Metropolitan Industries ion Take Control MSE50V User manual

Ion Technologies MSE50V

Sewage Pump

OPERATION MANUAL

Dated: 03/30/2020

Document Name: MSE50V_OM

Page 1 of 8

www.ionproducts.net

Safety WarningS

Thank you for purchasing your Ion Technologies

Pump. To help ensure years of trouble-free operation,

please read the following manual carefully.

CAUTION/ WARNING: Read these safety

warnings rst before installing, servicing, or

operating any pump.

DANGER: Keep pump equipment out of

the reach of children! Failure to follow the

directions given could cause serious risk to individuals

or objects.

Before Installation

This manual contains important information for the safe

use of this product. Read this manual completely and

follow the instructions carefully. Reasonable care and

safe methods relating to the installation and operation

of this product should be practiced. Check local codes

and requirements before installation.

WARNING: Risk Bronze/brass tted pumps

may contain lead levels higher than considered

safe for potable water systems. Government agencies

have determined that leaded copper alloys should not

be used in potable water applications.

WARNING: Installation, wiring, and junction

connections must be in accordance with the

National Electric Code and all applicable state and

local codes. Requirements may vary depending on

usage and location.

WARNING: Installation and servicing is to be

conducted by qualied personnel only.

DANGER: Rotating machinery. Amputation or

severe lacerations can result. Keep clear of

suction and discharge openings. DO NOT insert

ngers into pump with power connected.

WARNING: Always wear eye protection when

working on pumps. Do not wear loose clothing

that may become entangled in moving parts.

DANGER: Pumps build up heat and pressure

during operation. Allow time for pumps to cool

before handling or servicing.

DANGER: Hazardous Voltage can shock,

burn, or cause death. This pump is not intended

for use in swimming pools or water installations where

human contact with pumped uid is possible.

DANGER: Risk of electrical shock. To reduce

risk of electrical shock, always disconnect

pump from power source before handling. Lock out

power & tag.

WARNING: Do Not use these pumps in water

over 145°F. Do not exceed manufactures

recommended maximum performance, as this could

cause the motor to overheat.

2 YEAR

WARRANTY

EXTENSION

2 Year Warranty Extension Available

Add an additional 2 years to the standard 1 year warranty

(from date of installation) for a total of 3 years of

complete warranty protection.

For more information, visit

store.ionproducts.net/product/m33v-50v-warranty-extension

Ion Technologies MSE50V

Sewage Pump

OPERATION MANUAL

Dated: 03/30/2020

Document Name: MSE50V_OM

Page 2 of 8

www.ionproducts.net

CAUTION: Make sure lifting handles are

securely fastened each time before lifting.

DANGER: Do not lift, carry or hang pump by

the electrical cables. Damage to the electrical

cables can cause shock, burns or death. Never handle

connected power cords with wet hands. Use

appropriate lifting device.

WARNING: Sump and sewage pumps often

handle materials which could cause illness or

disease. Wear adequate protective clothing when

working on a used pump or piping. Never enter a basin

after it has been used.

DANGER: Failure to permanently ground the

pump, motor and controls before connecting to

power can cause shock, burns or death.

DANGER: These pumps are NOT to be

installed in locations classied as hazardous

in accordance with the National Electric Code, ANSI/

NFPA 70.

WARNING: Do not introduce into any sewer, waste

disposal unit or toilet: Seafood Shells, Aquarium

Gravel, Cat Litter, Plastic Objects, Sanitary Napkins or

Tampons, Diapers, Rags, Disposable Wipes or Cloth,

Medications, Flammable Material, Oil or Grease,

Strong Chemicals, Gasoline.

• Operation against a closed discharge valve will

cause premature bearing and seal failure on any

pump.

• Any wiring of pumps should be performed by a

qualied electrician.

• Cable should be protected at all times to avoid

punctures, cuts, bruises, and abrasions —inspect

frequently.

• Never handle connected power cords with wet

hands.

• Never let cords or plugs lie in water outside the

sump pit.

Do not throw away or lose this manual. Keep it in a safe

place so that you may refer to it often for the continued

safe operation of the product.

receiving and inStallation

Pump-Down Test - Be sure pump has been plugged

in, lowered into the basin or sump, check the system

by lling with liquid and allowing the pump to operate

through its pumping cycle. The time needed to empty

the system, or pump-down time along with the volume

of water, should be recorded.

Thermal Protection

The normally closed (N/C) over temperature sensor

is embedded in the motor windings and will detect

excessive heat in the event an overload condition

occurs. The thermal sensor will trip when the windings

become too hot and will automatically reset when the

pump motor cools to a safe temperature.

