MEWOI MEWOI3800P User manual

Built-in Non-Contact Ground

Resistance Online Detector

MEWOI3800P

CONTENT

I. Brief Introduction ...........................................................................1

II. Technical Specifications................................................................2

III. Detector Structure and Dimensions .............................................4

IV. Usage method...............................................................................5

V. The Principle andApplication of Detection...................................6

VI. Basic Equipment........................................................................14

Attention Items:

Thank you for purchasing MEWOI3800P Built-in Non-Contact

Ground Resistance Online Detector of the company In order to

make better use of the product please be certain:

——To read this user manual carefully.

——To comply with the operating cautions presented in this

manual.

Apply to return circuit ground resistance, metallic return con-

nection resistance, grounding conditions, cable anti-theft

on-line monitoring.

Single point grounding system, needs to increase assistance

after the ends of the earth form a loop, then install detector.

Note that this detector specified measuring range and using the

environment.

Protection against rain shower and water logging of installation.

The detector and the circuit board can be built into other

equipment crate, which is convenient for integration.

Install waterproof and rainproof of device at outdoors.

The dismantling, calibration and maintenance the Detector shall

be operated by the authorized staff.

If the continuing use of it would be dangerous, the Detector

should be stopped using immediately, and immediately sealed

for the treatment by the authorized agencies.

-1-

I. Brief Introduction

Built-in Non-Contact Grounding Resistance Online Detector is

our company devotes ourselves to Grounding resistance test tech-

nical research’s another new high-tech product for more than ten

years, built for online monitoring grounding down lead connection

status, return circuit grounding resistance and metal return circuit

connection resistance well-designed manufactured. on-line testing,

non-contact measurement, grounding wire pass through the hole,

real time on-line testing. Detector provides RS232 and RS485 signal

interface, provides standard MODBUS-RTU communication pro-

tocol. The detector and the circuit board can be built into other

equipment crate, which is convenient for secondary development

integration.

Non-Contact Grounding Resistance Online Detector is widely

applied in electric power, telecommunications, petrochemical, rail-

way, meteorology, military and other industries, building facilities,

electric power, electrical equipment, warehouse and oil depot of the

lightning protection grounding, protective grounding, or working

grounding, and also applied in anti-theft monitoring for ground wire

and metal cable.

Non-Contact Grounding Resistance Online Detector can be in-

dependent installation to use, and also can organizes a wire or wire-

less network system.

-2-

II. Technical Specifications

Function

Return circuit grounding resistance on-line

monitoring, metal return resistance connection

online monitoring, grounding condition moni-

toring, ground wire and metal cable anti-theft

monitoring.

Power Supply

Detector: DC6V~ DC9V, 50ma Max.

Resistance

Range

0.01Ω~ 200Ω

Resolution

0.001Ω

Indication

Range

0.00Ω~ 200Ω

Accuracy

±2 % rdg±3dgt(20°C ±5°C , below 70%RH)

Detector Di-

mensions

110mm×80mm×55mm

PCB Dimen-

sions

166mm×56mm×20mm

Grounding

Wire Perfora-

tion Size

60mm×30mm, closed mode

Overflow Indi-

cation

When show value is beyond 200Ω, detector

send out “OLΩ”

PCB Interface

J1: signal output, power supply input interface

J2: Detector and PCB interface

J1 Identifier

P+: power supply input anode;

P-: power supply input cathode;

GND: signal cathode, connects with power

supply input cathode by short circuit connec-

-3-

tion

R+: signal output anode

R-: signal output cathode

J2 Identifier

I+,I-: current coil interface

U+,U-: voltage coil interface

GND: common ground

Connecting

Line

A one meter long wire(5cores shielded wire)

Connection

Identifier

Red/brown---power supply input anode;

Black--- power supply input cathode;

Blue---RS485 signal anode;

Grey---RS485 signal cathode;

White--- analog grounding (power supply input

cathode can connects with analog grounding by

short circuit connection)

Protocol

Standard

RS232, RS485 or MODBUS-RTU communi-

cation protocol

Quality

Detector: 680g

Working Tem-

peratureAnd

Humidity

-20°C ~55°C ;20% RH~90% RH

Humiture Er-

ror

Within 5%

Shift

Automatic shift

GND Interfer-

ence Current

Prohibited

External Mag-

netic Field

< 40A/m

-4-

External Elec-

tric Field

< 1V/m

Single Meas-

urement Of

Time

About 0.5 second

Power Con-

sumption

50ma Max.

