EM-8160 Rev.2 P. 1 / 5

MG CO., LTD. www.mgco.jp

5-2-55 Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

INSTRUCTION MANUAL

LIGHTNING SURGE PROTECTOR FOR PHOTOVOLTAIC SYSTEM

(750 V DC, 1000 V DC use) MODEL MATPH

BEFORE USE ....

Thank you for choosing us. Before use, please check con-

tents of the package you received as outlined below.

If you have any problems or questions with the product,

please contact our sales office or representatives.

■PACKAGE INCLUDES:

Surge protector....................................................................(1)

■MODEL NO.

Check that the model No. described on the specifications

matches the operational line voltage and other specifica-

tions as shown in ‘PERFORMANCE’ hereafter.

■INSTALLATION / INSTRUCTION MANUAL

This manual describes necessary points of caution when

you use this product, installation, and basic maintenance

procedure.

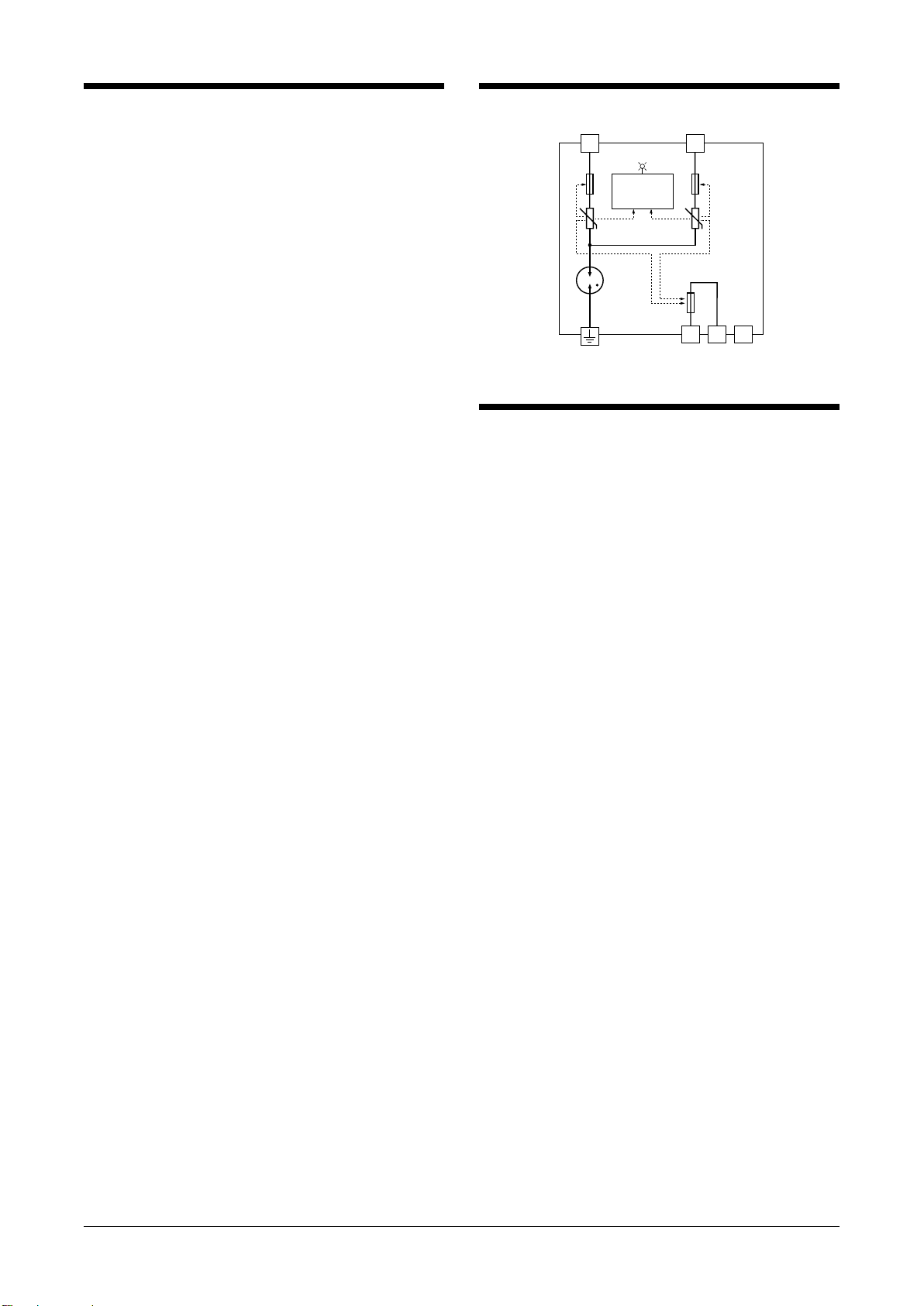

LIMITATION APPLICABLE TO MATPH

The MATPH will protect electronics equipment from

damage caused by induced lightning by absorbing most

of the surge voltages.

However, MATPH may not be effective against certain

extremely high voltages exceeding its discharge current

capacity (20 kA @ 8/20 µsec. waveform) caused by a di-

rect or almost direct hit by lightning.

The MATPH must be installed according to this installa-

tion / instruction manual.

PERFORMANCE

Max. continuous operating voltage (Uc, Line to line):

750 V DC for MATPH-750

1000 V DC for MATPH-1000

Discharge voltage (Line to earth): 500 V DC

Voltage protection level (Up):

• MATPH-750

Line to line: 2.5 kV (@In)

Line to earth: 1.8 kV (@In)

• MATPH-1000

Line to line: 3.3 kV (@In)

Line to earth: 2.1 kV (@In)

Maximum discharge current (Imax): 20 kA (8/ 20 μsec.)

Nominal discharge current (In): 10 kA (8/ 20 μsec.)

Response time:

Line to line: ≤ 4 nsec.

Line to earth: ≤ 20 nsec.

Leakage current: ≤ 1 mA

Insulation resistance: ≥ 100 MΩ with 500 V DC (line to

alarm output)

Dielectric strength: 2000 V AC @ 1 minute (line to alarm

output)

POINTS OF CAUTION

■CONFORMITY WITH EU DIRECTIVES

• Altitude up to 2000 meters.

• The equipment must be installed such that appropriate