In the event of an over temperature, the source of

this condition should be determined and repaired

immediately. Thermal protection shall not be used as a

motor overload device.

Maintenance

Minimal maintenance is required. Perform the following

checks when pump is removed from operation or when

pump performance deteriorates:.

a. Inspect motor chambers for oil level and

contamination.

b. Inspect impeller and body for excessive build-up

or clogging.

c. Inspect motor and bearings.

d. Inspect seal for wear or leakage.

Servicing

Cooling Oil - Anytime the pump is removed from

operation, the cooling oil in the motor housing should

be checked visually for oil level and contamination.

To check oil, set unit upright. Remove pipe plug from

housing. With a ashlight, visually inspect the oil in the

housing to make sure it is clean and clear, light amber

in color and free from suspended particles. Milky white

oil indicates the presence of water. Oil level should be

just above the motor when pump is in vertical position.

Oil Testing

• Drain oil into a clean, dry container by placing pump

on it’s side. Remove pipe plug, from housing.

• Check oil for contamination using an oil tester with

a range to 30 Kilovolts breakdown.

Ion Technologies MSE50V

Sewage Pump

OPERATION MANUAL

Dated: 03/30/2020

Document Name: MSE50V_OM

Page 3 of 8

www.ionproducts.net

• If oil is found to be clean and uncontaminated

(measuring above 15 KV. breakdown), rell the

housing.

• If oil is found to be dirty or contaminated (or

measures below 15 KV. breakdown), the pump

must be carefully inspected for leaks at the shaft

seal, cable assembly, o-ring and pipe plug, before

relling with oil. To locate the leak, perform the

following pressure tests.

After leak is repaired, dispose of old oil properly, and

rell with new oil.

Pressure builds up extremely fast, increase

pressure by “TAPPING” air nozzle. Too much

pressure will damage seal.

DO NOT exceed 10 P.S.I.

Motor Housing Pressure Test:

If oil has been drained, ll to normal level before

performing pressure test. Remove pipe plug from

motor housing.

Apply pipe sealant to pressure gauge assembly and

tighten into hole. Pressurize motor housing to 10 P.S.I.

Use soap solution around the sealed areas above the

oil level and inspect joints for “air bubbles”. For sealed

areas below oil level, leeks will seep oil. If, after ve

minutes, the pressure is still holding constant, and no

“bubbles” /oil seepage is observed, slowly bleed the

pressure and remove the gauge assembly. Replace

oil. Leak must be located and repaired if pressure does

not hold.

Oil Replacement Motor Housing

Remove pipe plug from motor housing.

Drain all oil (if not already done so) from motor housing

and dispose of properly per Local Code. Set pump

upright and rell with new cooling oil, see “Cooling Oil”

chart. Fill to just above motor (1.2L) as an air space

must remain in the top of the motor housing to

compensate for oil expansion. Apply pipe thread

compound to threads of pipe plug then assemble to

motor housing. Check that o-ring is in place and does

not need to be replaced. Reassemble cord cap to

motor housing.

DO NOT overll oil. Overlling of housing

with oil can create excessive and dangerous

hydraulic pressure which can destroy the pump

and create a hazard. Overlling oil voids warranty.

Cooling Oil Recommended Supplier/Grade

BP Enerpar SE100

Conoco Pale Parafn 22

Mobile D.T.E. Oil Light

Shell Canada Transformer-10

Texaco Diala-Oil-AX

WARNING: Before any service work is done,

disconnect and lock out electrical power to

pump.

Volute - Remove screws from volute.

Impeller - Remove impeller by turning counter-

clockwise careful application of heat may be necessary.

Do Not store pump without impeller in place.

Seal- Handle seal parts with care. Remove rotating

member from shaft. Remove pressed-in spring

component from seal plate. Examine all seal parts.

Inspect contact faces for signs of uneven wear tracks

on stationary face, chips and scratches on either seal

face. DO NOT interchange seal components, replace

the entire shaft seal if necessary.

Seal Plate - Remove screws from seal plate. Remove

seal plate and o-ring.

Bearings - Using a bearing puller or arbor press

remove bearing from shaft. Remove upper motor

bearing from shaft with a bearing puller.

IMPORTANT!- ALL PARTS MUST BE CLEAN

BEFORE REASSEMBLY. HANDLE SEAL

PARTS WITH EXTREME CARE. DO NOT DAMAGE

LAPPED SURFACES.

CAUTION: Operating pump builds up heat and

pressure; allow time for pump to cool to room

temperature.

