MGC SD-100 Series User manual

LT-1055 rev 3 12/14/22

1

25 Interchange way, Vaughan Ontario. L4K 5W3

Phone: 905.660.4655; Fax: 905.660.4113

Web: www.mircomgroup.com

GENERAL DESCRIPTION

• Model SD-100-2WT: 2-Wire Photoelectric Smoke Detector with Heat

Sensor and Remote Indicator

• Model SD-100-4WT: 4-Wire Photoelectric Smoke Detector with Heat

Sensor

• Model SD-100-2WP: 2-Wire Photoelectric Smoke Detector with

Remote Indicator

• Model SD-100-4WP: 4-Wire Photoelectric Smoke Detector

All models incorporate a microprocessor with an advanced optical sensing

chamber. Models SD-100-2WT and SD-100-4WT feature a restorable,

fixed temperature (135°F/57.2°C) thermal detector. SD-100 Series

detectors are designed to provide open area protection.

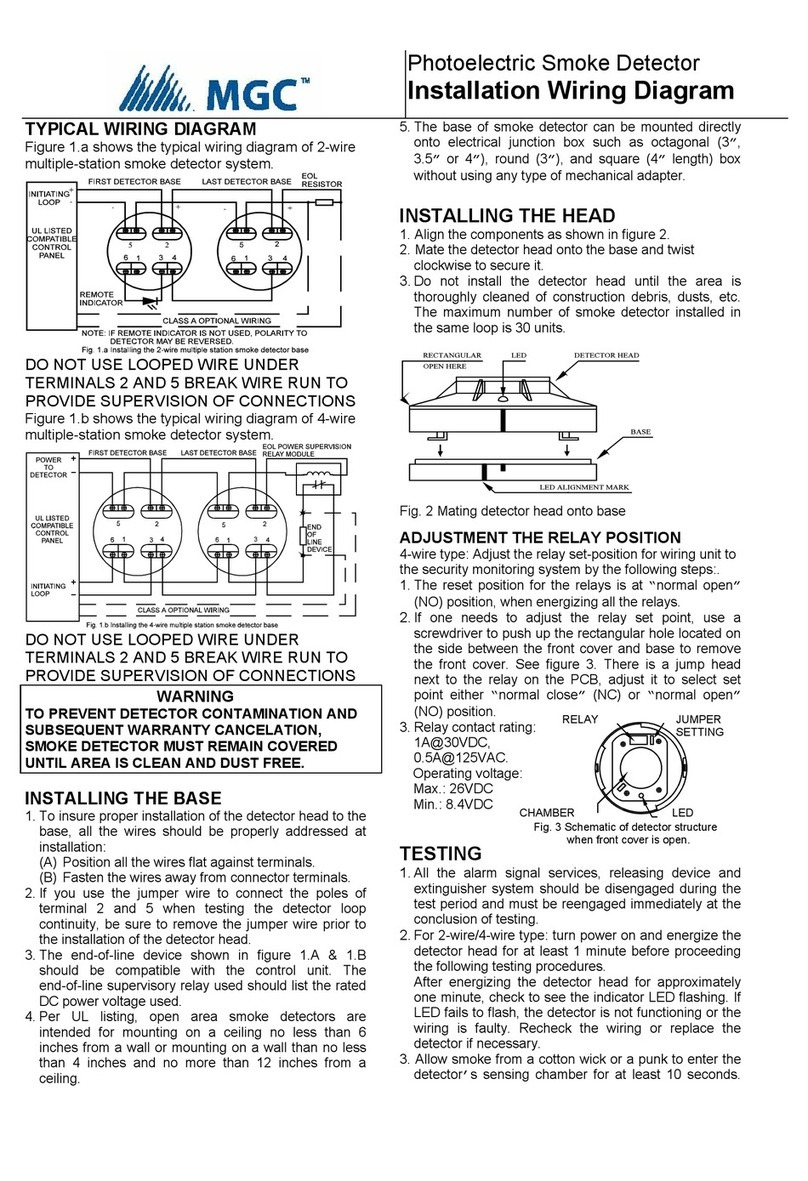

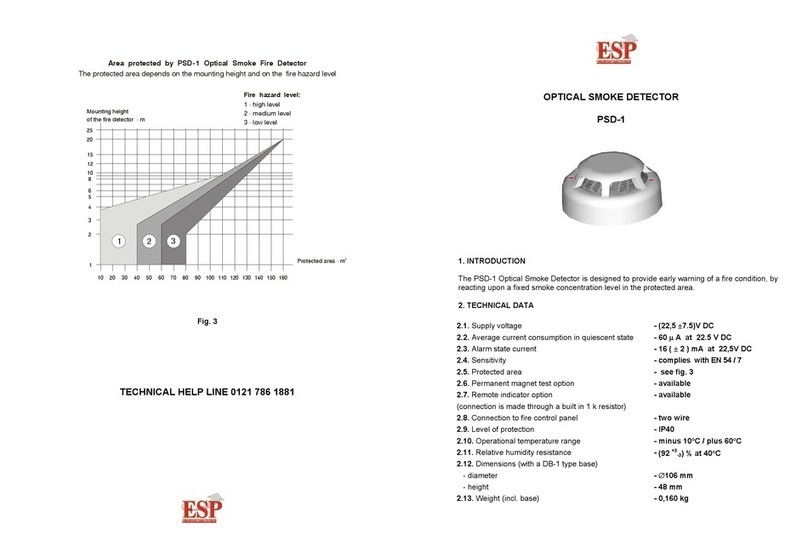

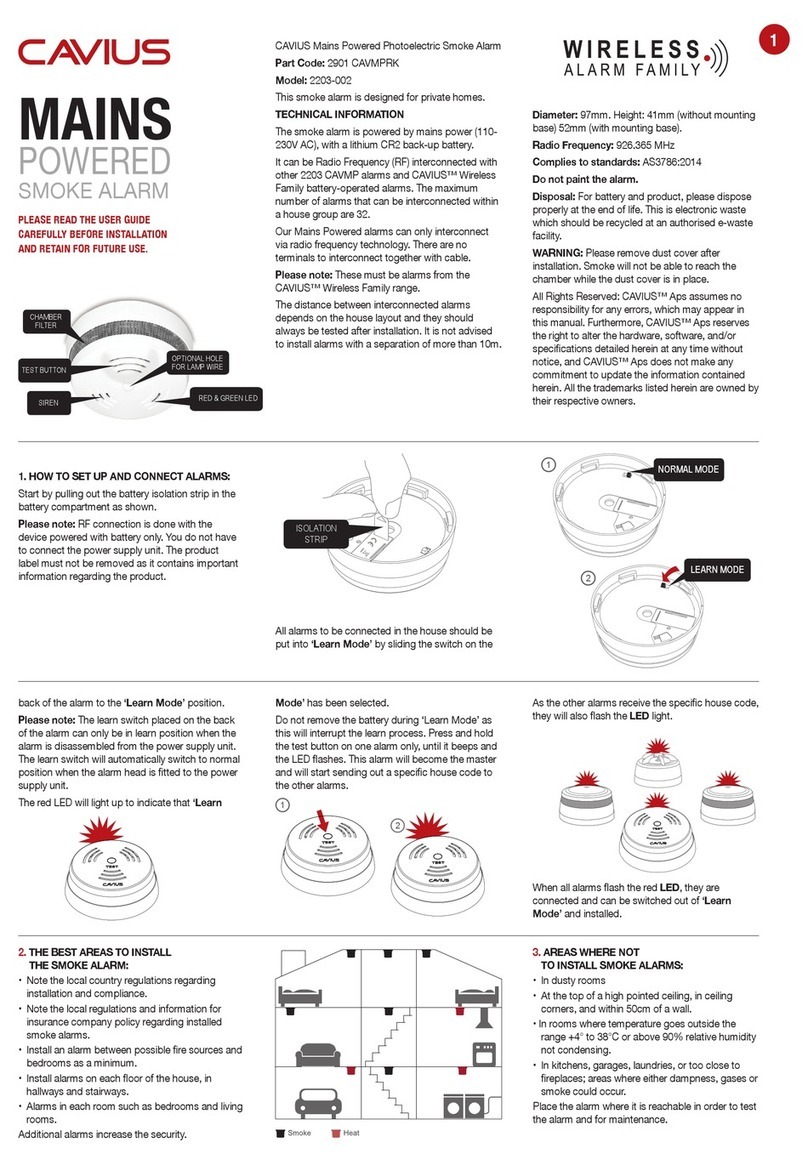

TYPICAL WIRING DIAGRAMS

FIGURE 1: Typical wiring diagram of the 2-wire multiple-station

smoke detector system

FIGURE 2: Typical wiring diagram of the 4-wire multiple-station

smoke detector system

CAUTION: DO NOT USE LOOPED WIRE UNDER TERMINALS 2 AND 5.

BREAK WIRE RUN TO PROVIDE SUPERVISION OF CONNECTIONS.

MISE EN GARDE: POUR LE CONTRÔLE DES SYSTÈMES – POUR

LES BORNES 2 ET 5, NE PAS UTILISER DE FIL ENROULÉ SOUS LES

BORNES. COUPER LE CÂBLAGE POUR ASSURER LA

SURVEILLANCE DES RACCORDEMENTS.

