Metrohm Easy PAT D2112 User manual

Edgcumbe Instruments Ltd.

Main Street

Bothwell

Glasgow G71 8EZ, U.K.

Tel: +44(0)1698 852574

Fax: + 44(0)1698 854442

E-mail: [email protected]

CMR0090

Issue 1 2/98

EasyPAT

LCD INDICATING PAT

MODEL: D2112

INSTRUCTION MANUAL

EdgcumbeInstrumentsLimited

®

TABLE OF CONTENTS

PAGE

TABLE OF CONTENTS i

1. SAFETY RULES 1

2. GENERAL DESCRIPTION 2-5

3. OPERATING INSTRUCTIONS 5-9

4. SPECIFICATIONS 9

4.1 ELECTRICAL 9-11

4.2 MECHANICAL 11

4.3 ENVIRONMENTAL 11

5. CLEANING 12

6. SPARES AND ACCESSORIES 12

7. REPAIRS 12

8. LIMITED WARRANTY 13

-i-

1. SAFETY RULES

WARNING CAUTION RISK OF ELECTRICAL SHOCK

DISCONNECT FROM SUPPLY BEFORE

OPENING TESTER.

This tester has been designed with your safety in mind. However, no design can completely

protect against incorrect use. Electrical circuits can be dangerous if lack of caution and/or

poor safety practices are used.

READ THE MANUAL

Read the Instruction Manual carefully and completely. Voltages and currents within the

capability of this instrument can be hazardous. Follow the instructions in this manual for

every test. Read and understand the general instructions before attempting to use this tester.

Do not exceed the limits of this tester.

SAFETY CHECK

Double check the lead connections before making a test.

Are you following all the instructions?

When replacing the fuse, disconnect the Mains Lead from the supply to ensure that the

instrument is de-energised.

Always connect the mains lead to a supply, the wiring of which has been checked and proved

safe.

Use only the specified type of fuse and insert it correctly.

Do not use leads that are damaged and in need of repair.

This instrument has been designed to be used in a clean dry environment. Do not use the

instrument outdoors in wet conditions.

THIS INSTRUMENT SHOULD ONLY BE USED BY A COMPETENT, SUITABLE

TRAINED PERSON.

REMEMBER!

SAFETY IS NO ACCIDENT!

-1-

8. LIMITED WARRANTY

Edgcumbe Instruments Limited warrant instruments and test equipment manufactured

by them to be free from defective material or factory workmanship and agree to repair

or replace such products which, under normal use and service, disclose the defect to be

the fault of our manufacturing, with no charge for parts and service. If we are unable to

repair or replace the product, we will make a refund of the purchase price. Consult the

InstructionManualforinstructionsregardingtheproperuseandservicingofinstruments

and test equipment. Our obligation under this warranty is limited to repairing, replacing

or making refund of any instrument or test equipment which proves to be defective

within twelve months from the date of original purchase.

This warranty does not apply to any of our products which have been repaired or altered

by unauthorised persons in any way so as, in our sole judgement, to injure their stability

or reliability, or which have been subject to misuse, abuse , altered defaced or removed.

Accessories, not of our manufacture used with this product are not covered by this

warranty.

To register a claim under the provisions of this warrant, return the instrument or test

equipment to Edgcumbe Instruments Limited, Main Street, Bothwell, Glasgow, G71

8EZ. Upon our receipt and inspection of the product we will advise you as to the

disposition of your claim.

ALL WARRANTIES IMPLIED BY LAW ARE HEREBY LIMITED TO A PERIOD

OF TWELVE MONTHS, AND THE PROVISIONS OF THE WARRANTY ARE

EXPRESSLY IN LIEU OF ANY OTHER WARRANTIES EXPRESSED OR

IMPLIED.

The purchaser agrees to assume all liability for any damages and bodily injury which

may result from the use or misuse of the product by the purchaser, his employees, or

others, and the remedies provided for in this warranty are expressly in lieu of any other

liabilityEdgcumbeInstruments Limited may have including incidental or consequential

damages.

Edgcumbe Instruments Limited reserve the right to discontinue models at any time, or

changespecification,priceordesign,withoutnoticeandwithout incurring any obligation.

