MGC RAXN-4000LCD User manual

MGC Network

Fire Control System

- System Normal -

Feb 21, 2018 2:21 PM

SIGNAL

SILENCE

FIRE

DRILL

SYSTEM

RESET

GENERAL

ALARM

ACKNOW-

LEDGE

LAMP

TEST

ENTER

TROUBLE

QUEUE

SUPV.

QUEUE

ALARM

QUEUE

MENU

CANCEL

INFO

MONITOR

QUEUE

A.C.

ON

PRE-

ALARM

GROUND

FAULT

Installation and Wiring Manual

Network Remote Annunciator Panel

LT-895MP Rev. 0

March 2021

RAXN-4000LCD

3

Table of Contents

1.0 Introduction 4

2.0 Installation Instructions 5

3.0 Jumper Settings 6

4.0 DIP Switch Settings 7

5.0 Wiring Instructions 8

6.0 Cable Connections 9

7.0 Specifications 10

8.0 Battery Calculations 11

9.0 Warranty and Warning Information 12

4

1.0 Introduction

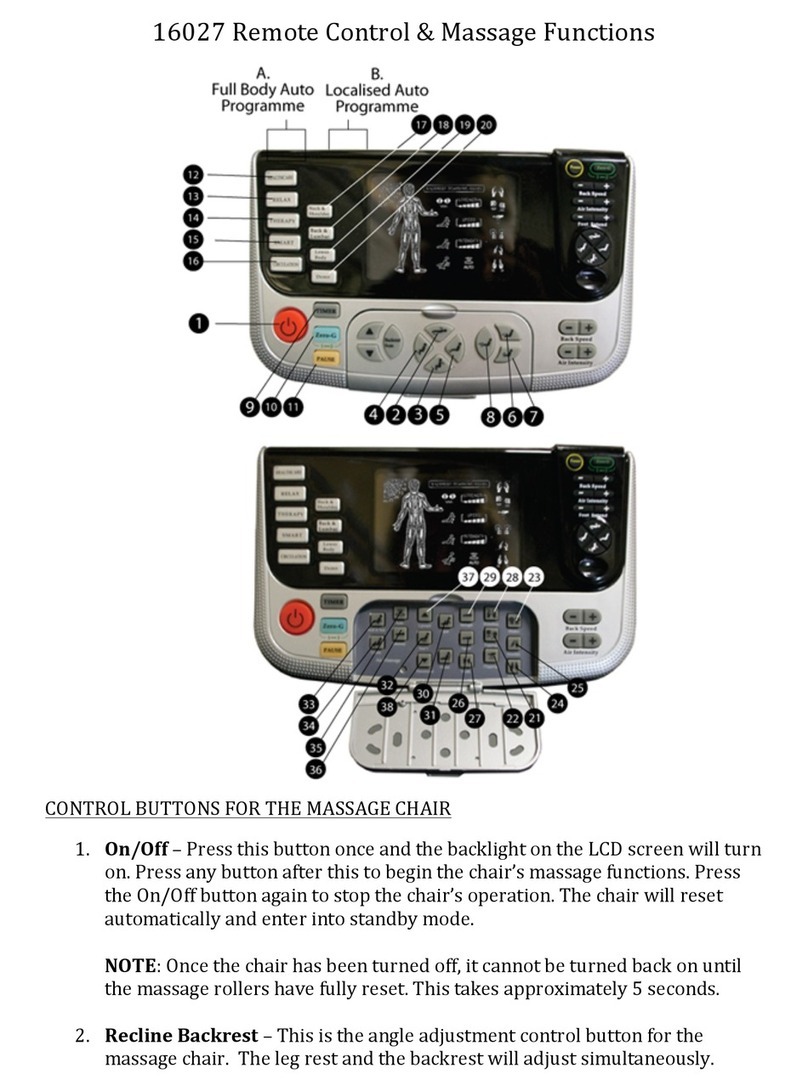

MGC’s remote shared display is the RAXN-4000LCD. The RAXN-4000LCD provides a replica

of the main Fire Alarm Panel display at a remote location. It is equipped with a large 4 line x 20

character back-lit alphanumeric LCD display that uses a simple menu system complete with a

directional keypad and switches for Enter, Menu, Cancel and Info. The display expands with

up to a total of 41 frames made up of display adder modules and up to 7 RAXN-4000LCDs per

node, refer to figure below. The RAXN-4000LCD may be mounted in the BB-1000 (MMX-BB-

1000) Series backboxes, the BB-5008, BB-5014, BBX-FXMNS (MMX-BBX-FXMNS) and FX-

LOC (MMX-LOC) enclosures.

