MFZ Ovitor RS 300 K User manual

MFZ Antriebe GmbH & Co. KG

Neue Mühle 4

D-48739 Legden

EN

Operating instructions leveller control RS 300 K

Page 2 / 24 –RS 300 K / Rev.A 05

EN

1 Contents

1 Contents

2 Key to symbols 2

3 General safety instructions 2

4 Overview of products 4

5 Initial operation instructions 6

6 Initial operation 7

7 Functional description 11

8 Further functions 12

9 Option Display 13

10 Error messages and rectification 20

11 Technical Data 21

2 Key to symbols

Danger of personal injury!

The safety instructions must be observed!

Warning! Danger to property!

The safety instructions must be observed!

Information

Special information

OR Reference to other sources of information

3 General safety instructions

Guarantee

The function and safety of the equipment is only guaranteed if the warning and safety

instructions included in these operating instructions are adhered to. MFZ Antriebe GmbH

& Co. KG is not liable for any personal injury or damage to property that occurs as a re-

sult of the warning and safety instructions being disregarded.

Using the equipment for its intended purpose

The RS300K controls are designed only for dock levellers with hinged lip.

RS 300 K / Rev. A 05 - Page 3 / 24

EN

Target group

Only qualified and trained electricians may connect, program and service the controls.

Qualified and trained electricians meet the following requirements:

-knowledge of the general and specific safety and accident prevention regulations,

-knowledge of the relevant electrical regulations,

-trained in the use and care of appropriate safety equipment,

-capable of recognizing the dangers associated with electricity.

Instructions for installation and connection

-The controls must be disconnected from the electricity supply before carrying out

electrical works. It must be ensured that the electricity supply remains disconnected

during the works.

-Local protective regulations must be complied with.

Regulations and bases for testing

For connecting, programming and servicing, the following regulations must be observed

(the list is not exhaustive).

Electromagnetic compatibility

- EN 50014-1

(radio disturbance, household appliances)

- EN 61000-3-2

(disturbances in supply system –harmonic currents)

- EN 61000-3-3

(disturbances in supply system –voltage fluctuations)

- EN 61000-6-2

(electromagnetic compatibility (EMC) –Part 6-2: Generic standards -

immunity for industrial environments)

- EN 61000-6-3

(electromagnetic compatibility (EMC) –Part 6-2: Generic standards -

emission standard for residential, commercial and light-industrial environ-

ments)

Machinery guidelines

- EN 1398

Dock levellers –safety requirements

- EN 60204-1

(safety of machinery, electrical equipment of machines, part 1: general

requirements)

- EN 12100-1

(safety of machinery, basic concepts, general principles for design. Basic

terminology, methodology)

Low voltage

- EN 60335-1

(household and similar electrical appliances - safety)