Fig. 1

2. GENERAL DESCRIPTION

The Metrohm EasyPAT is an LCD indicating portable appliance tester, which is housed in a

rugged injection moulded case with a removable lid. The base of the case contains the complete

power and electronic circuitry. Basic safety instructions are presented on the inside of the lid,

and a pannier bag, which provides storage for the flash gun, supply adapters and comprehensive

instruction manual, clips onto the top of the lid.

Operation of the Metrohm EasyPAT is straightforward. The five tests, continuity, insulation,

run current, run leakage and flash, provided by this instrument are selected by depressing one

of five push-button switches on the front panel. A three position rocker switch selects a test

current of 100m A d.c., 8A a.c. or 25A a.c. for the continuity test. While the key is depressed

the relevant measurement is displayed on the large, custom LCD Display.

The Metrohm EasyPat allows fast, simple testing on all tools, appliances and I.T equipment in

accordance with the recommendations of the Electricity At Work Act, the Health And Safety

Executives and the Electronic And Business Equipment Association. It should be noted that

-2-

-13-

Class I equipment is earthed whereas Class II equipment is not earthed (double-insulated),

usually denoted by the symbol .

Fig . 2

The instrument can be connected directly to a 240V supply using the 13Amp plug fitted on

the supply lead or to a 110V supply, using the adapter supplied. On power up the EasyPAT

monitors the supply voltage, adjusts its measurement circuits and selects the correct test socket

accordingly. The display indicates the supply voltage on which tests will be carried out.

Appliances to be tested should be connected into the appropriate test socket and should be

compatible with the supply voltage to the instrument. If the appliance has an on/off switch, it

should be set to the on position to ensure that the appliance is fully tested.

1) EARTH / CONTINUITY (8 AND 25Amps)

For this test a voltage of 6V a.c. is applied between the earth pin of the plug of the

appliance being tested and its exposed metal work, via the wander earth lead. The

magnitude of the test current is reduced to 8A by a limiting resistor selected by the

three position rocker switch. The high current applied in this test verifies that the

protective earth path will carry the fault current in the event of an insulation breakdown

within the appliance.

2) EARTH / CONTINUITY (100m A)

The test is similar to that described in (1) except that a constant current of 100m A

d.c. is applied. This reduced current is required to test I.T equipment whose earth

path could be damaged by the higher currents.

5. CLEANING

Do not use volatile liquids such as thinner or benzene to clean the tester. Wipe the tester with

a soft, dry cloth or moisten the cloth with a neutral non abrasive detergent and wring the cloth

outthoroughly before wipingover the surface. Ensure that all traces of moisture have evaporated

before using the tester.

6. SPARES & ACCESSORIES

1) PAT Verification Unit D2101

2) PAT Extension Lead / IEC Cord Tester D2102

3) Mains Adapter - 110V plug to 240V Socket DFK0056

4) Flash Gun DFH0377

5) 16Amp, FF, 11/4”, HBC Ceramic fuss (Front panel) CEF0107

6) Instruction Manual CMR0090

7. REPAIRS

Please return the tester to:

EDGCUMBE INSTRUMENTS LIMITED

MAIN STREET

BOTHWELL

GLASGOW

G71 8EZ

Be sure to clearly explain the problem in detail.

