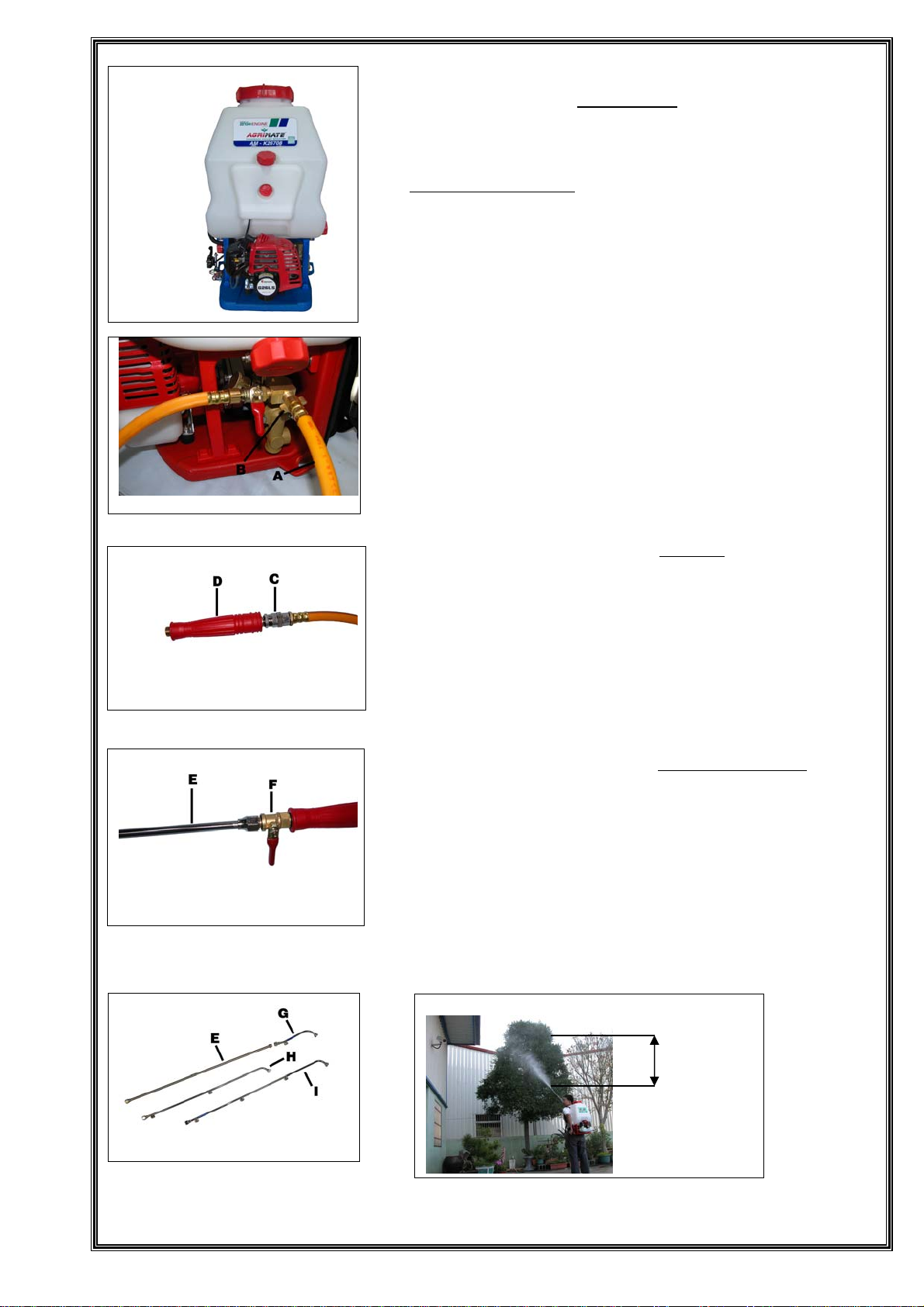

INTRODUCTION

To correctly use the sprayer and prevent accidents, do not start work without having first carefully

read this manual. You will find explanations concerning the operation of the various parts plus

instructions for necessary checks and relative maintenance.

SAFETY PRECAUTIONS

WARNING: If correctly used, the sprayer is a quick, easy to handle and efficient tool: if used

improperly, or without the due precautions it could become a dangerous tool. For pleasant and

safe work, always strictly comply with the safety rules that follow and throughout this manual.

1- The sprayer must be used only by adults with knowledge of the operating instructions.

2- Do not use the sprayer when you are physically tired.

3- Wear gloves, protective glassed and ear protection. Wear long trousers; DO NOT WEAR

short trousers. Wear non-ship footwear; DO NOT work with open sandals or barefooted.

4- Never allow bystanders to remain within your working area.

5- Always work from a firm-footed and safe position.

6- Transport the sprayer with the engine switched off and the liquid tank empty.

7- Do not attempt to service the sprayer while the engine is running.

8- Fill the tank away from sources of heat and with the engine stopped. Never smoke while

filling. Never take the cap off the tank when the engine is running. If fuel spills over while

filling, move the sprayer at least 3 meters (10 ft) away before starting.