Page 4 / 24 –RS 300 K / Rev.A 05

EN

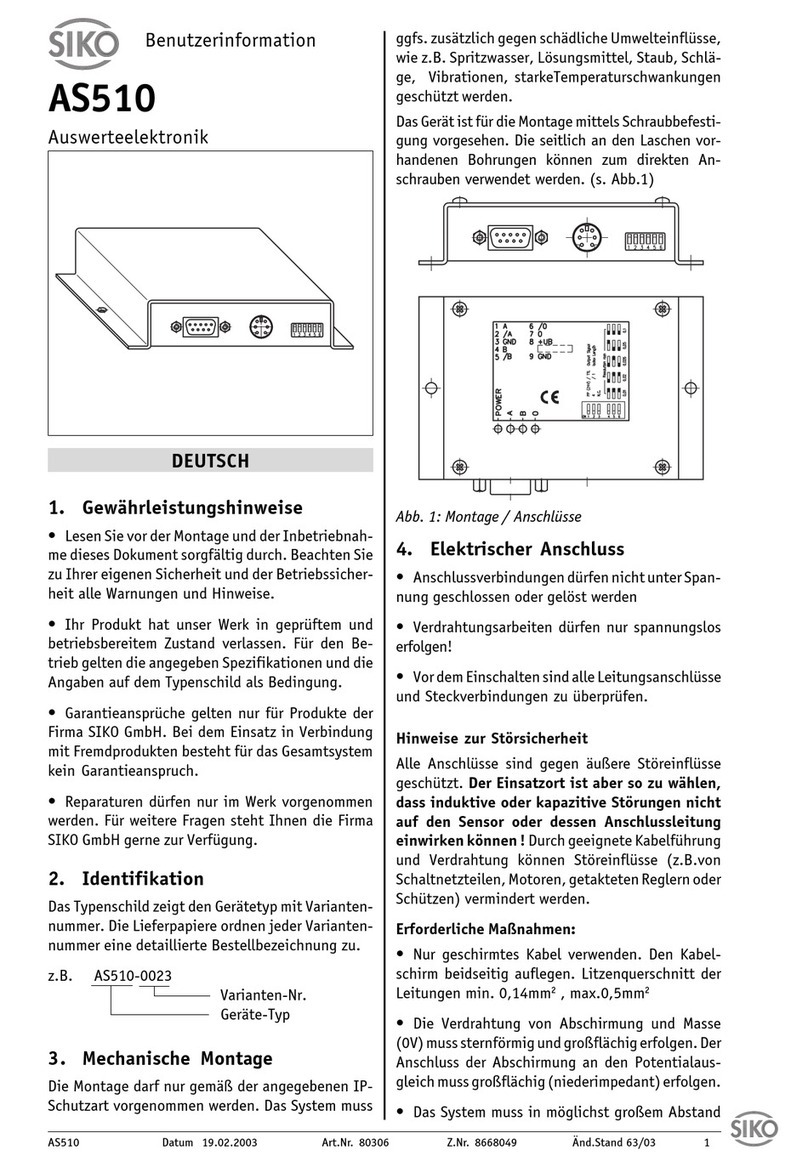

4. Housing

Key

Mains switch

Button UP

Button Autoreturn

RS 300 K / Rev. A 05 - Page 5 / 24

EN

4.2 PCB

B1

B2

U

V

W

X2

X1

PE

X6

X3

LED 1

X5

X7

X4

X8

X9

230 400

Key:

X1: terminal block

mains connection

230/400: terminal block

adjustment of mains voltage

PE: terminal block PE

HS1 …HS6: connection mains

switch

X2: terminal block hydraulic

unit

X3: terminal block command

devices

X4: terminal block tube motor

and signal devices

X5: terminal block valves and

door

X6: socket for internal push

buttons

X7: terminal block LCD

X8: terminal block traffic lights

X9: RS485 interface

K1: Contactor

F1 … F3: overload protection

hydraulic unit

F4: Overload protection 24VDC

J1: Jumper phase rotation

Page 6 / 24 –RS 300 K / Rev.A 05

EN

5 Initial Operation –general instructions

Warning!

To guarantee that the equipment functions properly, the following points

must be ensured:

-The dock leveller is installed and operational.

-The command and safety devices are installed and ready for opera-

tion.

-The control housing with the RS300K is installed.

-All motor connections are correct and on the motor side screwed

tight.

Information:

For the installation of the dock leveller, the hydraulic unit and the com-

mand and safety devices, the relevant manufacturer’s instructions are to

be adhered to.

Mains connection

Danger!

To guarantee that the controls function properly, the following points

must be ensured:

- The mains voltage must correspond to the voltage stated on the type

plate.

- For a three-phase current, a clockwise rotating field is required.

- For a three-phase connection, only 3-way automatic circuit breakers

(6A) may be used.

Warning!

After completion of the wiring and prior to switching on for the first time,

the control should be checked that all motor connections are correct and

screwed tight.

RS 300 K / Rev. A 05 - Page 7 / 24

EN

6 Initial Operation

Mains voltage adjustment

A wrong adjustment of the mains

voltage can destroy the control.

Factory setting 400V

400V

230V

Mains supply X1

N L3 L2 L1

PE PE PE

400V 3~/PE

230V 3~/PE

X1

Mains switch

L2'

L2

S3

S4

S1

S2

L1 L1'

S5

S6

L3'

L3

X2 Hydraulic unit

Note rotating field! LED 1 indicates

whether a correct rotational field is

applied. Release can only be

undertaken with a clockwise rotat-

ing field.

