AdvanteX VCOM AX20-A1 User manual

Anchorage Tank II Inc., 2723 Rampart Drive, Anchorage, AK 99501 907-272-3543 anchoragetank.com Page 1

VCOM AX20-A1 Control Panel Installation Manual

Successful installation of an AdvanTex Control Panel requires an understanding

of all this information.

So, before rolling up your sleeves, please take the time and read through this manual.

Reading this manual and maintaining current and accurate records will save everyone time,

trouble, and money in the long run.

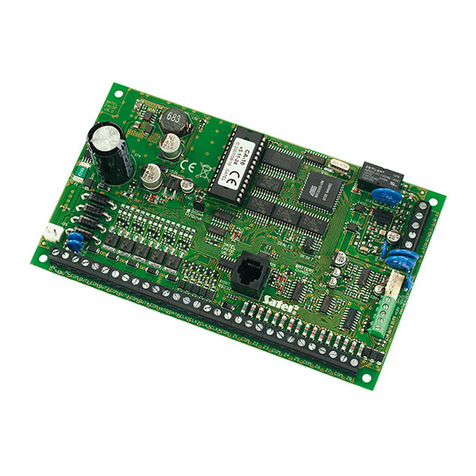

A

Panel

for Gravity Discharge

Anchorage Tank II Inc., 2723 Rampart Drive, Anchorage, AK 99501 907-272-3543 anchoragetank.com

Page 2

VCOM AX20-A1 Control Panel Installation Manual

Installing the Control Panel

In the Municipality ofAnchorage, an electrician must be employed to do the

wiring. Outside the city, whether required or not, this is a good idea unless

one is thoroughly familiar with wiring and local codes.

Key Point: Thecontrolpanelhasadistinctidentityandhas

been assigned to the address of that particular

job site.

On the inside of the control panel door, you will find a label that shows

the model number and a six-digit RTU number. (RTU stands for Remote

Telemetry Unit). The RTU number is the identity of the system for as

long as it is in operation. Why is this a big deal to you? Well... if you are

installing and taking possession of more than one system at a time, it is

easy to simply grab the first panel you find... and it may end up at the

wrong house! Anchorage Tank makes the RTU / address assignments

as systems are sold so if you get confused - please callAnchorage Tank.

This has happened before. Imagine how much fun it is to have a control

panel “phone home” with an issue and the Service Provider shows up at

the wrong house where nothing is wrong.

Placement of the Control Panel

There has been a lot of debate where to place the Control Panel. Each site

is different but the rule of thumb is that the physical installation of the Con-

trol Panel should be within view of the Tank & Filter, at a convenient height,

usually 5 feet above grade.

The Control Panel contains motor contactors that make a clunking sound

each time the pump is activated. If the Panel is attached to the wall of a

house, it sounds like a moose kicking the wall every twenty minutes. With

that in mind, it is preferable to mount the Panel on a treated 4x6 post right

next to the wall.

The Control Panel should NOT be placed

inside the home. The idea is for the Service

Providertoaccessthepanelformaintenance

and emergency situations and NOT bother

the homeowner.

Initially it may sound good to have the panel

locatedindoors but it actually isn’t. Thepanel

is designed to be located outside.

IMPORTANT:

4 x 6

Anchorage Tank II Inc., 2723 Rampart Drive, Anchorage, AK 99501 907-272-3543 anchoragetank.com Page 3

VCOM AX20-A1 Control Panel Installation Manual

Installing the Control Panel

Floats and Pumps

Do not remove the colored

markers or the paper tags from the

float cords. These should be left

on the float cord, outside the splice

box.

Do not thread the markers and

tags through the cord grips.

Adequate length of cord should

be left within the splice box to allow

for easy removal for future discon-

necting and re-splicing.

Wire that is improperly sized

(too small) can cause excessive

voltage drop, poor pump perfor-

mance, and premature failure.

Splices that are not waterproof

will cause malfunction of the pump

controls if water should leak into

the splice box.

We’ve seen it happen.

