If a malfunction should occur, turn the machine off immediately and correct the problem, before

restarting the machine. If there are any questions as to the safe operation of this equipment, please

do not hesitate to contact us at 1-800-963-4458.

HAZARD IDENTIFICATION

Principle of operation

The portable vacuums that Meyer & Sons manufactures are based on a centrifugal fan design that

utilizes a high-speed material handling style wheel enclosed in a scroll-shaped housing. The air is drawn

in towards the center of the wheel and thrown outward as the wheel rotates. The shape of the housing

directs the air out perpendicular to the inlet. Because of the design, the wheel is accessible via either

the inlet or outlet. The Versa-Vac™ and Veloci-Vac® have interlock switches, consisting of an inlet

switch and an outlet switch that are electrically connected to the engine. These switches must be

depressed in order for the engine to start and continue running. The Porta-Vac® design incorporates

permanent inlet and outlet grates.

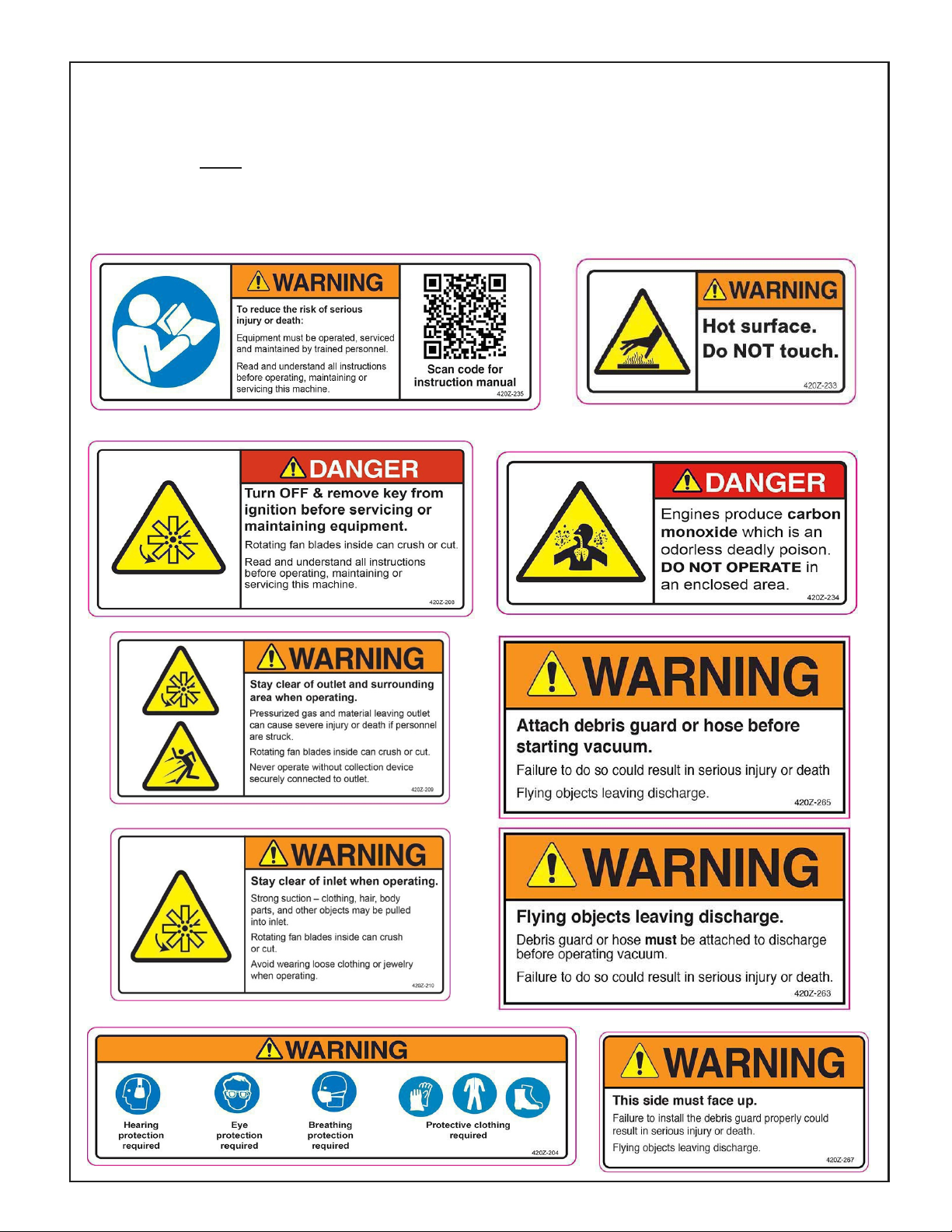

Amputation hazard

The centrifugal fan wheel of the vacuum is driven by an engine at a relatively high rpm. If either the inlet

or outlet openings are left unguarded, the fan wheel presents a serious personal injury hazard, including

but not limited to amputation. Any part of the human body in the way of the fan wheel will be cut off.

Guarding inlet

In order for the vacuum to function, the inlet must be connected to a hose or other ducting through

which the vacuum (negative pressure airflow) is drawn. The inlet is guarded by virtue of being

connected to ducting of sufficient length to not allow a body part to come in contact with the fan wheel.

There is an inlet switch (models Versa-Vac™ & Veloci-Vac®) that is electrically connected to the vacuum

engine that must be engaged in order for the engine to start and continue to run. The switch is engaged

by placing ducting over the switch lever and inlet opening prior to start up. Disengaging the switch does

not immediately stop the fan wheel rotation; it will take a few seconds before it comes to a complete

stop. DO NOT defeat this switch. Circumventing this switch will render the vacuum unsafe to use. It is

the responsibility of the equipment owner/operator to ensure that the inlet is not exposed and that the

inlet switch is in good working order and the vacuum is safe to operate.

Guarding outlet

The outlet of vacuum is, by design, open and can expose a person to the interior of the vacuum and thus

the fan wheel. This opening, like the inlet, (model Versa-Vac™) has a switch that must be engaged in

order for the vacuum engine to start and continue to run. A hose or collection device/debris guard must

be attached to the outlet so that no one can access the interior of the vacuum. DO NOT defeat the

outlet switch or circumvent its utility in any way. Doing so will render the vacuum unsafe to use. The

Veloci-Vac® has a self-closing grate the must be lifted up to access the outlet. It is the responsibility of

the equipment owner/operator to ensure that the outlet is not exposed and that the outlet switch is in

good working order and the vacuum is safe to operate.

Training

The owner also bears the responsibility to ensure that personnel who may be working around or operating

the vacuum are properly trained. Personnel must be aware that: (1) anything coming into contact with the

moving fan wheel will be cut off/amputated; (2) before working on, cleaning, repairing or maintaining a

vacuum, Lockout/Tagout procedures must be strictly followed; and (3) the vacuum must not be operated

without guarding in place. Before working around a vacuum, personnel must read the Operator’s Manual.