U V W

M

PE PE PE

X2

1 2

Emergency stop

U V W

X2

1 2

Page 8 / 24 –RS 300 K / Rev.A 05

EN

Valve:

Y1: stop valve 24 VDC 100%

1 2 3 4 5 6 7 8 9 10 11 12

GND

Y1

X5

Connection to the door control

Door Release: Potential-free contact for

locking the door system. The contact

opens as soon as the dock leveller is not in

the home position.

IMPULSE door close: During operation of

the door leveller the contact is open. Only

when the door leveller is in its home posi-

tion is the contact closed

Interlock door - leveller: The control of

the dock leveller is locked via a potential-

free contact of the door system or a

sensor. The polarity of the signal can be

adjusted. The dock leveller can be

operated only when a release of the door

system is present. If during operation the

door release is removed both traffic light

will turn red.

1 2 3 4 5 6 7 8 9 10 11 12

X3

Interlock

door - leveller

24V

NC contact

1 2 3 4 5 6 7 8 9 10 11 12

X5

STOP

IMPULSE

close

1 2 3 4 5 6 7 8 9 10 11 12

X3

Interlock

door - leveller

24V

black

brown

blue

pnp open

collector

GND GND

24 VDC for external units

max. 250 mA

1 2 3 4 5 6 7 8 9 10 11 12

X5

GND 24V

max. 250mA

RS 300 K / Rev. A 05 - Page 9 / 24

EN

Traffic lights

Inside green light (terminal 2)

Inside red light (terminal 3)

Outside green light (terminal 4)

Outside red light (terminal 5)

Max. load

24VDC max. 100mA

230 VAC max. 40 W

1 2 3 4 5 6

X8

COM

2 3 4 5

COM

24 VDC 12

X5

24V

11

GND

123456

X8

COM

2 3 4 5

COM

230 VAC 1

X4

L1

2

N

Tube motor for shelter door and 230 V

Output

The functions of the 230 VAC output have

to be programmed via the display.

MOD 1: Horn (standard)

MOD 2: Shelter fan

MOD 3: Loading lamp automatic

MOD 4: Loading lamp manual

1 2 3 4 5 6

X4

ÈN L1

Ç N

M

7 8

L1 N

Vehicle detector:

Visual and audible collision safety applied

by an approach sensor. If a vehicle in front

of the gate activates the approach sensor

a warning signal sounds and the lights

outside red turns. Optionally, a door

locking can be activated. This utility must

be activated via the input function.

Wheel block:

The wheel block is used to secure the

vehicle during the loading process. This

utility must be activated via the input

function.

1 2 3 4 5 6 7 8 9 10 11 12

X3

Wheel block

24V

NC contact

Vehicle detector

24V

NC contact

1 2 3 4 5 6 7 8 9 10 11 12

X3

Wheel block

24V

Vehicle detector

black

brown

blue

pnp open

collector

GND GND

24V

black

brown

blue

pnp open

collector

Page 10 / 24 –RS 300 K / Rev.A 05

EN

Free Connection

The operation of the free input can be se-

lected via the input fuction to;

Traffic light confirmation: (NO contact)

The outer green traffic light turns on when

the leveller is retracted, the wheel block is

removed and the reset button has been

pressed.

Safety fence: (NC Contact)

When the security fence is closed the dock

leveller is locked.

Selector switch Shelter

Selector switch for the manual operation of

the dock shelter.

1 2 3 4 5 6 7 8 9 10 11 12

X3

Free connection

24V

Limit switch door leveller

The limit switch indicates that the dock

leveller is in the home position.

1 2 3 4 5 6 7 8 9 10 11 12

X3

Limit switch

24V

NC contact

Cover button connections

All buttons are as No contact to close.

The cover LED (option) has the same func-

tion as the inner green light.

1 2 3 4 5 6 7 8

X6

Dock up

GND 24V

Lip out

LIP in

Dock down

AR

LED

RS 300 K / Rev. A 05 - Page 11 / 24

EN

7 Functional description - Version hinged lip

7.1 Operation of the dock leveller

Raise the dock leveller with the button (dock UP) in dead-man operation mode. When

the dock leveler reaches its upper end position the lip folds out automatically. The button

should be released when the lip is completely folded out. The dock leveller descends au-

tomatically into the loading position (floating position).