Installation

Grounding wire through Detector centre bore

Installation

Requirements

The circuit board need built into other equip-

ment crate, avoid rain and water logging

Power Supply

Mode

External power supply (Equipped by user)

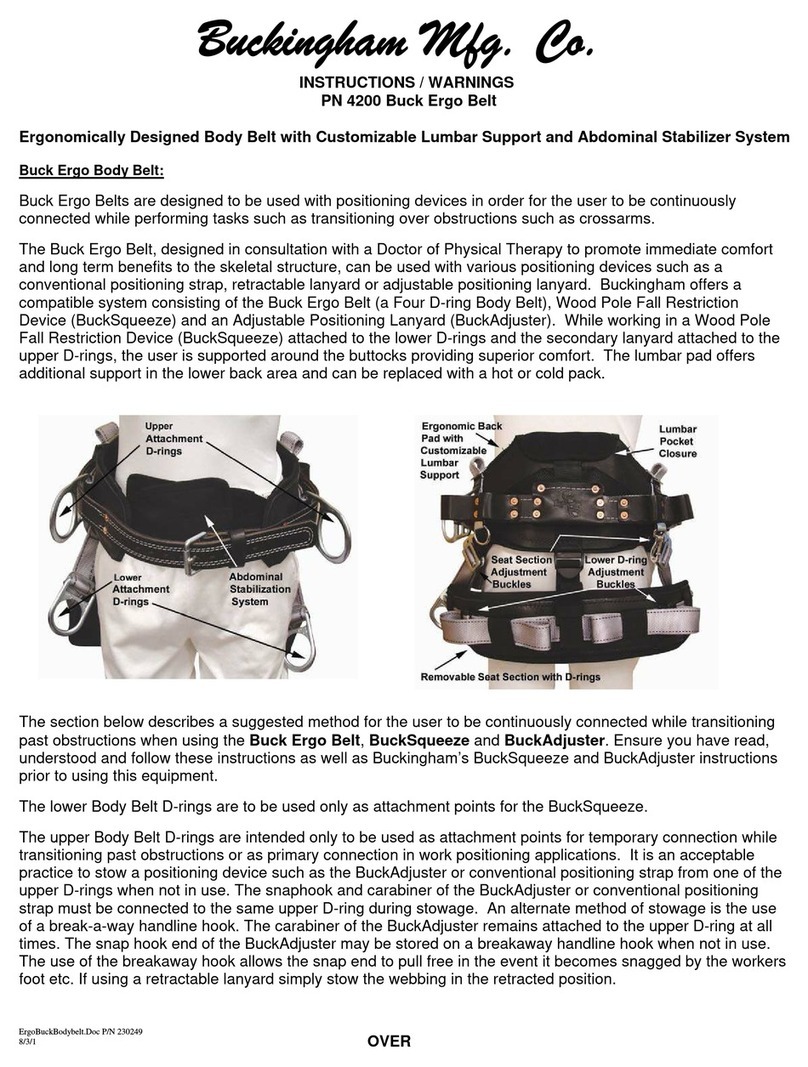

III. Detector Structure and Dimensions

1. Grounding wire perforation size: 66mm×36mm.

2. Detector.

3. Signal output, power supply input thread

4. Signal output and power supply input connecting wire.

5. Detector and PCB connecting wire.

-5-

6. PCB.

IV. Usage method

1. Independent Installation and Use.

2. Set up Network Installation and Use

According to RS232, RS485 or MODBUS-RTU communication

protocol to set up a variety of networks to achieve remote monitor-

ing.

