of the shaker is controlled by the external source,

not by the HI-913. The frequency of the input signal is not

displayed on this mode.

2. The amplitude and sensivity values displayed on the screen are

for reference only. The measurements are not accurate while in

Ext Sig mode and do not fall under the published specicaons

for the product.

Do not exceed 1V RMS! Overdriving the unit may cause clipping,

unwanted distoron and damage to the unit.

Monitor Reference Output

The HI-913 is controlled by an internal shear mode quartz reference accelerometer.

The voltage output of the reference accelerometer can be monitored through the

available Monitor Reference BNC Output by connecng it to a readout device (e.g.

voltmeter or oscilloscope).

USB Connecon

The USB connecon for model HI-913 has no funconality unless power supply

accessories like HI-913-PS02 24 VDC power supply or HI-913-CALROUTE is ordered.

It is used at Metrix, Inc. during the manufacturing and calibraon processes.

Doc# 100929 • HI-913-Shaker • January 2018 - RevD Page 8 of 21

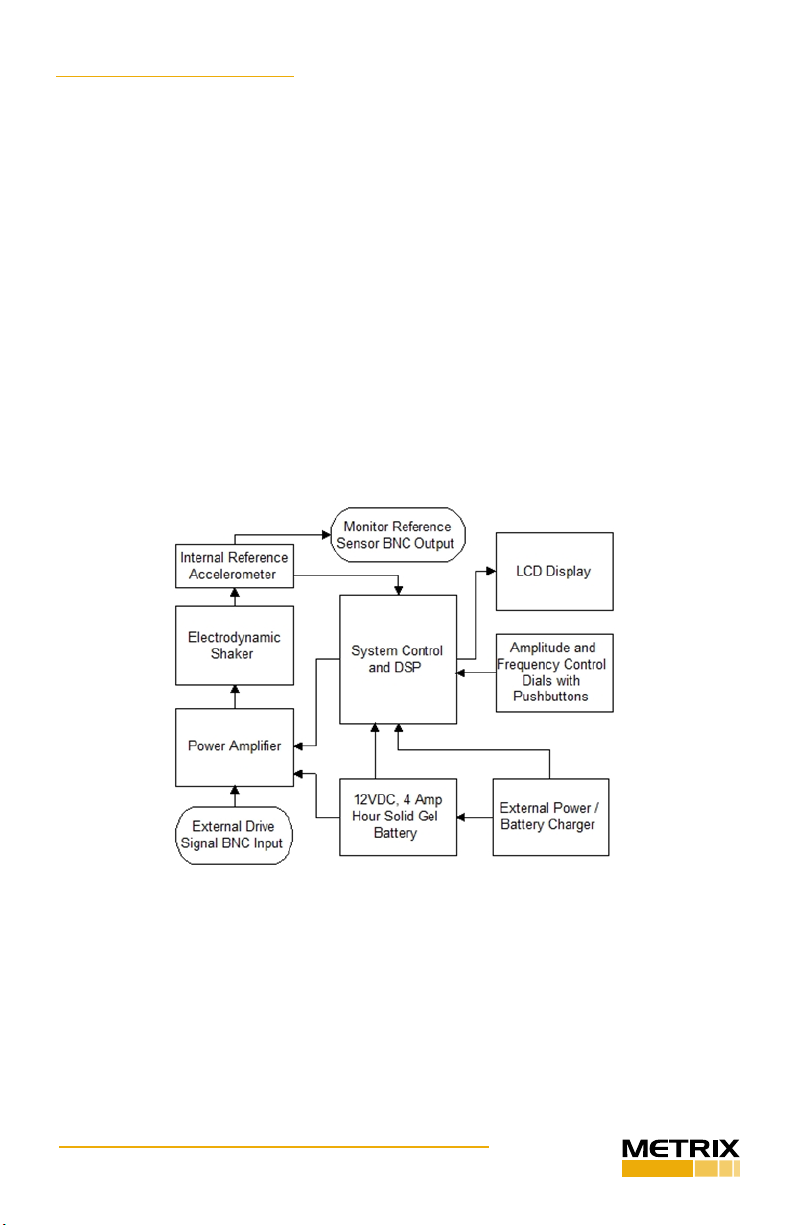

3. THEORY OF OPERATION

Instrumentaon

The Model HI-913 Portable Shaker Table internal electrical system is comprised of

several dierent mechanisms:

