7

3.2 Verlegung

Dieser Abschnitt bezieht sich auf die Verlegung der Folie und des Trafos.

Die Verlegung der Leitungen und der elektrischen Anschlüsse ist im Ab-

schnitt 3.3 Elektrischer Anschluss erklärt. Berücksichtigen Sie die Min-

destverarbeitungstemperatur von +5°C.

Bei Wänden unterhalb von 2,3 m Höhe und in Decken, die weniger als

45° zur Senkrechten geneigt sind, sollte die Heizfolie ca. 15 cm kürzer als

die Länge der Montagefläche sein. Die Heizfolie kann bei Bedarf senk-

recht zu den Kupferbahnen einmalig geteilt werden. Beschnitte immer

nur von der unkontaktierten Seite der Heizfolie vornehmen.

Jede andere unsachgemäße Beschädigung der Folie wie z. B. Einrisse

durch scharfe Gegenstände oder Knicke sind zu vermeiden. Bewahren Sie

die Heizfolie deshalb bis zum Einbau im gerollten Zustand in der Verpa-

ckung auf (Mindestbiegeradius beachten, siehe 4. TECHNISCHE DATEN).

Nach erfolgter Verlegung können jedoch Löcher, wie in Abschnitt 2.2

Funktion und Anwendung beschrieben, eingebracht werden.

Warnhinweis:

Beachten Sie, dass Schrauben nur dann in die Heizfläche eingebracht

werden dürfen, wenn diese mit Kunststoffdübeln zur elektrischen Isolati-

on installiert werden. Zusätzlich dürfen zwei Schrauben nicht mit einem

elektrisch leitfähigen Material (z.B. Metallbilderrahmen, Metallzierleiste,

Regalsystem aus Metall) verbunden werden. Verwenden Sie keine Nägel.

3.2.1 Vorbehandlung des Untergrunds

Die Heizfolie kann auf jedem tragfähigen, sauberen und ebenen Unter-

grund aus anorganischen Materialien wie Stein, Estrich, Putz, etc. oder

organischen Materialien wie Holz, Kork, Kunststoff (evtl. mit Oberflä-

chengrundierung / Haftvermittler), etc. angebracht werden. Die Un-

ter- und Deckschichtmaterialien müssen bis 70 °C temperaturbeständig

sein. Im Zweifel kontaktieren Sie den Hersteller dieser Materialien.

Unregelmäßige Oberflächen sind zu vermeiden (z.B. sichtbare Holz/

Stein - Ausmauerungen). Unter Umständen ist die Fläche vorab mit Aus-

gleichsputz oder Nivelliermasse auszugleichen.

Es ist besonders darauf zu achten, dass keine spitzen Erhebungen wie

Steine, Schraubenköpfe, Nägel oder ähnliches aus dem Untergrund her-

vorstehen.

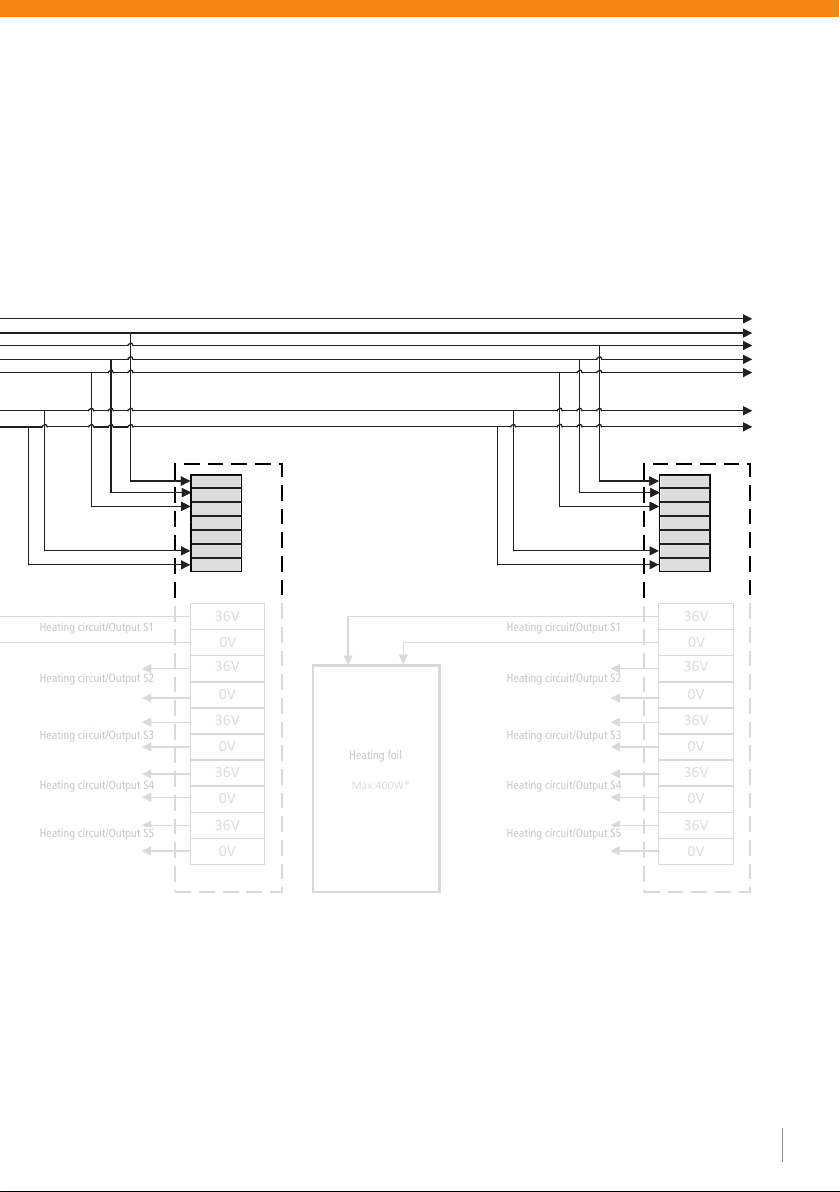

3.2 Installation

This section relates to installation of the film and the transformer. Ins-

tallation of the supply lines and the electrical connections is explained

in Section 3.3 Electrical connection. Note that the minimum processing

temperature is +5 °C.