-6-

V. The Principle and Application of Detection

1. Testing Principle.

Built-in Non-Contact Grounding Resistance Online Detector’s

fundamental is measuring return circuit resistance. firstly Sensor

send out a drive pulse signal to be measured ground return circuit,

then measured ground return circuit responses a pulse electromotive

force E, under the influence of electromotive force E there will gen-

erate current I in the be measured ground return circuit. Sensor

measures E and I, and immediately gets resistance of be measured

ground return circuit through the formula: R=E/I.

2. Return Circuit Resistance Definition.

As picture: return circuit is a composite value includes A spot

grounding resistance, grounding down lead metallic conductor’s

resistance, metal overhead line’s resistance, connection re-

sistance(contact resistance)between grounding down lead and metal

overhead line, B spot grounding resistance. For the formative

above-mentioned return circuit’s grounding system, Detector can be

installed directly for monitoring, if the grounding system not form a

return circuit, it need adding auxiliary grounding electrode to form a

return circuit, further install the Detector, see the after-mentioned

single point grounding system. If the Detector measured out return

circuit’s composite value of grounding network A and grounding

network B is 5.0Ω, that is: RA+RB+RC+ RD=5.0Ω(RC and RD re-

spectively represent resistance of metal overhead line and grounding

down lead ), actual grounding resistance value of grounding network

A and grounding network B’s in parallel resistances less than or

equal to 2.5Ω, accordingly judge actual grounding resistance value

of grounding network A and grounding network B parallel connec-

-7-

tion whether qualified. If grounding network A and grounding net-

work B’s in parallel resistances less than engineering standard re-

quired value, so grounding network A and grounding network B are

all qualified.

3. Metal Return Circuit Connection Resistance Testing.

If grounding network A and grounding network B up and down are

connected together on the ground, then Detector measures out metal

return circuit resistance’s value is very small general speaking, only

few of an Ohm, this is the connection resistance of metal return cir-

cuit, namely equipotential resistance, isn’t grounding resistance.

Therefore the Detector is convenient to test metal return circuit’s

connection resistance, and also applied in anti-theft monitoring for

ground wire and metal cable.When the cable is cut, metal loop re-

sistance is infinite, the Detector will alarm.

In the large-scale grounding grid, such as converting station ground

connection, oil depot ground connection, building construction

-8-

ground connection and so on, they are all an integral large-scale

grounding grid under the ground, meanwhile there are many

grounding down lead extends to the ground, and connects the other

on the ground, as the following picture. To such large-scale ground-

ing grid, its grounding grid’s maximum diagonal distance is about a

few hundred meters to thousands of meters, testing its grounding

resistance is very difficult and troublesome. If it exist unqualified

grounding resistance, that problem is appearing at the connection

position of grounding down lead and grounding grid (direction of

arrow of the welding position in the picture), engineering reform is

to excavate grounding down lead’s position, then again weld

grounding down lead. Actually it’s impossible to reform the whole

grounding grid, or the whole grounding grid and surface facilities

need to pull down and rebuild, this is impossible.

Therefore, for the large-scale grounding grid, we can install Detector

on the primary grounding down lead and secondary grounding down

lead to monitor connection status between the grounding down lead

and the grounding grid, judge the grounding down lead’s grounding

conditions by testing metal return circuit connection resistance.

-9-

4. Single Point Grounding System.

If grounding network A and grounding network B is without over-

head line, and doesn’t connect together on the ground, then ground-

ing network A and grounding network B can regard as standalone

single point grounding connection. Detector cannot test single point

grounding system’s grounding resistance directly. This moment it

needs adding one or more auxiliary grounding electrode, to form

multipoint return circuit, then to install Detector. In the small range,

if there are two or more single point grounding system, it can use

metallic conductor to connect all single point grounding system’s

grounding down lead together on the ground, to form a return circuit,

then install the Detector to monitor.

5. Three-point method

As figure, A is the tested ground pole, B and C are auxiliary ground

poles. Ground pole A, B and C are connect together on the ground.

In the grounding down lead of the three ground pole A, B and C,

install the Detector respectively, can accurately test the grounding

resistance ofA point. Calculation is as follows:

R1=RA+RB∥RC--------(1);

R2=RB+RA∥RC--------(2);

R3=RC+RA∥RB--------(3).