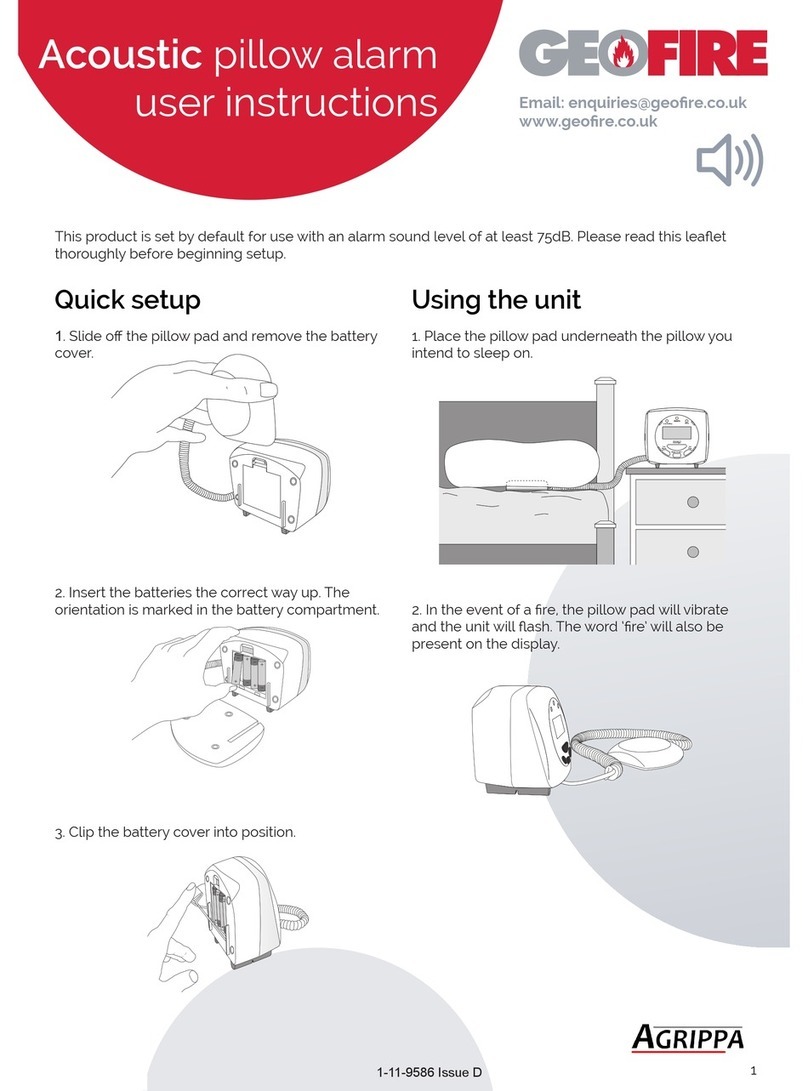

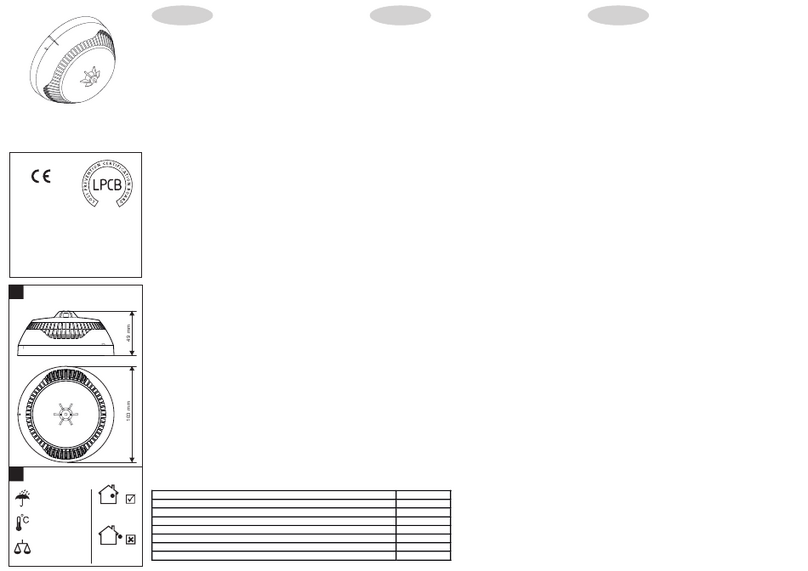

INSTALLING THE BASE

FIGURE 3: Installing 6” base

Notes: The end-of-line devices shown in Figures 1 and 2 must be

compatible with the control panel. The end-of-line supervisory relay must

be rated for the DC power voltage used.

Open area smoke detectors are intended for mounting on a ceiling or a

wall in accordance with the fire standard in your country.

There is a limit of 21 smoke detectors on one loop.

1. Ensure that all wires are properly identified, and fasten the wires

away from the connector terminals.

2. If you used a jumper wire to connect the poles of terminals 2 and 5

when testing the detector loop continuity, remove the jumper wire

before you install the detector head.

3. Mount the base of the smoke detector directly onto an electrical

junction box such as an octagonal (3”, 3.5” or 4”), a round (3”), or a

square (4”) box without using any type of mechanical adapter.