REASSEMBLY

Bearing - Be careful not to damage the rotor shaft

when replacing bearing. Using an arbor press, hold the

rotor and press the upper bearing on the rotor shaft,

applying force to the inner race of the bearing only.

In the same manner replace lower bearing onto rotor

shaft.

inStallation and Service

Ion Technologies MSE50V

Sewage Pump

OPERATION MANUAL

Dated: 03/30/2020

Document Name: MSE50V_OM

Page 4 of 8

www.ionproducts.net

Inlet pipe

Power cord

pipe

Gate valve

Elbow

Union

Check valve

Seal Plate - Lubricate and set o-ring in bottom of seal

plate. Place seal plate over shaft, being sure o-ring is

not twisted and in the groove. Place four capscrews

through holes in motor housing and into seal plate and

torque to 6.5 ft/lbs.

Outer Seal - Clean and oil stationary seal cavity in seal

plate. Slide seal guide tool over motor shaft. Lightly oil

(Do not use grease) outer surface of seal’s stationary

member.

Press stationary rmly into seal plate using a seal

pusher tool. Be sure the stationary member is in

straight. Nothing but the seal tool is to come in contact

with seal face.

IMPORTANT! Do not hammer on the seal

pusher. It will damage the seal face.

With lapped surface of rotating member facing inward

toward stationary, slide rotating member and onto

shaft, until lapped faces of stationary and rotating seal

are together.

Impeller - Place impeller on motor shaft by turning

clock-wise. Blue thread locking compound is

recommended.

Volute - Place volute on seal plate. Place screws

through volute and into seal plate Then torque evenly

to 11 ft/lbs.

PUMP DOES NOT RUN AND MAKES HUMMING

SOUND

• Line circuit breaker is off, or fuse is blown or loose

• Water level in sump has not reached turn-on level

as indicated in installation drawing.

• Pump cord is not making contact in receptacle.

• Float is stuck. It should operate freely in basin.

• If all of the above are OK, then the motor could be

malfunctioning.

PUMP RUNS BUT DOES NOT DELIVER WATER

• Check if valve is installed backwards.

• Arrow on valve should point direction of ow

• Discharge shut-off valve (if used) may be closed.

• Impeller or volute openings are fully or partially

clogged. Remove pump and clean.

• Pump is air-locked. Start and stop several times

by plugging and unplugging cord. Check for

clogged vent hole in pump case.

• Inlet holes in pump base are clogged. Remove

pump and clean the openings.

• Vertical pumping distance is too high. Reduce

distance or change the discharge ttings of the

pump.

PUMP RUNS AND PUMPS OUT SUMP, BUT DOES

NOT STOP

• Float is stuck in up position. Be sure oat operates

freely in basin.

• Defective oat switch. Replace oat switch.

PUMP RUNS BUT ONLY DELIVERS A SMALL

AMOUNT OF WATER

• Pump is air-locked. Start and stop several times

by plugging in and unplugging cord. Check for

clogged vent hole in pump case.

• Vertical pumping distance is too high. Reduce

distance or change the discharge tting of the

pump. Inlet holes in pump base are clogged.

Remove pump and clean the strainer and

openings.

troubleShooting

Ion Technologies MSE50V

Sewage Pump

OPERATION MANUAL

Dated: 03/30/2020

Document Name: MSE50V_OM

Page 5 of 8

www.ionproducts.net

• Impeller or volute openings are fully or partially

clogged. Remove pump and clean.

• Pump impeller is partially clogged with tar or

paint, causing motor to run slow and overload.

Remove pump and clean.

FUSE BLOWS OR CIRCUIT BREAKER TRIPS

WHEN PUMP STARTS

• Pump impeller is partially clogged causing motor

to run slow and overload. Remove pump and

clean.

• Motor stator may be defective.

• Fuse size or circuit breaker may be too small.

(must be 15 amps).

• Impeller or volute opening are fully or partially

clogged. Remove pump and clean.

MOTOR RUNS FOR A SHORT TIME, THEN STOPS

• Inlet holes in pump base are clogged. Remove

pump and clean the openings.

• Pump impeller is partially clogged causing motor

to run slow and overload. Remove pump and

clean.

• Motor stator may be defective.

• Impeller or volute openings are fully or partially

clogged.

• Remove pump and clean. Also clean the strainer

if one is installed.

ELECTRICAL PRECAUTIONS

WARNING: Before servicing a pump, always

shut off the main power breaker and then

unplug the pump. Make sure you are not standing

in water and are wearing insulated protective sole

shoes, under ooded conditions. Contact your local

electric company or a qualied licensed electrician

for disconnecting electrical service prior to pump

removal.