Illustration: R1, R2, R3 are the test values, RA, RB, RC are the

grounding resistance of the ground pole A, B and C. By solve the

three equations, can be accurate calculate the grounding resistance of

ground pole A, at the same time, it can know the grounding re-

sistance of auxiliary ground pole B,C and the grounding resistance

of parallel connectionA, B and C.

-10-

Three-point method has another advantage: Due to auxiliary ground

pole B and C is parallel to the tested ground pole A, so that the actu-

al grounding resistance will be less than RA to improve the tested

grounding pole. RA∥RB∥RC<RA. At the actual construction, the

grounding resistance of auxiliary ground pole B and C must less

than 10 times of the grounding systems engineering standard value.

If the engineering requirements of the grounding resistance value

cannot exceed 4Ω,then RC<40Ω,RB<40Ω. RB, RC as small as

possible, more can improve measured grounding system.

6. Application.

(1). Power Transmission System Pole Ground Connection.

It forms multipoint grounding system through overhead ground wire

connection; test conveniently, its equivalent circuit as the following

picture on the right.

-11-

Illustration:R1 is predicted grounding resistance, R0 is the equiva-

lent resistance of all the other pole’s grounding resistance parallel

connection, that is R0=R2∥R3∥R4∥…∥Rn, if the greater n is (the

more grounded junction), the closer R0gets to 0,far smaller than R1,

from engineering point of view, R0=0,so, the data Detector receives

should be R1’s value.

(2). Underground Mine Power Transformation Ground Connection.

Respectively, primary grounding electrode R,R1~R3…Rnis a inde-

pendent grounding body under the ground, don’t connect together,

are multipoint grounding system, convenient to test. Detector is in-

stalled on the primary grounding electrode, the Detector’s indication

is Rr=R+R1∥R2∥R3∥…∥Rn. If the more part grounded junctions

are, so R1∥R2∥R3∥…∥Rn≈0,then Rr=R. It’s the four-code cable

in the picture, one code is ground lead among it, all the devices and

part grounding connection are connected to be a network by cable

grounding connection, dotted line is bare copper wire of grounding

connection.

-12-

(3). Generator Room and Launch Tower Grounding Connection.

Generator Room and Launch Tower is independent outdoors gener-

ally, connect both together to form second return circuit, then install

detector, as the picture below. It also can add 2 auxiliary ground

poles, use the three-point method to monitor.

-13-

(4). Construction Grounding Connection.

If R1~R6…Rnis a independent grounding body under the ground,

don’t connect together, are multipoint grounding system, convenient

to test grounding resistance. If R1~R6…Rnare connected together

under the ground, for the single point grounding system, testing

grounding resistance in accordance with single point grounding sys-

tem, direct installation test return circuit resistance, can judge

grounding connection condition.

For the large-scale construction grounding grid, it is to monitor its

equipotential value of grounding condition between grounding down

lead and grounding network. If problems occur, it would be located

at the connection point between grounding down lead and ground-

ing network, and judging that whether its equipotential value quali-

fied or not.

-14-

(5).Oil Storage Tank’s loading and Unloading Point Grounding

Connection.

Base on JJF2-2003<<Grounding Type Antistatic Device Test Speci-

fication>>, gas station mainly need to test the grounding resistance

and connect resistance of the facility shows below.

No.

Item

Technical Speci-

fication

1

Grounding resistance of oil storage

tank

≤10Ω

2

Grounding resistance of load or unload

place

≤10Ω

3

Grounding resistance of Fuel dis-

penser

≤4Ω

4

Resistance of oil hose which connect

to the Fuel dispenser and fuel truck

nozzle

≤5Ω

VI. Basic Equipment

Detector

1Set

-15-

PCB module

1PCS

Connecting wire

1 Set

User's Manual, Warranty Manual, Certification

1 Set

-16-

Table of contents

Other MEWOI Security Sensor manuals

Popular Security Sensor manuals by other brands

Teledata

Teledata SF1000E quick start guide

Red Sea

Red Sea ReefATO+ user manual

UMAX Technologies

UMAX Technologies U-Smart Door Sensor user manual

B.E.G.