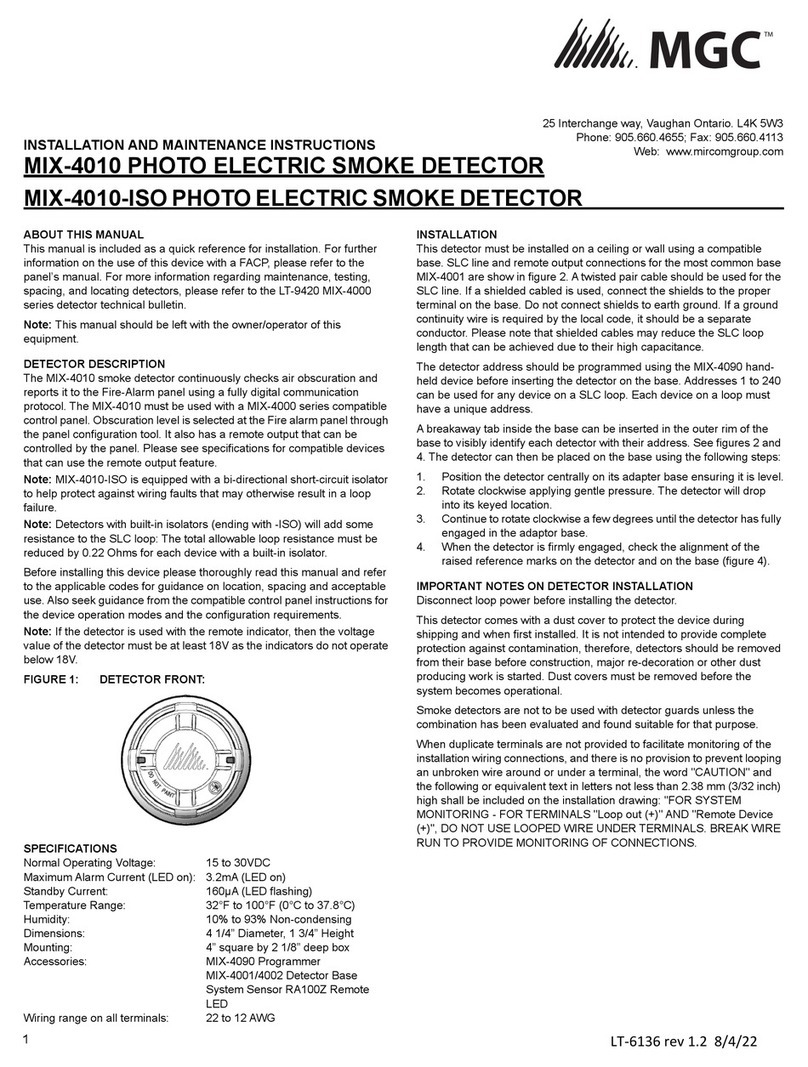

INSTALLING THE HEAD

1. Thoroughly clean the area of construction debris and dust.

2. Align the mark on the detector head with the short mark on the base

and twist the head clockwise to secure it. The mark on the head

should line up with the long mark on the base.

FIGURE 4: Attaching detector head onto base

WARNING

TO PREVENT DETECTOR CONTAMINATION AND SUBSEQUENT WARRANTY

CANCELLATION, THE SMOKE DETECTOR MUST REMAIN COVERED UNTIL

AREA IS CLEAN AND DUST FREE.

AVERTISSEMENT

POUR ÉVITER LA CONTAMINATION DU DÉTECTEUR ET ANNULER LA

GARANTIE, LE DÉTECTEUR DE FUMÉE DOIT RESTER COUVERT TANDIS

QUE L'ENDROIT EST PROPRE ET SANS CONTAMINER DES POUSSIÈRE.

INITIATING

LOOP

UL864

LISTED

COMPATIBLE

CONTROL

PA N EL

+

í

FIRST DETECTOR BASE

LAST DETECTO R BASE

EOL

DEVICE

í

+í

REMOTE

INDICATOR

CLASS A OPTIONA L WIRING