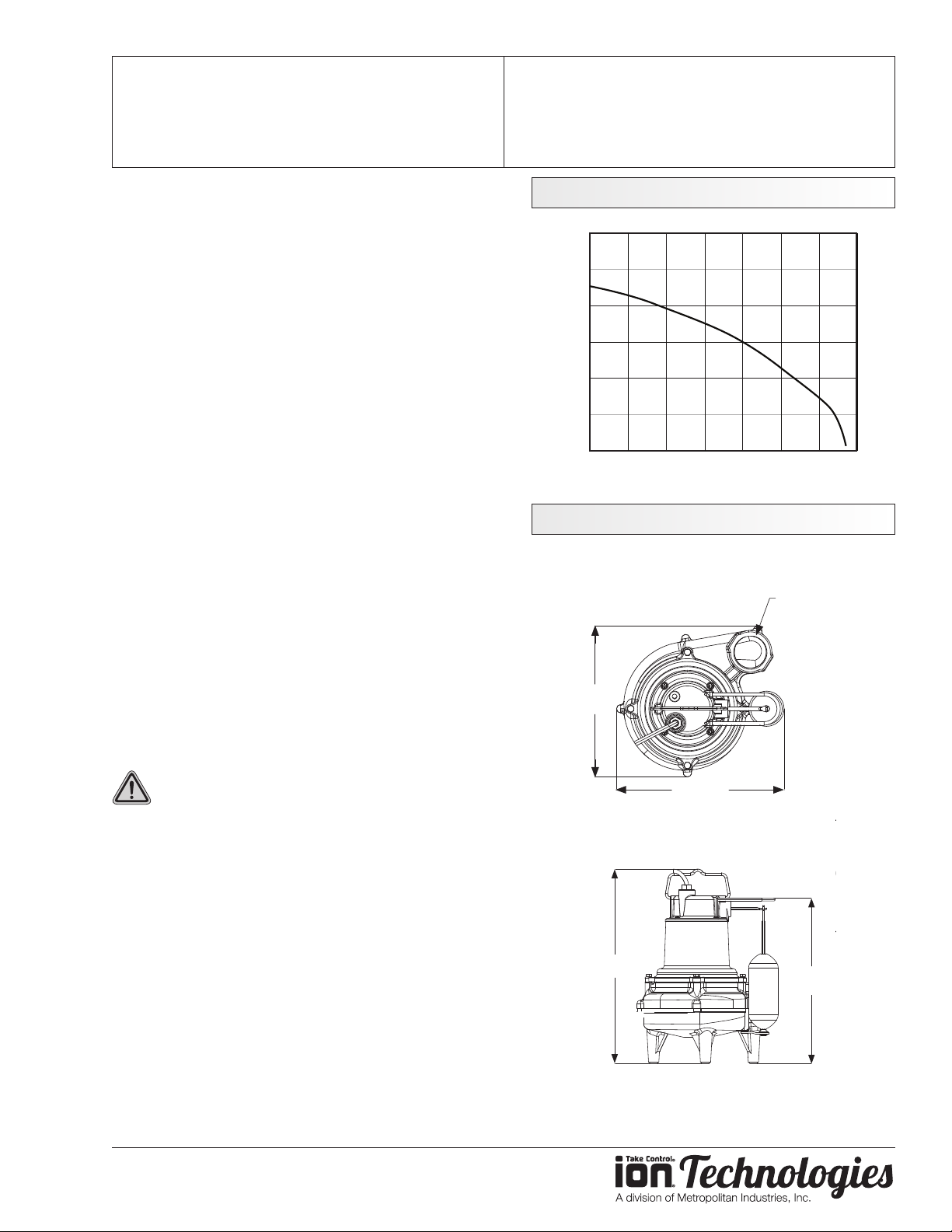

Performance

SPecificationS

15.91”

13.53”

10.4”

11.53”

2” NPT

15.91”

13.53”

10.4”

11.53”

2” NPT

Head - feet

Capacity - US GPM

0

25

15

5

10

20

30

0 10080604020 120

140

Ion Technologies MSE50V

Sewage Pump

OPERATION MANUAL

Dated: 03/30/2020

Document Name: MSE50V_OM

Page 6 of 8

www.ionproducts.net

noteS

noteS

Ion Technologies MSE50V

Sewage Pump

OPERATION MANUAL

Dated: 03/30/2020

Document Name: MSE50V_OM

Page 7 of 8

www.ionproducts.net

noteS

Ion Technologies MSE50V

Sewage Pump

OPERATION MANUAL

Dated: 03/30/2020

Document Name: MSE50V_OM

Page 8 of 8

www.ionproducts.net

Ion|StormPro 1 Year/ 18 Months Year Residential Warranty

1. Coverage and Term. Metropolitan Industries, Inc. (“Metropolitan”) warrants to the original

purchaser (the “Buyer”) of each Ion|StormPro product (the “product”), that any part thereof which proves to

be defective in material or workmanship for a period of one year from date of installation or 18 months from

date of manufacture, which ever comes fi rst, will be replaced at no charge with a new or remanufactured part,

