Metrix 440 User manual

440 & 450 ELECTRONIC VIBRATION SWITCHES

Installaon Manual

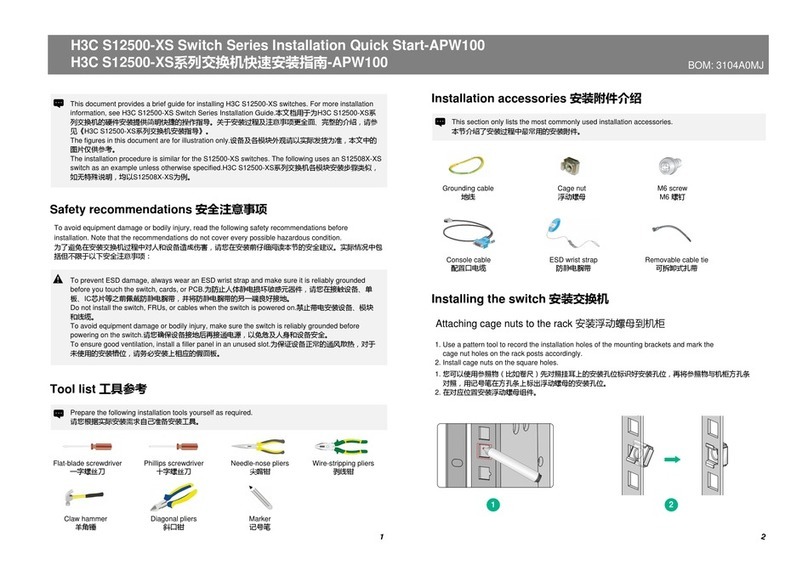

1. OVERVIEW

1.1 Introducon

The single setpoint models (SR) contain one

trip limit for shutdown. The oponal dual

setpoint models (DR) contain two indepen-

dent trip limits; one for alarm and one for

shutdown. Shutdown and alarm limits are

in engineering units of velocity. In addion,

a 4-20 mA output proporonal to vibraon

velocity is provided.

Models 440 and 450 use idencal design

and dier only in the enclosure. The model

440 is designed to be used in non-hazardous

or non-incendive hazardous locaon (Class

I, Division 2, Groups B, C, D, and NEMA

4X). The model 450 is designed to meet

explosion-proof requirements for Class

I, Division 1, Groups B, C, D installaons.

Unless otherwise noted, all discussions and

diagrams herein assume the model 440, but

apply equally to the model 450.

1.2 KeyCapabilies

• Shutdown and alarm sengs are based

on vibraon severity. The internal sen-

sor (unless the external sensor opon

has been specied (Ordering Opon

I=5 – see note in Secon 5.4) is a piezo-

electric crystal with built in microelec-

tronics to reduce noise sensivity. The

output signal is electronically integrat-

ed to measure and trip on velocity.

• Calibrated setpoint controls permit set-

point adjustment of vibraon velocity

levels up to full scale range. DR model

Doc# 90018-031 • REV L (April 2016)

Doc# 90018-031 • REV L (April 2016) Page 2 of 16

NOTE: Discrete outputs should be manually bypassed during

this procedure, parcularly if used to trip the machine. They will

change state aer the me delay, and should be externally jump-

ered or otherwise disabled to prevent nuisance trips.

Calibrated setpoint controls

enable operator to set specic

velocity alarm/shutdown levels.

Adjustable me delay of 2-15 seconds.

LED illuminates immediately when vibraon ex-

ceeds setpoint (but alarm or shutdown discrete

outputs will change state only aer me delay).

1.3UserInterface

KeyCapabilies(connued)

switches have dual setpoints – one for alarm and one for shutdown – that are indepen-

dently adjustable.

• 4-20 mA output provides a convenient interface for trending and displaying vibraon

amplitude in a programmable logic controller (PLC), SCADA system, data logger, or oth-

er instrumentaon. 4mA corresponds to no vibraon, and allows the user to disnguish

between no power to the switch (0mA) and a funconal switch but with no vibraon

present (4mA). 20mA corresponds to full scale vibraon amplitude.

• Discrete outputs used for alarming and shutdown can be selected from triac, solid-

state analog switch (FET), or electromechanical relays, but must be specied at me of

ordering. These outputs are independently congurable for open on alarm/shutdown

or close on alarm/shutdown .