With activated current detection, the upper position of the dock leveller is detected (un-

folding of the lip) when lifting from the home position. If the upper end position is not

reach within a minimum of 2 seconds, the control assumes that the lip in not completely

unfolded and lowers the bridge back to its home position. When this position takes long-

er as 2 seconds to be reached, bridge lowers into the floating position.

7.2 Automatic return (AR)

Upon completion of the loading, the dock leveller is returned to its home position by

pressing the AR button.

The AR function expires upon reaching the home position.

AR Version with current control (Standard)

-The dock leveller is raised until the upper end position is reached (this position is rec-

ognized through the current detection or by the time “AR RAISE 1”).

To use the current detection, the time “AR RAISE 1” must be set at a high value.

-The leveller descends for the time “AR DROP 1”

-The leveller is raised again for the time “AR RAISE 2”

-The dock leveller descends automatically to the home position.

-After the interval “AR DROP 2”the leveller will continue with the program sequence.

AR Version timed function:

-The leveller raises for the time “AR RAISE 1”

-The leveller descends for the time “AR DROP 1”

-The leveller is raised again for the time “AR RAISE 2”

-The dock leveller descends automatically to the home position.

-After the interval “AR DROP 2”the leveller will continue with the program sequence.

Page 12 / 24 –RS 300 K / Rev.A 05

EN

8 Further functions

8.1 Protection circuit

The control RS300K has an integrated protection circuit. If an emergency stop signal is

received or the power is interrupted during the operation of the dock leveller, the stop

circuit is switched off and locks the bridge in position.

Only after pressing the lift button can the bridge be moved into its home or floating posi-

tion.

8.2 Detection of the phase rotation

The control RS300K has an integrated circuit for the detection of the phase rotation. The

circuit checks to see if a clockwise rotating field has been applied before allowing a

through connection. Where no clockwise rotating field is detected, then the contactor

does not switch on. Furthermore, the circuit is protected against phase failure. Both of

these errors are signaled by the LED 1.

The Detection of the phase rotation is possible only with the 400V mains supply. If the

mains voltage 230 V 3Phasen should used, then the Detection of the phase rotation must

be deactivated with the Jumper 1.

8.3 Current detection in the folding lip version

The RS300 control has an integrated current measurement for the hydraulic unit. This

measurement allows the detection of the upper end position of the dock leveller.

1. Recognition of the upper end position (unfolding of the lip) when lifting from the

home position.

With activated current detection, the upper position of the dock leveller is detected (un-

folding of the lip) when lifting from the home position. If the upper end position is not

reach within a minimum of 2 seconds, the control assumes that the lip in not completely

unfolded and lowers the bridge back to its home position. When this position takes long-

er as 2 seconds to be reached, bridge lowers into the floating position.

2. Recognition of the upper end position during automatic return

Using “AR RAISE 1” the upper end position is recognized by the current detection or the

set time. After detecting the upper limit position, the bridge lowers automatically to the

home position.

