Meyer Sound Microphones User manual

CONSTELLATION INSTALLATION GUIDE

Microphones, Processors, and

Loudspeakers

Please visit www.meyersound.com for release notes, software

updates, and forum support.

Copyright ©2008 Meyer Sound Laboratories

05.166.005.01 A2

Constellation Installation Guide

Published 2009-Feb-05

The contents of this manual are furnished for informational purposes only, are subject to change without notice, and

should not be construed as a commitment by Meyer Sound Laboratories Inc. Meyer Sound assumes no responsibility

or liability for any errors or inaccuracies that may appear in this manual. Except as permitted by applicable copyright

law, no part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form or by any

means, electronic, mechanical, recording, or otherwise, without prior written permission from Meyer Sound.

Galileo, Compass, TruShaping, and Composite EQ are trademarks and Meyer Sound, Meyer Sound MAPP Online and

SIM are registered trademarks of Meyer Sound Laboratories Inc. (Reg. U.S. Pat. & Tm. Off.). All third-party trademarks

mentioned herein are the property of their respective trademark holders.

Printed in the U.S.A.

ii

TABLE OF CONTENTS

About This Document v

Chapter 1: Power Requirements 1

Building Power 1

Equipment Rack Power 2

Power Specifications 3

Chapter 2: Wiring Installation 5

Conduit 5

MM-4XP Cabling 6

Microphone Cabling 6

Polarity 7

Chapter 3: Loudspeaker Locations and

Installation 9

Loudspeaker Locations and Installation 9

Loudspeaker Installation 13

Chapter 4: Microphone Locations and

Installation 15

Microphone Placement 15

Microphone Details and Accessories 15

Microphone Installation 18

Chapter 5: Constellation Processor Installation 21

Choosing an Equipment Rack 21

Installing Processors in the Equipment Rack 21

Chapter 6: System Control Options 25

Chapter 7: Initial System Tests 27

Setting Up CueStation 27

Routing Signal to Outputs 28

Using Wild Tracks as a Signal Source 29

Checking Signal on Microphone Inputs 29

Chapter 8: Meyer Sound Technical Support 31

iii

PREFACE : ABOUT THIS DOCUMENT

This guide will take you through the installation process of all Constellation components, in

preparation for the calibration tuning phase. Each component has unique requirements for

power, audio signal, and best wiring practices. Follow all of the guidelines in this manual to

guarantee the highest-quality sound for your venue.

There are several main components to a Constellation system:

Constellation Processors

The Constellation processors provide all of the audio processing and signal routing functions

necessary for a Constellation system. The processors are typically rack-mounted in an

equipment room with other audio components. See Chapter 5, Constellation Processor

Installation (p. 21) for more information.

Constellation Loudspeakers

Constellation loudspeakers can be mounted directly on a surface or hidden within a

back-can. Your Constellation design will specify the exact number and type of loudspeakers

required for your venue's Constellation system. Loudspeaker installation instructions can

be found in Chapter 3, Loudspeaker Locations and Installation (p. 9).

Constellation Microphones

Constellation microphones are typically hung from the ceiling, or surface-mounted on a

wall or ceiling. Your Constellation design will specify the exact number and type of

microphones required, as well as their placement within the venue. Microphone installation

instructions can be found in Chapter 4, Microphone Locations and Installation (p. 15).

System Control

Each Constellation system will include a method for the client to select Constellation

settings. This may include a simple touchscreen mounted on a wall, a web page, or direct

control of the system through CueStation™software. Installing a control device may require

a network or serial connection to the Constellation processors. See Chapter 6, System

Control Options (p. 25) for more information.

v

CHAPTER 1: POWER REQUIREMENTS

The type, quality, and correct connection of the electrical system that will be used to supply

power to the Constellation system is very important. The effect of poor, inadequate, or low-quality

power will have a detrimental result in the sound quality of the system. The following information

is the Meyer Sound specification for proper powering of the various components of a

Constellation System.