• Electrodynamic Shaker

• Power Amplier

• Reference Accelerometer

• Signal Generaon Electronics

• Sensor Signal Measurement Electronics

• LCD Digital Display

• Two Dials with Detent and Integrated Push Buons

• 12 VDC, 4 Amp Hour Solid Gel Baery

• External Charger

The LCD display connuously shows the frequency of the shaker drive signal and

the vibraon amplitude of the mounng plaorm as measured by the reference

accelerometer.

The reference accelerometer is a PCB Piezotronics ICP® quartz shear sensor,

integrated into the mounng plaorm. A calibraon “standard” maintained by

Metrix is used to calibrate the HI-913 as a complete system and provides NIST

traceability.

The power amplier is specially designed to provide the current required to drive

the electrodynamic shaker.

Doc# 100929 • HI-913-Shaker • January 2018 - RevD Page 9 of 21

The electronic signal processing system produces a variable frequency sine wave,

which becomes the source of the driving signal to produce the vibraon at the

mounng plaorm.

The frequency of the shaker drive signal is controlled by the front panel

FREQUENCY dial. The amplitude of the shaker drive signal is controlled through a

feedback loop, to maintain the stability of the actual moon. Adjusng the front

panel AMPLITUDE dial adjusts the target vibraon amplitude.

Pressing the FREQUENCY dial toggles the frequency units between CPM and Hz.

Pressing the FREQUENCY dial one more me enables the External Source Input.

Pressing the AMPLITUDE dial toggles the amplitude measurement units through

the following choices:

Frequency Acceleraon Velocity Displacement

Hz

CPM

External Signal

g’s pk

g’s RMS

m/s2 pk

m/s2 RMS

in/s pk

in/s RMS

mm/s pk

mm/s RMS

mils p-p

µm p-p

3.2 Baery and Charger

The Model HI-913 can be operated from AC line power or from its internal

rechargeable baery. When the external power supply is connected, it becomes

the primary power source, operang the unit while simultaneously charging the

baery.

NOTE: It is good pracce to perform calibraons on baery power. Disconnecng

from line power ensures a power surge will not cause the calibrator to power down

during test. If excess current is detected during use, the portable calibrator shuts

down to prevent damage.

Baery power is supplied by a sealed solid gel lead acid 12 VDC rechargeable

baery. The baery can be permanently damaged if completely drained. To

prevent damage, the HI-913 will automacally shut o when the baery power

level gets too low. Keeping the baery fully charged ensures the unit is always

ready for use.

Under mild operang condions, a fully charged baery will allow the HI-913 to

operate for up to 18 hours. The charge life of the baery depends on both the

length of use and the amount of power (dependent upon payload, frequency and

amplitude) required for a parcular test. When tesng requires high vibraon

levels, the charge life will be shorter than during less rigorous tesng. For example,

connuous tesng of a 100 gram payload at 10 g pk will drain the baery charge in

approximately 1 hour.

A “Baery Life” indicator is displayed on the LCD screen to approximate the unit’s

remaining charge life. Replacement baeries (Model HI-913 BAT01) and power

supplies/chargers (Model HI-913-PS01) are available from Metrix, Inc.

Doc# 100929 • HI-913-Shaker • January 2018 - RevD Page 10 of 21

The HI-913 calibrators connuously monitor the state of baery charge during

operaon, storage and charging. During operaon, if the baery capacity falls

near minimum, the unit will shut o aer approximately 2 minutes of inacvity

rather than the usual 20 minutes. During storage, if the baery voltage falls near

the minimum, the unit will go into deep sleep, requiring connecon of AC power

and reset of me and date before resumpon of operaon. During charging, the

unit connuously displays charging indicaon and state of charge, depending upon

operaon level and me of charge.