RS 300 K / Rev. A 05 - Page 13 / 24

EN

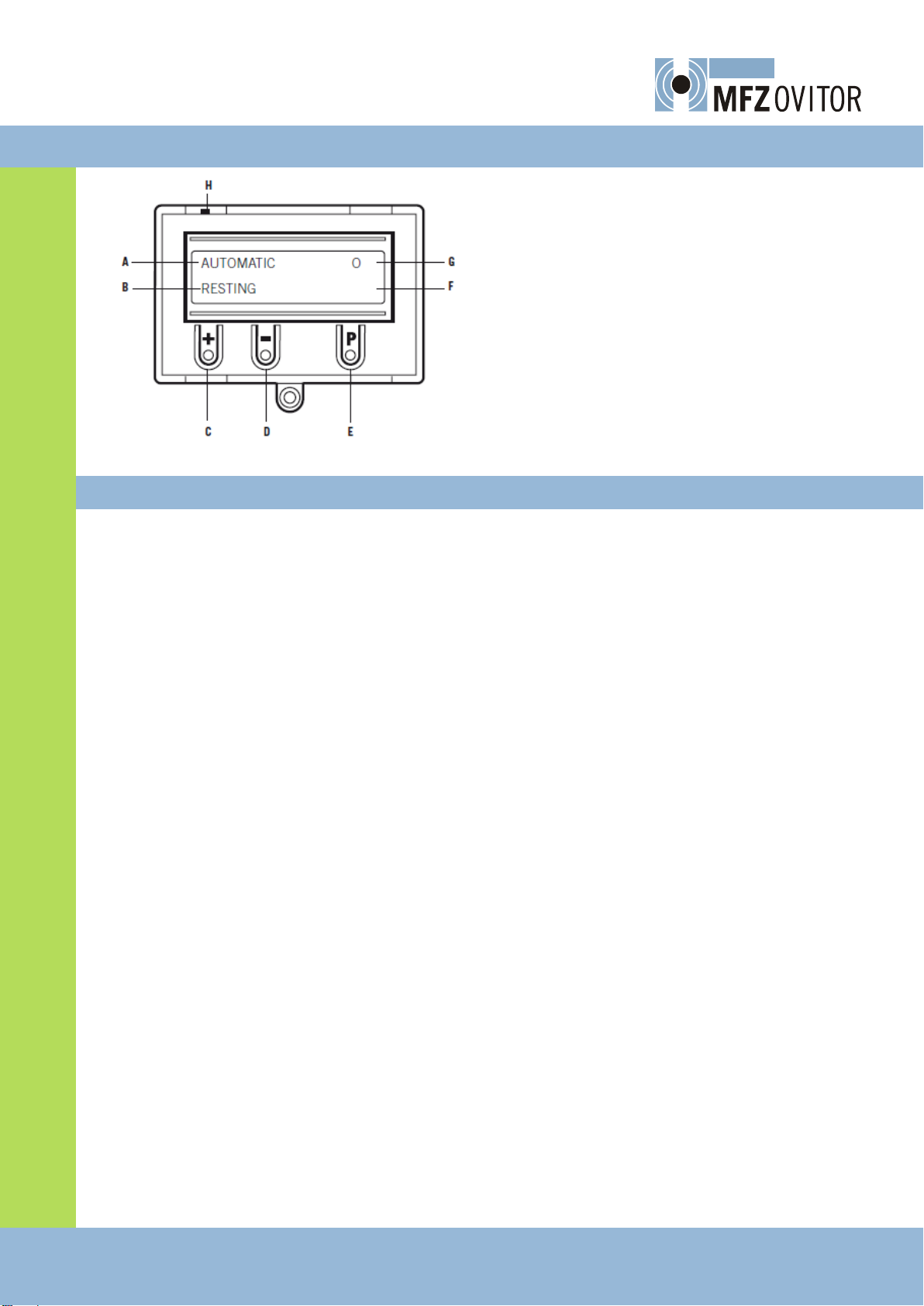

9 Options DISPLAY

Key:

A: Operating mode / Diagnostic info

B: Parameters / Diagnostic info

C: + button

D: - button

E: P button

F: value / status

G: value / status

H: jumper

9.1 Operation mode of the LCD screen

With the LCD screen, the control is provided with 4 operation modes. If the Jumper H is

pulled out, the key buttons +, - and P do not function. The display will continue to func-

tion.

Operation mode 1: AUTOMATIC

The dock is operated in the operation mode AUTOMATIC.

Display: - Notice about the running function

- Notice about the possible errors

Operation mode 2: INPUT

The values of the different parameters can be changed in the operation mode INPUT.

Display: - Notice about selected parameters

- Notice about the set values / status

Operation mode 3: DIAGNOSTIC

Controls specific to the leveller can be examined in the operation mode DIAGNOSTIC.

Display: - Notice about controls

- Notice about the control status

Operation mode 4: MAINTENANCE

MAINTENANCE mode allows the dock leveller to be operated via the installed housing

buttons. The MAINTENANCE mode is only for commissioning. No floating positions are

available.

Display: - Notice about the running functions.