• An adjustable (2-15 seconds) me delay is standard. This prevents false alarms/shut-

downs on high startup vibraons and also from non repeve transient events.

• Self-test and vericaon: An LED adjacent to each setpoint control illuminates the

instant the measured vibraon level exceeds the setpoint. The unit can be periodically

veried on line by turning the setpoint control down unl the LED comes on. This set-

ng is then compared with the vibraon amplitude measured via a portable vibraon

meter at the same locaon as the switch’s sensing element, providing a vericaon

check of the unit.

Doc# 90018-031 • REV L (April 2016) Page 3 of 16

NOTE: Turning either adjustment knob to the TEST posion reduces

the corresponding setpoint to its minimum allowable value, eec-

vely meaning that any vibraon will exceed the setpoint. Although

the LED will come on immediately, the discrete output will change

state only aer the duraon of the adjustable me delay has elapsed.

If the TEST posion is maintained for less than the duraon of the me delay,

the discrete output will not change state.

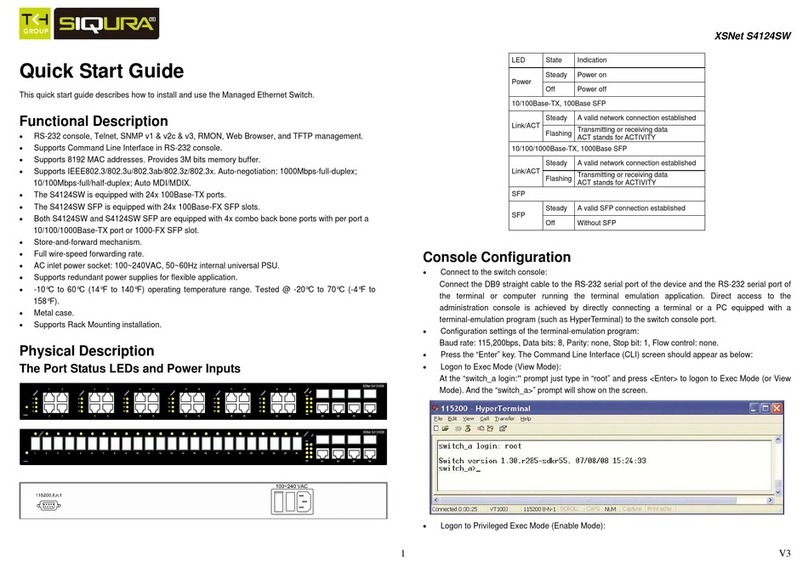

VDE approved terminal strip

accepts #12 AWG wire. All

hardware is capve.

Each discrete output is inde-

pendently eld congurable to

open on alarm (N.C.) or close

on alarm (N.O.)

3. SAFETY WARNINGS

CAUTION - SHOCK HAZARD 230/110 VOLTS

The terminal block inside the 440 is connected to AC power

(110 VAC or 230 VAC depending on model) except DC input

power models.

If adjustments to the device are being made with power applied, exer-

cise cauon to avoid contact with the terminal block screws by any part

of the body or electrically conducve tool.

EQUIPMENT OPERATION

Model 440 and 450 vibraon switches must be installed and operated

as described in this manual and in accordance with published datasheet

specicaons. Operaon outside these limits may adversely aect the

switch’s alarming and shutdown capabilies, resulng in damage to

machinery and property as well as jeopardizing personnel safety.

2. SPECIFICATIONS

Refer to product datasheet 1004730, available online at www.metrixvibraon.com.

Doc# 90018-031 • REV L (April 2016) Page 4 of 16

4. MECHANICAL INSTALLATION

4.1 Where to Mount the Switch

It is desirable to mount the electronic switch (or transducers for switches with external

transducer opon) on a bearing housing, since the forces generated by the rotang parts

through unbalance, misalignment, bearing wear, etc., are transmied to the machine’s cas-

ing through the bearings.

Most bearing housings are curved so it is necessary to aach a bracket with a at surface for

mounng the switch. If the machine has bolted end plates on the bearings or horizontally

split bearing housings, these bolts can be used to aach the bracket.

When bolt holes are not available or are not suitable, an alternave way is to weld an angle

iron bracket similar to that in the sketch, but oriented so as to straddle the bearing housing.

The best approach will typically be to mount a gusseted bracket, as shown below.

The guiding principle is to ensure that the bracket is suitably s such that machinery

vibraon is completely transmied through the bracket to the vibraon switch or sensor.

