MexAir RC E-Banshee User manual

E-Banshee Manual MexAir RC PH: 315.532.6826

www.mexairrc.com

1

50 " Wingspan

332 Square Inch Main Wing

3-Channel Electric Sport, Free Flight, or SAM "Legal" Construction

The E-BANSHEE

Based on Leon Shulman's Famous 1941 Banshee

Cover Photo - Courtesy of the Shulman Family

http://shulmanaviation.com/

E-Banshee Manual MexAir RC PH: 315.532.6826

www.mexairrc.com

2

Introduction

This manual is intended to supplement details provided on the E-Banshee plan sheet. A

seasoned model builder may be able to construct the E-Banshee using only the plans and

previous experiences in model construction. In providing this supplement, we have assumed

that the builder is a novice with little or no prior building experience. We include suggested

construction steps, detailed pictures, and other information that may be useful to the beginner

and seasoned modeler alike. The details of accessory assemblies, recommended electronics,

and hardware and construction materials are described throughout this manual.

In addition to the kit version described herein, a “short kit” is also available. The "short kit"

includes the necessary laser cut pieces and machined small parts (user supplies standard balsa

strips and hardware available from any good R/C hobby shop). Consult the Appendices for

supplemental information and variations.

The E-Banshee kit may be built as a fully radio controlled (R/C) electric powered sport model. In

addition, it can also be constructed as a Free-Flight (FF) model, and may be modified as a SAM (Society

of Antique Modelers) "legal" model for SAM competition. Each variation is shown on the plans and is

further described herein.

Recommended Motors:

In keeping with modern construction techniques, the model has been designed to accept any variety of

rear-mount brushless motors. The motor may be mounted with a typical aluminum mount (supplied

with many motors), or directly from the motor housing rear through the plywood firewall. Motor

selection is left to the builder based on individual preferences and availability.

Servos:

Two mini/micro servos are used for rudder and elevator control. High torque is not required as the

control surfaces are not oversized. A good recommended torque would be 18 to 22 oz-in. A short servo

arm is necessary (usually supplied with servo). A removable electronics platform assembly is supplied

with the kit. We recommend the use of the platform assembly although there are many other ways that

the servos may be placed and mounted. Use of the assembly also provides additional support for the

motor mount / firewall. The servo mount will fit most mini/micro servos.

Battery Compartment:

A large battery compartment is integral to the design. Since the E-Banshee center of gravity (CG) is

approximately 1/2 way back from the wing leading edge, and that the fuselage has a long "moment

arm", it will be necessary to place the battery as far forward as possible and into the nose section. If

necessary, the builder should modify the "as supplied" parts to provide sufficient air cooling to the

battery compartment volume. Cooling flow holes may be placed in the nose block and/or battery

compartment sides, with air exit holes placed in the battery compartment hatch cover. There is more

than sufficient room in the battery compartment to also place the receiver and motor speed control.