Page 14 / 24 –RS 300 K / Rev.A 05

EN

9.2. Navigator

AUTOMATIC

STANDBY

P- > 1 sec.

INPUT

+ and –> 2 sec.

INPUT

DEUTSCH

Scroll up through menu:

+ > 2 Sec

Scroll down through

menu:

- > 2 sec.

Select value:

P > 1 sec.

Increase value:

+

Decrease value:

-

Save value:

P

Return to INPUT mode:

+ and - > 1 sec.

INPUT

VALVE VER.: 1

INPUT

AR RASIE 1 1.0

INPUT

AR DROP 1 5.0

INPUT

AR RAISE 2 6.0

INPUT

AR DROP 2 2.0

INPUT

TIME HYDR.: 50

INPUT

TRAFFIC LIGHT MOD. 3

INPUT

HORN/LIGHT: MOD 1

INPUT

AUTORETURN: MOD 2

INPUT

WHELL BLOCK: MOD 1

INPUT

VEHICLE SENSOR MOD 1

INPUT

SHELTER: MOD 1

INPUT

SHELTER TIME: 1

INPUT

RELEASE + / - MOD 1

INPUT

RELEASE MOD 1

INPUT

FREE 1 MOD 1

INPUT

CURRENT CTRL 20%

INPUT

DELAY TIME 0%

INPUT

Y1 RAISE 0

RS 300 K / Rev. A 05 - Page 15 / 24

EN

P- > 1 sec.

DIAGNOSIS

.

STOP CHAIN ON

WHELL BLOCK OFF

Scroll up through menu:

+ > 2 sec.

Scroll down through

menu:

- > 2 sec.

Return to AUTOMATIC

mode:

P

Only queries are possible

INTERLOCK ON

HOME LS OFF

ACKOWLEDGE OFF

VEHICLE SENSOR OFF

LIP FORWARD OFF

LIP BACK OFF

RAISE OFF

HOME OFF

DROP ON

CYCLE OFF

P- > 1 sec

MAINTENNACE

.

MANUAL OPERATION OF THE DOCK

LIFT

LOWER (AR)

FORWARD

BACK

P- > 1 sec

Page 16 / 24 –RS 300 K / Rev.A 05

EN

9.3 Operating mode Automatic

Display

Meaning

AUTOMATIC

STANDBY

The dock leveller is in initial position.

AUTOMATIC

FLOATING

The dock leveller is in working position.

AUTOMATIC

EMERGNCY STOP

The dock leveller is in the EMERGENCY STOPS status. For setting the leveller back

into the initial position, the button leveller up must be pressed first and then the

button automatic returns.

AUTOMATIC

ADJUSTMENT

Delay before the leveller is lowering.

AUTOMATIC

RAISE

The dock leveller is raised.

AUTOMATIC

FOLD OUT

The lip is folded out.

AUTOMATIC

AUTORETURN xxx

Automatic return cycle is active.

9.4 Operating mode Diagnosis

DISPLAY

Meaning

Status

STOP CHAIN

Stop circuit, Emergency Stop

ON: circuit closed

OFF: interrupted (fault)

WHEEL BLOCK

Wheel block

ON: activated

OFF: not activated

INTERLOCK

Interlock Door - leveller

ON: activated

OFF: not activated

HOME LS

Limit switch dock leveller

OFF: activated

ON: not activated

ACKOWLEDGE

Acknowledged Traffic lights

ON: activated

OFF: not activated

VEHICLE

Vehicle Sensor

ON: activated

OFF: not activated

LIP-FORWARD

Push button Lip forward

ON: activated

OFF: not activated

LIP-BACK

Push button Lip back

ON: activated

OFF: not activated

RAISE

Push button dock up

ON: activated

OFF: not activated

AR

Push button automatic return

(AR)

ON: activated

OFF: not activated

DROP

Push button drop

(Option)