-3- -12-

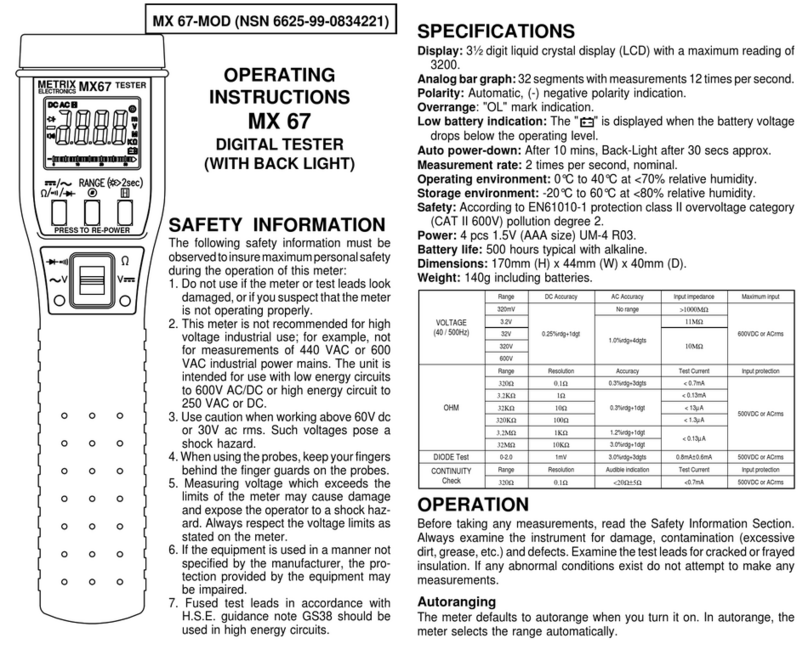

Fig.3

FUSES

Front Panel: 16A (FF) 1¼” HBC (Ceramic)

Plug: 13A 1”HBC (Ceramic)

Internal: 3.15A (F) 5x20mm, HBC (Ceramic)

Internal fuse is not user replaceable.

NOTE: The front panel fuse protects the 240V test socket only. The 110V socket

is wired direct to the mains input plug fuse.

SAFETY

EMC: Meets BS EN 50081-1

BS EN 50082-1

LVD: Meets BS EN 61010-1

4.2 MECHANICAL

CASE

Size: 330x263x144mm (Excluding bag)

Material: ABS/Polycarbonate

Colour: Yellow/Clear

Weight: 5.25kg nominal

4.3 ENVIRONMENTAL

TEMPERATURE

Operating: 0°C to 35°C

Storage: -10°C to 50°C

This instrument has been designed to be used in a clean dry environment. Do not use the

instrument outdoors in wet conditions.

3) INSULATION

500V d.c. is applied between the appliance phase and neutral joined together

and earth to ensure that this insulation is at an acceptable level.

4) RUN / CURRENT

The appliance under test is operated at the nominal supply voltage and the current to

it is monitored. Care should be taken to ensure that there is no mechanical hazard

with this test and that the wander earth lead is disconnected.

5) RUN LEAKAGE

This test is similar to that described in (4) except that the current flow in the

earth lead is monitored to check that no potentially hazardous, voltage induced,

earth leakage paths are created when the appliance is operating.

6) FLASH

This is an optional test that may be omitted. On Class I appliances 1.5kV a.c. is

applied between the phase and neutral joined together and earth. The flash

probe is not required for Class I appliances but on Class II appliances 3kV a.c.

is applied between the phase and neutral joined together and the tip of the flash

gun which is touched onto exposed appliance metalwork. This test is a further

verification that functional and supplementary insulation levels have not

deteriorated.

Though all tests can be performed in any desired sequence, it is recommended

that the Continuity test is always carried out first on Class I appliances and if

this results in a fail no further tests should be carried out on the appliance until

the fault in its protective earthing has been rectified.

For both Class I and Class II appliances, it is recommended that an Insulation

test is successfully carried out before attempting a Run test or a Flash Test.

The results of the tests are displayed on a high contrast 2½ digit LCD which

also indicates the parameter being tested,(Ω,MΩ, mA,A) and also the current

supply voltage which can be either (110 or 240V). See Fig.2.

-4-

-11-

If the value for the measured parameter is outside the range of the EasyPat

then the display will show overrange. This is indicated on the display by a

single 1. with no following zeros. Fig. 3 shows the earth continuity display

if the measured value is greater than 1.99ohms.

A red light which is located below the display illuminates if the instrument

overheats during a continuity test sequence. All test functions are disabled

for as long as this indicator is illuminated and will only be restored after

the instrument has cooled and the red indicator has turned off. See Fig. 2.

3. OPERATING INSTRUCTIONS

Connect the appliance tester to a suitable supply.

Check that the mains voltage annunciator comes on and that the indicated voltage corresponds

to that of the appliances to be tested. Plug the appliance under test into the appropriate socket

provided on the EasyPat. Ensure that the appliance is switched on and that it is suitably

mounted.

The following tests can be carried out.

a) EARTH CONTINUITY (8 and 25 Amps)

This test is only required for earthed (Class I) appliances.