Problems can occur when the bracket is too compliant, and may allow bracket resonance

to amplify the actual machinery vibraon, resulng in false shutdowns or alarms. For many

applicaons, 3/8 Inch material (preferably steel) will be suitable.

4.2 SwitchSensiveAxis

The sensive vibraon “measuring” axis is perpendicular to the mounng base of the unit

(vibraon switch or transducer). Always mount the unit such that the desired vibraon of

the equipment being monitored will occur along this axis.

NOTE: Models using an external sensor will be sen-

sive along the sensor’s axis, not the switch’s axis.

Doc# 90018-031 • REV L (April 2016) Page 5 of 16

4.3 ChoosingMounngOrientaon

The vibraon switch can be mounted in the vercal or horizontal orientaon (or anything in

between) without a change in its sensivity. Ideally, the mounng orientaon will be chosen

by measuring the vibraon levels in both direcons with a vibraon meter and then select-

ing the direcon in which the highest vibraon occurs. This will typically be horizontal, since

most machine structures are less rigid horizontally than vercally.

4.4 NumberofPointsperMachine

Anywhere from one to four switches are used per machine (depending on how crical the

machine is to the process or how expensive it is), one on each end of the motor and one on

each end of the compressor, fan, pump or whatever is being driven. If there is a gear box in

between, one may be used here also.

It is quite common to use only one switch. In this case, it is best to mount on or near the

driven bearing. For example, if you have a motor and large fan with a bearing on each end

of the fan, the fan bearing on the motor side would be the driven bearing. It will usually see

the highest forces and have the highest vibraon level.

4.5 MounngatotherLocaons

When it is not possible to mount the switch directly on the bearing housing, the switch can

be located elsewhere, keeping in mind that it is usually machinery vibraon that is being

measured (not bracket, piping, or other vibraon). Do not mount the switch in locaons

where very lile machinery vibraon is transmied, as the switch will be less sensive to

damaging changes in machinery vibraon levels. Again, it is desirable to survey the machine

with a vibraon meter. If the level at the intended locaon is not aenuated by more than

about 50% relave to the levels directly on the bearing housing, it will probably be sasfac-

tory. However, alarm and shutdown sengs should then be reduced proporonately as well.

4.6 MounngSurface

Choose or fabricate a solid (rigid) surface (on the equipment being monitored) to mount

the vibraon switch or transducer. This will ensure transfer of the vibraon to the vibraon

transducer, while not introducing erroneous vibraons. In addion, the surface presented to

the base of the unit should be at. Fasten using sturdy hardware at all places provided.

4.7 TemperatureConsideraons

The switch is designed to dissipate internal heat by conducon through its base. Hence, it is

important to keep the mounng surface below the switch max temperature limit of 140°F. If

the equipment being monitored is going to exceed this limit, consideraon should be given

to either using one of the remote transducers, or thermally isolang the switch. To ensure

accurate switch performance, a warm up me of 5 minutes is recommended.

4.8 ElevaonConsideraons

The reduced atmospheric pressure at elevaons more than 2,000 meters (~6600 feet) above

Doc# 90018-031 • REV L (April 2016) Page 6 of 16

sea level does not allow heat to dissipate as readily as at lower elevaons, and the maximum

operang temperature must be de-rated by 2% per 300 meters. Thus, a switch installed at

an elevaon of 2,600 meters will have a maximum operang temperature 4% lower than

a switch installed between seal level and 2,000 meters. Refer to datasheet 1004730 for

complete specicaons.

4.9 Cable/Wiring

The method chosen to electrically connect to the switch or transducer should be mechani-

cally exible, to eliminate the measurement of vibraon of material not of interest (piping,

etc.), and provide a moisture barrier as well.

Although seal ght and other exible conduit have been used successfully, in areas of

extreme humidity or moisture it is recommended that a “SO” type cable together with a

suitable rain-ght CGB ng be used.

No stress should be possible on the wiring to the terminal block. If such protecon is not

provided by the conduit system, some form of stress relief must be installed where the wir-

ing exits the 440.

To reduce suscepbility to EMI/RFI, any signal-level wiring such as transducer, reset, lockout,

or 4-20 mA loop should ulize shielded cable in EMI-proof conduit, separate from any power

wiring. The signal-wiring conduit and power-wiring conduits can be connected at the switch

entry via a “T” ng.

