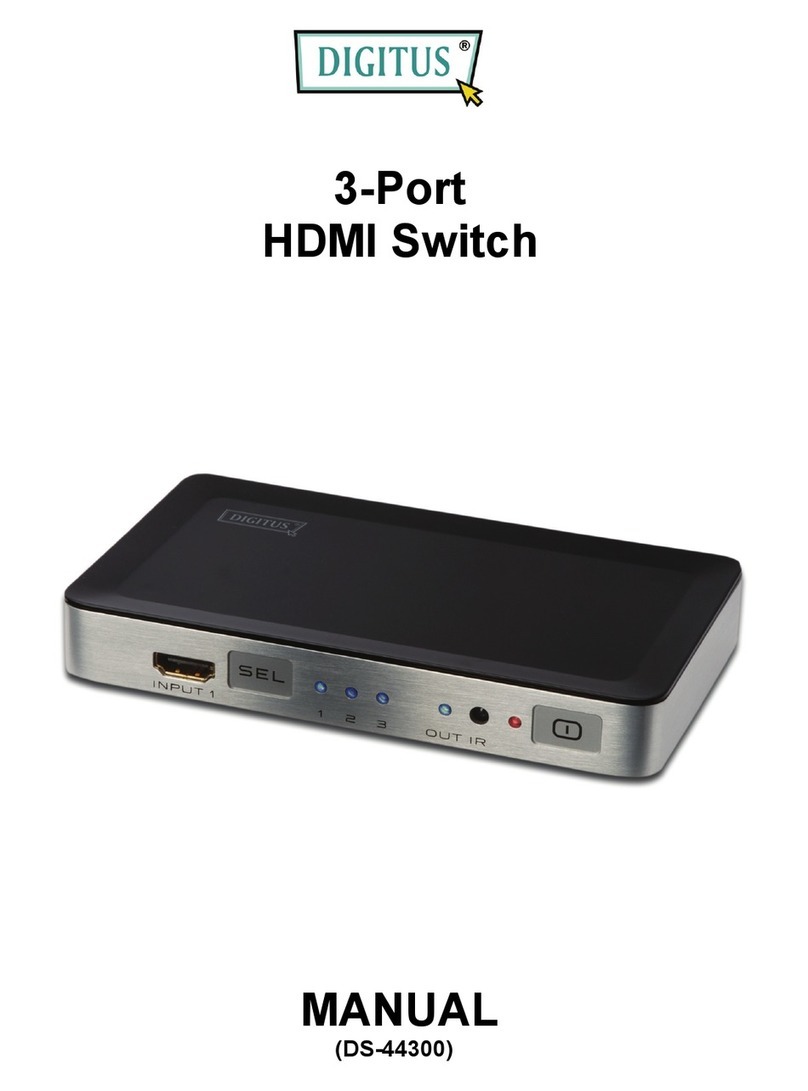

Metrix 5550 User manual

5.130

4.230

5.563

4.250

SET POINT

ADJUSTMENT

SCREW

RESET PUSH

BUTTON

1x M20

3.688

2.313

4X 10-32 UNF

REV.

ECO NO

DESCRIPTION

BY

DATE

A

Initial Release

RAP

6/11/2020

VENDOR

MODEL NUMBER

Metrix Instrument Co.

5550-411-04

Metrix Instrument Co.

5550-311-04

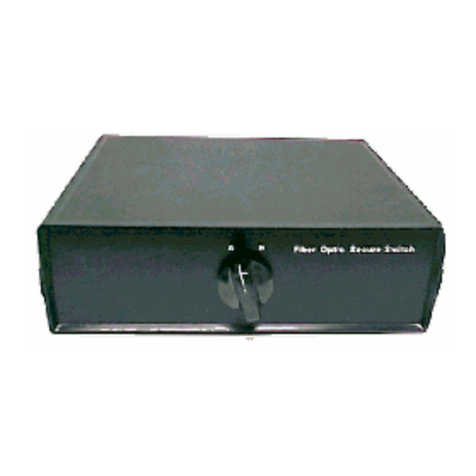

Vibration Switch

SHEET 1 OF 1

REV

DRAWING NUMBER:

DESCRIPTION:

MAT'L #:

MAT'L:

DESCRIPTION:

CHECKED BY:

MODELED BY:

PURCHASED

3003 Alloy

3/22/2011

KLB

1:4

Metrix 5550-411-04 Single Pole, Double Throw

Switch Vibration ATEX SPDT

A

028-000-481

THIS DRAWING IS THE SOLE PROPERTY OF

GREAT WESTERN MFG. CO. INC.