When operang the HI-913 at high amplitudes and heavy payloads

with the baery charger plugged in, the current draw to the shaker

and amplier can be large enough to overload the charging circuit

resulng in an unstable output signal. Operang the HI-913 under

these condions can result in damage to the electrical components in

the system. In order to re-establish a stable output signal, turn down

the amplitude level of the HI-913 or unplug the charger.

Baery Informaon and Care

• The unit is delivered in a parally charged state. Fully charge unit for 20 hours

before using for the rst me. (The unit cannot be overcharged by keeping it

plugged into the power supply.)

• To recharge the unit, use only the universal power supply included. All

baeries lose energy from self-discharge over me and more rapidly at higher

temperatures. A full charge cycle can take up to 20 hours.

• If not used for a prolonged period of me, recharge every 2 months.

• Suggested Best Pracce: Charge unit fully prior to eld use. Recharge the unit

as soon as possible aer use.

4. SPECIFICATIONS AND PERFORMANCE

General

Frequency Range

(operang, 100 gram

payload)

7 Hz - 10 kHz 420 - 600 k CPM

Maximum Amplitude

(100 Hz no payload)

20 g pk

15 in/s pk

50 mils pk-pk

196 m/s2 pk

380mm/s pk

1270 µm pk - pk

Maximum Payload[1] 800 gram 800 gram

[1] Operang range reduced at higher payloads. Reference manual for full details

Doc# 100929 • HI-913-Shaker • January 2018 - RevD Page 11 of 21

Accuracy of Readout

MEASURED WITH 10 GRAM QUARTZ REFERENCE ACCELEROMETER

Acceleraon (30 Hz to 2 kHz) ± 3%

Acceleraon (7 Hz to 10 kHz) ±1 dB

Velocity (10 Hz to 1000 Hz) ± 3%

Displacement (30 Hz to 150 Hz) ± 3%

Amplitude Linearity (100 gram

payload, 100 Hz)

< 1% up to 10 g pk

Waveform Distoron (100 gram

payload, 30 Hz to 2 kHz)

< 5% THD (typical) up to 5 g pk

Units of Readout

Amplitude

Acceleraon g pk m/s2 pk

g RMS m/s2 RMS

Velocity in/s pk mm/s pk

in/s RMS mm/s RMS

Displacement mils pk-pk µm pk - pk

Frequency Hz CPM

Power Requirements

Internal Baery

(sealed solid gel lead

acid)

12 VDC, 4 amp hours 12 VDC, 4 amp hours

AC Power

(for recharging baery)

110 – 240 Volts,

50 - 60 Hz

110 – 240 Volts,

50 - 60 Hz

Operang Baery Life[2]

100 gram payload, 100

Hz, 1 g pk

18 hours

100 gram payload, 100

Hz, 10 g pk

1 hour

[2] As shipped from factory in new condion

Temperature

Operang 32° - 122 °F 0° - 50 °C

Physical

Dimensions (H x W x D) 8.5 in x 12 in x 10 in 22 cm x 30.5 cm x 28 cm

Weight 18 pounds 8.2 kg

Sensor Mounng

Plaorm Thread Size

¼ - 28

Doc# 100929 • HI-913-Shaker • January 2018 - RevD Page 12 of 21

Shaker Loading

Maximum advisable vibraon levels are dependent upon the maximum frequency

of operaon and the payload. The chart below shows the maximum vibraon

levels as a funcon of both frequency and payloads. Payloads exceeding 800 grams

should not be tested on the Model HI-913.

Excessive loads may result in damage to the moving coil and exure. Care must be

taken when tesng payloads with large footprints, parcularly those with an oset

center of gravity. Severe rocking modes can produce high transverse moon and

lateral loads on the moving coil and exure, resulng in damage. When ng test

transducers and xtures onto the mounng plaorm, aim to keep the center of

gravity directly above, and in line with the center axis of the ¼-28 threaded hole.