4.10 Sealing

In installaons where temperature and humidity condions vary around the dew point, it is

important that the cover be evenly and rmly fastened down with the four screws provided

(model 440) or via the threaded cover (model 450).

Although the switch enclosures meet NEMA standards for water ghtness, this assumes the

cover is properly seated and wiring/conduit entrances use proper seals.

5. ELECTRICAL INSTALLATION

5.1 WiringtotheVibraonSwitch

See terminal numbering legends below. Refer also to the wiring diagrams of secon 8.

NOTE: Unless proper drains and/or poured seals are used,

conduit can allow moisture entry into the switch. Use good

installaon pracces that slope conduit away from the

switch, use drains (non-XP installaons only), and make

certain that cable jackets are not nicked or scued which might

allow moisture to wick into the switch via the conductors.

Doc# 90018-031 • REV L (April 2016) Page 7 of 16

5.1.1 Input Power

Connect a grounding wire to the grounding screw provided in the switch. This is impor-

tant for safety as well as noise. For AC powered units, power only with the voltage level

indicated on the inner cover label. Orientaon of AC power to terminals 1 and 2 is not

important. For DC powered units, connect +24V to Pin 1 and Ground to Pin 2.

5.1.2 Shutdown Circuit

The internal shutdown switch circuit is designed to be wired in series with the external

shutdown circuit i.e.; motor starter, relay, contactor, etc.

5.1.3 RemoteReset

Shielded wire is required. To avoid creang ground loops, the N.C. remote switch contacts

should be electrically isolated from other circuits or grounds. NOTE: Remote reset is dis-

abled if pushbuon reset opon is selected.

Lockout(Oponal)

Terminal 7 will be labeled “Lockout”. Shielded wire is recommended. To avoid the possibility

of ground loops, the remote N.O. lockout switch contacts should be electrically isolated from

other external circuitry or grounds.

5.1.4 4-20mAAnalogOutput

To avoid the possibility of ground loops, the 4-20 mA remote meter terminals should be

electrically isolated from external grounds. Shielded wire is recommended to protect

against damage due to long wire runs and the possibility of high induced voltage spikes

from storms, etc. The 4-20 mA output is self powered and therefore requires no external

power source.

5.1.5 AlarmCircuits

The internal single pole solid state switch between terminals 13 and 14 is designed to be

wired in series with the external alarm circuit i.e.; annunciator, lamp, relay, etc.

5.2 FunconalDescriponandInstallaonConsideraons

5.2.1 Alarm or Shutdown

5.2.2 UnitswithTriacOutputs(orderingoponsDand/orE=1)

The triacs used in model 440/450 vibraon switches carry medium power rangs and are

useful in controlling relays, contactors, and most motor starters directly. Maximum noise

immunity is obtained when used in the open on alarm (N.C.) mode. Consult Metrix prod-

uct datasheet 1004730 for comprehensive specicaons pertaining to triac outputs.

5.2.3 UnitswithAnalogSwitch(FET)Outputs(orderingoponsDand/orE=2)

For light loads such as computers or PLCs, the analog switch output is easier to interface

since it has virtually no leakage current. The analog switch does not require the 50 mA

holding current of a triac and operates equally well with AC or DC. Consult Metrix product

datasheet 1004730 for comprehensive specicaons pertaining to FET outputs.

NOTE: DR models have both Shutdown and Alarm

circuit present; SR models have only Shutdown circuit.

Doc# 90018-031 • REV L (April 2016) Page 8 of 16

5.2.4 UnitswithElectromechanicalRelayOutputs(orderingoponsDand/orE=4)

Electromechanical relays are also available and represent the most exible type of output.

They are a good choice for a variety of applicaons. Consult Metrix product datasheet

1004730 for comprehensive specicaons pertaining to relay outputs.

5.2.5 Open/CloseonAlarm

The alarm and shutdown triacs (or analog switches) are independently eld seable

for N.O. (close on alarm) or N.C. (open on alarm). The switches are accessible with a

non-conducve screwdriver via the inner side panels. Open on alarm is recommended in

installaons where triac lines are likely to be noisy, i.e.: large transient voltage spikes due to

unsuppressed relay, solenoid or other inducve loads.

5.2.6 AutoResetMode

In this mode, alarm and shutdown switches are automacally reset to the non-alarm/non-

shutdown condion when the vibraon level falls below the set point.