AND IS PROTECTED UNDER ALL APPLICABLE

COPYRIGHT LAWS. THIS DRAWING MAY NOT BE

REPRODUCED WITHOUT PRIOR WRITTEN PERMISSION.

WE RESERVE THE RIGHT TO MAKE IMPROVMENTS OR

CHANGES. THIS DRAWING IS LOANED SUBJECT

TO RETURN ON DEMAND.

UNLESS OTHERWISE NOTED DIMS. ARE IN INCHES

AND TOLERANCES ARE AS FOLLOWS:

MACHINING

.003 WELDING

.060 ANGLES

1

FORMING

.015 ASSEMBLY

.060

DATE:

DATE:

A

SIZE

SCALE:

6.197

4

Switches

Tel: 713-461-2131 • 800-638-7494 (US) • Fax: 713-461-8223

Vibralert®Mechanical Switch

Model 5550

The Model 5550 vibration switch is designed to meet all requirements for me-

chanical switches in a single, affordable package. This unit provides economical vibra-

tion protection for low to medium speed machinery. An inertia sensitive mechanism

activates an snap-action switch with SPDT output contacts if the vibration exceeds

an adjustable setpoint. The Model 5550 contacts can be used to activate an

alarm or initiate equipment shutdown. The housing is weatherproof with an op-

tional hazardous area rating. Electrical (remote) reset with start-up time delay

and a second set of SPDT output contacts to accomodate DPDT needs (e.g.

separate trip and trip light circuits) are available.

Features

•Meets all requirements

for mechanical switches

in one package

•Weatherproof and optional

hazard area rating

•Local and optional remote

reset with startup delay

•SPDT or (2)SPDT switch

output contacts

Applications

•Heat Exchanger Fans

•Cooling Tower Fans

•Recip Engines

•Recip Compressors

NOTE:

(2) SPDT

contacts

and

reset coil

optional

User Wiring Diagrams

(2) SPDT CONTACTSSPDT CONTACTS

Typical Installation Diagrams

COOLING

TOWER

FAN

GEARBOX

VIBRATION SWITCH

LOCATION

MOTOR

SWITCH

LOCATION

MOTOR

HEAT

EXCHANGER

FAN

Application Note:

For an upgrade to velocity (ips or mm/s)

monitoring or for dual limits (i.e. separate

alarm and trip setpoints), see SW Series

electronic switches.

BASIC MODEL

NUMBER

5550

APPLICATION TIPS

-Lowest cost vibration protection;

-Baseplates available to accomodate most previous

Metrix or competitor’s switch models for easy retrofit.

-Watertight & optional hazardous area rated enclosure

-Options for built-in start up trip delay and/or remote reset.

4.7

4

Switches

Tel: 713-461-2131 • 800-638-7494 (US) • Fax: 713-461-8223

Model 5550 Weight & Dimensions

Function: Armature mechanism trips

on high vibration and operates snap action

switch(es).

Vibration Range: See How to Select “C”

Frequency Range: 0 to 3600 RPM

Set Point Adjust: 0 to 100% of range.

External set point adjustment.

Reset: Local reset, plus optional remote

reset electrical coil. See How to Select.

Start Delay: Applying reset coil voltage at

start up holds mechanism from tripping for

20-30 seconds, after which the switch is

automatically activated. Requires electric

reset option (D¹0).

Temperature Limit: -40° to +70°C

(-40° to +158° F)

Enclosure: Cast Aluminum

Environmental Rating: NEMA 4, IP 65 & CE

mark

Switch Contact(s) Rating: 15 amps,

125, or 480 vac; 1/8 hp, 125 vac;

1/4 hp, 250 vac; 1/2 amp, 125 vdc;

1/4 amp, 250 vdc.

Hazard Rating: See How to Select “A”

Weight: 1.8 kg (4.0 lbs.)

Specifications

How To Select...