NOTE: IF REMOTE INDICATOR IS NOT USED, REVERSING POLARITY ON DETECTOR IS

PERMITTED.

+

2A

2B

65

4

3

1

2A

2B

65

4

3

1

2A

2B

65

4

3

1

2A

2B

65

4

3

1

INITIATING

LOOP

UL864

LISTED

COMPATIBLE

CONTROL

PAN EL

+

í

FIRST DETECTOR BASE LAST DETECTOR BASE

CLASS A OPTIONAL WIRING

+

POWER

TO

DETECTOR

í

EOL

POWER

SUPERVISION

RELAY

MODULE

END

OF

LINE

DEVICE

PUSH TAB WITH

RAISED PLASTIC

DOT AND TURN

HEAD TO UNLOCK

RECTANGULAR

OPENING HERE

LED DETECTOR HEAD

4” BASE

SHORT ALIGNMENT MARK

LONG ALIGNMENT MARK

RECTANGULAR

OPENING HERE

DETECTOR HEADLED

LONG ALIGNMENT MARK SHORT ALIGNMENT MARK

6” BASE

INSTALLATION AND MAINTENANCE INSTRUCTIONS

SD-100 Series Photoelectric Smoke Detectors

LT-1055 rev 3 12/14/22

2

ALARM AND SMOKE SENSOR TESTING

1. Disengage all the alarm signal services, releasing devices, and

extinguisher systems during testing.