The resistance of the earth circuit in the appliance and associated mains wire

and plug is displayed.

Select the required test current, 8 or 25 Amps , with the three position

Rocker Switch.

Carefully fit the wander earth lead to any exposed earthed metal on the

appliance then press and hold the ‘CONT’ key. The display will show the

measured continuity value for the appliance for as long as the key is held

down. To prevent overheating of the EasyPAT and the earth circuit of the

appliance this test should be as short as possible.

With 0.5mm2this should not be longer than 2-3 seconds and in any case the

‘CONT’ button should not be held down for more than 5 seconds for any one

reading.

Accuracy of Indication: ±10% of reading ±1 digit

RUN LEAKAGE TEST

Display Range: 0 - 19.9mA a.c.

Accuracy of Indication: ±10% of reading ±1 digit

FLASH TEST

Test voltage: 1.5kV a.c. nominal - Class I

3.0kV a.c. nominal - Class II

Display Range: 0 - 19.9mA a.c.

Usable Range: 0 -3.5mA a.c. nominal

(Current trip @ 4mA nominal)

(Short circuit current 5mA nominal)

Accuracy of Indication: ±5% of reading ±1 digit

LEADS

Mains: 1.7 fixed lead, with a 13A moulded plug

Earth Continuity: 1.5m long, fixed lead, heavy duty

crocodile/alligator clip.

Flash Test : 1.3m long, detachable, with flash gun at

one end and a shrouded 4mm safety plug

at the other.

110/240V Adapter: 110v 16A plug (BS 4343) to

240V 13A free socket (BS 1363)

SOCKETS

Mains: 240V 13A to BS 1363

110V 16A to BS4343

Flash: 4mm safety type

LAMPS

Flash: Neon lamp which illuminates when a

flash test is active.

Over Temperature: Red light emitting diode which illuminates when

the temperature limit for the instruments has been

exceeded.

-5- -10-

If the leakage current exceeds the preset limit the EasyPAT will automatically

switch off the high voltage.

4. SPECIFICTION

4.1 ELECTRICAL

SUPPLY VOLTAGE

Voltage: 110V/240V±10% 50/60Hz

POWER CONSUMPTION: 10/220 (excluding run)

EARTH CONTINUITY TEST (8 and 25 Amps)

Test Voltage: 6V a.c. nominal with no load

Test Current: 25 a.c. nom @ 0.1Ω

10 A a.c. nom @ 0.5Ω}25 Amps

8A a.c. nom @ 0.1Ω

5A a.c. nom @ 0.5Ω }8 Amps

Display Range: 0 - 1.99Ω

Accuracy of Indication: ±10% of reading ±2 digits

EARTH CONTINUITY TEST (100m Amps)

Test Voltage: 130mV d.c. nominal open circuit

Test Current: 100mA d.c. nominal constant current

Range: 0 - 1.99Ω

Accuracy: ±10% of reading ±2 digit

INSULATION TEST

Test Voltage: 500V d.c. 0%, ±20% at 0.5MΩ

Short Circuit Current: 1.5mA d.c. nominal

Display Range: 0 - 19.9MΩ

Accuracy Of Indication: ±5% ±1 digit of reading

RUN CURRENT TEST

Display Range: 0 - 19.9A

Usable Range: 0 - 13.0A

(Dependent on mains plug fuse)

The following table gives a guide to the maximum cable length for a 0.1

ohm pass limit.

Cross Section Max length Cable rating

0.5 mm22 metres 3 amp

0.75mm23 metres 6 amps

1.0 mm24 metres 10 amps

1.5 mm26 metres 15 amps

2.5 mm210metres 20 amps

To establish the maximum cable lengths permissible for other settings of

earth continuity divide the new setting by 0.1 and multiply by length for 0.1Ω,

e.g.

Maximum cable length for 0.5mm2on 0.1Ω setting = 2 metres

Maximum cable length for 0.5mm2on 0.2Ωsetting = (0.2 /0.1) x2 = 4 metres

NOTE: During this test high currents are generated by the EasyPAT which will cause a rapid

increase in the temperature within the instrument.

