GENERAL DESCRIPTION

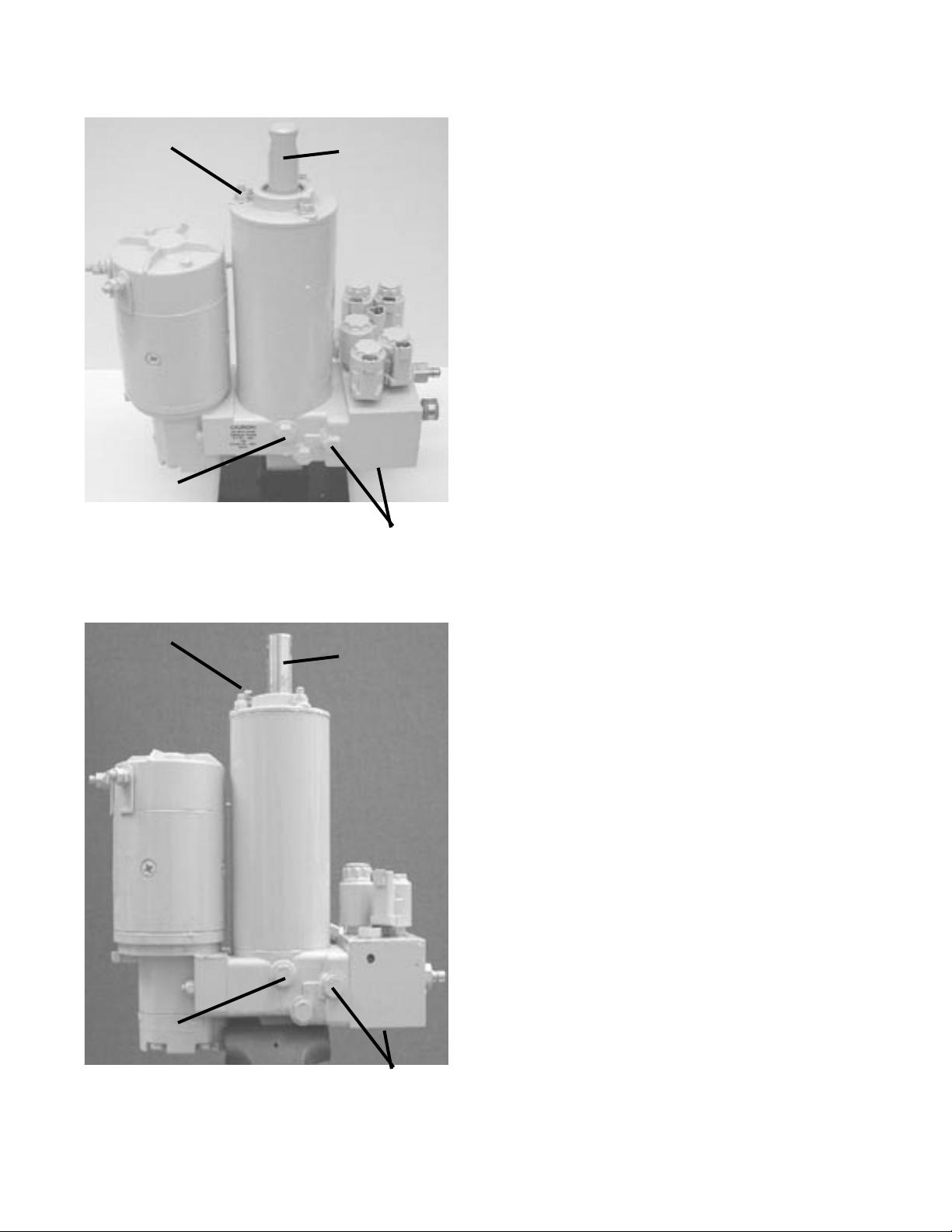

E-58H, E-78 & E-88 unit is an electrically powered and

electrically controlled hydraulic mechanism specifically

designed for use with Meyer Snow Plows. The E-88

and E-78 raises and lowers the plow with an integral

8” stroke hydraulic cylinder. The E-88 will also mount

and dismount the Xpress plow system from the vehicle

using a hydraulic Mount/Dismount Cylinder.

In addition to raising and lowering the plow hydraulically,

the E-58H, E-78 & E-88 angles the plow hydraulically,

left and right, via remote hydraulic cylinders.

The Electro Lift® unit consists of a specially designed

high torque 12-volt DC motor which is directly coupled

to a gear-type hydraulic pump. The pump obtains its

supply of hydraulic fluid from an integral reservoir

which totally surrounds the integral hydraulic cylinder

which raises and lowers the plow.

The E-88 includes an integral valve body which

contains five electrically controlled solenoid valve

cartridges. Solenoid valve cartridge “A” which is

energized to allow the plow to lower by gravity.

