MGF 932299 User manual

General Information

General Information

SERVICE

For any form of echnical assis ance you can con ac us in one of he following ways:

elephone: +39 0521 818301

fax: +39 0521 818202

email: assis enza@mgf ools.com

We will serve you as soon as possible.

The shipmen of ma erial under repair mus be previously au horized by means of he RMA form (binding condi ion for he

collec ion of any goods under repair).

WARRANTY TERM

The produc warran y covers any manufac uring defec for a period of ime equal o one (1) year from he da e of

manufac ure for produc s purchased wi h invoice, 2 years for produc s purchased by priva e individuals.

The following clauses expressly exclude he produc from guaran ee:

•Consumables such as fuses, disposable ba ery, ..., insofar as he malfunc ion is caused by normal wear of he par s

•Damage caused by improper opera ion

•Bad main enance

•Machine ampering or modifica ion

The company excludes from i s responsibili y any indirec damage, damage caused o people and hings by defec s and

machine down ime, incorrec use, lack of main enance.

Introduction

Introduction

The FGAS Leak De ec or ar . 932299 is he mos reliable nega ive corona halogen leak

de ec or a presen . We in egra e all our experience and cus omers’ feedback in o his

produc , in hope ha i could provide our cus omer he bes price, performance and

reliabili y.

The sensi ive elemen s adop he advanced and reliable corona refrigeran sensor which

has grea sensi ivi y and excellen repea abili y; he es program is con rolled by he

ar ificial in elligen microcompu er, wi h reasonable work procedure, easy and convenien

o opera e, comple e func ions and mul iple self-adap ive capabili ies; dual-color LED

indica or ligh , wi h visual and clear display; smar and por able design is convenien for

your mobile opera ion. When here is excessive refrigeran in he leak gas, his uni will

au oma ically audio alarmed o effec ively es he refrigeran leak.

Technical fea ures

•Adop advanced, low power consumed, eigh -bi microprocessor con roller

•Dual-color LED indica or ligh wi h progressive and real ime display

•Sensi ivi y adjus able, seven level alarming indica ed by LED display

•Modular sensor, convenien for main enance

•Seven levels audible and visual alarm

•Au o rese es ing when he de ec or is urned on

•Ba ery level indica ion

2

MGF

MGF srl –– Via Chico Mendes, 8 – 43058 Sorbolo Mezzani (PR) I aly – Tel. +39 0521-818301 Fax: +39 0521-818202

e-mail: info@mgf ools.com – www.mgf ools.com – www.nebulizzare.com

Technical Specifications

Technical Specifications

•Sensor ype: nega ive corona sensor

•Ul ima e sensi ivi y: 3 g/yr

•Warm-up Time: 3

•Applica ion:

◦De ec leaks in o her sys ems and filling vessels. I will respond o all halogena ed (including Chlorine and

Fluorine) refrigeran s. This includes, bu is no limi ed o:

▪CFCs e.g. R12, R11, R500, R503 e c…

▪HCFCs e.g. R22, R123, R124, R502 e c…

▪HFCs e.g. R134a, R404a, R125 e c…

▪Mix ures such as AZ-50.HP62.MP39 e c…

◦De ec E hylene Oxide gas leaks in hospi al s erilizing equipmen

◦De ec SF-6 in high vol age circui breakers

◦De ec mos gases ha con ain chlorine, Fluorine and Bromine (halogen gases)

◦De ec cleaning agen s used in dry cleaning applica ions such as perchloroe hylene.

•Opera ing Environmen : Tempera ure 0°C~50°C

•Humidi y: <95% RH (non-condensing)

•Power supply: wo (2) “C” Alkaline Ba eries supplied

•Sensor ip life under con inuous opera ion: more han 50 hours in normal de ec ing s a us

•Size: 230 x 60 x 55 mm

•Probe leng h: 36 cm

•Weigh (leak de ec or only): 0,41 Kg

•Weigh (wi h carrying case): 1,35 Kg

3

MGF

MGF srl –– Via Chico Mendes, 8 – 43058 Sorbolo Mezzani (PR) I aly – Tel. +39 0521-818301 Fax: +39 0521-818202

e-mail: info@mgf ools.com – www.mgf ools.com – www.nebulizzare.com

Operations

Operations and installation

and installation

Opera ion ins ruc ion

•Power key: long press ON/OFF o urn on/off he de ec or.