MODEL A B C D E F

5550 - -

AHazard Area Rating

0= None

1= UL, cUL Explosion Proof

Class I, Groups C & D, Div 1

Class II, Groups E,F & G, Div 1

2= UL, cUL Explosion Proof

Class I, Groups B, C & D, Div 1

Class II, Groups E,F & G, Div 1

3= CENELEC Flameproof

EEx d IIB T6

4= CENELEC Flameproof

EEx d IIB+H2T6

BContacts

1= SPDT

2= (2) SPDT (use for

DPDT too)

Standard

5550 - 0 1 1 - 0 1

CFull Scale Vibration Range

1= 5 g

2= 2 g

3= 10 g

DReset Coil & Start Up Delay

0= None

1= 115 VAC

2= 230 VAC

3= 24 VDC

4= 115 VDC

EWiring Entry/Mounting Plate

(See Chart below for E)

1 = 3/4” NPT/Metrix 5173 or 5175

2 = 3/4” NPT/Metrix 5097; VS-2-EX; 366

3 = 3/4” NPT/Metrix 5078; 365

4*= M20 x 1.5/Metrix 5097; VS-2-EX; 366

(L) (W) (A) (B)

E = 1

E = 2; 4

E = 3

165 mm [6.50]

152 mm [6.00]

165 mm [6.50]

38 mm [3.25]

121 mm [4.75]

121 mm [4.75]

141 mm [5.56]

118 mm [4.63]

136 mm [5.37]

*FOR E=4, A ≠1 OR 2

108 mm [4.25]

142 mm [5.60]

135 mm [5.33]

113 mm [4.43]

48 mm [1.88]

4X 19.0mm X 9.5 mm

(.750 x .375)

Vibralert®Mechanical Switch

Model 5550

4.8

Internal Mechanism

FEnvironmental Rating

1= NEMA 4X

59 mm [2.33]

79 mm [3.12]

92 mm [3.62]

CHART FOR HOW TO

SELECT “E”

!1711 Townhurst DR., Houston, TX 77043-2899

Tel: 713-461-2131 Fax: 713-461-8223

e-mail: [email protected]

M8905 05/02 ERO 8848

INSTALLATION OF METRIX MODEL 5550

MECHANICAL VIBRATION SWITCH

MW

SERIES

Thisbulletin should beused byexperienced personnel asa guide

to the installation of the Model 5550 vibration switch. Selection

or installation of equipment should always be accompanied by

competent technical assistance. We encourage you to contact

Metrix Instrument Co. or its local representative if further informa-

tion is required.

IMPORTANT: BEFORE PROCEEDING TO INSTALLAND WIRE

THE UNIT, READ AND THOROUGHLY UNDERSTAND THESE

INSTRUCTIONS.

THE SWITCH MODEL NUMBER SHOULD BE CHECKED TO

CONFIRM THAT YOU HAVE THE CORRECT HAZARDOUS

AREA RATING FOR YOURAPPLICATION. SEE HOW TO OR-

DER INFORMATION. "A"

INSTALLATION:

1) The sensitive axis of the vibration switch is perpendicular to

the mounting base. The preferred mounting is with the sensitive

axis in the horizontal plane, since most machines vibrate more in

that plane. Mount the switch solidly to the frame of the machine.

2) Remove the cover and wire the switch(es) into the alarm or

shutdown circuit. Do not exceed switch contact ratings listed in

the specifications. Keep field wiring away from the moving

part of the mechanism.

3) Observe all local electrical codes.

SETPOINT ADJUSTMENT:

1)Thevibrationsetpoint adjustment isaccessibleexternally. Turn-

ing the setpoint adjustment clockwise (CW) increases the vibra-

tion setpoint.

2) When the switch is shipped from the factory, the setpoint ad-

justment is set to 2g when installed in the vertical position and 1g

when installed in the horizontal position (with reference to the

setpoint adjustment shaft).

3)Tocheck factorycalibration, place unmounted unit in your hand

and rotate per diagram D. The switch(es) should activate at dead

bottom position. If necessary, adjust setpoint using the setpoint

adjustment screw.

4) To preset switch at other than factory setpoint, start with step

three (3) and then rotate adjustment screw 1/8 turn per g until

you reach the required set point.

5) To adjust setpoint when installed on the machine, mount and

wire the unit. Reset the switch by depressing the reset plunger

andstart the machine. Whenthe machinehas reached fullspeed,

slowly turn the vibration setpoint adjustment counter-clockwise

until the switch trips. Then turn the adjustment clockwise a small

amount (approx. 1/8 turn). Reset the switch and restart the ma-

chine to determine whether the machine starting roughness will

cause the switch to trip, in which case it may be necessary to

increase the setpoint.

ELECTRICAL RESET AND STARTUP LOCKOUT:

The optional electrical reset circuit consists of an electrical sole-

noid in series with a thermistor. If the rated voltage is continu-

ously applied to the reset circuit at machine startup, the reset

solenoid energizes for a fixed time interval (approx. 30 sec.), af-

ter which time the solenoid is automatically de-energized by the

thermistor. This action provides a trip lockout during machine

startup roughness. The voltage must be removed from the reset

circuit when the machine is stopped to allow the thermistor to

cool off. The switch mechanism can then be reset electrically by

a momentary application of the reset voltage or it can be reset

manually.