Building Power

A dedicated transformer or a balanced power transformer of adequate size for the Constellation

system shall be attached to the building power system. The ground conductor of the transformer

will be connected directly to the ground used by the building’s main service transformer. All of

the ground wires of the Constellation electrical system will be joined at the dedicated transformer.

An uninterruptible power supply should be placed in-line with the output of the transformer. It

should be of adequate size and type to provide enough current for an appropriate amount of

time to continue to meet the systems power needs in the event of power disruption to the input

of the transformer. Check with your electrical engineer to properly size this transformer.

At the grounding point of the ISO transformer, the chassis ground, or mechanical ground, the

isolated ground, and the neutral buss will be connected. The chassis or mechanical ground will

connect the sub-panels, conduit, enclosures, racks, etc.

The neutral bus, through the distribution and sub-panels, will be connected to the neutral

terminal of all electrical sockets or the neutral connector of equipment.

The isolated ground will NOT be connected to any electrical panel, conduit, or any other

conductor EXCEPT for the ground connection to a piece of equipment through its power supply

cord or directly to the chassis of the equipment.

The chassis of equipment connected to the isolated ground system shall not have contact with

any material that is connected to the chassis or mechanical ground. This includes structural

steel, aluminum studs, and non-isolated racks.

No microphones, loudspeakers, Constellation processors, computers, monitors, termination

blocks, XLR connectors, or any other equipment associated with the Constellation system can

come in contact with any conductive material that is attached to any of the building’s chassis

1

or mechanical ground system or the Constellation electrical systems’chassis or mechanical

ground. This will prevent the “shorting”of the Constellation system’s isolated ground system.

Equipment Rack Power

The equipment racks for the loudspeaker power supplies and Constellation processors should

be isolated from any other conductive material and connected directly to the isolated ground.

Using a PVC connection box and rubber feet on your rack will isolate the power source and

keep the isolated power ground from touching common power ground.

Insulate all cables in the rack room from conduit and extraneous grounds. Do not tie the shell

of cable type microphone connectors to shield except within microphones themselves.

Connectors which utilize their shells as conductors for shield, i.e., 3-circuit phone jacks, shall

be insulated from their mounting plate.

Because of the great number of possible variations in grounding systems, it shall be the

responsibility of the contractor to follow good engineering practice, as outlined above, and to

deviate from these practices only when necessary to minimize crosstalk and to maximize

signal-to-noise ratios in the audio and control systems.

The electrical contractor, along with the system contractor, shall be responsible for confirming

that the technical ground is properly electrically bonded to the building technical ground system.

It is not acceptable to use wall plugs for the rack installation; always use AC distribution inside

the rack. Because electrical code may vary from state to state and country to country, always

check with your electrical engineer and the laws in your area for specific code requirements.

2

CHAPTER 1: POWER REQUIREMENTS

Power Specifications

It is important to make sure that each powered component receives the required amount of

electrical power.

Matrix3 Processors

The Matrix3 Constellation processors require 200 watts maximum per unit.

Stella-188 Power Supply

The Stella-188 Power Supply can supply power for up to 16 Stella-4 loudspeakers, or 8

Stella-8 loudspeakers. Current draw: Burst Current (<1 sec) 5.2 A rms (115V AC), 3 A rms

(230 V AC), 6.7 A rms (100 V AC)

MPS-488E Power Supply

The MPS-488E Power Supply can supply power for up to 8 MM-4XP loudspeakers, through

5-pin SwitchCraft EN3 connectors. Current draw: Burst Current (<1 sec) 15 A rms (115 V

AC), 7.5 A rms (230 V AC)

3

CONSTELLATION INSTALLATION GUIDE

MPS-488P Power Supply

The MPS-488P Power Supply can supply power for up to 8 MM-4XP loudspeakers, through

5-pin Phoenix connectors. Current draw: Burst Current (<1 sec) 15 A rms (115 V AC), 7.5

A rms (230 V AC)

Multiple power supplies should be installed in the rack with no empty spaces between them.

The power ratings for all Meyer Sound products can be found online at

http://www.meyersound.com, listed by individual product.