IPS-2424DS

Programmable

Input Switches

[2 Frames]

QAZT-5302DS

Zoned Paging and

Telephone Selector

[1 Frame]

QMT-5302N

Master Telephone

[1 Frame]

QMP-5101N

Master Paging

[1 Frame]

QMP-5101NV

Master Paging

[1 Frame]

QMT-5302NV

Master Telephone

[1 Frame]

FDX-008W/KI

Fan Damper

Controller

[1 Frame]

RAX-1048TZDS

Adder

Annunciator

[3 Frames]

AGD-048

Graphic

Driver

[1 Frame]

PTR-2000-1

Line Printer

RAXN-4000LCD

Annunciator

External RS-485

RS-485 from Main Fire Alarm Board

The RAXN-4000LCD can support up to a maximum of 41

frames in any combination of annunciator type modules.

RS-232

5

2.0 Installation Instructions

The RAXN-4000LCD chassis is mounted with four hex nuts. Figure below shows the RAXN-

4000LCD mounted into a BB-1001D/DR/DS (MMX-BB-1001D/DR) backbox. Dimensions for

height and mounting hole locations change for the various backboxes as shown in the table

below.

BACKBOX MODEL

HEIGHT

OF

BACKBOX

H (IN.)

WIDTH OF

BACKBOX

(IN.)

HORIZONTAL

MOUNTING

HOLE DIM.

A (IN.)

VERTICAL

MOUNTIN

HOLE DIM.

B (IN.)

BB-1001D/DR/DS (MMX-BB-1001D/DR) 9.0” 12.75” 9.95” 7.5”

BB-1002D/DR/DS (MMX-BB-1002D/DR) 18.0” 12.75” 9.95” 16.5”

BB-1003D/DR/DS (MMX-BB-1003D/DR) 26.5” 12.75” 9.95” 24.9”

BB-1008D/DR/DS (MMX-BB-1008D/DR) 33.0” 22.5” 9.95” 35.2”

BB-1012D/DR/DS (MMX-BB-1012D/DR) 45.0” 22.5” 9.95” 52.0”

BACKBOX CAN BE MOUNTED

WITH STANDARD 4" X 4"

ELECTRICAL BOXES

BB-1001D/DR/DS BACKBOX IS SHOWN

RAXN-4000LCD ANNUNCIATOR

GB-1001RAXN GUARD BRACKET

B

12.75”

H

A

#6-32

HEXNUTS

1.85”

WALL

DOOR

BACKBOX

6

3.0 Jumper Settings

There are 3 jumpers located on the top left-hand side of the board position left to right as JW2,

JW1 and JW3.

Jumper Function

JW1 Left OPEN, used for hard reset.

JW2 CLOSED (jumper installed) for watchdog timer.

JW3 Left OPEN, if buzzer (located on the right-side of jumper JW3) is to be silenced.

Note: There are jumpers located in connectors P6 and P7. Remove these jumpers

when using adder modules beyond the first 13 frames. Refer to the Fire Alarm

Panel manual for further details.

i

RS-485 TERMINALS 24V POWER

TERMINALS

SW1

L

CD Display

C

ontrast Adjust

P5

P6 P7

up to a total of 13 frames.

P6 is an expansion connector for the next

14 frames and P7 for the next 14 frames

beyond that for a total of 41 frames. RS-232 Port for

Printer Connection

Jumpers:

JW2, JW1, JW3

ALARM

QUEUE

SUPV.

QUEUE

TROUBLE

QUEUE

MONITOR

QUEUE

MGC Network

Fire Alarm Control System

- System Normal -

SIGNAL

SILENCE

GENERAL

ALARM

ACKNOW-

LEDGE

FIRE

DRILL

SYSTEM

RESET

LAMP

TEST

February 21, 2018 10:08 AM

P5 connects to rst set of display modules,

7

4.0 DIP Switch Settings

Each RAXN-4000LCD Shared Display Annunciator needs to be assigned a unique address

via the DIP switches of SW1.

The RAXN-4000LCD SW1 DIP switches are set by selecting the active ON. The addresses

available for the RAXN-4000LCD are 33 to 39, inclusive. Set the address as follows in the

table below:

RAXN-4000LCD Remote Annunciator Address Setting (DIP SWITCH

SW1)

DIP switches are for assigning an address to the RAXN-4000LCD. Binary addresses 33 to 39

are available with the least significant bit being switch SW1-1 on the left and the most

significant bit being SW1-6. The ON setting is active binary. DIP switches SW1-7 and SW1-8

are not used.

