Meyn 0100-5 Operating instructions

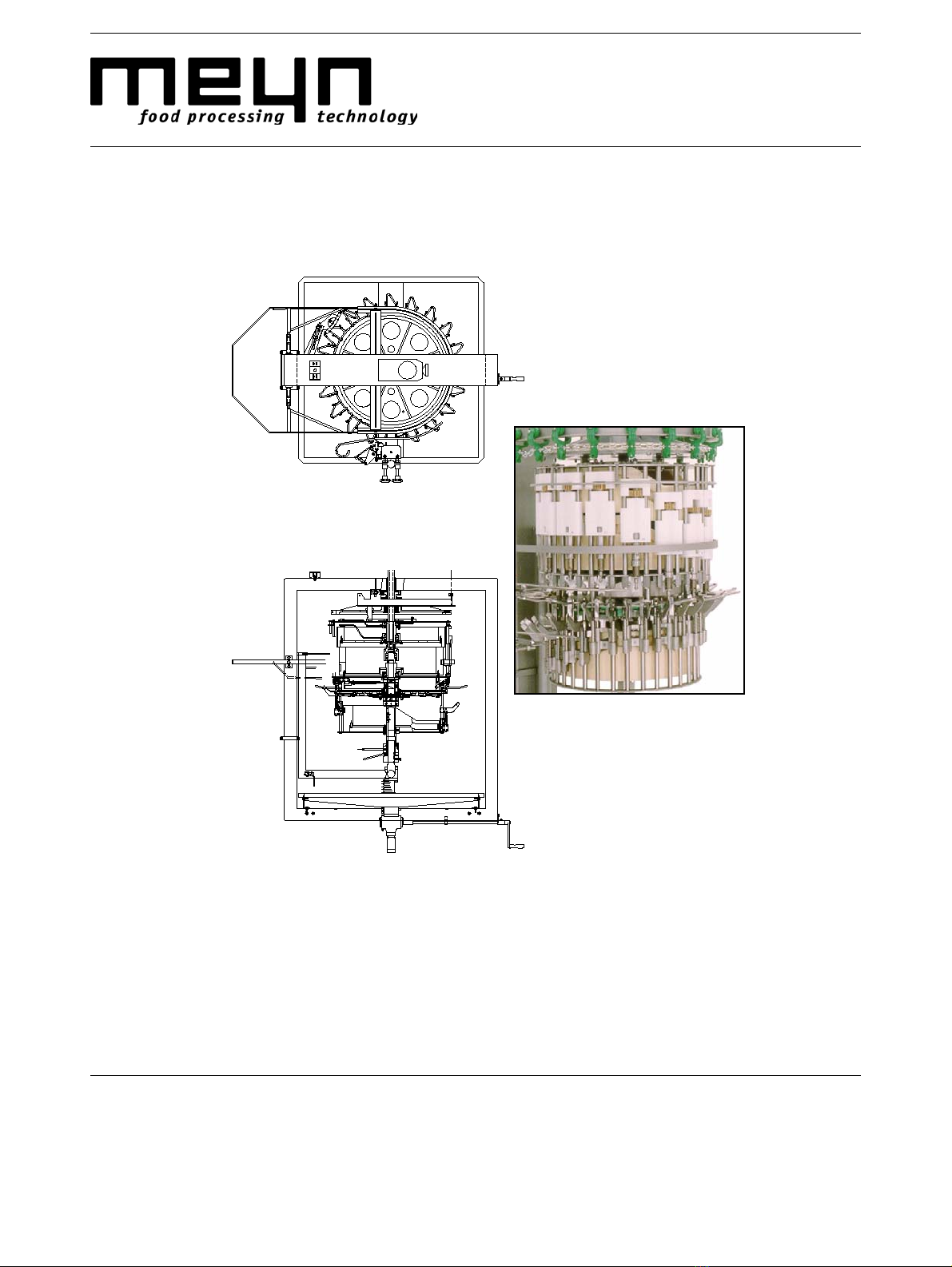

Vent Cutter

Meyn Food Processing Technology B.V., Noordeinde 68, 1511 AE Oostzaan, the Netherlands,

P.O. Box 16, 1510 AA Oostzaan, the Netherlands,

Phone: +31 (0) 75 684 3355, Fax:+31 (0) 75 684 4150,

E-mail: sales@meyn.nl, Website: www.meyn.nl,

Chamber of Commerce Zaandam nr. 35015165

User- and Maintenance manual

0100-5

Table of contents

© Meyn Food Processing Technology B.V. 1

Table of contents

Foreword.............................................................................................................................3

This manual ................................................................................................................ 4

1 Introduction..................................................................................................................... 5

1.1 Technical specifications........................................................................................ 5

1.2 General arrangement drawing.............................................................................. 8

1.3 What is a Meyn Vent cutter................................................................................... 9

1.4 The end product.................................................................................................. 10

1.5 The Meyn Vent cutter technical .......................................................................... 10

1.6 Performance of the machine............................................................................... 10

2 Safety............................................................................................................................. 11