5.2.7 Latch Mode

In this mode, alarm and shutdown switches remain “latched” in alarm (shutdown) condi-

on when the vibraon level exceeds the set point for the duraon of the me delay. The

unit is in this condion when the reset terminal is connected to common.

RemoteResetMode

When wired in this mode, the alarm and shutdown switches latch in “trip”, but can be reset

to the “non-alarm/non-shutdown” mode by momentarily interrupng the connecon from

terminal Reset to Common. This can be accomplished with a normally closed momentary

switch. The switch contacts should be isolated from other circuits, potenals or grounds.

5.2.8 20-SecondLockout(oponal)

With this opon, the shutdown and/or alarm triacs will not be permied to actuate for 20

seconds aer Lock out is connected to Common.

5.2.9 4-20 mA Output

This loop supplies its own 24Vdc power and provides a 4-20 mA output current propor-

onal to vibraon.

Most switches are supplied with ordering opon B=2 (absolute 4-20mA output reference)

where 4mA = no vibraon and 20mA = full scale vibraon (refer to product datasheet

1004730 for full scale range opons). A small number of older switches may use a B op-

on other than 2, designang an analog output that is proporonal to the setpoint rather

than the full-scale range. Consult the factory for addional informaon.

5.3 SpecialConsideraons

NOTE: Remote reset is disabled if

pushbuon reset opon is selected.

NOTE: Do NOT connect the 4-20mA output to an exter-

nal source of loop power as this may damage the switch.

Doc# 90018-031 • REV L (April 2016) Page 9 of 16

5.3.1 LightLoads

The solid state triacs used in the standard 440 series are a special high transient immunity,

medium power type. O state leakage is 1 mA max and should not create any problems,

even when interfaced with a load as light as a programmable controller.

Minimum load required to keep the triac on is 20 mA typical and 50 mA max due to the

“holding current” specicaons. If the load is less than this, a resistor may have to be

placed in parallel with the load, i.e.; for 115 VAC light load (50 mA or less) a 2K-ohm 10

wa power resistor is recommended.

5.3.2 D.C.Loadswithtriacs

Although most applicaons use AC input power and AC on the triac outputs (alarm and

shutdown), these triacs may be used in DC applicaons providing minimum loading re-

quirements are met. When DC is used, a triac will automacally latch in the “on” condion

aer trip, thus only “close on alarm” (N.O.) can be used. To reset an external reset switch,

the rest switch must be wired in series with the load. To avoid large voltage drops during

DC operaon, the triac should be connected as follows:

Shutdown: Term 4 POS Alarm: Term 14 POS

Term 3 NEG Term 13 NEG

5.3.3 170mAAnalogSwitchOpon

The special condions of secons 5.3.1 and 5.3.2 do not apply. However, maximum cur-

rent is limited to 170 mA.

5.4 FunconalCircuitBlockDescripon

An internal transducer module consisng of a crystal assembly and integral charge amplier

senses vibraon. Thus, the electrical output of the transducer is a well-buered (low imped-

ance) signal directly proporonal to vibratory acceleraon levels (g) at the switch.

The raw acceleraon signal goes to a custom hybrid circuit that integrates the signal and pro-

vides an AC signal proporonal to vibratory velocity instead of acceleraon. This signal is then

routed through an amplier, the gain of which is controlled by the shutdown setpoint.

Next, the signal is processed through a true RMS-to-DC stage and compared against a preset

internal voltage reference. If the signal level is higher than reference, the shutdown LED is

illuminated.

If the voltage level stays above the reference for the duraon of the me delay, an output

trip occurs and the shutdown solid-state relay will trip.

Alarm trip is derived in much the same manner, branching from the output of the RMS-to-

DC stage. Likewise, the DC output is directed to the voltage-to-current hybrid.

NOTE: Models using an external (Ordering Opon I=5)

sensor do not have an internal accelerometer and will

measure vibraon at the sensor locaon, not the switch

locaon. Refer to Metrix product datasheet 1004730 for a list

of ordering opons characterizing external transducers.

Doc# 90018-031 • REV L (April 2016) Page 10 of 16

6. CONTROL SETTINGS

6.1 SengTripPoints

The Model 440DR provides two setpoints: one for alarm and one for shutdown.

The rst alarm is normally set at a vibraon alarm level to provide early warning that the

condion of the machine is deteriorang. If the machine condion connues to deteriorate,

the shutdown setpoint provides protecon against catastrophic failure. The shutdown and

alarm setpoints are set directly in inches/seconds or mm/sec.