4

CHAPTER 1: POWER REQUIREMENTS

CHAPTER 2: WIRING INSTALLATION

The installer should be a recognized experienced local installer with a good track record of

previous related installations. Meyer Sound does not authorize companies for product installation;

however, Meyer Sound expects all installation companies to follow universal standards set out

by NSCA, NAB, and other universally accepted standards.

Conduit

When installing Constellation wiring, be sure to use the NSCA or similar guide lines for installation

of low voltage wiring. Use no wire tuggers please! Microphone cable, digital cable, and most

low voltage cabling can not withstand tuggers without damage to the wiring itself.

Except where otherwise shown in Contract Documents, use separate conduits for following

circuits:

■Microphone-level (below –30 dBu, 20 Hz to 20kHz)

■Line-level (–30 dBu to +24 dBu, 20 Hz to 20 kHz)

■Loudspeaker (greater than +24 dBu, 20 Hz to 20 kHz)

■Control (switching or synchronous, DC from 0 to 50 volts, AC from 0 to 48 volts)

■AC power (greater than 48 volts, 60 Hz)

CAUTION: Microphone and line level conduit should not run parallel to AC power

conduits within 36”if possible.

5

MM-4XP Cabling

The MPS-488(E/P) MM-4XP power supply provides both audio signal and power to the MM-4XP

loudspeakers. To connect the signal conducts of the Belden 1502 cable to a Phoenix connector:

1. Follow insulation stripping lengths.

2. Connect the shield to pin one at both ends of the cable.

Do not “lift”the ground conductor at either end.

3. When stripping insulation do not nick the insulation of

individual conductors.

4. Completely remove any exposed foil shield.

5. Protect the conductors from shorting against any other

conductor by using heat shrink or Teflon tubing on the

ground conductor.

6. Apply heat shrink at the point that the exterior jacket exposes the individual conductors.

Microphone Cabling

When connecting the signal conductors of the microphone cable to the XLR connector for

connection to the Constellation microphones:

1. Connect the shield to pin one at both ends of the cable. Do not “lift”the ground conductor

at one end. Do not attach ground connector to the chassis of the XLR connector. When

stripping the outer insulation, make sure to not damage the insulation of individual conductors.

2. Completely remove any exposed foil shield.

3. Protect the conductors from shorting against any other conductor by using Teflon tubing on

the ground conductor. Apply heat shrink at the point that the exterior jacket exposes the

individual conductors. Do not strip more insulation away from the individual conductors than

is necessary to have maximum contact with the solder cup of the XLR connector.

4. Pre-tin all three solder cups of the XLR connector and the wire conductors before making

the solder connection between the two. Do not overheat the wire conductors, as this may

cause melting of the insulation.

6

CHAPTER 2: WIRING INSTALLATION

Polarity

Polarity must be maintained between all microphone and loudspeaker cables. Follow the “pin

two is hot”standard for wiring balanced lines. Maintain continuity of shields at all connecting

points, except as required by standard specified practice for “floating”shields.

7

CONSTELLATION INSTALLATION GUIDE

CHAPTER 3: LOUDSPEAKER LOCATIONS AND

INSTALLATION

Loudspeaker Locations and Installation

Loudspeaker placement will be specified in the Constellation system design. The Meyer Sound

representative will provide plans showing the exact placement of each loudspeaker and

microphone within the venue. If there are conflicts in any drawings or conflicts in field locations

due to other equipment, please notify the consultant and Meyer Sound representative

immediately with those conflicts so the issue may be resolved.

IMPORTANT: Please do not make any unauthorized field changes. This will affect the

performance of the system. Any changes to the location of a loudspeaker or microphone

must be approved by the acoustical consultant and Meyer Sound. In most cases, the

architect should also be notified. Notifications must be in writing.

Mounting an MM-4XP

Mounting an MM-4XP on a surface typically requires a U-bracket and a wiring box.