When walls are less than 2.3 m high and ceilings slope less than 45°, the

heating film should be about 15 cm shorter than the length of the ins-

tallation area. If necessary, the heating film can be divided once at right

angles to the copper conductors. Make sure that cutting is always from

the uncontacted side of the heating film.

All other inappropriate damage to the film, such as tears caused by

sharp objects or kinks, must be avoided. It is therefore important to keep

the heating film rolled up in its packaging until it is required for installa-

tion (note the minimum bending radius, see 4. TECHNICAL DATA).

After installation has been completed, holes may, however, be made in

the film, as outlined in Section 2.2 Function and use.

Warning:

Note that screws may only be fitted in the heating surface if they are in-

stalled with plastic plugs for electrical insulation purposes. In addition

to this, two screws may not be connected by a material that conducts

electricity (e.g. metal picture frames, decorative metal trim, metal shel-

ving system). Do not use any nails.

3.2.1 Preparation of the substructure

The heating film can be applied to any viable, clean and flat substructure

made from inorganic materials like stone, screed, plaster etc. or organic

materials like wood, cork, plastic (possibly with surface finishing / a tie la

yer) etc. The substrate and top layer materials must resist temperatures

of up to 70°C. Contact the manufacturer of these materials if you are in

any doubt.

Irregular surfaces must be avoided (e.g. visible wood/stone – brickwork).

Under certain circumstances, the surface may need to be evened out be-

forehand with plaster or a levelling compound.

Particular care must be taken to make sure that no pointed objects like

stones, screw heads, nails etc. are projecting out of the substructure.

7

3.2 Verlegung

Dieser Abschnitt bezieht sich auf die Verlegung der Folie und des Trafos.

Die Verlegung der Leitungen und der elektrischen Anschlüsse ist im Ab-

schnitt 3.3 Elektrischer Anschluss erklärt. Berücksichtigen Sie die Min-

destverarbeitungstemperatur von +5°C.

Bei Wänden unterhalb von 2,3 m Höhe und in Decken, die weniger als

45° zur Senkrechten geneigt sind, sollte die Heizfolie ca. 15 cm kürzer als

die Länge der Montagefläche sein. Die Heizfolie kann bei Bedarf senk-

recht zu den Kupferbahnen einmalig geteilt werden. Beschnitte immer

nur von der unkontaktierten Seite der Heizfolie vornehmen.

Jede andere unsachgemäße Beschädigung der Folie wie z. B. Einrisse

durch scharfe Gegenstände oder Knicke sind zu vermeiden. Bewahren Sie

die Heizfolie deshalb bis zum Einbau im gerollten Zustand in der Verpa-

ckung auf (Mindestbiegeradius beachten, siehe 4. TECHNISCHE DATEN).

Nach erfolgter Verlegung können jedoch Löcher, wie in Abschnitt 2.2

Funktion und Anwendung beschrieben, eingebracht werden.

Warnhinweis:

Beachten Sie, dass Schrauben nur dann in die Heizfläche eingebracht

werden dürfen, wenn diese mit Kunststoffdübeln zur elektrischen Isolati-

on installiert werden. Zusätzlich dürfen zwei Schrauben nicht mit einem

elektrisch leitfähigen Material (z.B. Metallbilderrahmen, Metallzierleiste,

Regalsystem aus Metall) verbunden werden. Verwenden Sie keine Nägel.

3.2.1 Vorbehandlung des Untergrunds

Die Heizfolie kann auf jedem tragfähigen, sauberen und ebenen Unter-

grund aus anorganischen Materialien wie Stein, Estrich, Putz, etc. oder

organischen Materialien wie Holz, Kork, Kunststoff (evtl. mit Oberflä-

chengrundierung / Haftvermittler), etc. angebracht werden. Die Un-

ter- und Deckschichtmaterialien müssen bis 70 °C temperaturbeständig

sein. Im Zweifel kontaktieren Sie den Hersteller dieser Materialien.

Unregelmäßige Oberflächen sind zu vermeiden (z.B. sichtbare Holz/

Stein - Ausmauerungen). Unter Umständen ist die Fläche vorab mit Aus-

gleichsputz oder Nivelliermasse auszugleichen.

Es ist besonders darauf zu achten, dass keine spitzen Erhebungen wie

Steine, Schraubenköpfe, Nägel oder ähnliches aus dem Untergrund her-

vorstehen.

3.2 Installation

This section relates to installation of the film and the transformer. Ins-

tallation of the supply lines and the electrical connections is explained

in Section 3.3 Electrical connection. Note that the minimum processing

temperature is +5 °C.

When walls are less than 2.3 m high and ceilings slope less than 45°, the

heating film should be about 15 cm shorter than the length of the ins-

tallation area. If necessary, the heating film can be divided once at right

angles to the copper conductors. Make sure that cutting is always from

the uncontacted side of the heating film.

All other inappropriate damage to the film, such as tears caused by

sharp objects or kinks, must be avoided. It is therefore important to keep

the heating film rolled up in its packaging until it is required for installa-

tion (note the minimum bending radius, see 4. TECHNICAL DATA).

After installation has been completed, holes may, however, be made in

the film, as outlined in Section 2.2 Function and use.

Warning:

Note that screws may only be fitted in the heating surface if they are in-

stalled with plastic plugs for electrical insulation purposes. In addition

to this, two screws may not be connected by a material that conducts

electricity (e.g. metal picture frames, decorative metal trim, metal shel-

ving system). Do not use any nails.

3.2.1 Preparation of the substructure

The heating film can be applied to any viable, clean and flat substructure

made from inorganic materials like stone, screed, plaster etc. or organic

materials like wood, cork, plastic (possibly with surface finishing / a tie la

yer) etc. The substrate and top layer materials must resist temperatures

of up to 70°C. Contact the manufacturer of these materials if you are in

any doubt.

Irregular surfaces must be avoided (e.g. visible wood/stone – brickwork).

Under certain circumstances, the surface may need to be evened out be-

forehand with plaster or a levelling compound.

Particular care must be taken to make sure that no pointed objects like

stones, screw heads, nails etc. are projecting out of the substructure.