ON: activated

OFF: not activated

CYCLE

cycle counter

Displays number of leveller cycles

RS 300 K / Rev. A 05 - Page 17 / 24

EN

9.5 Operating mode INPUT

Function

Description

Setting options

Factory setting

DEUTSCH

Select the menu language

DEUTSCH, ENGLISH,

NEDERLANDS

DEUTSCH

Valve version

1: 1 Valve standard

1 Valve

Function

Raise

Lower

Floating mode

Emergency mode

standard

Contactor

1

0

0

0

stop

Y1

1

1

1

0

2: 1 Valve special

1 Valve

Function

Raise

Lower

Floating mode

Emergency mode

special

Contactor

1

0

0

0

stop

Y1

0

1

1

0

3: 2 Valve special

2 Valve

Function

Raise

After Y1 time has elapsed

Lower

Floating mode

Emergency mode

special

Contactor

1

1

0

0

0

Y1

1

0

0

0

0

Y2

0

0

1

1

0

1 … 3

1

AR-RAISE 1

Initial time to raise the dock leveller during

the AR function from the floating position.

0,5 … 25 Sek.

1 Sek.

AR-DROP 1

Time to drop the dock leveler during AR

function to ensure that the lip is folded in

completely before dropping to home posi-

tion.

1 … 5 Sek.

5 Sek.

AR-RAISE 2

Second time to raise the dock leveller dur-

ing AR function..

1 … 20 Sek.

6 Sek.

AR-DROP 2

Time to drop the dock leveller into home

position.

1 … 20 Sek.

2 Sek.

TIME HYDR

Maximum running time of the hydraulic

unit. The watchdog timing of individual

movement serves for the avoidance of

overload due to defect push buttons or de-

fective limit switches.

0 … 254 Sek.

50 Sek.

TRAFFIC LIGHT

MOD

Traffic lights are

MOD 1: no traffic lights

MOD 2: OFF in position home

MOD 3: ON in position home

MOD 1 … MOD 3

MOD 3

Page 18 / 24 –RS 300 K / Rev.A 05

EN

Function

Description

Setting options

Factory setting

Horn/LIGHT

MOD 1: Horn

Produces warning signal, if for example the

wheel block is removed during the loading.

MOD 2: Fan

The fan is necessary for the function shelter

as well as the tubular drive. During the

activation of Shelter, MOD 2 is pre-selected

and cannot be changed.

MOD 3: Dock loading light

After reaching the loading position the light

is switched on and remains on, as long as

to the dock leveler returns to home posi-

tion.

MOD 4:

MOD 1 … MOD 4

MOD 1

AUTORETURN

MOD 1: Autoreturn not active

MOD 2: Autoreturn active

MOD 3: = MOD 2

MOD 4 = MOD 2

MOD 1 … MOD 4

MOD2

WHEEL BLOCK

MOD1: Wheel block not active

MOD2: Wheel block active, with actuation

during loading procedure the red traffic

lights are switched on and the horn signal-

izes this.

MOD3: Wheel block active, with actuation

during loading procedure, all buttons are

blocked.

MOD 1 … MOD 3

MOD1

VEHICLE

SENSOR

MOD 1: vehicle sensor not active

MOD2: Optical and acoustic vehicle detec-

tion.

When a vehicle drives in front of the door

and activates the vehicle sensor, this is

signalized by red traffic lights and the horn.

The dock leveller is released for operation.

MOD3: Optical and acoustic vehicle detec-

tion.

When a vehicle drives in front of the door

and activates the vehicle sensor, this is

signalized by red traffic lights and the horn.

The door (stop contact) is released for op-

eration.

MOD 1 … MOD 3

MOD1

RS 300 K / Rev. A 05 - Page 19 / 24

EN

Function

Description

Setting options

Factory setting

SHELTER

MOD1: not active

MOD2: Controlled via the program.

MOD3: Controlled via the selector switch.

(see free input)

MOD1 … MOD3

MOD 1

SHELTER TIME

The time defines the delay for the release

of the door before the start of the loading

procedure as well as for the release of the

green traffic light outside after the loading

procedure.

0 … 255 Sec.

5 Sec.

RELEASE +/-

MOD 1: NC contact

MOD 2: NO contact

MOD 1, MOD2

MOD1

RELEASE

MOD1: active,

if the door interlock is interrupted during

the loading procedure, the leveller remains

in floating position, both traffic lights switch

to red, the buttons are locked and hydraulic

unit is switched off.