Key Points: At this point, the floats and pump is in place and their wires have

been stabbed into the splice box.

Just in case they aren’t, thread the float and pump cords through

the cord grips into the PVC splice box, leaving adequate length of

electrical cord coiled inside the riser to allow easy removal of the

pump and float assembly. Tighten the cord grips by hand and then

check the tightness by tugging on each cord.

The wires from the Control Panel to the splice box should be run

in conduit. A conduit seal should be used to prevent infiltration

of water into the splice box. The number of wires depends upon

the number of pumps and floats, but most 3-float 1-pump systems

use 2 runs of 3-wire 12 GA direct-burial. That gives you a total of 6

wires and two bare grounds.

All splices made in the splice box should use waterproof wire nuts

or butt connectors and heat shrink tubing.

At the home’s electrical panel, you will use two 20 amp

breakers, one for the control side of the panel and the

other for the pump side.

HANDY HINT

Don’t forget the remote alarm. This

connects to the control panel using

phone wire and is normally placed

inside the garage.

The remote alarm is a code require-

ment.

IMPORTANT:

Anchorage Tank II Inc., 2723 Rampart Drive, Anchorage, AK 99501 907-272-3543 anchoragetank.com

Page 4

VCOM AX20-A1 Control Panel Installation Manual

Connecting to the Control Panel

Connect the wires coming from the floats to the terminals in the Control

Panel. Refer to the appropriate Float & Splice Box Wiring Diagram for the

correct terminal locations for your system.

Connect the wire coming from your pump to the pump terminal. The Panel

WiringDiagramwilldisplay the correct terminal connections for your system.

Connect the incoming power to the panel. Power to the panel must be ap-

propriate to the Control Panel and pump motor e.g., 120 VAC, single phase

for a 120 VAC motor, 240 VAC single phase for a 240 VAC motor, etc.)

Ensure that the panel is properly grounded and that the fuse or breaker

and wire size, from the main power panel to the pump, are correctly sized.

A separate circuit for the pump controls and each of the pump motors is

recommended.

Note: Voltage for the controls in the panel is always 120 VAC, although

the pump voltage may be 120 VAC or 240 VAC.

Use 600 CU conductors only. Torque to the following: Terminal blocks @ 15

LB-IN. Circuit breaker @ 20 LB-IN and ground lugs @ 45 LB-IN.

Do not service the pump or any elec-

trical wiring in the pump vault without

disconnecting the power at the circuit

breaker and/or fuse.

Serious injury and/or damage to the

system could result if the panel is not

properly grounded. Ensure that the

fuse, breaker, and wire size, from the

main power panel and to the pump,

are sized correctly.

The pump vault is a hazardous area

and may contain explosive gas-

es. Take appropriate precautions

according to local, state, and federal

regulations before commencing work

in the pump vault.

It is the responsibility of the installer

to comply with all local, state, and

federal regulations that may govern

the installation of systems of this

nature. Failure to comply with such

regulations may void the manufac-

turer’s warranty and could possibly

cause bodily injury.

Key Points:

To permit remote monitoring of the system, the VeriComm Control Panels have the option to utilize a common phone

line or a high speed internet connection. You will need to check with the homeowner to determine which connection

method is available or desired.

Should they decide on a regular phone line, please be aware these panels do not need a dedicated phone line,

merely an extension of an existing line.

Installation of a tradional copper-wire analog telephone line is straight-forward. You’ll notice a phone jack connection in

the middle of the control panel. A DSL line filter/surge arrestor is also installed. Once you have a dial tone at the end of

this phone line, just plug it in and you’re good to go.

Digital connections (internet) will require an ethernet cable run from the House Internet Router out to the control

panel to connect to the Lantronics equipment mounted on the inside of the control panel door.