07

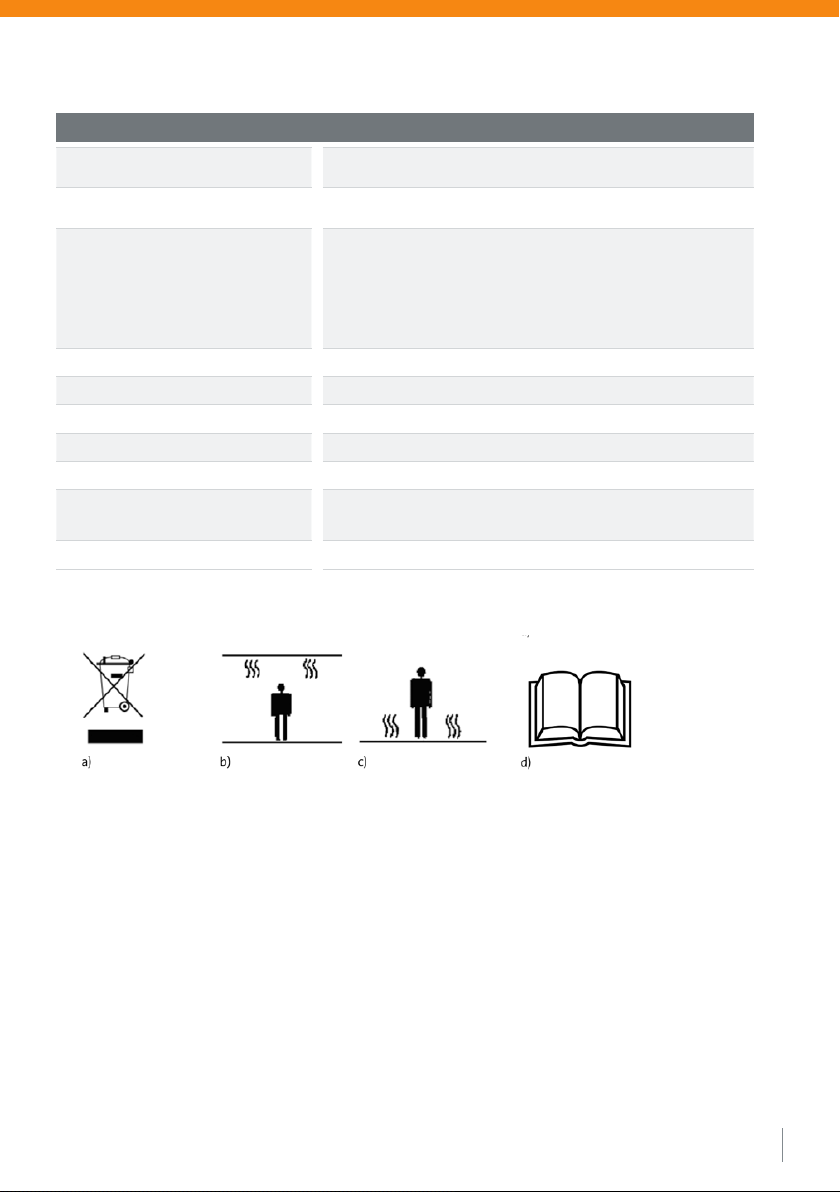

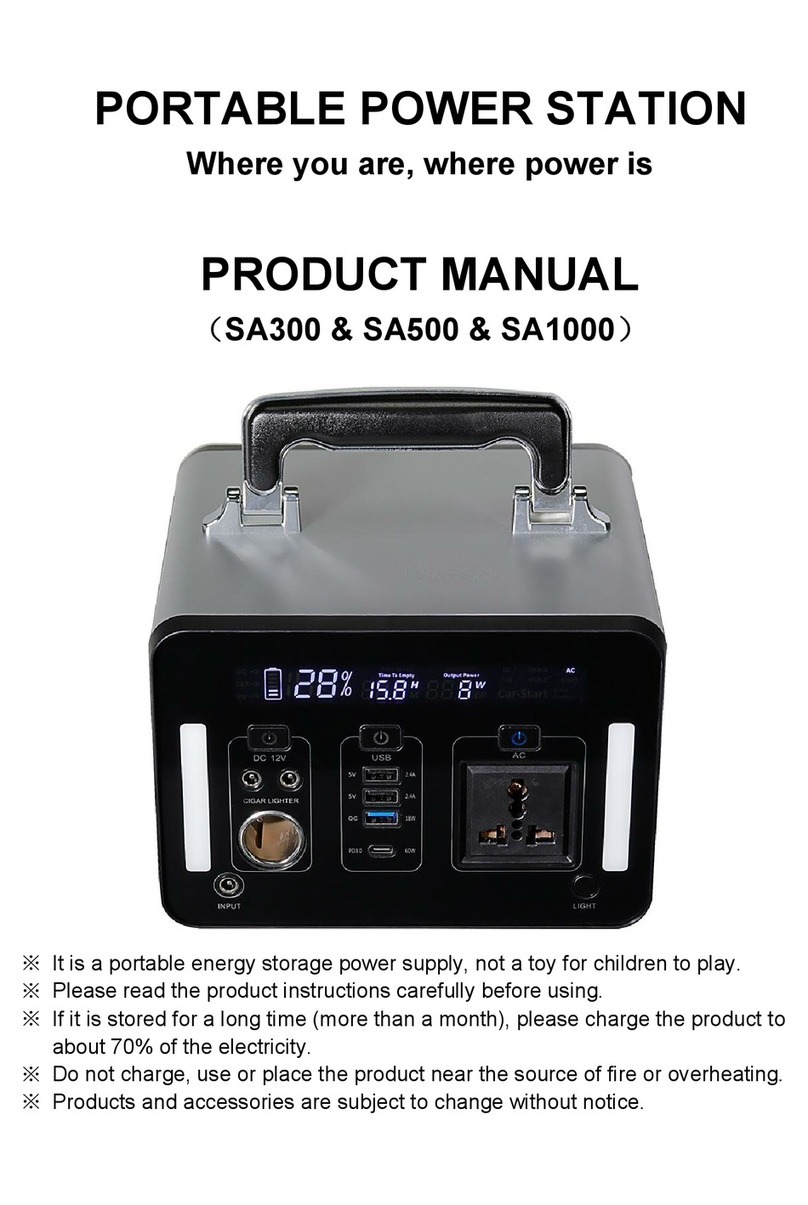

The E-NERGY CARBON heating foil is not designed for installation as a storage heating system and therefore

cannot be used for installation within the floor screed. The closer the heating foil is installed to the surface of the

room, the faster the heating system reacts and emits the pleasant heat radiation into the room.