F.O.B. factory. Buyer shall be responsible for all freight charges and all costs of fi eld labor or other charges

incurred in the removal and/or reinstallation of any product, part or component thereof.

2. Exclusions. THE WARRANTY IS SUBJECT TO THE FOLLOWING CONDITIONS AND

EXCLUSIONS:

(a) The Warranty excludes products or workmanship which becomes defective as a result

of: (i) earthquake, fi re, storms, the elements or any other acts of God; (ii) normal wear and tear from use;

(iii) accident, misuse, abuse or neglect; (iv) modifi cations made by Buyer or any third party, other than

Metropolitan; and (v) Buyer’s failure to properly install, maintain, service and/or operate the product under

normal conditions and according to manufacturer’s instructions.

(b) Metropolitan shall not be responsible for, and the Warranty shall not cover, extended

damage which occurs because of Buyer’s failure to notify Metropolitan promptly in writing of apparent

defects.

(c) Any part or component designated as manufactured by anyone other than Metropolitan

shall be covered only by the express warranty of the manufacturer thereof.

(d) The Warranty shall lapse upon Buyer’s failure to fully comply with the terms and conditions

of its contract with Metropolitan, including Buyer’s failure to pay the purchase price for the product or any

portion thereof. Buyer’s subsequent compliance with the terms and conditions of any such contract, will not

cause the term of the Warranty to extend beyond the time period set forth above.

(e) No actions taken by Metropolitan to correct a defect in a product shall extend the Warranty

beyond the period set forth above. Metropolitan shall not be obligated to remedy any defect, where otherwise

required pursuant to the Warranty unless and until Buyer notifi es Metropolitan in writing of the defect and

then only if such notifi cation is made prior to the expiration of the period set forth above.

3. Process of Claims and Repairs. Metropolitan agrees that if the product or any part or component

thereof shall fail to conform to the terms of this Warranty, Metropolitan shall replace such nonconforming

product, part or component at the original point of delivery and furnish instruction for its disposition. Any

transportation charges involved in such disposition and all costs of fi eld labor or other charges incurred in the

removal and/or reinstallation of any product, part or component thereof shall be the responsibility of Buyer.

4. Limitation on Liability. Notwithstanding any provision to the contrary, Metropolitan’s entire

liability under this Warranty shall not in the aggregate exceed, and Buyer’s exclusive and sole remedies

are, to the extent permitted by law, shall be to secure replacement of the defective product. UNDER NO

CIRCUMSTANCES SHALL METROPOLITAN BE LIABLE UNDER THE WARRANTY FOR

ANY INDIRECT, PUNITIVE, SPECIAL, EXEMPLARY, CONSEQUENTIAL OR INCIDENTAL

DAMAGES (INCLUDING LOST PROFITS, REVENUE, USE OR ECONOMIC ADVANTAGE).

5. Express Waiver of Any Other Warranties. THE EXPRESS WARRANTY SET FORTH IN THIS

WRITTENWARRANTYISTHE ONLYWARRANTYMADE BYMETROPOLITAN, ORANYOTHER

PARTY, IN CONNECTION WITH ANY PRODUCT PURCHASED FROM METROPOLITAN.

NEITHER METROPOLITAN, NOR ANY OTHER PARTY, MAKES ANY OTHER EXPRESS OR

IMPLIED WARRANTY WHICH IS NOT SET FORTH HEREIN, AND METROPOLITAN HEREBY

DISCLAIMS AND BUYER HEREBY WAIVES ALL IMPLIED WARRANTIES, INCLUDING THE

IMPLIED WARRANTY OF MERCHANTABILITY AND THE IMPLIED WARRANTY OF FITNESS

FOR A PARTICULAR PURPOSE.

6. Not Transferable. The Warranty may not be transferred and shall be void on the sale or other transfer

of the product.

7. Products and Warranty Subject to Change. Metropolitan reserves the right to make revisions to its

products and their specifi cations, and to revise this Warranty and related information without notice.

Table of contents

Other Metropolitan Industries Water Pump manuals