Connecting for Remote Monitoring

Anchorage Tank II Inc., 2723 Rampart Drive, Anchorage, AK 99501 907-272-3543 anchoragetank.com Page 5

VCOM AX20-A1 Control Panel Installation Manual

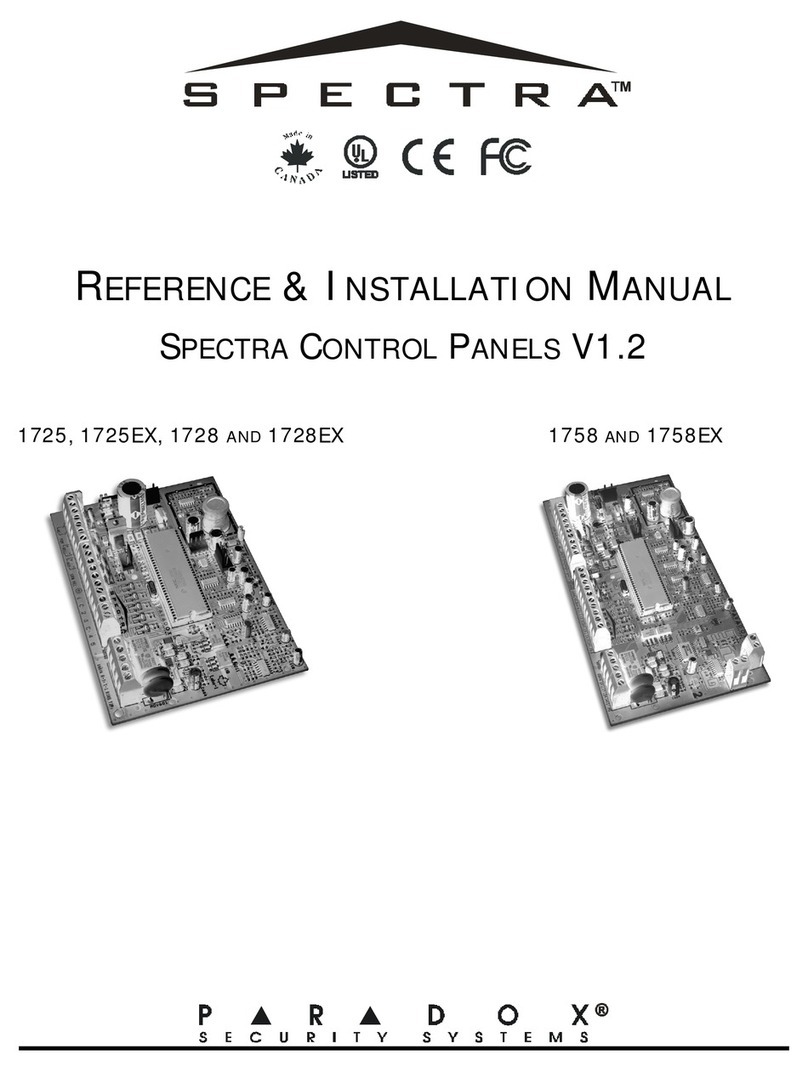

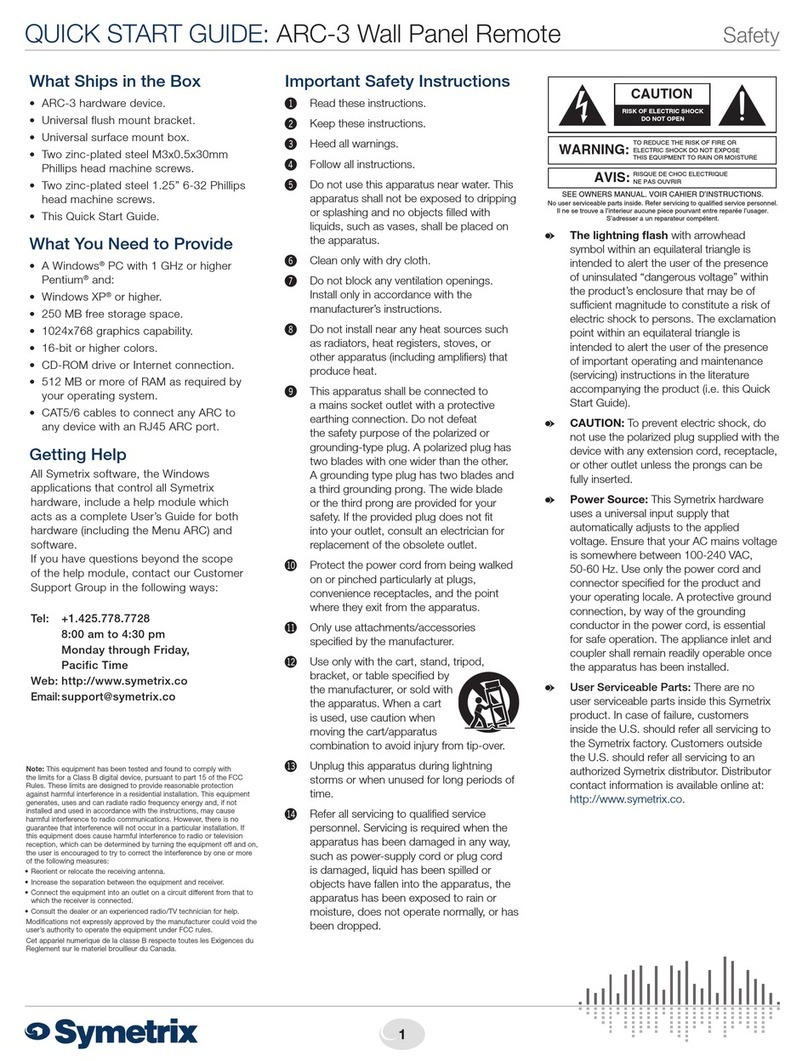

Control Panel Wiring Diagram

Model VCOM-AX20A1 RA IP

Pump

115 VAC / 1 Hp.

1 Phase / 60 Hz.

EDW-WD-AX-121

Rev. 8.0 © 06/24/13

From Main Power Panel

115 VAC, 1 Phase, 60 Hz.

Pump

L1

Pump

Neutral

N1 PCB

20A

Factory default.

Wire as shown.

Two Circuits One Circuit

Use one wire nut to connect the pump

and controls circuit breakers together

with the incoming L1 power line. Use

another wire nut to connect the pump

and controls neutral blocks together

with the incoming neutral line.

Power Wiring Options

Pump Neutral

ON

20

PUMP

ON

10

CONTROLS

Ground

Controls Neutral

Pump L1

Controls L1

N1

Ground

L1

Neutral

ON