To facilitate your personal planning and documentation of the installation work, you should use the installation sketch

(page 2). Heating foils with contacts on both sides can be shortened into two individual foils at a later date. If heating

foils contacted on both sides are to be used over their entire length, the contacts at one end of the foil must be remo-

ved (see sketch 3.1). The foil must always be contacted electrically at the pre-assembled contacts.

General wall construction Foil trimming Foil savings

min. 50 mm | max. 5 recesses per 1 m

7

3.2 Verlegung

Dieser Abschnitt bezieht sich auf die Verlegung der Folie und des Trafos.

Die Verlegung der Leitungen und der elektrischen Anschlüsse ist im Ab-

schnitt 3.3 Elektrischer Anschluss erklärt. Berücksichtigen Sie die Min-

destverarbeitungstemperatur von +5°C.

Bei Wänden unterhalb von 2,3 m Höhe und in Decken, die weniger als

45° zur Senkrechten geneigt sind, sollte die Heizfolie ca. 15 cm kürzer als

die Länge der Montagefläche sein. Die Heizfolie kann bei Bedarf senk-

recht zu den Kupferbahnen einmalig geteilt werden. Beschnitte immer

nur von der unkontaktierten Seite der Heizfolie vornehmen.

Jede andere unsachgemäße Beschädigung der Folie wie z. B. Einrisse

durch scharfe Gegenstände oder Knicke sind zu vermeiden. Bewahren Sie

die Heizfolie deshalb bis zum Einbau im gerollten Zustand in der Verpa-

ckung auf (Mindestbiegeradius beachten, siehe 4. TECHNISCHE DATEN).

Nach erfolgter Verlegung können jedoch Löcher, wie in Abschnitt 2.2

Funktion und Anwendung beschrieben, eingebracht werden.

Warnhinweis:

Beachten Sie, dass Schrauben nur dann in die Heizfläche eingebracht

werden dürfen, wenn diese mit Kunststoffdübeln zur elektrischen Isolati-

on installiert werden. Zusätzlich dürfen zwei Schrauben nicht mit einem

elektrisch leitfähigen Material (z.B. Metallbilderrahmen, Metallzierleiste,

Regalsystem aus Metall) verbunden werden. Verwenden Sie keine Nägel.

3.2.1 Vorbehandlung des Untergrunds

Die Heizfolie kann auf jedem tragfähigen, sauberen und ebenen Unter-

grund aus anorganischen Materialien wie Stein, Estrich, Putz, etc. oder

organischen Materialien wie Holz, Kork, Kunststoff (evtl. mit Oberflä-

chengrundierung / Haftvermittler), etc. angebracht werden. Die Un-

ter- und Deckschichtmaterialien müssen bis 70 °C temperaturbeständig

sein. Im Zweifel kontaktieren Sie den Hersteller dieser Materialien.

Unregelmäßige Oberflächen sind zu vermeiden (z.B. sichtbare Holz/

Stein - Ausmauerungen). Unter Umständen ist die Fläche vorab mit Aus-

gleichsputz oder Nivelliermasse auszugleichen.

Es ist besonders darauf zu achten, dass keine spitzen Erhebungen wie

Steine, Schraubenköpfe, Nägel oder ähnliches aus dem Untergrund her-

vorstehen.

3.2 Installation

This section relates to installation of the film and the transformer. Ins-

tallation of the supply lines and the electrical connections is explained

in Section 3.3 Electrical connection. Note that the minimum processing

temperature is +5 °C.

When walls are less than 2.3 m high and ceilings slope less than 45°, the

heating film should be about 15 cm shorter than the length of the ins-

tallation area. If necessary, the heating film can be divided once at right

angles to the copper conductors. Make sure that cutting is always from

the uncontacted side of the heating film.

All other inappropriate damage to the film, such as tears caused by

sharp objects or kinks, must be avoided. It is therefore important to keep

the heating film rolled up in its packaging until it is required for installa-

tion (note the minimum bending radius, see 4. TECHNICAL DATA).

After installation has been completed, holes may, however, be made in

the film, as outlined in Section 2.2 Function and use.

Warning:

Note that screws may only be fitted in the heating surface if they are in-

stalled with plastic plugs for electrical insulation purposes. In addition

to this, two screws may not be connected by a material that conducts

electricity (e.g. metal picture frames, decorative metal trim, metal shel-

ving system). Do not use any nails.

3.2.1 Preparation of the substructure

The heating film can be applied to any viable, clean and flat substructure

made from inorganic materials like stone, screed, plaster etc. or organic

materials like wood, cork, plastic (possibly with surface finishing / a tie la

yer) etc. The substrate and top layer materials must resist temperatures

of up to 70°C. Contact the manufacturer of these materials if you are in

any doubt.

Irregular surfaces must be avoided (e.g. visible wood/stone – brickwork).

Under certain circumstances, the surface may need to be evened out be-

forehand with plaster or a levelling compound.

Particular care must be taken to make sure that no pointed objects like

stones, screw heads, nails etc. are projecting out of the substructure.

7

3.2 Verlegung

Dieser Abschnitt bezieht sich auf die Verlegung der Folie und des Trafos.

Die Verlegung der Leitungen und der elektrischen Anschlüsse ist im Ab-

schnitt 3.3 Elektrischer Anschluss erklärt. Berücksichtigen Sie die Min-

destverarbeitungstemperatur von +5°C.

Bei Wänden unterhalb von 2,3 m Höhe und in Decken, die weniger als

45° zur Senkrechten geneigt sind, sollte die Heizfolie ca. 15 cm kürzer als

die Länge der Montagefläche sein. Die Heizfolie kann bei Bedarf senk-

recht zu den Kupferbahnen einmalig geteilt werden. Beschnitte immer

nur von der unkontaktierten Seite der Heizfolie vornehmen.