This is a safeguard against side loading the shaker.

In some cases of extremely heavy shaker payloads at high vibraon levels

(depending on the frequency), the HI-913 may exhibit both frequency and

amplitude instabilies. In this case, please reduce the excitaon amplitude and/or

the payload to eliminate the eect.

The HI-913 electronics incorporates a shaker power amplier with thermal

protecon. If the shaker payload amplitude and run me exceed safe thermal

ranges, the shaker table power amplier will protect itself and shut o. The unit

should be turned o and allowed to cool before resuming operaon.

Doc# 100929 • HI-913-Shaker • January 2018 - RevD Page 13 of 21

Doc# 100929 • HI-913-Shaker • January 2018 - RevD Page 14 of 21

5. RECOMMENDED PRACTICES

Operaonal Vericaon and Recalibraon

As with all calibraon systems, periodic vericaon of the system’s performance

is strongly recommended. This is best done by calibrang a dedicated vericaon

accelerometer each day that the unit will be used. This pracce conrms proper

calibraon of the equipment at the me of use.

Results of the vericaon should be compared to previous results obtained with

that dedicated, controlled accelerometer. If the calibraon result of the vericaon

sensor changes, the HI-913 should be evaluated further to determine the root

cause of the discrepancy.

Field repair of the HI-913 is not possible, so if performance of the HI-913

is out of specicaon, it should be sent back to Metrix, Inc. for evaluaon,

repair and recalibraon. Please contact Metrix at info@metrixvibraon.com or

+1.281.940.1802 for a Return of Material Authorizaon (RMA) number.

Standard Checks for Transducers

Linearity and frequency response checks should be performed periodically to

validate vibraon transducer funconality.

Linearity is checked by subming the sensor to dierent vibraon levels while

frequency is kept constant (typically at 100 Hz or any other frequency specied

by the transducer’s manufacturer). The vibraon is set to dierent levels within

the dynamic range of the sensor, trying to cover (as much as possible) from low

to high operang levels. The sensor output is recorded and checked if it remains

proporonal (linear) to the sensor excitaon input. Alternavely, the sensor

sensivity can also be recorded and its deviaon observed for the dierent test

points (it should not vary too much for sensors that are linear).

The frequency response of a vibraon transducer can be tested by checking the

sensor output across dierent frequency points within the operaonal frequency

range of the transducer. Typically, the vibraon level of the unit is set at a constant

value (10m/s² and 1g are common choices for accelerometers) and the sensor

output (or the sensor sensivity) is observed and recorded at dierent frequency

points.

Typical Accelerometer & Velocity Sensor Checkout

Accelerometers & velocity sensors are tested by performing a frequency response

calibraon. This is done by measuring the sensivity of the sensor at a variety of

frequencies within its linear range. Per the ISO 16063-21 accelerometer calibraon

standard, the amplitude at each frequency is at the discreon of the user and need

not be kept consistent. Best pracce is to use amplitude safely above the noise

oor and but low enough not to create distoron on the shaker. Thus 1.0 g’s peak is

the most common aplitude for accelerometers.

The ISO 16063-21 standard recommends tesng at the center frequencies of the

1/3 octave bands. For accelerometers with 10 kHz high frequency response that

would mean 29 dierent test points, which can be me consuming. Accelerometer

manufacturers test at far less points. In general as long as the test covers the

praccal usage of the sensor and the test points are evenly dispersed through the

Doc# 100929 • HI-913-Shaker • January 2018 - RevD Page 15 of 21

test range the user will perform a good and thorough test of an accelerometer.

A good pracce within industrial applicaons is to follow the American Petroleum

Instute Standard 670 “Machinery Protecon Systems” recommendaons for

accelerometer and velocity sensor test points. Standard 670 recommends tesng at

the following frequencies for both accelerometers and velocity sensors:

• 10, 20, 50, 60, 100, 200, 500, 1000, 2000, 5000 and 10000 Hz

o Model HI-913 is not capable of 61.44 Hz, only

integer numbers such as 61 or 62.

