EM-8128 Rev.10 P. 1 / 3

MG CO., LTD. www.mgco.jp

5-2-55 Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

INSTRUCTION MANUAL

LIGHTNING SURGE PROTECTOR FOR

STRAIN GAUGE USE MODEL MDP-LC

BEFORE USE ....

Thank you for choosing us. Before use, please check con-

tents of the package you received as outlined below.

If you have any problems or questions with the product,

please contact our sales office or representatives.

■PACKAGE INCLUDES:

Surge protector....................................................................(1)

DIN rail mounting adaptor*...............................................(1)

Screws for DIN rail mounting (M4 × 8)* ...........................(2)

*Included with option code /A33

■MODEL NO.

Confirm Model No. marking on the product to be exactly

what you ordered.

■INSTRUCTION MANUAL

This manual describes necessary points of caution when

you use this product, including installation, connection and

basic maintenance procedures.

LIMITATION APPLICABLE TO M-RESTER

The M-RESTER will protect electronics equipment from

damage caused by lightning by absorbing most of the

surge voltages.

However, M-RESTER may not be effective against cer-

tain extremely high voltages caused by a direct or almost

direct hit by lightning.

M-RESTER must be installed according to this installa-

tion / instruction manual.

GENERAL

■FUNCTION & FEATURES

• Designed to protect strain gauge transmitters from light-

ning surge damage that enters on the wiring between the

strain gauge and the transmitter

• Absorbs surges only without affecting instrumentation

signal

• No interruption of signal by unplugging the protector el-

ement

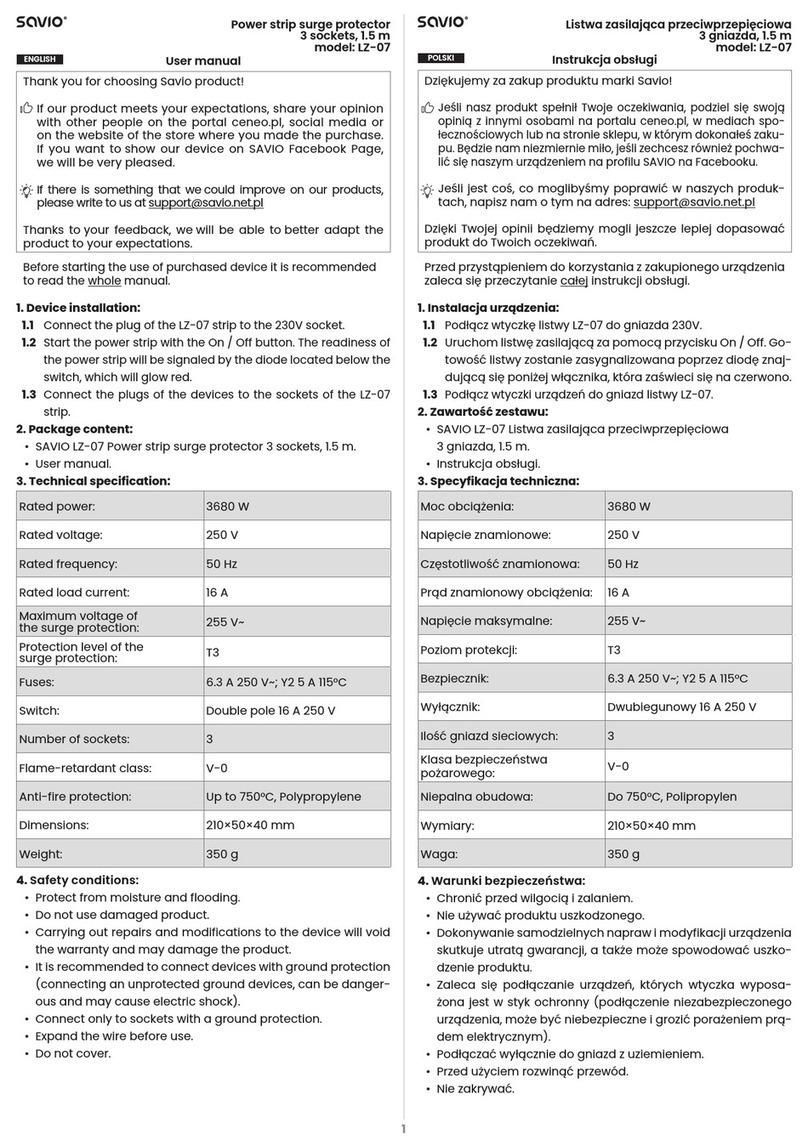

■SPECIFICATIONS

OUTPUT

SIDE

EXCITATION

SIDE

LINE TO

EARTH

Max. continuous

operating voltage (Uc)

±0.3V. 15V ±15V

Voltage protection level

(Up) @Imax

±15V 30V ±30V

Max. discharge current

(Imax) (8 / 20 µs)

100A 50A 50A

Max. discharge current

(Imax) (10 / 1000 µs)

25A 25A 25A

Leakage current ≤ 0.2µA

@±0.3V DC

≤ 2µA

@15V DC

≤ 2µA

@±15V DC

Capacitance @1 MHz ≤ 100 pF ≤ 4 nF ≤ 2 nF

Response time ≤ 5 nanoseconds

POINTS OF CAUTION

■ENVIRONMENT

• When heavy dust or metal particles are present in the

air, install the surge protector inside proper housing with

sufficient ventilation.