MOD2: active,

if the door interlock is interrupted during

the loading procedure, the leveller remains

in floating position, both traffic lights switch

to red.

MOD1, MOD2

MOD1

FREE INPUT

MOD 1: not active

MOD 2: Traffic light acknowledge

MOD 3: safety fence

MOD 4: Selector switch shelter

MOD 5: only for telescopic lip

MOD1 … MOD 5

MOD1

Current control

threshold

The value of the current control represents

the increased height of the current of the

hydraulic unit with the impact into an end

position. This parameter must be adapted

to the respective unit.

0= off

0% … 35 %

in percent

20%

Time Base

With this parameter different speeds of the

telescopic lip can be adapted when drawing

in and driving out. A negative value must

be selected, if the lip is faster drawn in than

driven out.

- 50 % … 50%

0%

Y1 Raise (Visi-

ble only when

mode value =

3)

After the set time value 1 (Y1) will the dock

leveller extend.

0,1 … 25,0

0

Page 20 / 24 –RS 300 K / Rev.A 05

EN

10. Error messages and rectification

Error messages

Cause

Rectification

System does not respond

No mains power

Check mains power to control box

Leveller is not rising when

the UP button is operated.

interlock door –leveller is

activated

Check interlock contact

Leveller is not raising when

the UP button is operated,

although motor is running,

the red LED is out

Connection of the hydrau-

lic unit is wrong

Swap two phase wires of the hydrau-

lic unit

Red LED ON

Fuse defectively or phase

is missing or to rotary

field of the mains supply

is wrong

Check hydraulic unit, cabling and

fuses

Error message Display / Op-

tion

Cause

Rectification

ERROR HY ZEIT

The programmed running time

been exceeded

Check buttons and cabling.

Re-programme the running time

ERROR ROT:FIELD

An incorrect rotating field is

connected to terminal X1

Ensure that a clockwise rotating field is

connected

EMERGENCY STOP

Emergency stop circle opened

or voltage failure during unde-

fined position

- check emergency stop circuit

- use the button up and AR to bring the

leveller into the initial position.

INTERLOCK

interlock door –leveller is

activated

Check interlock contact

Table of contents

Popular Control Unit manuals by other brands

claber

claber 90826 user manual

Sawo

Sawo STAINLESS STEEL TOUCH CONTROL manual

H3C

H3C SFP-GE-SX-MM850-A manual

Siemens

Siemens SIMATIC ET 200S Original operating instructions

Blake Water Solutions

Blake Water Solutions MOD-EMU-BWS Operation & installation instructions

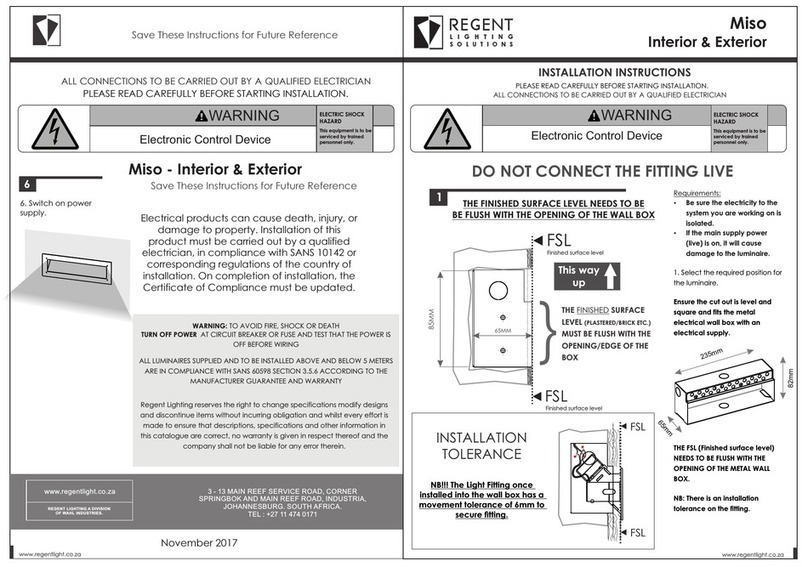

Regent Lighting Solutions

Regent Lighting Solutions Miso installation instructions