For accelerometers the recommended amplitudes in API 670 are:

• 0.15 g’s peak (1 m/sec2 RMS) for 10 Hz

• 1 g peak (7 m/sec2 RMS) for 20-1000 Hz

• 4 g’s peak (30 m/sec2 RMS) for 2000-10000 Hz

For velocity sensors the recommended amplitudes in API 670 are:

• 0.92 ips peak (15.92 mm/sec RMS) for 10 Hz

• 3.08 ips peak (55.70 mm/sec RMS) for 20 Hz

• 1.23 ips peak (22.28 mm/sec RMS) for 50 Hz

• 0.62 ips peak (11.14 mm/sec RMS) for 100 Hz

• 0.31 ips peak (5.57 mm/sec RMS) for 200 Hz

• 0.12 ips peak (2.23 mm/sec RMS) for 500 Hz

• 0.06 ips peak (1.11 mm/sec RMS) for 1000 Hz

• 0.12 ips peak (2.39 mm/sec RMS) for 2000 Hz

• 0.05 ips peak (0.95 mm/sec RMS) for 5000 Hz

• 0.02 ips peak (0.48 mm/sec RMS) for 1000 Hz

o Note that velocity is not recommended as a vibraon

measurement scale at frequencies greater than 1000

Hz. Thus many sensor manufacturers install low-pass

lters on velocity sensors at 1000 Hz or lower.

Praccal Industrial (Predicve Maintenance) Tesng Recommendaons

While tesng to the API 670 or ISO 16063-21 standard is certainly thorough it is not

always praccal and is me consuming especially for the predicve maintenance

user. Thus Metrix makes the following recommendaons for industrial vibraon:

• For permanent mount accelerometers/velocity sensors routed

to an online monitoring system or juncon box, at least test

the sensors at 1x and 2x running speed and conrm both the

vibraon alert (high) and alarm (high-high).

• For route-based predicve maintenance where one sensor

is magnecally mounted on many machines at many

points, perform a complete frequency response test of the

accelerometer. Its accuracy is important at many frequencies.

Test to Fmax on the vibraon analyzer. If high frequency bearing

Doc# 100929 • HI-913-Shaker • January 2018 - RevD Page 16 of 21

fault detecon methodologies are in use, test the sensor to the

highest possible bearing defect frequency.

o Tip: magnecally mounng sensors greatly reduces high

frequency response. A ferrous magnet target, mounng

pad, is included with the HI-913. One can install this pad

on the shaker and mount accelerometers magnecally.

Always rock the sensor in place as one would on the

machine. Test the accelerometer to Fmax on the

analyzer to see if response is amplied at relevant high

frequencies.