Jede andere unsachgemäße Beschädigung der Folie wie z. B. Einrisse

durch scharfe Gegenstände oder Knicke sind zu vermeiden. Bewahren Sie

die Heizfolie deshalb bis zum Einbau im gerollten Zustand in der Verpa-

ckung auf (Mindestbiegeradius beachten, siehe 4. TECHNISCHE DATEN).

Nach erfolgter Verlegung können jedoch Löcher, wie in Abschnitt 2.2

Funktion und Anwendung beschrieben, eingebracht werden.

Warnhinweis:

Beachten Sie, dass Schrauben nur dann in die Heizfläche eingebracht

werden dürfen, wenn diese mit Kunststoffdübeln zur elektrischen Isolati-

on installiert werden. Zusätzlich dürfen zwei Schrauben nicht mit einem

elektrisch leitfähigen Material (z.B. Metallbilderrahmen, Metallzierleiste,

Regalsystem aus Metall) verbunden werden. Verwenden Sie keine Nägel.

3.2.1 Vorbehandlung des Untergrunds

Die Heizfolie kann auf jedem tragfähigen, sauberen und ebenen Unter-

grund aus anorganischen Materialien wie Stein, Estrich, Putz, etc. oder

organischen Materialien wie Holz, Kork, Kunststoff (evtl. mit Oberflä-

chengrundierung / Haftvermittler), etc. angebracht werden. Die Un-

ter- und Deckschichtmaterialien müssen bis 70 °C temperaturbeständig

sein. Im Zweifel kontaktieren Sie den Hersteller dieser Materialien.

Unregelmäßige Oberflächen sind zu vermeiden (z.B. sichtbare Holz/

Stein - Ausmauerungen). Unter Umständen ist die Fläche vorab mit Aus-

gleichsputz oder Nivelliermasse auszugleichen.

Es ist besonders darauf zu achten, dass keine spitzen Erhebungen wie

Steine, Schraubenköpfe, Nägel oder ähnliches aus dem Untergrund her-

vorstehen.

3.2 Installation

This section relates to installation of the film and the transformer. Ins-

tallation of the supply lines and the electrical connections is explained

in Section 3.3 Electrical connection. Note that the minimum processing

temperature is +5 °C.

When walls are less than 2.3 m high and ceilings slope less than 45°, the

heating film should be about 15 cm shorter than the length of the ins-

tallation area. If necessary, the heating film can be divided once at right

angles to the copper conductors. Make sure that cutting is always from

the uncontacted side of the heating film.

All other inappropriate damage to the film, such as tears caused by

sharp objects or kinks, must be avoided. It is therefore important to keep

the heating film rolled up in its packaging until it is required for installa-

tion (note the minimum bending radius, see 4. TECHNICAL DATA).

After installation has been completed, holes may, however, be made in

the film, as outlined in Section 2.2 Function and use.

Warning:

Note that screws may only be fitted in the heating surface if they are in-

stalled with plastic plugs for electrical insulation purposes. In addition

to this, two screws may not be connected by a material that conducts

electricity (e.g. metal picture frames, decorative metal trim, metal shel-

ving system). Do not use any nails.

3.2.1 Preparation of the substructure

The heating film can be applied to any viable, clean and flat substructure

made from inorganic materials like stone, screed, plaster etc. or organic

materials like wood, cork, plastic (possibly with surface finishing / a tie la

yer) etc. The substrate and top layer materials must resist temperatures

of up to 70°C. Contact the manufacturer of these materials if you are in

any doubt.

Irregular surfaces must be avoided (e.g. visible wood/stone – brickwork).

Under certain circumstances, the surface may need to be evened out be-

forehand with plaster or a levelling compound.

Particular care must be taken to make sure that no pointed objects like

stones, screw heads, nails etc. are projecting out of the substructure.

7

3.2 Verlegung

Dieser Abschnitt bezieht sich auf die Verlegung der Folie und des Trafos.

Die Verlegung der Leitungen und der elektrischen Anschlüsse ist im Ab-

schnitt 3.3 Elektrischer Anschluss erklärt. Berücksichtigen Sie die Min-

destverarbeitungstemperatur von +5°C.

Bei Wänden unterhalb von 2,3 m Höhe und in Decken, die weniger als

45° zur Senkrechten geneigt sind, sollte die Heizfolie ca. 15 cm kürzer als

die Länge der Montagefläche sein. Die Heizfolie kann bei Bedarf senk-

recht zu den Kupferbahnen einmalig geteilt werden. Beschnitte immer

nur von der unkontaktierten Seite der Heizfolie vornehmen.

Jede andere unsachgemäße Beschädigung der Folie wie z. B. Einrisse

durch scharfe Gegenstände oder Knicke sind zu vermeiden. Bewahren Sie

die Heizfolie deshalb bis zum Einbau im gerollten Zustand in der Verpa-

ckung auf (Mindestbiegeradius beachten, siehe 4. TECHNISCHE DATEN).

Nach erfolgter Verlegung können jedoch Löcher, wie in Abschnitt 2.2

Funktion und Anwendung beschrieben, eingebracht werden.

Warnhinweis:

Beachten Sie, dass Schrauben nur dann in die Heizfläche eingebracht

werden dürfen, wenn diese mit Kunststoffdübeln zur elektrischen Isolati-

on installiert werden. Zusätzlich dürfen zwei Schrauben nicht mit einem

elektrisch leitfähigen Material (z.B. Metallbilderrahmen, Metallzierleiste,

Regalsystem aus Metall) verbunden werden. Verwenden Sie keine Nägel.

3.2.1 Vorbehandlung des Untergrunds

Die Heizfolie kann auf jedem tragfähigen, sauberen und ebenen Unter-

grund aus anorganischen Materialien wie Stein, Estrich, Putz, etc. oder

organischen Materialien wie Holz, Kork, Kunststoff (evtl. mit Oberflä-

chengrundierung / Haftvermittler), etc. angebracht werden. Die Un-

ter- und Deckschichtmaterialien müssen bis 70 °C temperaturbeständig

sein. Im Zweifel kontaktieren Sie den Hersteller dieser Materialien.