•Sensi ivi y adjus men key: Adjus he sensi ivi y level according o he de ec ion demands. (Long press his key

could adjus he sensi ivi y quickly.)

•Rese key: Rese he background halogen level a he ip o “zero”, any level higher han his “zero” is considered o

be a leak and rigger he alarm.

•Mu e key: Se he buzzer sounds or no during he de ec ion process.

•Ba ery es key: Check he ba ery level.

The in erface and keys of halogen leak de ec or please refer o Figure 2:

•Ba ery Ins alla ion:

WARNING! To reduce he risk of igni ing flammable gases in a closed a mosphere, ba eries mus be replaced in an open

area or closed space wi hou flammable gas.

1. See figure 3. Using a humb o push open he ba ery door loca ed a he bo om of he de ec or; hen o remove

he door.

2. Ins all wo “C” alkaline ba eries in o he de ec or, observing he polari y markings on he side of he case and hen

place he ba ery door back.

4

MGF

MGF srl –– Via Chico Mendes, 8 – 43058 Sorbolo Mezzani (PR) I aly – Tel. +39 0521-818301 Fax: +39 0521-818202

e-mail: info@mgf ools.com – www.mgf ools.com – www.nebulizzare.com

Detecting method

Detecting method

Halogen leak de ec or opera ion me hod:

When he de ec or is urned on or off by long pressing POWER key, all LED indica or ligh s are on for hree seconds and he

de ec or will au oma ically rese . Af er au o-rese , only he firs LED indica or ligh on he lef will be on. (Green, ba eries

fine, orange, ba eries ge ing weak, replace as soon as possible; red indica es he ba eries need o be replaced before

normal de ec ing). A his ime, he beeping sounds regularly and he de ec or se s he a mosphere halogen level o “zero”,

ready for de ec ion.

Opera ion ins ruc ion

1. Check he ba ery level by observing he cons an power indica or ligh .

2. Once urn on he de ec or, he defaul sensi ivi y level is level 4. You will hear rapid, bu s eady beep sound. The

sensi ivi y can be adjus ed by pressing SENSITIVITY ” “ or SENSITIVITY “ “ according o your requiremen .

3. Begin searching for leaks. When refrigeran is de ec ed, a siren will be sounded, wi h a ra e qui e differen from

previous beep sound. And he indica or ligh s will progressively urn on.

4. Sensi ivi y can be adjus ed a any ime during opera ion by pressing ” “ and “ “ key. This adjus men will no

in errup de ec ion.

5. If alarm occurs before he sensing ip ouches wi h he leakage source, press “Rese ” key o rese he curren o 0

un il here is no alarm, hen you could de ec again.

6. Press “ Mu e” key o close he alarm sound; press i again o ac iva e alarm sound, loop opera ion.

7. Press he “BATTERY TEST” key o check he ba ery level.

Halogen leak de ec or de ec ing me hod:

See Figure 4

1. Visually exam he refrigera ion sys em. The oily and dir y spo s, node valves, coils, connec ors, or pipelines are he

areas mos likely o leak gases.

2. S ar leak de ec ing a he join a a speed of 1cm per second and he dis ance be ween sensor ip and he join

should be 1-3cm.

3. When an alarm is riggered, i may indica e a leak is close by. De ec around ha area again and see if he alarm is

repea able. If a leak is confirmed, pinpoin he leak source by moving slowly from no-leaking (no-alarm) area o he

leaking area from differen direc ions. Besides, you could also pinpoin he leak by moving he de ec or away from

he leaking area and rese he uni , adjus ing he sensi ivi y lower and repea ing he above process.. Once confirmed,

mark around he leak and con inue de ec ing he whole line of he sys em.