Solenoid valve cartridge “B” is energized to route the

pressurized hydraulic fluid to the integral hydraulic

cylinder to raise the plow. Solenoid valve cartridge

“C” is energized to route the pressurized hydraulic

fluid to the left remote hydraulic cylinder to angle

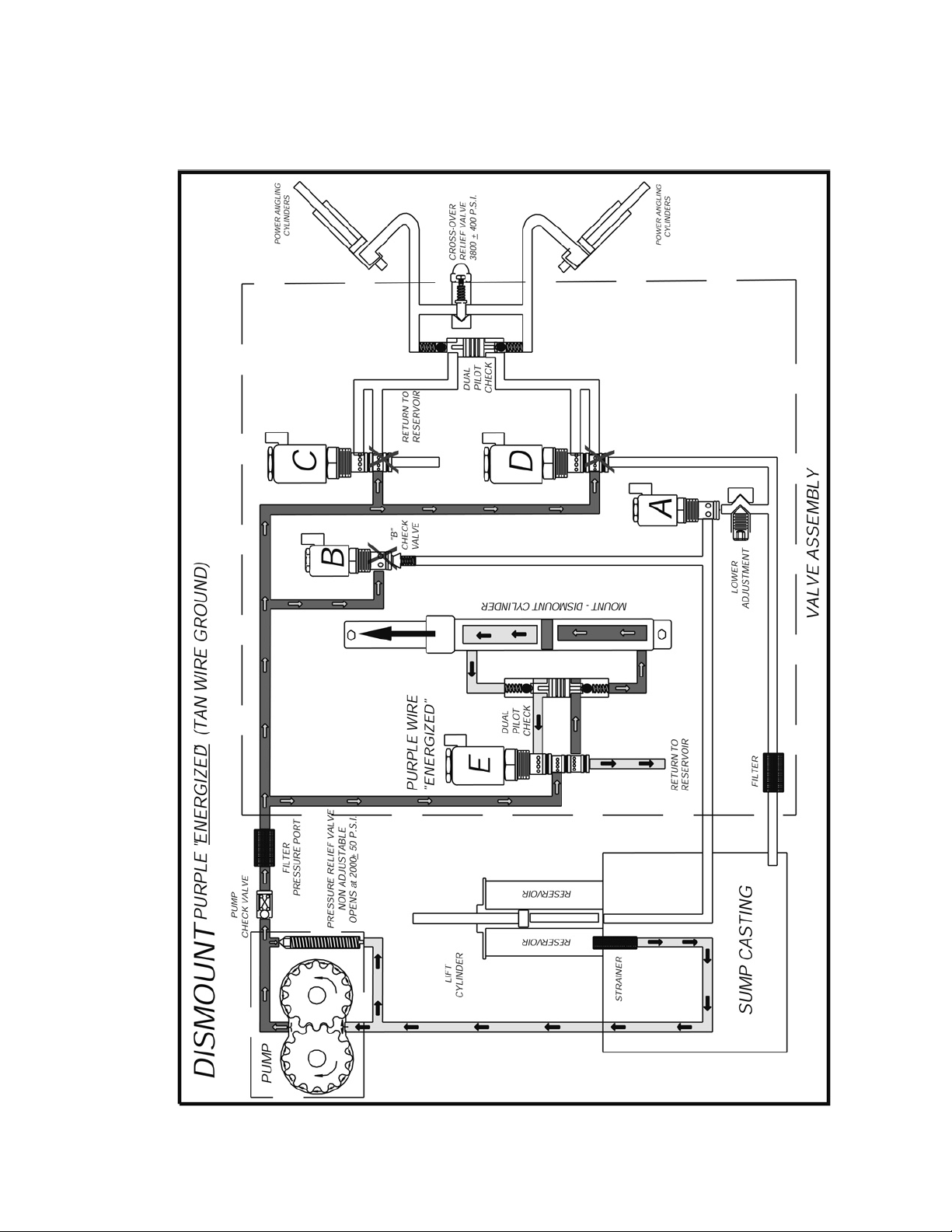

the plow to the right. Solenoid valve cartridge “D” is

energized to route the pressurized hydraulic fluid to

the right remote hydraulic cylinder to angle the plow

to the left. Solenoid valve cartridge “E” is energized

to route the pressurized hydraulic fluid to extend the

mount/dismount hydraulic cylinder to remove the plow

from the vehicle. Mounting the plow to the vehicle only

requires energizing the electric motor since the normal

route for the pressurized hydraulic fluid is to retract the

mount hydraulic cylinder.

The E-58H & E-78 includes an integral valve body

which contains three electrically controlled solenoid

valve cartridges. Solenoid valve cartridge “A” which

is energized to allow the plow to lower by gravity.

Solenoid valve cartridge “B” is energized to route the

pressurized hydraulic fluid to the integral hydraulic

cylinder to raise the plow. Solenoid valve cartridge “C”

is energized to route the pressurized hydraulic fluid

to the left remote hydraulic cylinder to angle the plow

to the right. When all cartridge are not energized and

the motor is running the pressurized hydraulic fluid

will flow to the right remote hydraulic cylinder to angle

the plow to the left.

Additional components which control and supply

electrical current to the E-58H, E-78 & E-88 units are

an operator controlled Touchpad (E-58H only), RCM

(Remote Control Module); a solenoid switch to supply

high amperage current to the unit’s motor (motor

solenoid); a PCM (Plow Control Module) (E-78 & E-88

only)and a HCM (Headlight Control Module)(E-78 &

E-88 only). valve cartridge(s); and short heavy gauge

cables to distribute high amperage current directly

from the positive terminal of the vehicle’s battery and

ground the unit directly to the negative terminal of the

vehicle’s battery.

THEORY OF OPERATION

FUNCTIONS

The E-88’s six basic functions performed are:

• Raise snow plow

• Lower snow plow

• Angle snow plow to right

• Angle snow plow to left

• Mount Xpress Snow Plow System

• Dis-mount Xpress Snow Plow System

Refer to Figures 1-1 through 1-6 (pages 6 thru 11) for

electrical and hydraulic flow chart for each function.

Each figure explains which component is actuated

and related in each function.

The E-58H & E-78’s four basic functions performed

are:

• Raise snow plow

• Lower snow plow

• Angle snow plow to right

• Angle snow plow to left

Refer to Figures 1-7 through 1-10 (pages 12 thru 15)

for electrical and hydraulic flow chart for each function.

Each figure explains which component is actuated and

related in each function.

-5-