9

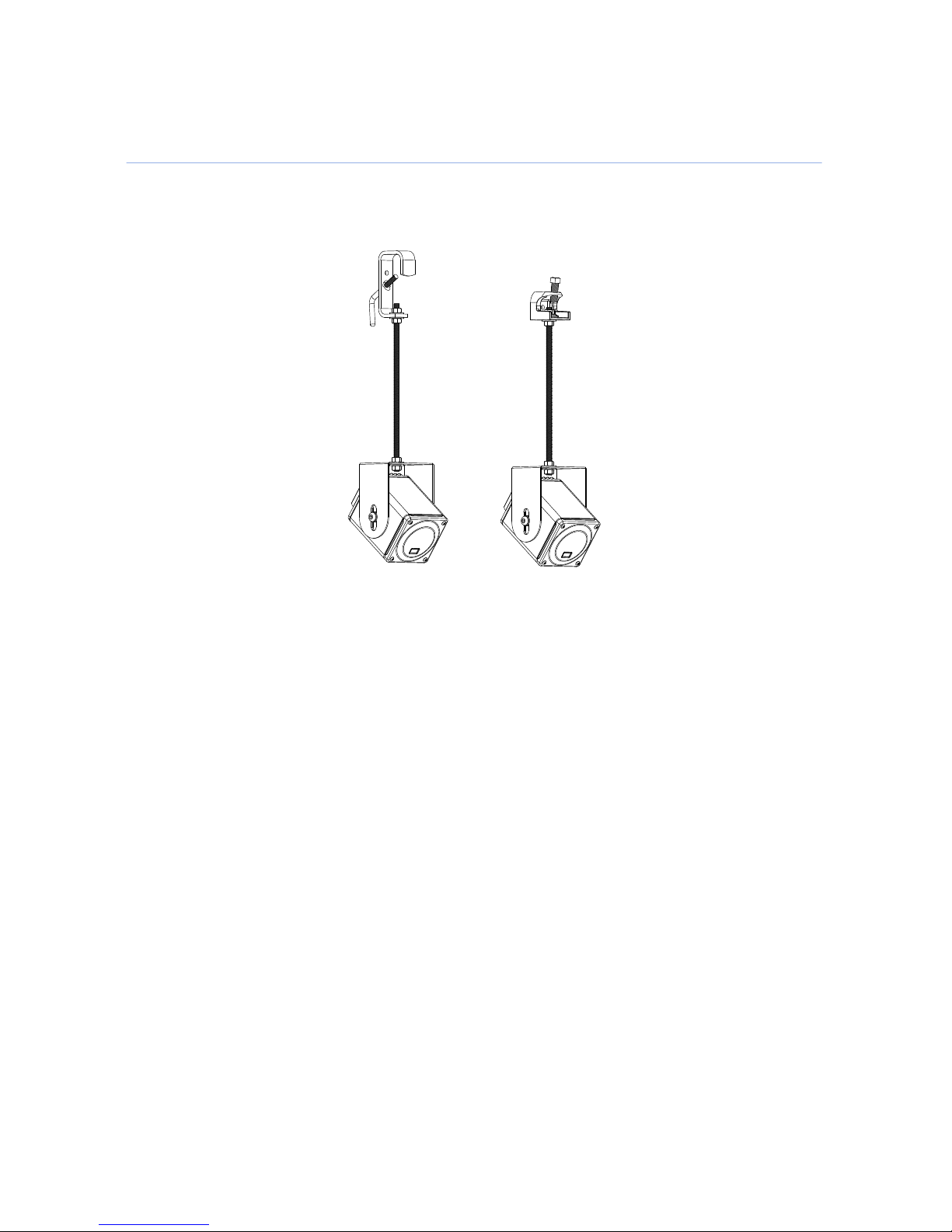

Hanging an MM-4XP from a pipe may require an all-thread extender. The all-thread can be

attached to a pipe using a C-clamp or a beam clamp:

10

CHAPTER 3: LOUDSPEAKER LOCATIONS AND INSTALLATION

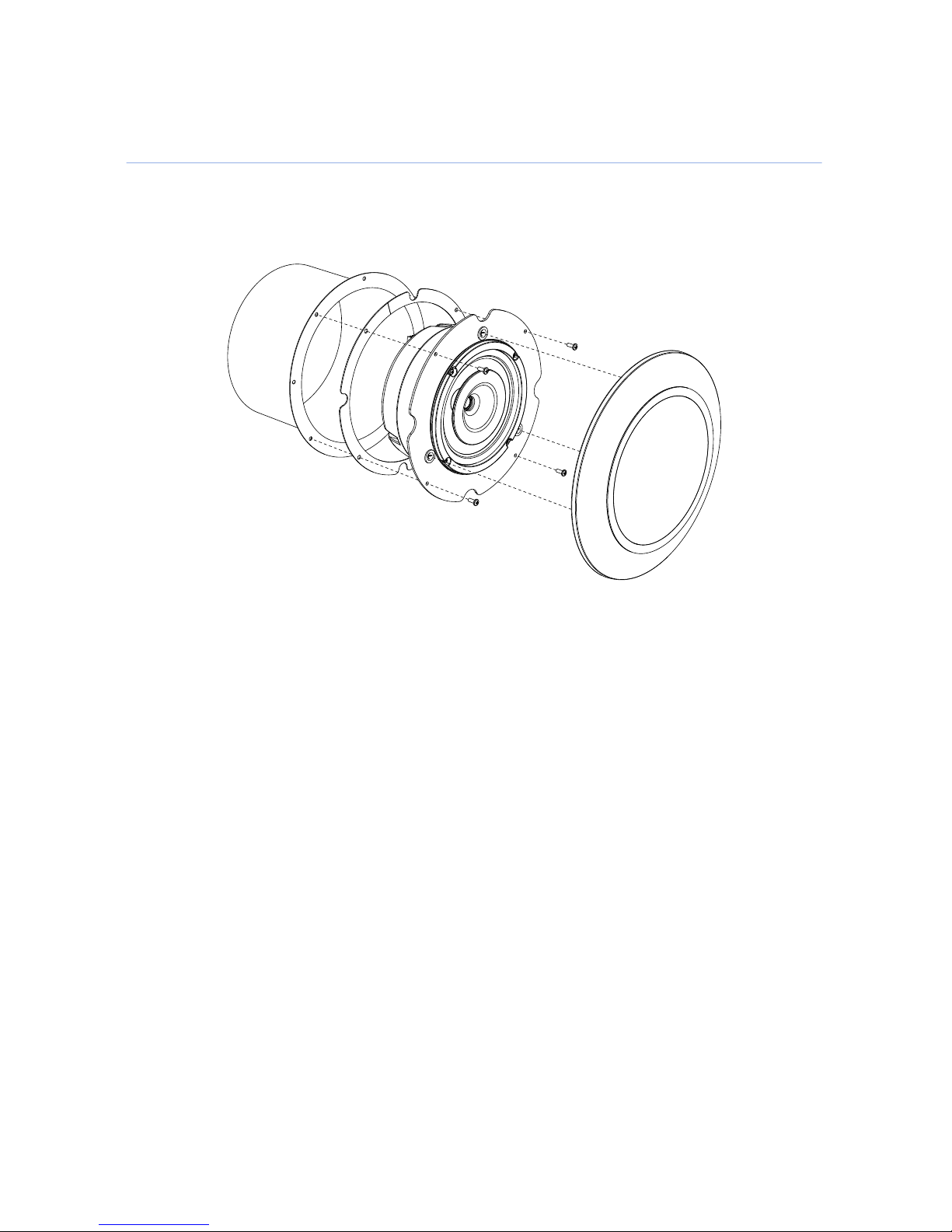

Mounting a Stella-8C

This diagram shows an exploded view of the Stella-8C.