Unregelmäßige Oberflächen sind zu vermeiden (z.B. sichtbare Holz/

Stein - Ausmauerungen). Unter Umständen ist die Fläche vorab mit Aus-

gleichsputz oder Nivelliermasse auszugleichen.

Es ist besonders darauf zu achten, dass keine spitzen Erhebungen wie

Steine, Schraubenköpfe, Nägel oder ähnliches aus dem Untergrund her-

vorstehen.

3.2 Installation

This section relates to installation of the film and the transformer. Ins-

tallation of the supply lines and the electrical connections is explained

in Section 3.3 Electrical connection. Note that the minimum processing

temperature is +5 °C.

When walls are less than 2.3 m high and ceilings slope less than 45°, the

heating film should be about 15 cm shorter than the length of the ins-

tallation area. If necessary, the heating film can be divided once at right

angles to the copper conductors. Make sure that cutting is always from

the uncontacted side of the heating film.

All other inappropriate damage to the film, such as tears caused by

sharp objects or kinks, must be avoided. It is therefore important to keep

the heating film rolled up in its packaging until it is required for installa-

tion (note the minimum bending radius, see 4. TECHNICAL DATA).

After installation has been completed, holes may, however, be made in

the film, as outlined in Section 2.2 Function and use.

Warning:

Note that screws may only be fitted in the heating surface if they are in-

stalled with plastic plugs for electrical insulation purposes. In addition

to this, two screws may not be connected by a material that conducts

electricity (e.g. metal picture frames, decorative metal trim, metal shel-

ving system). Do not use any nails.

3.2.1 Preparation of the substructure

The heating film can be applied to any viable, clean and flat substructure

made from inorganic materials like stone, screed, plaster etc. or organic

materials like wood, cork, plastic (possibly with surface finishing / a tie la

yer) etc. The substrate and top layer materials must resist temperatures

of up to 70°C. Contact the manufacturer of these materials if you are in

any doubt.

Irregular surfaces must be avoided (e.g. visible wood/stone – brickwork).

Under certain circumstances, the surface may need to be evened out be-

forehand with plaster or a levelling compound.

Particular care must be taken to make sure that no pointed objects like

stones, screw heads, nails etc. are projecting out of the substructure.

wrong

3.2. Installation

This section refers to the laying of the film. The laying of the cables and electrical connections is explained in the

section Electrical connection. Take into account the minimum processing temperature of +5 °C.

For walls below 2.3 m in height and in ceilings that are inclined less than 45° to the vertical, the heating foil should

be approx. 15 cm shorter than the length of the mounting surface. If necessary, the heating foil can be divided once

vertically to the copper tracks. The resulting resistance values can be taken from the resistance values depending on

the length. Always cut only from the uncontacted side of the heating foil.

Any other improper damage to the film, such as tears caused by sharp objects or kinks, is not permitted. For this

reason, keep the heating foil in its rolled state in the packaging until installation (observe minimum bending radius,

see Technical Data). After installation, however, holes can be made as described in Section 2.3 Function and Appli-

cation. Warning: Note that screws may only be inserted into the heating surface if they are installed with plastic

7

3.2 Verlegung

Dieser Abschnitt bezieht sich auf die Verlegung der Folie und des Trafos.

Die Verlegung der Leitungen und der elektrischen Anschlüsse ist im Ab-

schnitt 3.3 Elektrischer Anschluss erklärt. Berücksichtigen Sie die Min-

destverarbeitungstemperatur von +5°C.

Bei Wänden unterhalb von 2,3 m Höhe und in Decken, die weniger als

45° zur Senkrechten geneigt sind, sollte die Heizfolie ca. 15 cm kürzer als

die Länge der Montagefläche sein. Die Heizfolie kann bei Bedarf senk-

recht zu den Kupferbahnen einmalig geteilt werden. Beschnitte immer

nur von der unkontaktierten Seite der Heizfolie vornehmen.

Jede andere unsachgemäße Beschädigung der Folie wie z. B. Einrisse

durch scharfe Gegenstände oder Knicke sind zu vermeiden. Bewahren Sie

die Heizfolie deshalb bis zum Einbau im gerollten Zustand in der Verpa-

ckung auf (Mindestbiegeradius beachten, siehe 4. TECHNISCHE DATEN).

Nach erfolgter Verlegung können jedoch Löcher, wie in Abschnitt 2.2

Funktion und Anwendung beschrieben, eingebracht werden.

Warnhinweis:

Beachten Sie, dass Schrauben nur dann in die Heizfläche eingebracht

werden dürfen, wenn diese mit Kunststoffdübeln zur elektrischen Isolati-

on installiert werden. Zusätzlich dürfen zwei Schrauben nicht mit einem

elektrisch leitfähigen Material (z.B. Metallbilderrahmen, Metallzierleiste,

Regalsystem aus Metall) verbunden werden. Verwenden Sie keine Nägel.

3.2.1 Vorbehandlung des Untergrunds

Die Heizfolie kann auf jedem tragfähigen, sauberen und ebenen Unter-

grund aus anorganischen Materialien wie Stein, Estrich, Putz, etc. oder

organischen Materialien wie Holz, Kork, Kunststoff (evtl. mit Oberflä-

chengrundierung / Haftvermittler), etc. angebracht werden. Die Un-

ter- und Deckschichtmaterialien müssen bis 70 °C temperaturbeständig

sein. Im Zweifel kontaktieren Sie den Hersteller dieser Materialien.

Unregelmäßige Oberflächen sind zu vermeiden (z.B. sichtbare Holz/

Stein - Ausmauerungen). Unter Umständen ist die Fläche vorab mit Aus-

gleichsputz oder Nivelliermasse auszugleichen.

Es ist besonders darauf zu achten, dass keine spitzen Erhebungen wie

Steine, Schraubenköpfe, Nägel oder ähnliches aus dem Untergrund her-

vorstehen.

3.2 Installation

This section relates to installation of the film and the transformer. Ins-

tallation of the supply lines and the electrical connections is explained

in Section 3.3 Electrical connection. Note that the minimum processing

temperature is +5 °C.

When walls are less than 2.3 m high and ceilings slope less than 45°, the

heating film should be about 15 cm shorter than the length of the ins-

tallation area. If necessary, the heating film can be divided once at right

angles to the copper conductors. Make sure that cutting is always from

the uncontacted side of the heating film.