E-Banshee Manual MexAir RC PH: 315.532.6826

www.mexairrc.com

3

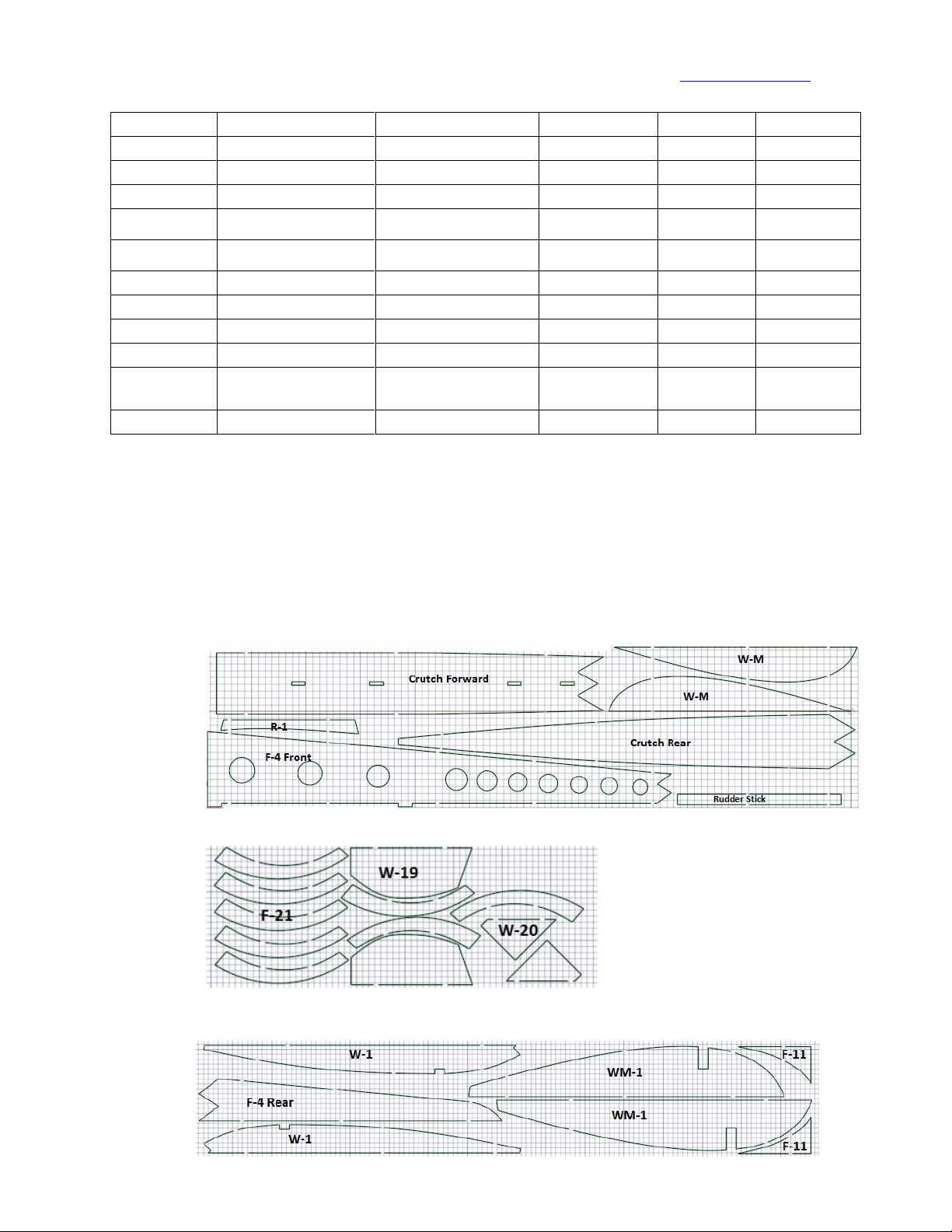

Kit Contents

The following table can be used as a reference in identifying each part. The plans identify parts using

the same designations as in this table. If not identified with "Sheet #" or as "Loose" - the listed parts are

supplied in stick bundles. Laser cut sheet panels are designated with a "P#" in the table.

Banshee

Parts List

Part

Size

Plan #

Req/Plane

Sheet #

BODY

Crutch

F-1A / F1B

1

P1

Pylon

F-2

1

P4

Pylon Rear

F-3

1

P4

Lower Body

F-4 / F-4 Rear

1

P1 / P3

Side Panel

F-5

2

P5

Former

F-6

1

P5

Former

F-7

2

P5

Former

F-8

1

P4

Former

F-9

1

P4

Former

F-10

2

P4 / P5

Former

F-11

2

P3

Former

F-12

2

P5

Former

F-13

2

P4 / P5

Former

F-14

1

P5

Former

F-15

2

P4 / P5

Floor Mtr

Compartment

F-16

1

Loose

Mtr Mount

F-17

1

Loose

LG Block

F-18

1

Loose

Hatch Cover Stop

F-19

1

Loose

Pylon Angle Block

Triangle Stock

F-20

4

Loose

Bottom Stringer

1/8X1/4X8-1/2

2

Dowel

3/16X2-5/16

2

Loose

Nose Blocks

F-21

8

P2

Hatch Cover

1/16X1-7/16 X5-1/16 Ply

HC

1

Loose

Body Wing Saddle

WM

2

P1

Wire, LG

3/32"