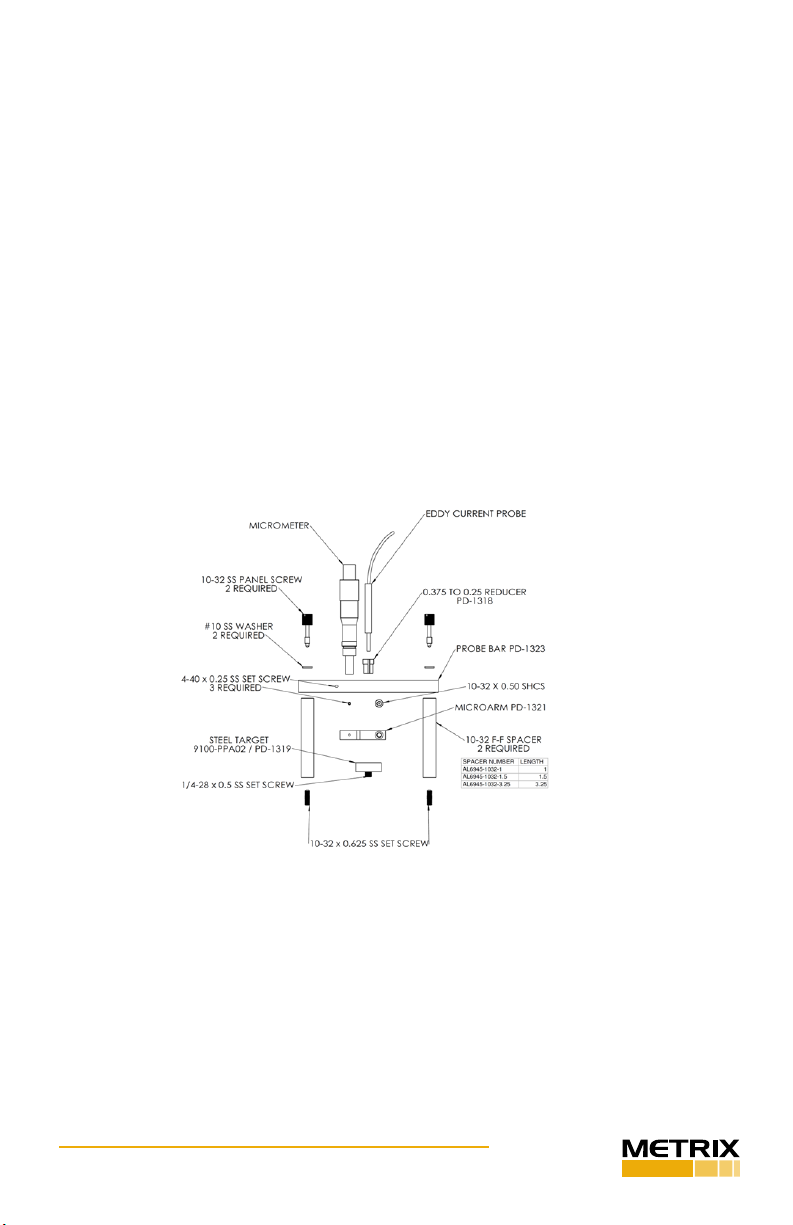

5.3 Non-Contact Displacement Sensor Calibraon

Non-contact displacement sensors, also known as proximity probes, eddy current

probes or simply displacement probes, can be checked for accuracy, linearity and

frequency response. Proximity probe systems require the use of the oponal

proximity probe adaptor kit, shown on the next page. The following secons detail

the procedure for performing linearity and frequency response checks on a non-

contact displacement sensor.

Non-Contact Displacement Sensor Test Set-Up

Note: The calculaons in these instrucons are based on a 200 mV/mil eddy current

proximity probe to provide an example based on nominal sensivity. In most cases,

the proper proximity probe, extension cable, and driver (proximitor®) must be

matched in order to obtain the expected output from this type of transducer.

[Proximitor is a registered trademark of Bently Nevada.]

Doc# 100929 • HI-913-Shaker • January 2018 - RevD Page 17 of 21

1. Remove the (2) 10-32 pan head screws on the user panel of the

portable shaker table (white arrows in picture below).

2. Install the AISI 4140 steel target into the shaker on the mounng

plaorm.

Doc# 100929 • HI-913-Shaker • January 2018 - RevD Page 18 of 21

3. Install the non-contact displacement sensor in the microarm aer

stringing the probe through the probe bar as shown in the picture

below. Please note: An 8 mm non-contact displacement sensor

with 3/8 - 24 threaded case will mount directly while a 5 mm non-

contact displacement sensor with a ¼ - 28 threaded case requires the

supplied bushing. Slide the non-contact displacement sensor into the

microarm; ghten the socket head cap screw inside the microarm to

lightly squeeze the probe to ensure the probe is held securely.

Carefully lay out the assembly to resolve the required spacer or spacers to hold the

non-contact displacement sensor the proper distance from the target as shown

below. The non-contact displacement sensor will need to be held so that the

sensor will contact the target and must be capable of traveling 100 mils before

the micrometer runs out of travel. (for 200 mV/mil probe with 10-90 mils range).