For example, address 33 is set by pushing DIP switch SW1-6 and SW1-1 to the ON position

and all the other DIP switches to the OFF position.

Refer to Network Fire Alarm Manual as to whether addresses 37 to 39 are available.

RAXN-4000LCD

Address SW1-1 SW1-2 SW1-3 SW1-4 SW1-5 SW1-6 SW1-7 SW1-8

33 ON OFF OFF OFF OFF ON

Leave in “OFF”

position as

Factory Set.

34 OFF ON OFF OFF OFF ON

35 ON ON OFF OFF OFF ON

36 OFF OFF ON OFF OFF ON

Refer to Network Fire Alarm Manual as to whether addresses 37 to 39 are available

37 ON OFF ON OFF OFF ON

38 OFF ON ON OFF OFF ON

39 ON ON ON OFF OFF ON

SW1

18

ON

OFF

DIP switch SW1 is used to

set the address of the

RAXN-4000LCD

8

5.0 Wiring Instructions

RS-485 Wiring

The RS-485 wiring to the

RAXN-4000LCD Display

Module is recommended to

be twisted shielded pair as

shown in the diagram to the

right. The RS-485 wire

gauge may be:

• 22 AWG up to 2000 ft.

• 20 AWG up to 4000 ft.

The RS-485 wiring from the

fire alarm control panel to

the annunciator(s) must be

point-to-point from the fire

alarm panel to the first

annunciator, then to the next

annunciator, and so on. No

star wiring or T-tapping is

allowed.

Each RAXN-4000LCD

Shared Display has a 120

ohm end-of-line resistor on its RS-485 output terminals. This resistor is removed on all except

the last wired annunciator.

24V DC Wiring

The 24 VDC field wiring needs to be of an appropriate gauge for the number of annunciators

and the total wiring run length. Refer to section 8 on page 11 to calculate the maximum current

for all annunciators summed together.

Attention: Accidentally connecting any of the 24 VDC wires to the RS-485 wiring will result

in damage to the annunciator and/or to the fire alarm control panel to which it is

connected.

Total Maximum

Current for all

Annunciators

Maximum Wiring Run to Last Annunciator Max. Loop

Resistance

18 AWG 16 AWG 14 AWG 12 AWG

Amperes ft mft mft mft mOhms

0.12 1180 360 1850 567 3000 915 4250 1296 15

0.30 470 143 750 229 1200 366 1900 579 6

0.60 235 71 375 114 600 183 850 259 3

0.90 156 47 250 76 400 122 570 174 2

1.20 118 36 185 56 300 91 425 129 1.5

1.50 94 29 150 46 240 73 343 105 1.2

1.70 78 24 125 38 200 61 285 87 1.0

24 VDC

INPUT

-

+

-

+

24 VDC

OUTPUT

24 VDC POWER FROM FIRE ALARM MAIN BOARD

OR PREVIOUS ANNUNCIATOR

24 VDC POWER TO

NEXT ANNUNCIATOR

+

-

S

S

-

+

RS-485

INPUT

RS-485

OUTPUT

RS-485 TO NEXT ANNUNCIATOR

(TWISTED SHIELDED PAIR)

RS-485 FROM FIRE ALARM MAIN BOARD OR PREVIOUS

ANNUNCIATOR (TWISTED SHIELDED PAIR)

RAXN-4000LCD

ALL CIRCUITS ARE POWER LIMITED

AND MUST USE TYPE FPL, FPLR, OR

FPLP POWER LIMITED CABLE

!

9

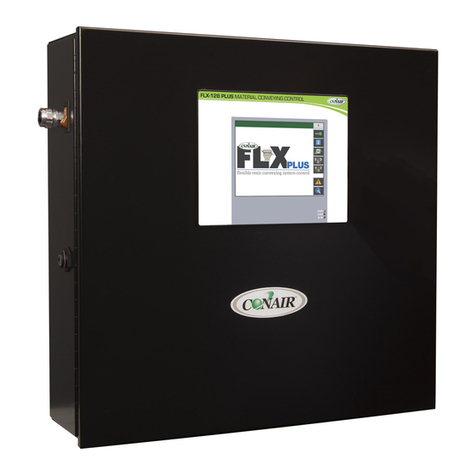

6.0 Cable Connections

The RAXN-4000LCD may be utilized by itself in a remote location or within a larger enclosure

together with other display modules. It may also be used as part of a mass notification system.