1

Loose

Tube, Brass

3/32"ID, 1/8"OD

1

Loose

F-9 Lining

1/8X1/8X8"

Hardwood Strip

1

E-Banshee Manual MexAir RC PH: 315.532.6826

www.mexairrc.com

4

ELEV &

RUDDER

Sub-Rudder

E-1

2

Loose

Elev Tip

E-2

2

Loose

Elev Rear Center

E-3

1

Loose

Fin

R-1

1

P1

Fin

R-2

1

P5

RIBS &

WINGS

W-1

W-1

2

P3

W-1A

W-1A

2

P6

W-2

W-2

2

P6

W-3

W-3

2

P6

W-4

W-4

2

P6

W-5

W-5

2

P6

W-6

W-6

2

P6

W-7

W-7

2

P6

W-8

W-8

2

P6

W-9

W-9

2

P6

W-10

W-10

2

P6

W-11

W-11

2

P6

W-12

W-12

2

P6

LE Inner

1/4X1/4X14

W-13

2

LE Outer

1/4X1/4X11

W-14

2

Trailing Edge Inner

3/16X3/4X14-1/2

W-15

2

Trailing Edge Outer

3/16X3/4X12

W-16

2

Spar- Inner

1/8X1/4X14

W-17

4

Spar- Outer

1/8X1/4X10-1/16

W-18

4

Wing Tip

W-19

2

P2

Wing Tip Angle

Brace

W-20

2

P2

Wing Plate

WM-1

2

P3

Center Wing Sheet

1/16X1-1/8X9

Pkg of 3

Pcs = 9"

Loose

Spar Webbing

1/16X3/4X2

24

P6

Gusset Material

Made From Scrap

Polyhedral Inner

Brace

W-21

1

Loose

Polyhedral Outer

Brace

W-22

2

Loose

ELEVATOR

Trailing Edge

3/16X1/2X9

2

Main Spar

1/4X3/8X22

1

Elev Spar & Side

1/4X3/8X12

2

E-Banshee Manual MexAir RC PH: 315.532.6826

www.mexairrc.com

5

Piece

LE

1/4X1/4X12

2

LE

1/4X1/4X5 ("Filler")

1

Center Section

3/8X1/2X3-1/8

1

Loose

Ribs

1/16X3/8X24

24+ Inch

Random Length

Ribs

1/8X3/8X20

20+ Inch

Random Length

RUDDER

Strip

1/8X3/8X6

1

P1

Strips

1/8X1/4X12

1

Servo Tray

EM Assembly

1

EM Precut

Ply

Hardware

See Note Below *

Many parts will be supplied in their laser cut sheets designated by a P#. All others will be "precut loose"

in suitable packaging or supplied as bundled "sticks".

* Supplied hardware may vary slightly from that pictured. Not all hardware will be used, depending on

building preferences.

The following "screen shots" are representative of the various sheet-supplied

panels

P1

P2

P3

Table of contents

Other MexAir RC Toy manuals

Popular Toy manuals by other brands

FUTABA

FUTABA GY470 instruction manual

LEGO

LEGO 41116 manual

Fisher-Price

Fisher-Price ColorMe Flowerz Bouquet Maker P9692 instruction sheet

Little Tikes

Little Tikes LITTLE HANDIWORKER 0920 Assembly instructions

Eduard

Eduard EF-2000 Two-seater exterior Assembly instructions

USA Trains

USA Trains EXTENDED VISION CABOOSE instructions