Non-contact displacement sensors come in various lengths so adjustability has

been designed into the assembly. Aach selected spacer or spacers using setscrews

provided, leaving threaded holes exposed.

Socket Head

Cap Screw Set Screw

Doc# 100929 • HI-913-Shaker • January 2018 - RevD Page 19 of 21

4.Finalize the assembly by aaching probe bar, microarm, non-contact

displacement sensor, and micrometer on top of the spacers and

secure with provided panel screws.

Doc# 100929 • HI-913-Shaker • January 2018 - RevD Page 20 of 21

Proximity Probe Dynamic Linearity Calibraon & Conrmaon of Vibraon

Alarms

IMPORTANT: The HI-913 powers up at the unit’s previous frequency and amplitude

sengs. Prior to using the HI-913 for calibrang non-contact displacement

sensors, set amplitude to a low level to avoid striking the p of the probe with the

target due to previously set large displacements.

1. Mount the proximity probe to the shaker facing the target by following

instrucons in the previous secon.

2. Gap the probe. With the non-contact displacement sensor powered

up and the output from the probe driver wired to a voltmeter set

to DC voltage, adjust the micrometer so the gap between the probe

p and the steel target is around 50 mils. If you are using a 200 mV/

mil proximity probe the voltmeter should read between -8 and -11

Volts DC, typically ~-9 Volts DC is 50 mils. Fiy mils is the typical

recommended gap seng for non-contact displacement sensors,

ensuring the sensor is in the center of its dynamic range. If the probe

is 50 mils from target (or rotang equipment before start-up) it can

accurately measure up to 80 mils peak-to-peak vibraon. Consult

your non-contact displacement sensor’s user manual for addional

informaon.

3. Power-on the shaker by pressing and holding the FREQUENCY dial.

4. Test the probe at running speed of the machinery it protects.

Primary vibraon issues occur at running speed. Thus ensuring the

proximity probe is accurate at running speed is the most praccal

and condence-building test. Test speed can be set in Hz or CPM

(see Secon 2: Operaon Guide for instrucons) by turning the

FREQUENCY dial.

5. Conrm vibraon alarms. Press the AMPLITUDE dial to cycle through

vibraon scales unl either mils p-p or µm p-p is displayed. Choose

the appropriate scale for your vibraon monitoring system. Turn the

AMPLITUDE dial, adjusng vibraon to the lowest vibraon alarm

threshold (somemes called “alert”). Conrm with control room that

displayed amplitude on model HI-913 shaker equals value read on

monitoring system. Conrm vibraon alarm is triggered, making sure

to wait long enough for programmed me delays to expire. Repeat the

process for each vibraon alarm threshold.

Troubleshoong the proximity probe system

If the vibraon alarms did not acvate at desired vibraon thresholds the most

common reason when using proximity probes is incorrect cabling. Advice on

troubleshoong follows below. Be sure to read the previous secon on conrming

vibraon alarms by dynamic linearity tesng.

• Connect the output of the probe driver to a volt meter measuring AC

voltage.

• The volt meter measures in AC voltage RMS. The HI-913 simulates

displacement vibraon in peak-to-peak scale. Thus one must convert

the RMS voltage measurement to peak-to-peak. To do so mulply the

measurement on the volt meter by 2.828.

o Example: when shaking target at 5 mils peak-to-peak and

3600 CPM, volt meter measures 353 mV AC. Mulply this

number by 2.828 to get 998 mV (353 mV x 2.828 = 998 mV).

Proceed to next step.

Table of contents

Popular Paint Sprayer manuals by other brands

WAGNER

WAGNER GM 4700AC operating manual

DAL DEGAN

DAL DEGAN ARES 6 Instructions for the use

Graco

Graco HYDRA-SPRAY N Series Instructions-parts list

Graco

Graco 311322L Operation, parts, service and repair

Lafferty

Lafferty 925025-E Installation & operation instructions

KISANKRAFT

KISANKRAFT FarmBoy FB-KPS-204/804 user manual