B.E.G. LUXOMAT PD4-M-2C-C Series Installation and operating instruction

Tatsuta Electric Wire & Cable

Tatsuta Electric Wire & Cable AD–AS–1CM Item Specification Document

Satel

Satel GRAPHITE manual

BUCKINGHAM MFG

BUCKINGHAM MFG Buck Ergo Belt 4200 Instructions & warnings

MSA

MSA Altair operating manual

Mitsubishi Electric

Mitsubishi Electric PZ-70CSD-E Installation and instruction manual

Sonotec

Sonotec SONOCHECK ABD05 Series operating manual

BEINAT

BEINAT SGM595/A-H2CH Installation and user guide

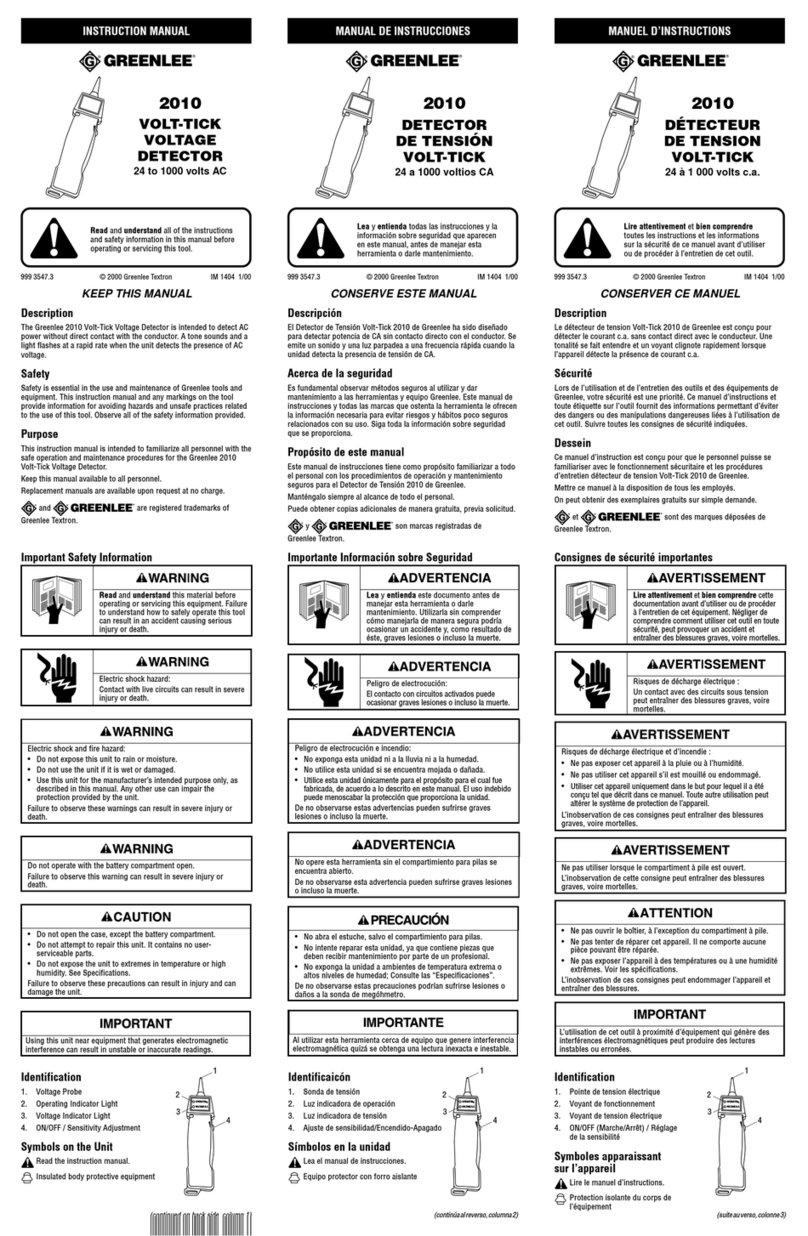

Greenlee

Greenlee 2010 instruction manual