The Warning Level Guide below indicates recommended starng points for vibraon warning

levels, dened as levels at which abnormal wear is occurring. Vibraon analysis by compe-

tent machinery diagnosc personnel is recommended when a warning alarm level has been

reached. Dierent warning levels are given for dierent types of machinery.

NOTE: SR models provide only

one setpoint (shutdown).

NOTE: The ranges below are typical. Each machine

will have its own acceptable levels of vibraon,

depending on how it is loaded, the parcular instal-

laon, and the tolerances of the machine itself. The chart

below is a guideline and does relieve the user of respon-

sibility for determining their own acceptable alarm and

shutdown levels for the equipment at hand.

WarningLevelGuide

6.2 SengofTimeDelay

An important feature of Model 440/450 switches is the built-in me delay. This prevents

triggering of the alarm or shutdown funcons from transient increases in vibraon levels. It

also avoids shutdown due to transitory vibraons occurring during start-up.

The me delay is adjustable. The factory default seng is three (3) seconds unless specied

otherwise.

Doc# 90018-031 • REV L (April 2016) Page 11 of 16

The me that the vibraon amplitude must persist above a setpoint before the discrete out-

put changes state is individually adjustable for shutdown and alarm from 2 to 15 seconds.

To readjust the me delay, turn the shutdown setpoint (or alarm setpoint for alarm me

delay) knob CCW unl the LED illuminates. The me from this point to relay actuaon is

the me delay. Change the me delay via a nylon non-conducve screwdriver. Set CW to

increase me delay (one complete turn is approximately 0.5 seconds). Then, recheck and

readjust unl the desired me delay is achieved.

6.3 TestMode

The TEST posion of both shutdown and alarm setpoint adjustment knobs is used to test

the switch funcons without the need for vibraon. When the shutdown knob is turned to

TEST, the shutdown LED should illuminate and the discrete output should change state aer

the delay me (see secon 6.2) has elapsed. The alarm TEST posion (available only on DR

model switches) funcons in similar fashion, but has no eect on the 4-20 mA output.

6.4 AscertainingCurrentVibraonLevels

When the 4-20mA output is not being used with a strip chart recorder, PLC, or other log-

ging device, you can place an ammeter across this output and the current measured. 4mA

corresponds to zero vibraon and 20mA corresponds to full scale vibraon. Readings in

between these two extremes can be ascertained by scaling proporonately from 0% (4mA)

to 100% (20mA). Alternavely, the LED indicators for alarm (DR model only) or shutdown

(both SR and DR models) can be used. Since these LEDs acvate instantaneously (i.e., before

the adjustable me delay of secon 6.2), they can be used in a momentary fashion to check

the machine’s actual vibraon level. Slowly decrease the setpoint by turning the setpoint

adjustment knob counter-clockwise unl the corresponding LED illuminates. Note this set-

ng and quickly return the knob to its original seng (before me delay runs out). The level

at which the LED illuminates corresponds to the actual vibraon level.

NOTE: If the shutdown or alarm knob is moved

to the TEST posion but then returned to a nor-

mal seng before the duraon of the me delay

has elapsed, the LED will come on but the discrete

output (triac, FET, or relay) will not change state.

NOTE: For DR model switches where both shut-

down and alarm setpoints will be available, it is

recommended that the alarm setpoint adjustment

be used for this procedure instead of the shutdown

setpoint, to prevent an inadvertent machine trip.