Below is an example of a RAXN-4000LCD and a RAX-1048TZDS 48 LED Annunciator

Display module in a BB-1002D/DR/DS (MMX-BB-1002D/DR) enclosure.

Connections on the

RAXN-4000LCD

Annunciator

P5: Connects to the RAX-

1048TZDS 48 LED Annunciator

module. This connector may

connect up to 13 frames of display

modules.

P6: Connects to next 14 frames (i.e.

frame 15 to 27) of display modules.

P7: Connects to next 14 frames (i.e.

frame 28 to 41) of display modules.

Terminals: Terminal wiring is

required for the RS-485 loop and the

24V DC power source. See section

5 on page 8 for details.

SW1: DIP switch SW1 is used to set

the address for the RAXN-4000LCD.

See section 6 on page 9 for details.

Connections on the RAX-1048TZDS 48 LED Annunciator Display Module:

P1: Connects to the main annunciator chassis RAXN-4000LCD P5.

P2: Connects to the next display module if used.

Note: The last annunciator must have a 120 ohm E.O.L. resistor connected to the RS-485

output terminals.

P2

RAX-1048TZDS Adder Annunciator or

IPS-2424DS Programmable Input Switches Module

POWER

TERMINALS

P1

P5

RAXN-4000LCD SHARED DISPLAY BOARD

RS-485

TERMINALS

SW1

ALARM

QUEUE

SUPV.

QUEUE

TROUBLE

QUEUE

MONITOR

QUEUE

MGC Network

Fire Alarm Control System

System Normal

February 21 2018 2:21PM

SIGNAL

SILENCE

GENERAL

ALARM

ACKNOW-

LEDGE

FIRE

DRILL

SYSTEM

RESET

LAMP

TEST

i

10

7.0 Specifications

Enclosure Models

BB-1001D/DR/DS (MMX-BB-1001D/DR): Backbox for one annunciator chassis with keylock

door.

BB-1002D/DR/DS (MMX-BB-1002D/DR): Backbox for up to two annunciator chassis with

keylock door.

BB-1003D/DR/DS (MMX-BB-1003D/DR): Backbox for up to three annunciator chassis with

keylock door.

BB-1008D/DR/DS (MMX-BB-1008D/DR): Backbox for up to eight annunciator chassis with

keylock door.

BB-1012D/DR/DS (MMX-BB-1012D/DR): Backbox for up to twelve annunciator chassis with

keylock door.

Other larger enclosures available are BB-5008, BB-5014, BBX-FXMNS (MMX-BBX-FXMNS)

and FX-LOC (MMX-LOC).

Annunciator Models

RAXN-4000LCD Remote Network Shared Display LCD Annunciator

• 24V DC nominal.

• Interconnects via one ribbon cable (or wiring) to the Main Network Fire Alarm Panel or to

previous RAXN-4000LCD.

• Provides exact functions as the main display.

• Standby: 139 mA Max., All LEDs ON: 164 mA Max.

RAX-1048TZDS Adder Annunciator Module (48 Display Points)

• Interconnects via one ribbon cable from RAXN-4000LCD or to previous RAX-1048TZDS

or IPS-2424DS to the next RAX-1048TZDS or IPS-2424DS.

• Annunciation of up to 48 additional points.

• Standby: 22 mA Max., All LEDs ON: 262 mA Max.

Note: Finish: Backbox painted black, white painted door (standard), suffix “R” for red

painted door or suffix “S” for stainless steel finish.

Material: 16 G.A cold rolled steel (CRS)

See section 2 on page 5 for enclosure dimensions.

i

11

8.0 Battery Calculations

Current Drain for Battery Calculations

The following are the currents for the RAXN-4000LCD to which is added the number of RAX-

1048TZDS and/or IPS-2424DS or FDX-008W(KI) used:

Normal Standby Current = 139 mA + ___________ x 22 mA + ___________ x 10mA = _______

[number of RAX-1048TZDS] [number of IPS-2424DS]

Maximum Alarm Current = 164 mA + ___________ x 35 mA + ___________ x 15mA = _______

[number of RAX-1048TZDS] [number of IPS-2424DS]

The Normal Standby Current is used for battery size calculations (see the Network Fire

Alarm Manual for battery calculations) and includes the current drain for the Trouble Buzzer,

Trouble LED, and one alarm LED. The Maximum Alarm Current is used to calculate the wire

size required (see section 5 on page 8).