A thermal trip has been incorporated into the instrument to protect against

over temperature. When triggered it will inhibit all test functions and illuminate

the red indicator which is located below the display. When the internal

temperature returns within acceptable limits normal operation of the instrument

will be restored and the red indicator will extinguish.

b) EARTH CONTINUITY (100mA)

This test is only required for earthed (Class I) appliances whose exposed metal

work is solely for screening RF Radiation. Such metalwork could be damaged

by the 25 amp test current, and so the test current is limited to 100mA.

The method of testing is similar to (a) except that the rocker switch is set to its

100mA position.

c) INSULATION

The integrity of the insulation of the appliance is tested by applying 500 volts

dc between phase/neutral linked together and earth. The measured insulation

resistance is displayed.

Fit the wander earth clip to any exposed metal on the appliance If there is no

exposed metalwork on the appliance, metal foil should be wrapped around

the appliance and the wander lead clip attached to the foil.

-6-

-9-

Press and hold the ‘INSULATION’ key. The display will show the measured insulation

value for as long as the button is held depressed. If filter components are fitted to the

appliance being tested these may cause erroneous readings during the first few

seconds of the test. To ensure a valid reading allow a few seconds before noting the

displayed result.

NOTE: It is important to test the earth continuity in a Class I appliance prior to this test.

Otherwise, this test may not be valid.

d) RUN

Full mains supply is applied to the appliance. The running current or the

earth leakage current, depending on the button pressed, can be measured

and displayed.

WARNING

This test can be hazardous if the earth continuity and insulation of the appliance have not been

checked prior to performing a run test. Always ensure that any appliance with electrically

energised moving parts is securely mounted before performing a test.

DO NOT TOUCH THE APPLIANCE DURING THE TEST.

DO NOT RUN THE APPLIANCE LONGER THAN NECESSARY.

DO NOT USE THE EASYPAT AS A MAINS POWER OUTLET.

Run current

Press and hold the ‘RUN AMPS’ key. The display will show the current drawn by the appliance

for as long as the button is held depressed.

Run Leakage Current

ENSURE THAT THE WANDER EARTH CLIP IS CONNECTED.

Press and hold the ‘RUN LEAKAGE’ key. The display will show the earth leakage current for

the appliance for as long as the button is held depressed.

WARNING

If the fuse in the EasyPat ruptures it must be replaced with a fuse as specified.

Fitting of any other type or rating of fuse is hazardous and may result in damage to the

EasyPAT.

e) FLASH

NOTE: Due to the high voltages present during this test it should only be carried out by

suitable trained operators. Always inspect the flash probe for damage before use.

Flash voltage is applied:

i) Along the mains lead phase/neutral and the earth for a Class I

instrument (test voltage 1.5kV).

ii) Along the mains lead phase/neutral and the flash probe for Class II

instruments (test voltage 3kV).

iii) Along the flash probe and the Wander earth clip for testing Class I

sub assemblies not connected to any mains plug (test voltage 1.5kV).

This test severely stresses the insulation of the appliance under test and

should not be carried out on a routine maintenance basis. Always check the

appliance manufacturers data to ensure that permanent damage will not be

done to the appliance if a flash test is carried out.

NOTE: With Class I appliances it is important to test the earth continuity prior to flash

testing otherwise the test may not be valid.

DO NOT TOUCH THE TEST APPLIANCE DURING TEST.

With Class II tests, the flash gun should be plugged into the safety test socket. The

flash gun is operated by pulling its trigger to expose its probe tip which should be

held firmly against any exposed metal surfaces on the appliance during the flash test.

Plug in the flash gun if required. The plug fits into the safety test socket.

With Class II tests the probe tip should be held firmly against any exposed

metal surfaces on the appliance for the duration of the flash test.

If there is not exposed metalwork on the appliance, metal foil should be

wrapped around the appliance and the Flash gun held in contact with the foil.

With sub assemblies attach the Wander earth clip to any metal which would

normally be connected to earth. Link together all connections which would

normally be connected to mains phase or neutral. Hold the probe tip firmly

against a mains connection for the duration of the test.

Press and hold the ‘FLASH’ key. The orange flash indicator will illuminate and

the flash leakage current will be measured and shown on the display for as long as

the key is held down.

-7- -8-

Table of contents

Other Metrohm Test Equipment manuals