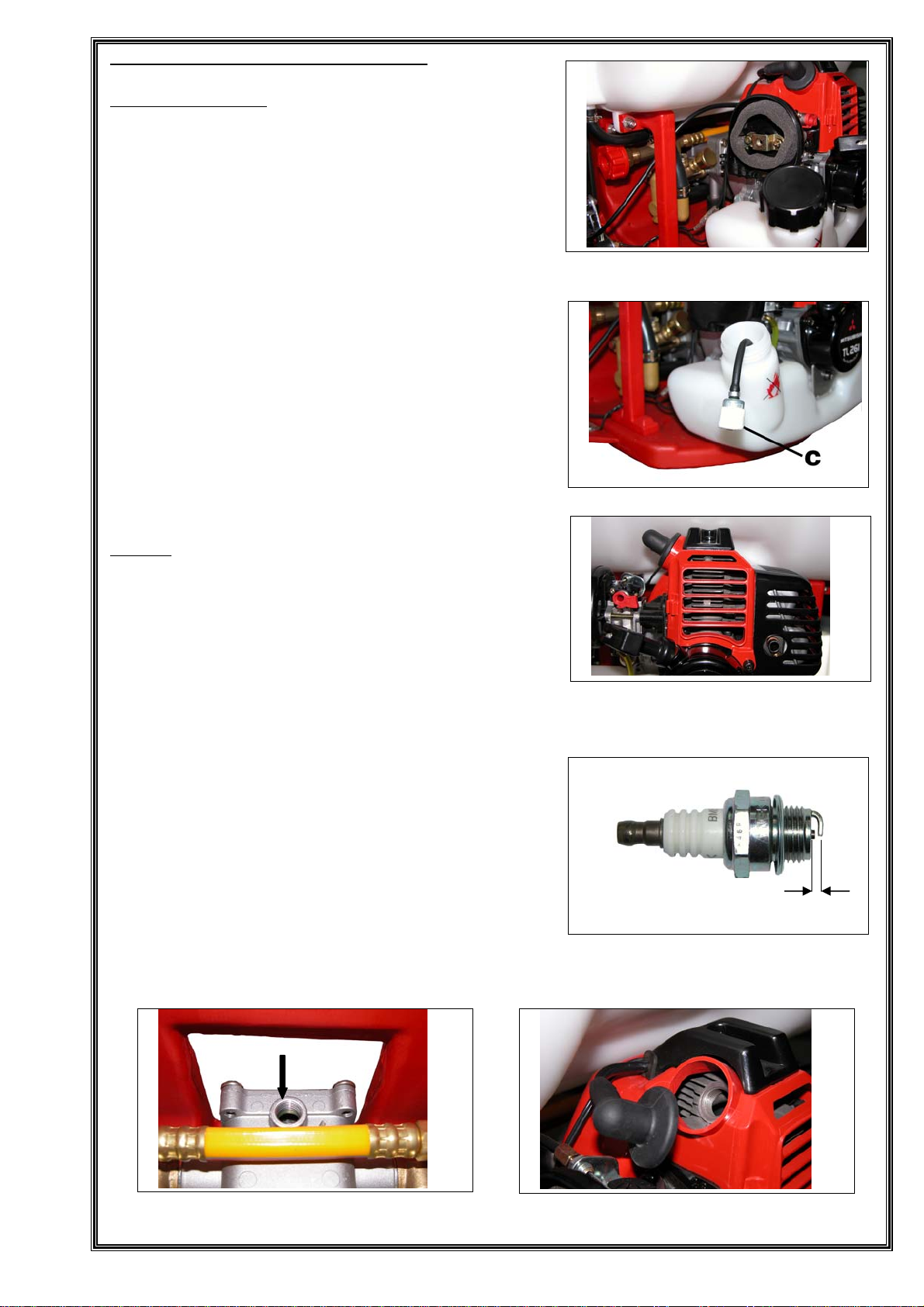

9- Before starting, make sure that the liquid cock is closed.

10-Check the sprayer each day to ensure that each device, whether for safety or otherwise, is

functional.

11-Always follow the manufacturer’s instructions for the maintenance operations.

12-Never use a damaged, modified, or improperly repaired or assembled sprayer. Do not remove

or damage any of the safety devices.

13-Never carry out operations or repairs on your own that are other than routine maintenance.

Call specialized and authorized workshops only.

14-Never use fuel for cleaning operations.

15-Keep the sprayer in a dry place, off the ground with the tanks empty.

16-Wear an approved respirator and protective overalls for protection against toxic liquids.

17-Do not operate the sprayer in explosive atmospheres or near inflammable substances. When

spraying in a greenhouse, ensure that the work area is well ventilated.

18-Do not use the sprayer until you have completely understood the specific operating method.

19-It is prohibited to attach a pump or any other implement not supplied by the manufacturer to

the power take – off the pump.

20-If your sprayer is no longer usable, dispose of it carefully without damaging the environment

by handing it into your local Dealer who will arrange for its correct disposal.

21-Only loan your sprayer to expert users who are completely familiar with sprayer operation and

correct use. Give other users the manual with operating instructions, which they should read

before using the sprayer.

22-Keep this manual on hand and consult it before each use of the tool.

23-Do not direct the lance and nozzles towards persons or animals.

24-Never start the machine without pump. It will cause serious damages to the engine parts as

well as the withdrawal of the warranty.

25-Do not use the sprayer set close to electrical equipment.

26-Take the cap off the spark plug each maintenance time, during cleaning or repair work.

27-The sprayer must always be kept upright to prevent liquid escaping from the tank.

28-Do not use the sprayer with inflammable and / or corrosive substances.

29-Do not assemble the pump on other motors or power transmissions.

30-The engine is 2-stroke. Always use mixture for the fuel. Gasoline without oil damages engine

Inashorttime. 2