12

9.0 Warranty and Warning Information

WARNING!

Please read this document CAREFULLY, as it contains important warnings, life-safety, and

practical information about all products manufactured by the Mircom Group of Companies,

including Mircom and Secutron branded products, which shall include without limitation all fire

alarm, nurse call, building automation and access control and card access products

(hereinafter individually or collectively, as applicable, referred to as “Mircom System”).

NOTE TO ALL READERS:

1. Nature of Warnings. The within warnings are communicated to the reader out of an

abundance of caution and create no legal obligation for Mircom Group of Companies,

whatsoever. Without limiting the generality of the foregoing, this document shall NOT be

construed as in any way altering the rights and obligations of the parties, governed by the legal

documents that apply in any given circumstance.

2. Application. The warnings contained in this document apply to all Mircom System and shall

be read in conjunction with:

a. the product manual for the specific Mircom System that applies in given circumstances;

b. legal documents that apply to the purchase and sale of a Mircom System, which may

include the company’s standard terms and conditions and warranty statements;

c. other information about the Mircom System or the parties’ rights and obligations as may

be application to a given circumstance.

3. Security and Insurance. Regardless of its capabilities, no Mircom System is a substitute for

property or life insurance. Nor is the system a substitute for property owners, renters, or other

occupants to act prudently to prevent or minimize the harmful effects of an emergency

situation. Building automation systems produced by the Mircom Group of Companies are not

to be used as a fire, alarm, or life-safety system.

NOTE TO INSTALLERS:

All Mircom Systems have been carefully designed to be as effective as possible. However,

there are circumstances where they may not provide protection. Some reasons for system

failure include the following. As the only individual in contact with system users, please bring

each item in this warning to the attention of the users of this Mircom System. Failure to

properly inform system end-users of the circumstances in which the system might fail may

result in over-reliance upon the system. As a result, it is imperative that you properly inform

each customer for whom you install the system of the possible forms of failure:

4. Inadequate Installation. All Mircom Systems must be installed in accordance with all the

applicable codes and standards in order to provide adequate protection. National standards

require an inspection and approval to be conducted by the local authority having jurisdiction

following the initial installation of the system and following any changes to the system. Such

inspections ensure installation has been carried out properly.

5. Inadequate Testing. Most problems that would prevent an alarm a Mircom System from

operating as intended can be discovered by regular testing and maintenance. The complete

system should be tested by the local authority having jurisdiction immediately after a fire,

storm, earthquake, accident, or any kind of construction activity inside or outside the premises.

13

The testing should include all sensing devices, keypads, consoles, alarm indicating devices

and any other operational devices that are part of the system.

NOTE TO USERS:

All Mircom Systems have been carefully designed to be as effective as possible. However,

there are circumstances where they may not provide protection. Some reasons for system

failure include the following. The end user can minimize the occurrence of any of the following

by proper training, testing and maintenance of the Mircom Systems:

6. Inadequate Testing and Maintenance. It is imperative that the systems be periodically

tested and subjected to preventative maintenance. Best practices and local authority having

jurisdiction determine the frequency and type of testing that is required at a minimum. Mircom

System may not function properly, and the occurrence of other system failures identified below

may not be minimized, if the periodic testing and maintenance of Mircom Systems is not

completed with diligence and as required.

7. Improper Operation. It is important that all system users be trained in the correct operation

of the alarm system and that they know how to respond when the system indicates an alarm.

A Mircom System may not function as intended during an emergency situation where the user

is unable to operate a panic or emergency switch by reason of permanent or temporary

physical disability, inability to reach the device in time, unfamiliarity with the correct operation,

or related circumstances.

8. Insufficient Time. There may be circumstances when a Mircom System will operate as

intended, yet the occupants will not be protected from the emergency due to their inability to

respond to the warnings in a timely manner. If the system is monitored, the response may not

occur in time enough to protect the occupants or their belongings.

9. Carelessness or Safety Hazards. Moreover, smoke detectors may not provide timely

warning of fires caused by carelessness or safety hazards such as smoking in bed, violent

explosions, escaping gas, improper storage of flammable materials, overloaded electrical

circuits or children playing with matches or arson.