• Do not install the surge protector where it is subjected to

continuous vibration. Do not subject the unit to physical

impact.

• Environmental temperature must be within -5 to +55°C

(23 to 131°F) with relative humidity within 30 to 90% RH

in order to ensure adequate life span and operation.

■DIELECTRIC STRENGTH TEST

• Loosen the screw located at the left-center of the element

and remove the element module from the base before

conducting a dielectric strength testing. Otherwise the

element will start discharging at a voltage exceeding the

max. continuous operating voltage (Uc), which can cause

insulation failure of the module.

Be sure to return the element and fasten securely after

the test.

■AND ....

• We recommend that you keep spare surge protectors so

that you can replace them when necessary.

• Lightning surge can enter not only through signal lines

but also through power supply lines. We recommend that

you also use the surge protectors for power line for suffi-

cient protection.

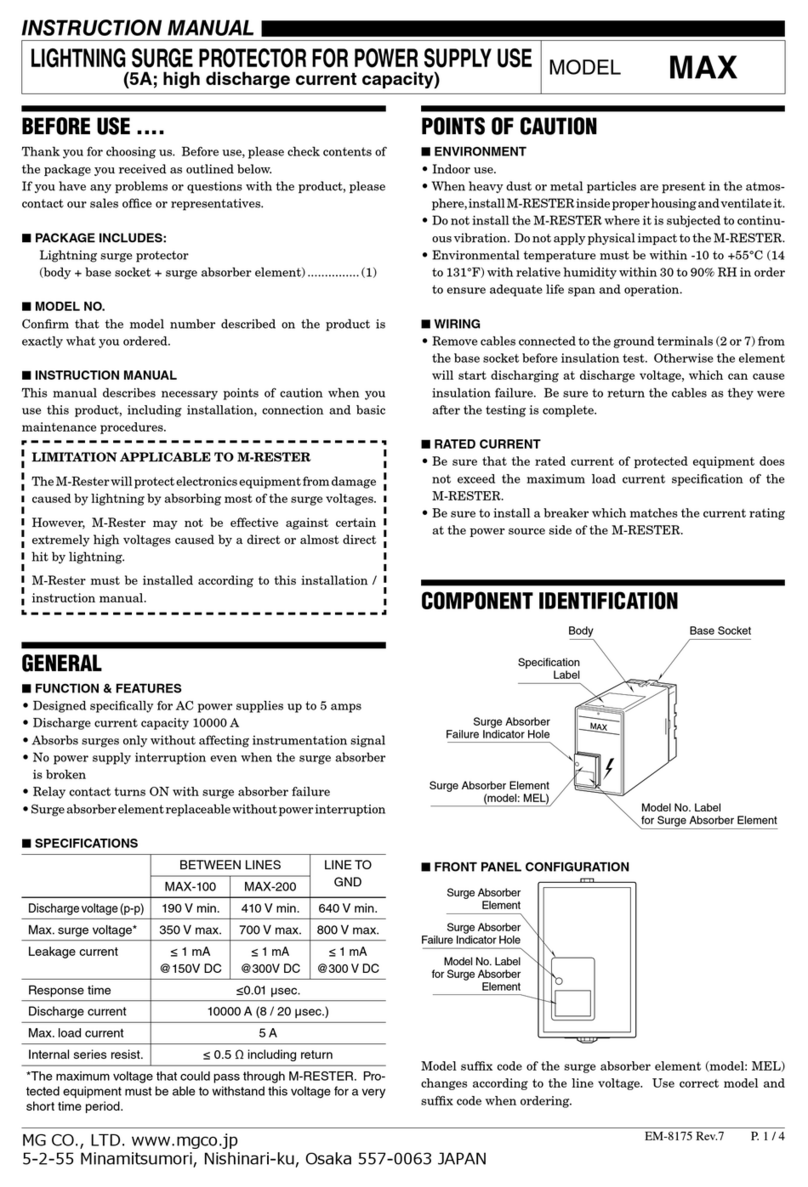

COMPONENT IDENTIFICATION

M•RESTER

Ground Terminal (G)

(used as mounting bracket)

Head Element Base

Specifications

Head Element is secured to Base

with screw when the surge protector