All other inappropriate damage to the film, such as tears caused by

sharp objects or kinks, must be avoided. It is therefore important to keep

the heating film rolled up in its packaging until it is required for installa-

tion (note the minimum bending radius, see 4. TECHNICAL DATA).

After installation has been completed, holes may, however, be made in

the film, as outlined in Section 2.2 Function and use.

Warning:

Note that screws may only be fitted in the heating surface if they are in-

stalled with plastic plugs for electrical insulation purposes. In addition

to this, two screws may not be connected by a material that conducts

electricity (e.g. metal picture frames, decorative metal trim, metal shel-

ving system). Do not use any nails.

3.2.1 Preparation of the substructure

The heating film can be applied to any viable, clean and flat substructure

made from inorganic materials like stone, screed, plaster etc. or organic

materials like wood, cork, plastic (possibly with surface finishing / a tie la

yer) etc. The substrate and top layer materials must resist temperatures

of up to 70°C. Contact the manufacturer of these materials if you are in

any doubt.

Irregular surfaces must be avoided (e.g. visible wood/stone – brickwork).

Under certain circumstances, the surface may need to be evened out be-

forehand with plaster or a levelling compound.

Particular care must be taken to make sure that no pointed objects like

stones, screw heads, nails etc. are projecting out of the substructure.

7

3.2 Verlegung

Dieser Abschnitt bezieht sich auf die Verlegung der Folie und des Trafos.

Die Verlegung der Leitungen und der elektrischen Anschlüsse ist im Ab-

schnitt 3.3 Elektrischer Anschluss erklärt. Berücksichtigen Sie die Min-

destverarbeitungstemperatur von +5°C.

Bei Wänden unterhalb von 2,3 m Höhe und in Decken, die weniger als

45° zur Senkrechten geneigt sind, sollte die Heizfolie ca. 15 cm kürzer als

die Länge der Montagefläche sein. Die Heizfolie kann bei Bedarf senk-

recht zu den Kupferbahnen einmalig geteilt werden. Beschnitte immer

nur von der unkontaktierten Seite der Heizfolie vornehmen.

Jede andere unsachgemäße Beschädigung der Folie wie z. B. Einrisse

durch scharfe Gegenstände oder Knicke sind zu vermeiden. Bewahren Sie

die Heizfolie deshalb bis zum Einbau im gerollten Zustand in der Verpa-

ckung auf (Mindestbiegeradius beachten, siehe 4. TECHNISCHE DATEN).

Nach erfolgter Verlegung können jedoch Löcher, wie in Abschnitt 2.2

Funktion und Anwendung beschrieben, eingebracht werden.

Warnhinweis:

Beachten Sie, dass Schrauben nur dann in die Heizfläche eingebracht

werden dürfen, wenn diese mit Kunststoffdübeln zur elektrischen Isolati-

on installiert werden. Zusätzlich dürfen zwei Schrauben nicht mit einem

elektrisch leitfähigen Material (z.B. Metallbilderrahmen, Metallzierleiste,

Regalsystem aus Metall) verbunden werden. Verwenden Sie keine Nägel.

3.2.1 Vorbehandlung des Untergrunds

Die Heizfolie kann auf jedem tragfähigen, sauberen und ebenen Unter-

grund aus anorganischen Materialien wie Stein, Estrich, Putz, etc. oder

organischen Materialien wie Holz, Kork, Kunststoff (evtl. mit Oberflä-

chengrundierung / Haftvermittler), etc. angebracht werden. Die Un-

ter- und Deckschichtmaterialien müssen bis 70 °C temperaturbeständig

sein. Im Zweifel kontaktieren Sie den Hersteller dieser Materialien.

Unregelmäßige Oberflächen sind zu vermeiden (z.B. sichtbare Holz/

Stein - Ausmauerungen). Unter Umständen ist die Fläche vorab mit Aus-

gleichsputz oder Nivelliermasse auszugleichen.

Es ist besonders darauf zu achten, dass keine spitzen Erhebungen wie

Steine, Schraubenköpfe, Nägel oder ähnliches aus dem Untergrund her-

vorstehen.

3.2 Installation

This section relates to installation of the film and the transformer. Ins-

tallation of the supply lines and the electrical connections is explained

in Section 3.3 Electrical connection. Note that the minimum processing

temperature is +5 °C.

When walls are less than 2.3 m high and ceilings slope less than 45°, the

heating film should be about 15 cm shorter than the length of the ins-

tallation area. If necessary, the heating film can be divided once at right

angles to the copper conductors. Make sure that cutting is always from

the uncontacted side of the heating film.

All other inappropriate damage to the film, such as tears caused by

sharp objects or kinks, must be avoided. It is therefore important to keep

the heating film rolled up in its packaging until it is required for installa-

tion (note the minimum bending radius, see 4. TECHNICAL DATA).

After installation has been completed, holes may, however, be made in

the film, as outlined in Section 2.2 Function and use.

Warning:

Note that screws may only be fitted in the heating surface if they are in-

stalled with plastic plugs for electrical insulation purposes. In addition

to this, two screws may not be connected by a material that conducts

electricity (e.g. metal picture frames, decorative metal trim, metal shel-

ving system). Do not use any nails.

3.2.1 Preparation of the substructure

The heating film can be applied to any viable, clean and flat substructure

made from inorganic materials like stone, screed, plaster etc. or organic

materials like wood, cork, plastic (possibly with surface finishing / a tie la

yer) etc. The substrate and top layer materials must resist temperatures

of up to 70°C. Contact the manufacturer of these materials if you are in

any doubt.

Irregular surfaces must be avoided (e.g. visible wood/stone – brickwork).

Under certain circumstances, the surface may need to be evened out be-

forehand with plaster or a levelling compound.