Doc# 90018-031 • REV L (April 2016) Page 12 of 16

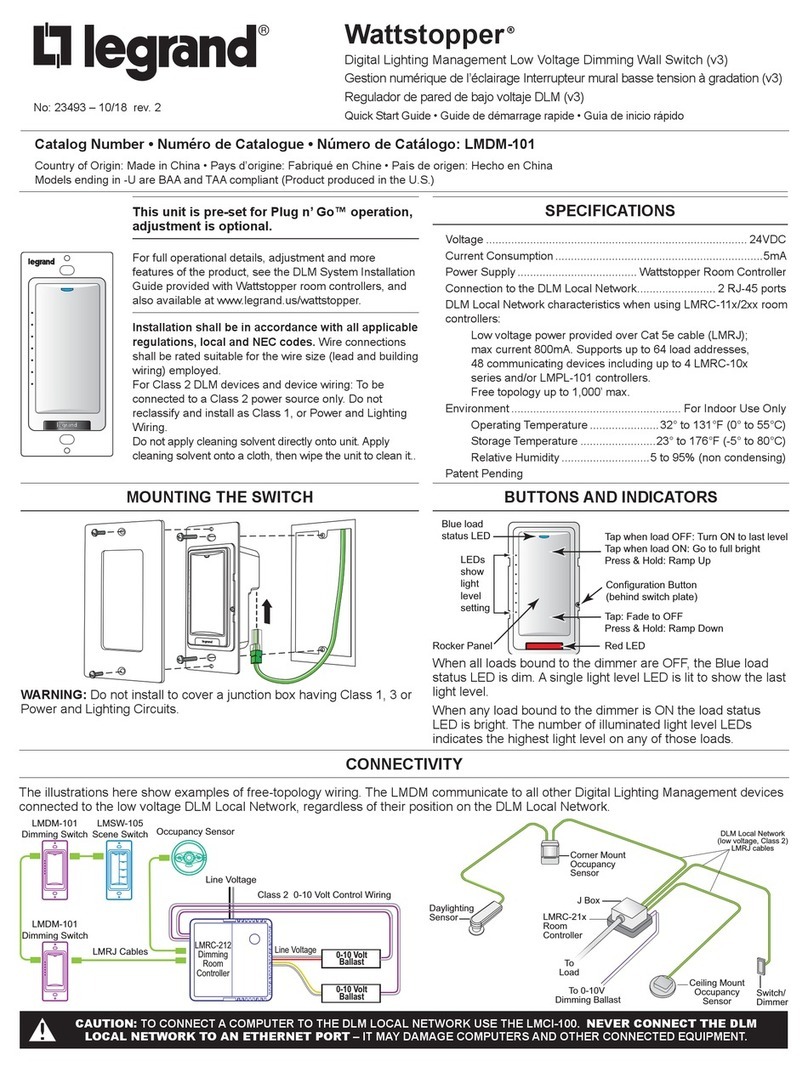

7. OUTLINE & DIMENSIONS

440 Model

Units: mm [in]

Doc# 90018-031 • REV L (April 2016) Page 13 of 16

450 Model

Units: mm [in]

Doc# 90018-031 • REV L (April 2016) Page 14 of 16

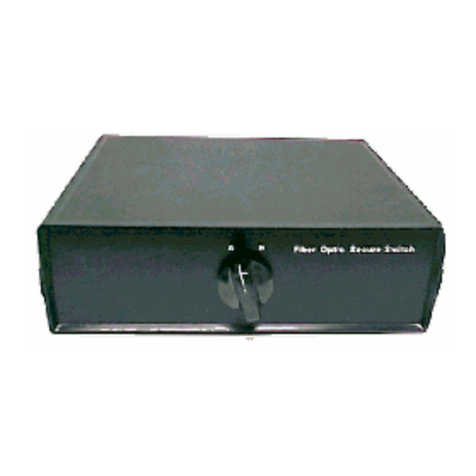

8. WIRING DIAGRAMS

These diagrams depict connecons for models with all opons present. Not all connecons

may be available on your specic switch(es), depending on whether oponal features were

specied at me of ordering.

Doc# 90018-031 • REV L (April 2016) Page 15 of 16

Doc# 90018-031 • REV L (April 2016) Page 16 of 16

info@metrixvibraon.com

www.metrixvibraon.com

8824 Fallbrook Dr. Houston, TX 77064, USA

Tel: 1.281.940.1802 • Fax: 1.713.559.9421

Aer Hours (CST) Technical Assistance: 1.713.452.9703

This electronic equipment was manufactured according to high quality stan-

dards to ensure safe and reliable operaon when used as intended. Due to its

nature, this equipment may contain small quanes of substances known to be

hazardous to the environment or to human health if released into the environ-

ment. For this reason, Waste Electrical and Electronic Equipment (commonly

known as WEEE) should never be disposed of in the public waste stream. The

“Crossed-Out Waste Bin” label axed to this product is a reminder to dispose of this product

in accordance with local WEEE regulaons. If you have quesons about the disposal pro-

cess, please contact Metrix Customer Services.

ENVIRONMENTAL INFORMATION

This manual suits for next models

1

Table of contents

Other Metrix Switch manuals