20

PUMP

ON

10

CONTROLS

Wire

Nut

NN1N

Terminal

Strip

Controls

Neutral

Ground

Green

Controls

L1

NOTE: Motors must have

internal overload protection

For float arrangement diagram,

see drawing no.

"EDW-FS-AX-1".

Main disconnect

provided by others.

A-+

AL

RMA1A2

X2X1

DO4

(4)

DO3

(3)

RTU

AS

5 6 N

M

L1

T1

M

L2

T2

PRL

GX1X2

Options*

COM

(5)

DO1

(1)

DO2

(2) TB2

DI1

(9)

DI2

(10)

DI5

(13)

DI4

(12)

DI3

(11)

DI6

(14)

DI7

(15)

RET

(17)

DI8

(16)

M1314

0DF

123

TR

TB1

J3

HT

AUTO

(MAN)

SA

Ground

Lug

CCB

10A

GX2X1

PL

J1

Options*

1234

Surge

Protected

Terminal Block Types

Standard

RET

(18)

24VDC

(8)

SA1 SA2

Options*

Remote Alarm Connections

Note: 115VAC signal is present

during alarm conditions.

Orenco Model

AHW or equiv.

Remote Alarm

Light Alarm

N0

For VCOM-AX20A

operation description,

see drawing no.

"EIN-CP-OP-505".