2. Energize the detector head for approximately one minute.

3. Make sure that the LED flashes green once every 5-7 seconds.

If it is not flashing, the detector is not functioning or the wiring is

faulty. Re-check the wiring or replace the detector if necessary.

4. Position the test magnet against the side of the detector opposite the

side marked DO NOT PAINT for at least 10 seconds.

The LED should illuminate steady red.

5. Reset the control panel to return to normal operation.

6. Allow smoke from a cotton wick or a test smoke aerosol to enter the

detector-sensing chamber for at least 10 seconds.

When sufficient smoke has entered the chamber, the LED illuminates

steady red. If it does not, then the detector requires service.

7. Reset each detector and control panel before testing any additional

detectors in the same zone.

8. Re-engage all the alarm signal services, releasing devices, and

extinguisher systems immediately after testing.

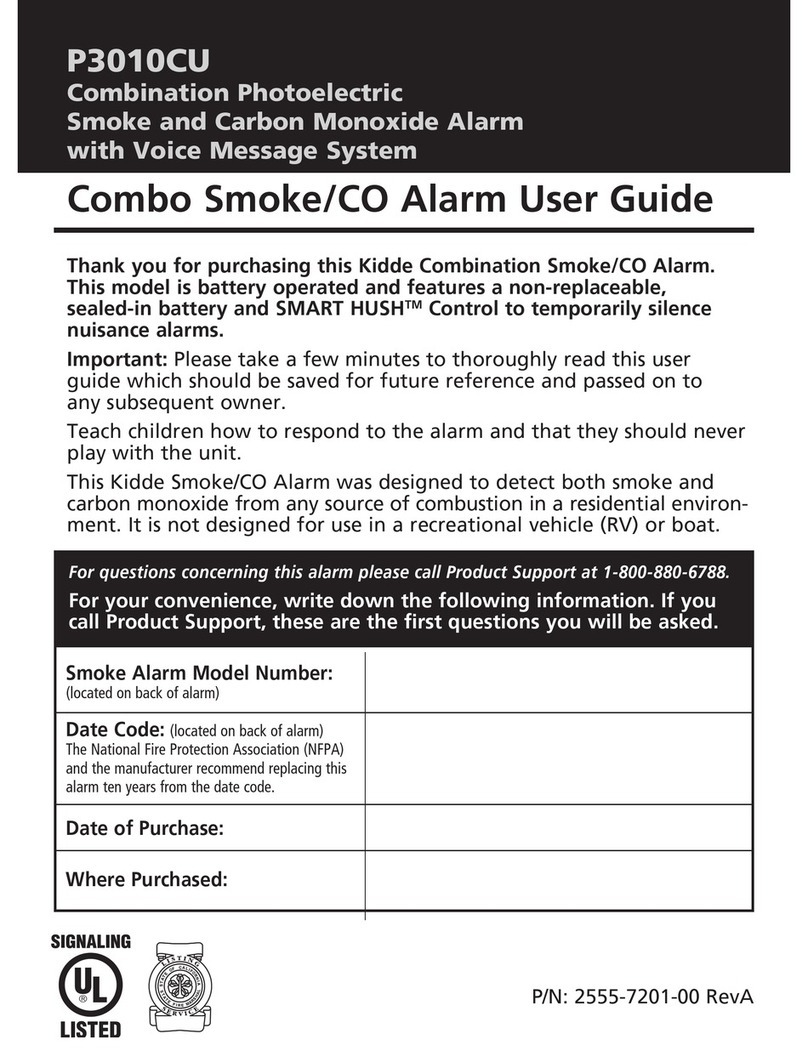

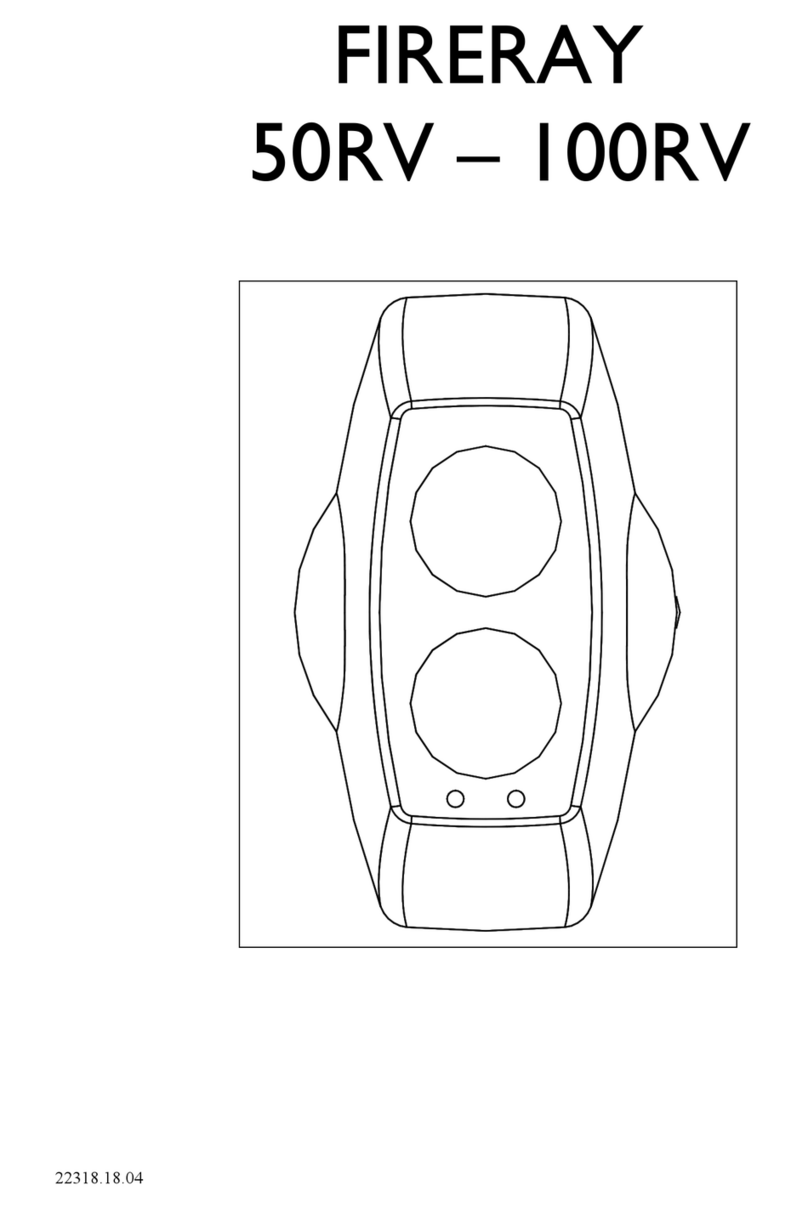

HEAT SENSOR TESTING (SD-100-2WT and SD-100-2WT)

1. Switch on a flow of hot air at a temperature between 65°C and 80°C.

This requirement can be met by some domestic hair dryers. Check

that the temperature is correct and stable.

2. From a distance of several inches, direct the airflow at the guard

protecting the thermistor. The detector should sound its alarm within

30 seconds.

FIGURE 5: Heat sensor testing

3. When the alarm sounds, immediately remove the heat source and

check that the LED is illuminated red.

4. Reset the detector from the control panel.

If the detector fails to sound its alarm within 30 seconds, it is too

insensitive. Return it to the distributor for servicing.

5. Check that the system is set for normal operation and notify the

appropriate authorities that the testing operation is complete and the

system is active again.

NOT SUITABLE FOR INSTALLATION IN AREAS WHERE AIR

VELOCITIES EXCEED 300 ft./min.

MAINTENANCE

The recommended minimum requirement for detector maintenance

consists of an annual cleaning of dust from the detector head by using a

vacuum cleaner. All maintenance operations must comply with NFPA-72A

standards.