11

CONSTELLATION INSTALLATION GUIDE

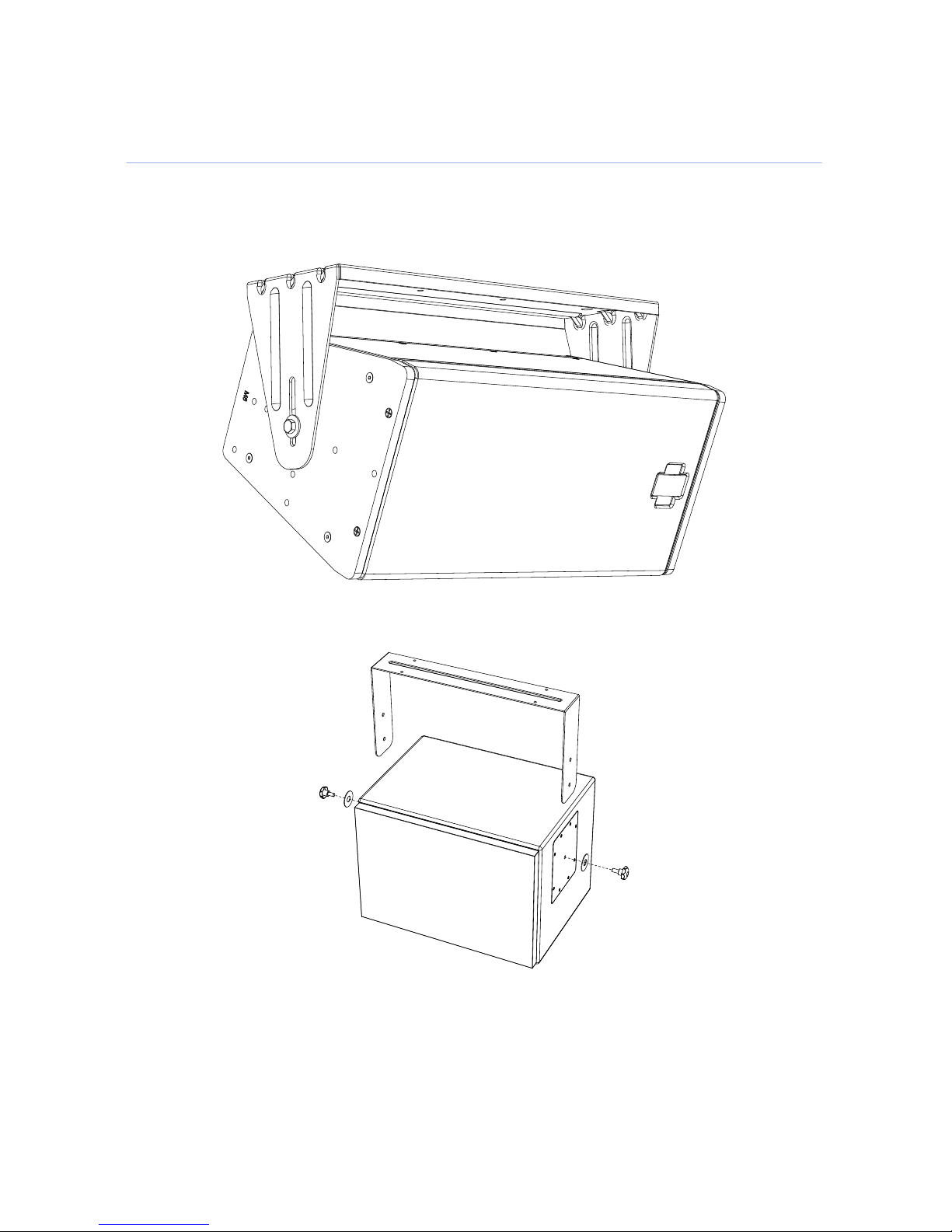

Mounting UltraSeries Loudspeakers

This diagram shows a UPJunior with the mountable U-bracket.

This diagram shows the UMS-SM with mountable U-bracket.

12

CHAPTER 3: LOUDSPEAKER LOCATIONS AND INSTALLATION

Loudspeaker Installation

One of the things that makes the Constellation system sound so natural is that it regenerates

the physical acoustics of a room. As a consequence, the resulting quality of a Constellation

system is dependent on the quality of the physical acoustics of the space. Make sure all mounts

for loudspeakers are secure, tight and free from buzzes, rattles, and acoustic distortion. Isolate

with rubber mounting where necessary. Use rated materials wherever and whenever possible.