clearance and creepage distances are maintained to con-

form to CE requirements. Failure to observe these re-

quirements may invalidate the CE conformance.

■INSTALLATION

• DANGER!

DO NOT install the MATPH at the point common to an

external lightning protection device such as a lightning

rod. The MATPH will be subject to the danger of direct

lightning.

• DANGER!

DO NOT perform an installation and wiring of the MAT-

PH during thunder storms.

• Indoor use.

• Be sure to house the MATPH inside an metal enclosure

for safety. Even though the MATPH is capable of with-

standing an induced discharge current expected in nor-

mal conditions, it is entirely possible to be hit by a certain

strong lightning exceeding its designed capacity. It is also

subject to a direct hit by a lightning. The MATPH will be

destroyed by such high lightning energy.

• We recommend to install the MATPH in a position where

the monitor LED is clearly visible to facilitate inspection

and maintenance.

• DO NOT install the MATPH where it is subjected to con-

tinuous vibration. Do not apply physical impact to the

MATPH.

• Environmental temperature must be within -25 to +80°C

(-13 to +176°F) and relative humidity within 30 to 90%

RH in order to ensure adequate life span and operation.

■HIGH TEMPERATURE

• DANGER!

The front parts of the surface may be hot. DO NOT grab

the sides of the module. When the MATPH’s discharge

element (zinc oxide element) gradually degrades, its

increased leakage current causes high temperature at

the surface of the MATPH, until the discharge element

is finally separated from the power line by the thermal

breaker. However, a part of the module may already be

too hot to touch safely if the module is near the end of its

life.

■DIELECTRIC STRENGTH TESTING

• Conduct the dielectric strength test with all power sup-

ply wires removed. The MATPH will start discharging at

the described discharge voltage if a test voltage is applied

with all power supply wires connected. It will result in an

insulation failure.

■AND....

• We recommend that you keep spare MATPHs so that you

can replace them quickly when necessary.