CAUTION: DO NOT ATTEMPT DISASSEMBLY OF THE FACTORY

SEALED SMOKE DETECTOR. THIS ASSEMBLY IS SEALED FOR

YOUR PROTECTION AND IS NOT INTENDED TO BE OPENED FOR

SERVICING BY USERS. OPENING THE DETECTOR HEAD WILL VOID

THE WARRANTY.

ATTENTION: NE PAS DEMONTRER LE DÉTECTEUR DE FUMÉE. CET

ENSEMBLE EST ÉTANCHE POUR VOUS VOUS PROTEGER

CONTRE LES ELEMENTS ET N'EST PAS PREVUE DE L'OUVRIR

POUR L'ENTRETENIR. EN OUVRANT LA TÊTE DE SONDE

ANNULERAIT LA GARANTIE RESPECTIVEMENT.

FOR MORE INFORMATION, REFER TO THE TECHNICAL BULLETIN

LT-5267 SD-100-2W/4W.

DIRECT AIRFLOW HERE

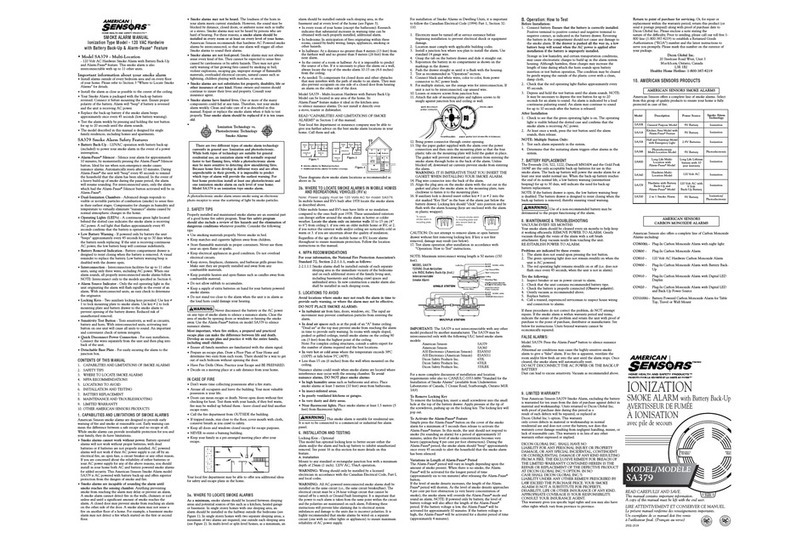

SPECIFICATIONS

Accessories: RSR-100 Remote Sensitivity Meter for SD-100 Detectors (LT-1146)

WARRANTY

Purchase of all Mircom products is governed by:

https://www.mircom.com/product-warranty

https://www.mircom.com/purchase-terms-and-conditions

https://www.mircom.com/software-license-terms-and-conditions

Model 2/4 wire Thermal Voltage

DC

Standby

Current

(Max.)

Alarm

Current

(Max.)

Surge

Current

(Max.)

Start-Up

Time

(Max.)

Permissible

Current

(Max.)

Frequency Alarm contact Base model

SD-100-2WP 2 - 12.0~28.0V 140μA 90mA 200μA 60 Seconds 90mA 5-7 Seconds — SDB-106-4 or

SDB-104-4

SD-100-2WT 2 57.2 °C 12.0~28.0V 140μA 90mA 200μA 60 Seconds 90mA 5-7 Seconds — SDB-106-4 or

SDB-104-4

SD-100-4WP 4 - 10.5~33.0V 140μA 48mA 200μA 60 Seconds 48mA 5-7 Seconds Form A SDB-106-4 or

SDB-104-4

SD-100-4WT 4 57.2 °C 10.5~33.0V 140μA 48mA 200μA 60 Seconds 48mA 5-7 Seconds Form A SDB-106-4 or

SDB-104-4

This manual suits for next models

4

Other MGC Smoke Alarm manuals