TL

Options*

PSA

Phone Line In

A

AL

AS

CCB

DF

M

PCB

RA

RTU

SEA

TL

TR

HT

PL

PRL

PSA

SA

Key

= Factory Wire

= Field Wire

= Alternate Field Wire

= Audio Alarm, 115 VAC

= Alarm Light

= Audio Silence Switch

= Controls Circuit Breaker

= Fuse, 120VAC/1A

= Motor Contactor

= Pump Circuit Breaker

= Remote Alarm Relay

= ATRTU-100 Controller

= Serial to Ethernet Adapter

= Terminal Link

= Transformer 120-36/18VAC

*Options

= Heater

= Power Light

= Pump Run Light

= Phone Line Surge Arrester

= Surge Arrester

SEA

RS232 Port

10/100

Port

9-30VDC

Port

CAT 5

10/100Base-T

Ethernet

Line In

J2

Communication

Cable

CR1 A2A1

RA

Remote Alarm

Dry Contact

22

21

CR1

1411

Control Panel Wiring Diagram

Installations in ex-

isting construction

may pose issues

in providing power

to the septic panel.

A suggestion is to

install a sub panel,

like they do for a

hot tub instattation.

Anchorage Tank II Inc., 2723 Rampart Drive, Anchorage, AK 99501 907-272-3543 anchoragetank.com

Page 6

VCOM AX20-A1 Control Panel Installation Manual

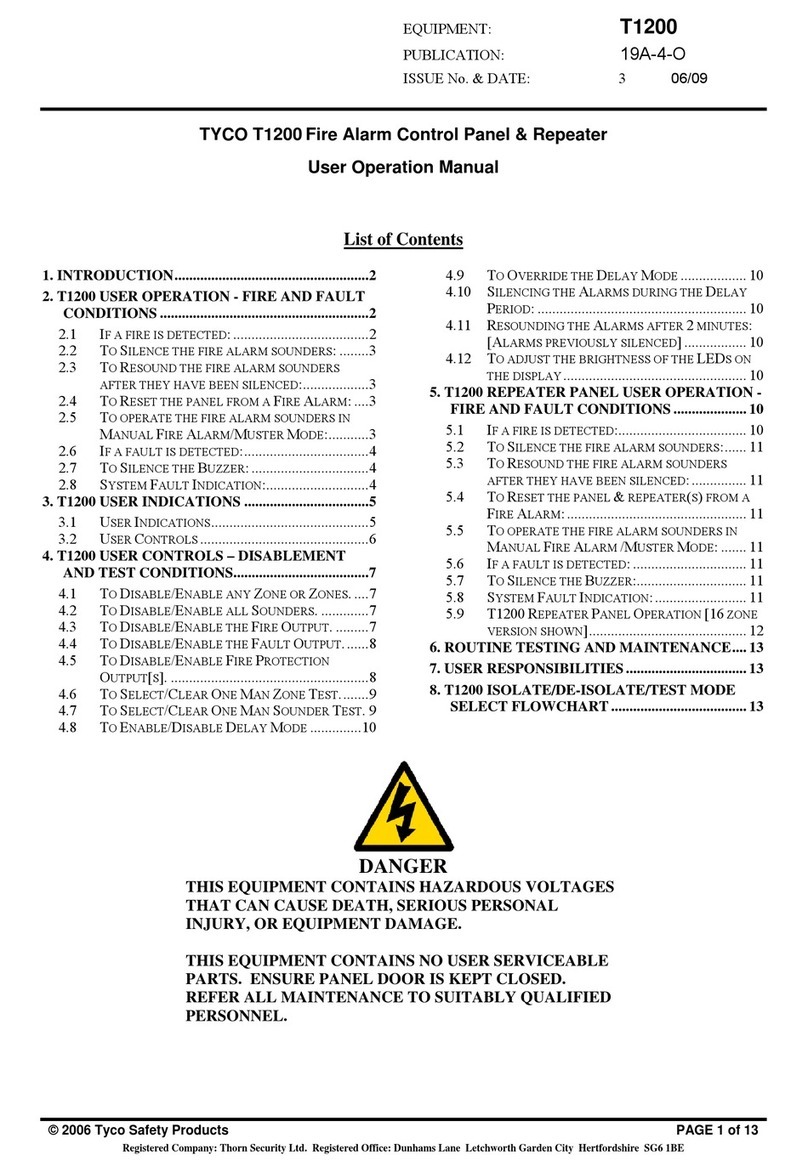

Float& Splice Box WiringDiagram

Drawing No.