NOTE: If the machine is restarted immediately after a shutdown,

the lockout period will be shortened because the thermistor will

be hot. An increase in the ambient temperature will also shorten

the lockout period.

ENGINE COMPRESSOR

COOLING TOWER FAN

GEARBOX

VIBRATION SWITCH

LOCATION

SWITCH

LOCATIONS

MOTOR

SWITCH

LOCATION

MOTOR

TYPICALINSTALLATIONS

HEAT EXCHANGER FAN

COMPRESSOR

1 g

SETPOINT

SWITCH

ACTIVATED

2 g

SETPOINT DIAGRAM D

SHAFT

Page 2 M8905

SPECIFICATIONS

Function: Armature mechanism trips on high vi-

bration and operates snap action switch(es).

Amplitude Range: See How to Order. "C"

Frequency Range: 0 to 3600 RPM.

Setpoint Adjust: 0 to 100% of range.

External setpoint adjustment.

Reset: Local reset, plus optional remote reset

electrical coil. See How to Order. "D"

Start Delay: Applying reset coil voltage at start

up holds mechanism from tripping for 20-30 sec-

onds, after which the switch is active. Requires

electric reset option.

Temperature Range: -40°C to 70°C

Enclosure: High strength copper-free (4/10 of

1% max) Aluminum alloy.

Environmental Rating: NEMA 4, IP 65 & CE

Mark (NEMA 4X OPTIONAL)

Switch Contact(s) Rating:15amps,125, or 480

Vac; 1/8 hp, 125 Vac; 1/4 hp, 250 Vac; 1/2 amp,

125 Vdc; 1/4 amp, 250 Vdc.

Hazard Rating: See How to Order. "A"

Weight: 2.1 kg (4.5 lbs.)

WIRING DIAGRAM

DPDT CONTACTS AND RESET COIL OPTIONAL

SPDT DPDT

DIMENSIONS IN mm (inches)

*Note: When option A1 or A2 is specified,

options E4, E5, E6 and E8 are not allowed.

L(+) RESET COIL

N(-) RESET COIL

GRN CASE

L(+) RESET COIL

N(-) RESET COIL

GRN CASE

(L) (W) (A) (B)

165mm [6.50] 83mm [3.25] 141mm [5.56] 59mm [2.33]

121mm [4.75] 152mm [6.00] 79mm [3.12] 118mm [4.63]

165mm [6.50] 121mm [4.75] 136mm [5.37] 92mm [3.62]

114mm [4.50] 127mm [5.00] 71mm [2.80] 108mm [4.25]

E=1, 6

E=2, 4, 5

E=3, 8

E=7

MODEL A B C D E F

5550 - """ -"""

How To Order...

A" Hazard Area Rating

0= None

1= UL, cUL Explosion Proof, Class I, Groups C & D, Div 1

Class II, Groups E, F & G, Div 1

2= UL, cUL Explosion Proof, Class I, Groups B, C & D, Div 1

Class II, Groups E, F & G, Div 1

3= CENELEC Flameproof, EEx d IIB T6 DEMKO 02 ATEX 0212409

4= CENELEC Flameproof, EEx d IIB+H2T6 CE 0600 II 2 GD

B" Contacts

1= SPDT 2= DPDT

C" Full Scale Range

1= 5 g 2= 2 g 3= 10 g

D" Reset Coil & Start Up Delay

0= None 1= 115 VAC 2= 230 VAC 3= 24 VDC 4= 115 VDC

E" Wiring Entry/Mounting Plate (retrofit)

1= 3/4” NPT/Metrix 5173 or 5175

2= 3/4” NPT/Metrix 5097; VS-2-EX; 366

3= 3/4” NPT/Metrix 5078; 365

4= M20 x 1.5/Metrix 5097; VS-2-EX; 366

5= Same as option 4 above with epoxy coated mounting plate

6= M20 X 1.5 / METRIX 5173 or 5175

7= 3/4” NPT / PMC/BETA 440

8= M20 X 1.5 / METRIX 5078; 365

F" Environmental Rating

0 (or blank) = NEMA 4, IP 65, CE

1 = NEMA 4X, IP 65, CE

Example

5550 - 0 1 1 - 0 1 0

*

*

*

*

*

Tested for Compliance with the

applicable EC Electromagnetic

Compatibility Requirements

*

Mounting Plate for

E=1, 6 Shown

Other manuals for 5550

2

Table of contents

Other Metrix Switch manuals