10. Power Failure. Some Mircom System components require adequate electrical power supply

to operate. Examples include: smoke detectors, beacons, HVAC, and lighting controllers. If a

device operates only by AC power, any interruption, however brief, will render that device

inoperative while it does not have power. Power interruptions of any length are often

accompanied by voltage fluctuations which may damage Mircom Systems or other electronic

equipment. After a power interruption has occurred, immediately conduct a complete system

test to ensure that the system operates as intended.

11. Battery Failure. If the Mircom System or any device connected to the system operates from

batteries it is possible for the batteries to fail. Even if the batteries have not failed, they must be

fully charged, in good condition, and installed correctly. Some Mircom Systems use

replaceable batteries, which have a limited life-span. The expected battery life is variable and

in part dependent on the device environment, usage and type. Ambient conditions such as

high humidity, high or low temperatures, or large temperature fluctuations may reduce the

expected battery life. Moreover, some Mircom Systems do not have a battery monitor that

would alert the user in the event that the battery is nearing its end of life. Regular testing and

replacements are vital for ensuring that the batteries function as expected, whether or not a

device has a low-battery monitor.

12. Physical Obstructions. Motion sensors that are part of a Mircom System must be kept clear

of any obstacles which impede the sensors’ ability to detect movement. Signals being

communicated by a Mircom System may not reach the receiver if an item (such as metal,

water, or concrete) is placed on or near the radio path. Deliberate jamming or other

inadvertent radio signal interference can also negatively affect system operation.

14

13. Wireless Devices Placement Proximity. Moreover all wireless devices must be a minimum

and maximum distance away from large metal objects, such as refrigerators. You are required

to consult the specific Mircom System manual and application guide for any maximum

distances required between devices and suggested placement of wireless devices for optimal

functioning.

14. Failure to Trigger Sensors. Moreover, Mircom Systems may fail to operate as intended if

motion, heat, or smoke sensors are not triggered.

a. Sensors in a fire system may fail to be triggered when the fire is in a chimney, walls, roof,

or on the other side of closed doors. Smoke and heat detectors may not detect smoke

or heat from fires on another level of the residence or building. In this situation the

control panel may not alert occupants of a fire.

b. Sensors in a nurse call system may fail to be triggered when movement is occurring

outside of the motion sensors’ range. For example, if movement is occurring on the other

side of closed doors or on another level of the residence or building the motion detector

may not be triggered. In this situation the central controller may not register an alarm

signal.

15. Interference with Audible Notification Appliances. Audible notification appliances may be

interfered with by other noise sources such as stereos, radios, televisions, air conditioners,

appliances, or passing traffic. Audible notification appliances, however loud, may not be heard

by a hearing-impaired person.

16. Other Impairments. Alarm notification appliances such as sirens, bells, horns, or strobes

may not warn or waken a sleeping occupant if there is an intervening wall or door. It is less

likely that the occupants will be alerted or awakened when notification appliances are located

on a different level of the residence or premise.

17. Software Malfunction. Most Mircom Systems contain software. No warranties are provided

as to the software components of any products or stand-alone software products within a

Mircom System. For a full statement of the warranties and exclusions and limitations of

liability please refer to the company’s standard Terms and Conditions and Warranties.

18. Telephone Lines Malfunction. Telephone service can cause system failure where telephone

lines are relied upon by a Mircom System. Alarms and information coming from a Mircom

System may not be transmitted if a phone line is out of service or busy for a certain period of

time. Alarms and information may not be transmitted where telephone lines have been

compromised by criminal tampering, local construction, storms or earthquakes.

19. Component Failure. Although every effort has been made to make this Mircom System as

reliable as possible, the system may fail to function as intended due to the failure of a

component.

20. Integrated Products. Mircom System might not function as intended if it is connected to a

non-Mircom product or to a Mircom product that is deemed non-compatible with a particular

Mircom System. A list of compatible products can be requested and obtained.

Warranty

Purchase of all Mircom products is governed by:

https://www.mircom.com/product-warranty

https://www.mircom.com/purchase-terms-and-conditions

https://www.mircom.com/software-license-terms-and-conditions

15

U.S.A

4575 Witmer Industrial Estates

Niagara Falls, NY 14305

Tel: (905) 660-4655

(888) 660-4655

Fax: (905) 660-4113

© Mircom 2021

Printed in Canada

Subject to change without prior notice

www.mircom.com

CANADA - Main Office

25 Interchange Way

Vaughan, ON L4K 5W3

Tel: (905) 660-4655

(888) 660-4655

Fax: (905) 660-4113

Table of contents