EDW-FS-AX-1

Control Panel Series

VCOM-AXA

Terminal Strip

High Level Alarm

Y-Yellow

Override Timer

On & Off

G-Green

Redundant Off &

Low Level Alarm

W-White

Float Function Color Code

YGW

Splice Box Model

SB4

1 2 3 4

Note:Multi-functionfloatswillhave

more than one marker

Float Tag Colors

Y

P

B

G

Yellow

Purple

Blue

Green

-

-

-

-

R

O

E

W

Red

Orange

Grey

White

-

-

-

-

Key

Black Wire

Green Wire

White Wire

Heat Shrink &

Butt Connector *

Waterproof

Wire Nut

Specs: contact - normally open

differential - no minimum

power rating - signal

Typical Orenco float model: A

Float Arrangement

Float Types

Splice Box Wiring

WG

Override Timer On & Off Redundant Off &

Low Level Alarm

High Level Alarm Pump Cord

Y

Attention: Failureto follow splicing

instructions will void warranty

* Refer to drawing EIN-SB-SB-1

for splicing instructions.

To Terminal

#4

To Terminal

#3

To Ground

Terminal

To Terminal

#6

To Terminal

#5

To Terminal

#2 To Terminal

#1

Cord Grip

Hand tighten each cord grip

so that the cord will not easily

slide through the grommet.

Float and Splice Box Wiring Diagram

Contrary to what this diagram shows, Orenco no longer color codes their float wires.

Because of this, you will want to mark the yellow float cords yourself with a black

Sharpiepen. For example: place a tickmark IforYellow,II forGreen, and III for White.

IMPORTANT:

I

II

III

I

II III

I

II III

Anchorage Tank II Inc., 2723 Rampart Drive, Anchorage, AK 99501 907-272-3543 anchoragetank.com Page 7

VCOM AX20-A1 Control Panel Installation Manual

The VCOM-AXA telemetry-enabled panel is used for remote moni-

toringandcontrol of timed, recirculating simplex pumping operations

with gravity discharge.

Basic control logic manages the day-to-day functionality of the

Control Panel. The VCOM-AXA system continuously recirculates,

until the Recirculating Splitter Valve (RSV) seats, then the system

discharges small amounts of treated wastewater throughout the

day. During peak flow conditions, more aggressive timer settings

(overrides) are used to manage the increased demand.

Fault conditions are automatically reported to the VeriComm Mon-

itoring System (a web-based database by Orenco Systems) and

not locally at the panel, making the system virtually invisible to the

homeowner. Alarms and Alerts cause an email to be forwarded to

Anchorage Tank personnel. However, if these conditions are not

respondedto, or thesystemcannotcommunicate with theVeriComm

Monitoring System (the phone line or internet might not be connect-

ed), then the local alarms at the Panel will activate.

To silence local alarms, press the “Push to Silence” button until the

audible alarm stops.

Control Panel Operation

What’s so special about this gray box?

Anchorage Tank II Inc., 2723 Rampart Drive, Anchorage, AK 99501 907-272-3543 anchoragetank.com

Page 8

VCOM AX20-A1 Control Panel Installation Manual

Now that you are finished..... call Anchorage Tank

When the system is complete and the communication line is installed, please give

a call to Anchorage Tank so we can get it registered with both Orenco Systems and

VeriComm, and schedule the System Start-Up with the Service Provider.

Any information you can provide is extremely helpful such as... Home for sale? Home

even built? Anyone living there now? Power turned on/off? Homeowner information

such as name & phone number.And anything else that might help the transition.

272-3543

Other AdvanteX Control Panel manuals