Meyer Sound loudspeakers will mount with any standard available mounting hardware or beam

clamp available in hardware outlets around the world. Most American manufacturers of hardware

will have a load rating stamped on the hardware itself. Use at least a 5:1 ratio to calculate loads.

(for instance, if you have a 100 lb. load, use a 500 lb. rated clamp.) Although non-stamped

hardware may well be suited for your application, if there is no stamped rating it may be a

liability if the hardware fails.

Carefully document and identify all buzzes, rattles and objectionable distortion in room finishes

or fixtures. Ask the general contractor to correct all causes of such defects, if possible. Always

notify the architect, consultant, and Meyer Sound representative indicating the cause of each

issue and suggested corrective procedures. Keep a written history of room problems in case

they show up again later.

13

CONSTELLATION INSTALLATION GUIDE

CHAPTER 4: MICROPHONE LOCATIONS AND INSTALLATION

Microphone Placement

As with the loudspeaker locations, each microphone’s location is specified by the Constellation

system design. If there are conflicts in any drawings or field locations due to other equipment,

please notify Meyer Sound and your consultant immediately with those conflicts so the issue

may be resolved.

Microphone Details and Accessories

Three Constellation microphones are offered; a compact cardioid, a miniature cardioid, and a

miniature omni. All Constellation microphones consist of the capsule, 10 meters of cable, and

are terminated by a microdot connector. A microdot to XLR adaptor is supplied with the

microphone.

The miniature cardioid microphone looks like this:

15

The miniature omni microphone looks like this:

The compact cardioid microphone looks like this:

The XLR connector that terminates these microphones has a barrel that is approximately 3"

long. It looks like this:

16

CHAPTER 4: MICROPHONE LOCATIONS AND INSTALLATION

Dimensions of the miniature capsules are shown below:

Miniature OmniMiniature Cardioid

A shock mount is available for the compact cardioid. The compact cardioid capsule is shown

with the shock mount below:

17

CONSTELLATION INSTALLATION GUIDE

Microphone Installation

Make sure all mounts for microphones are secure and tight. Use rated materials wherever

possible. Try to maintain as much distance as possible from electrical equipment and fixtures,

without modifying the microphone placement guidelines. Be aware of large transformers, as

well as high voltage lighting instrument locations. These devices may still have an impact on

the performance of the microphones.

Most microphones can hang in place suspended by their own wire. Suspending a microphone

that is tied to a piece of 1/8”all-thread works very well for rigid applications and for judging

elevations at a particular location. All-thread is a common construction material and is available

with many accessories such as a sturdy beam clamp for attachment to existing steel. All-thread

comes in a variety of lengths and sizes.

The Constellation system requires a large number of Constellation microphones to be installed

using various methods depending on location and type of microphone being used. In all cases,

special attention is needed regarding the ground of the signal path attached to the microphone.

Pin-1 of the signal, otherwise known as Ground, should have only one path between the output

of the microphone and the ground terminal of the Constellation processor. If alternate ground

paths exist via wiring or connectors, increased noise, usually hum, will be added to the system

and will have to be corrected. Many times this involves re-installing cabling or providing insulation

to connectors to prevent connection to other grounds or conductors.

In an effort to prevent these kinds of installation faults, the following guidelines need to be

practiced:

■Starting at the microphone, the metallic parts of the microphone capsule should not come

into contact with any conductive material. This will provide a connection of the signal

ground to the mechanical ground of the building or other ground path, which can induce

noise at the microphone input of the Constellation processor.

■The metal shell of the XLR that is connected to the microphone is attached to signal ground.

Pin-1 of this connector is tied to the chassis of the connector. This XLR connector, and all

others, must be insulated so that they cannot come into contact with any other material

that could provide an alternate ground path, including other XLR connectors attached to

other microphones.

■Combining of Pin-1 conductors at a terminal block is not permitted.

■When using an input type XLR patch box to accept a number of individual microphone

inputs and combine them into one multi-core cable/snake, the box should be tested for

18

CHAPTER 4: MICROPHONE LOCATIONS AND INSTALLATION

This manual suits for next models

1

Table of contents