2.1 The most important safety risks.......................................................................... 11

2.2 Safety devices (if applied)................................................................................... 12

2.3 Safety measures to be taken.............................................................................. 13

2.3.1 Preparing for safe operation.................................................................... 13

2.3.2 Safety measures during operation........................................................... 14

2.4 Know the pictograms .......................................................................................... 15

3 Installation..................................................................................................................... 17

3.1 Installing the Meyn vent cutter............................................................................ 17

3.1.1 Required floor area.................................................................................. 17

3.2 The connection of the Meyn vent cutter.............................................................. 18

4 Operation....................................................................................................................... 19

4.1 The manual controls ........................................................................................... 19

4.2 Preparing for the starting-up procedure.............................................................. 19

4.3 Start-up procedure.............................................................................................. 19

4.4 In production....................................................................................................... 19

4.5 The stop procedure............................................................................................. 19

4.6 The emergency stop........................................................................................... 20

5 Cleaning ........................................................................................................................ 23

5.1 Cleaning preparations......................................................................................... 23

5.1.1 Disassembly/assembly for cleaning ........................................................ 23

5.2 General cleaning schedule ................................................................................. 24

5.2.1 High-pressure water cleaning.................................................................. 25

5.2.2 Alkaline foam cleaning............................................................................. 26

5.2.3 Disinfection.............................................................................................. 27

5.2.4 Acid foam cleaning.................................................................................. 28

5.3 Advising cleaning chemicals to the customer..................................................... 29

Table of contents

2 © Meyn Food Processing Technology B.V.

6 Maintenance and trouble shooting table.................................................................... 31

6.1 Lubricants ........................................................................................................... 31

6.2 Checklist ............................................................................................................. 32

6.3 Lubrication-point list............................................................................................ 33

6.4 Trouble shooting table ........................................................................................ 34

7 Disassembly/assembly and adjustments................................................................... 37

7.1 Basic adjustments............................................................................................... 37

7.2 Adjustments with machine not running .............................................................. 38

7.2.1 The guide bars. ....................................................................................... 38

7.2.2 Adjust the Cams...................................................................................... 39

7.2.2.1 Top cam.............................................................................................................. 40

7.2.2.2 Knife unit cam.................................................................................................... 40

7.2.2.3 Tail clip cam....................................................................................................... 41

7.2.2.4 Back plate cam................................................................................................... 41

7.2.2.5 The bottom cam ................................................................................................. 42

7.2.3 Position of the cams................................................................................ 42

7.2.3.1 In feed side......................................................................................................... 42

7.2.3.2 Out feed side ...................................................................................................... 43

7.2.3.3 Back plate cam................................................................................................... 44

7.2.4 The in feed .............................................................................................. 46

7.2.5 The probes (vent cone)........................................................................... 46

7.2.6 Vent knife ................................................................................................ 47

7.2.7 Position of the back plates....................................................................... 48

7.2.8 High pressure nozzle .............................................................................. 49

7.2.9 Length of the intestines........................................................................... 50

7.2.10 Removing units...................................................................................... 51

7.2.11 Torque switch (if applied) ...................................................................... 52

7.3 Adjustments with machine running .................................................................... 53

7.3.1 Height of the Machine.............................................................................. 53

Foreword

© Meyn Food Processing Technology B.V. 3

Foreword

Meyn Food Processing Technology B.V. is one of the worlds leading designers and

manufactures of systems and equipment for the poultry processing industry.

Meyn's flexible service and support organisation and its constant emphasison product

innovation through extensive research and development, enable Meyn to supply

today's customers with the solutions of tomorrow.

Regardless of the size or complexity of the process, Meyn will supply its customers

with situation specific solutions that are critical in reaching their objectives.

Therefore, Meyn combines a solid knowledge of the customers business with expert

process design skills. This is crucial, as only well focused solutions generate the

desired returns.

Our ambition is to supply solutions that support fully controlled in line processing;

handling and tracking every product or batch throughout the entire facility while

controlling the quality of the output, combined with the ability to match the incoming

birds with the sales orders in the most optimal manner.

Meyn is worldwide represented by a network of subsidiaries and agents. In order to

supply complete integrated solutions to our customers, Meyn has a number of

strategic partners in the following processing sectors:

• Bonescan.

• Mechanical deboning.

• Logistic systems.

• Refrigeration.

• Water treatment.

• Vacuum transport.

• Rendering.

• Convenience food.

Table of contents

Popular Commercial Food Equipment manuals by other brands

Diamond

Diamond AL1TB/H2-R2 Installation, Operating and Maintenance Instruction

Salva

Salva IVERPAN FC-18 User instructions

Allure

Allure Melanger JR6t Operator's manual

saro

saro FKT 935 operating instructions

Hussmann

Hussmann Rear Roll-in Dairy Installation & operation manual

Cornelius

Cornelius IDC PRO 255 Service manual

Moduline

Moduline HSH E Series Service manual

MINERVA OMEGA

MINERVA OMEGA DERBY 270 operating instructions

Diamond

Diamond OPTIMA 700 Installation, use and maintenance instructions

Diamond

Diamond G9/PLCA4 operating instructions

Cuppone

Cuppone BERNINI BRN 280 Installation

Arneg

Arneg Atlanta Direction for Installation and Use