Particular care must be taken to make sure that no pointed objects like

stones, screw heads, nails etc. are projecting out of the substructure.

wrong

right

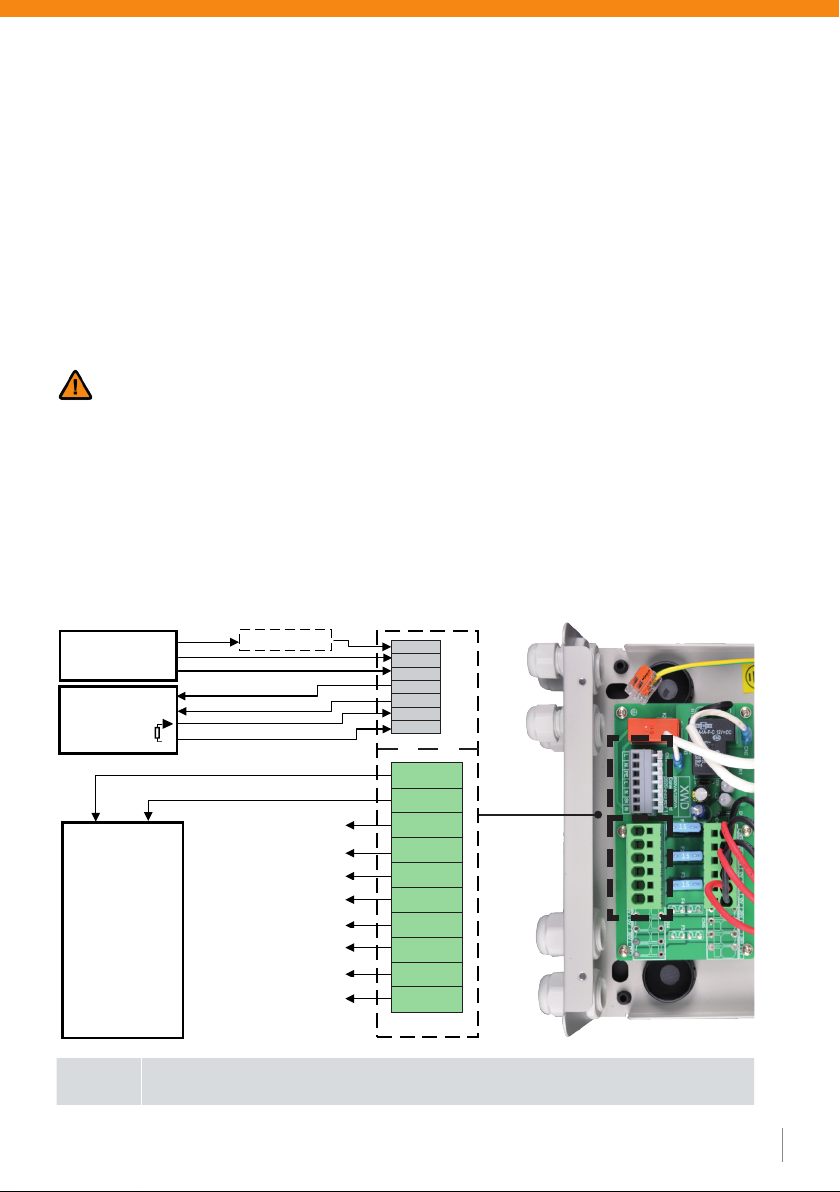

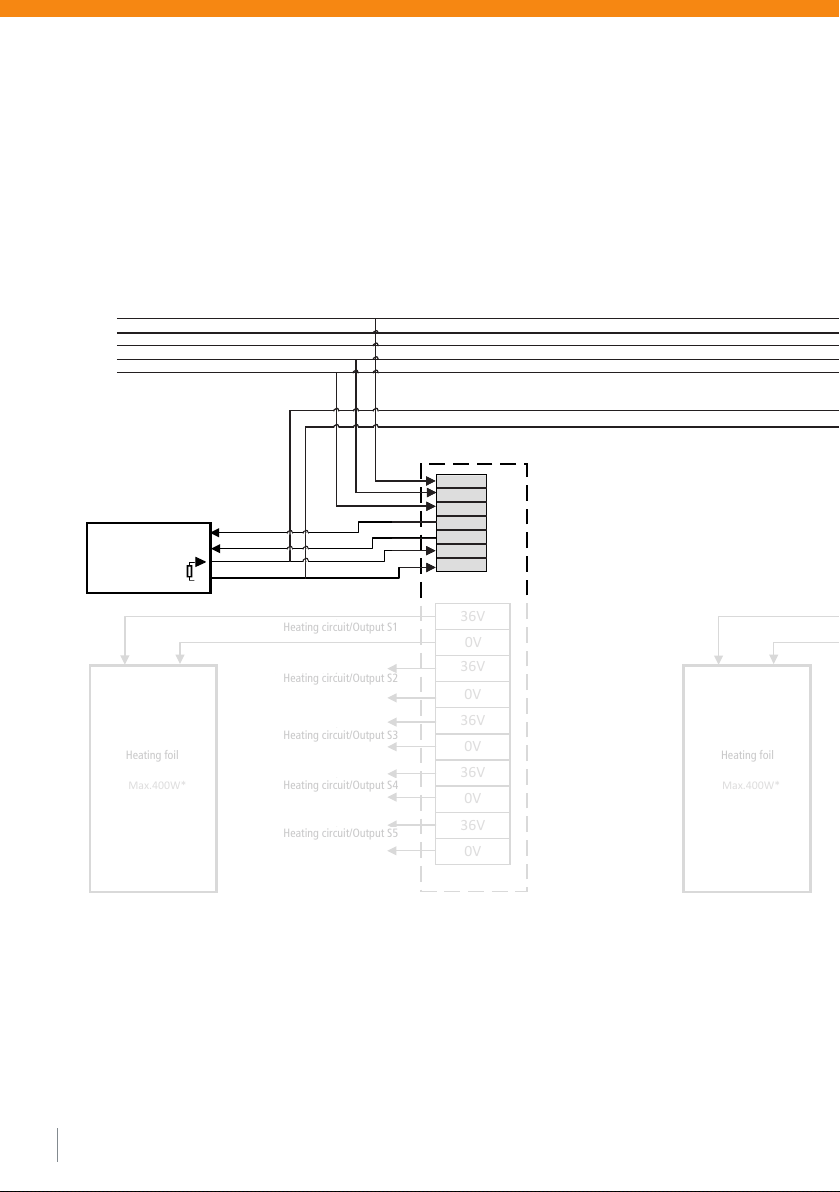

(1) Heating foil (2) Transformer (3) Controller (4) Sensor