5

MGF

MGF srl –– Via Chico Mendes, 8 – 43058 Sorbolo Mezzani (PR) I aly – Tel. +39 0521-818301 Fax: +39 0521-818202

e-mail: info@mgf ools.com – www.mgf ools.com – www.nebulizzare.com

4. Addi ional work may be needed o elimina e possible ambigui y, like o her con aminan s a he spo may make he

de ec or alarm, Clean he leaking area wi h dry clo h and blow clean dry air o he leaking area and repea s ep 3

above o confirm he leak.

5. Leak on evapora or coil is more difficul o de ec han o her areas because i is difficul for sensor ip o access o

he whole evapora or coil. Mos evapora or coils are composed of modules and are ins alled in a closed space wi h

fan for hea exchange. The sys em wi h he fan should be urned on for 10 seconds and hen urn off he fan, wai

10-15 minu es a he evapora or, hen use de ec or o de ec he ou le of he condensa e (make sure he sensor ip

doesn’ ouch wi h he condensa e), or de ec he air inside he evapora or chamber. Mos halogens are ligh er han

he air and likely o accumula e a he highes spo in he closed space. Ana alarm may indica e a leak a he

evapora or coil, bu is hard o repair evapora or by pinpoin ing he precise leak loca ion. In mos cases, he whole coil

has o be replaced.

No es before leak de ec ing:

1. In order o de ec leak in a refrigera ion sys em, he sys em mus have normal opera ing pressure, or a leas

par ially reaches o minimum 50 PSI. Low environmen al empera ure (lower han 59°F or 15°C) may lower he

sys em required pressure and may make he leak less likely o be de ec ed. No leak de ec ed does no mean he

sys em does no have gas leak. Check he pressure before making he conclusion.

2. Leaking areas are usually covered wi h con aminan s such as compressor oil or dir , be careful no o le he sensor

ip in con ac wi h hese con aminan s.

3. The de ec or’s func ion is o de ec halogen’s rela ive change a he sensor ip. Pinpoin ing he leak source needs o

manually adjus he sensi ivi y and rese he de ec or by he echnician. You could follow recommenda ions below:

(1) In areas where he a mosphere is con amina ed wi h halogen refrigeran , press rese key o “ignore” he leak in

he background. Make sure no move he sensor ip away from he con amina ed background while rese ing he

de ec or.

(2) In windy area, he leaked halogen refrigeran may be quickly dilu ed or removed from leak source. The

echnician may use a wind shield o isola e he leak area or emporarily orn off he fan.

(3) To avoid false alarm, preven he sensor ip agains ouching any mois ure or o her solven .

Maintenance

Maintenance

Proper main enance is impor an and may ex end he service life and improve he performance of your de ec or.

Warning: Turn he power off before replacing he sensor ip. Vol age across he ip may pose an elec rical hazard.

Keep he sensor ip clean: Use co on clo h or dry air o clean he shield on he sensor ip if i ge s con amina ed. If he

sensor ip i self is con amina ed, soak he ip in absolu e alcohol for a few minu es, and hen use compressed air o blow i

dry, or dry i wi h clo h.

No e: Never use s rong solven s such as Gasoline, mineral oil, urpen ine, hese solven s may coa he sensor wi h a hin film

and reduce he sensi ivi y of he de ec or and make he de ec or slow o respond o a leak.

Pu he de ec or and he ip in a dry and clean place; remove he ba eries if he de ec or is no used for a long ime.

Troubleshooting

Troubleshooting

Symp om Possible reasons Solu ion

The de ec or could no urn on

A) The energy of ba eries is oo low o

urn on.

B) The pole piece of ba ery connec or

has been oxidized.

A) Please replace new ba eries.

B) Please scrape he oxidiza ion layer.

6

MGF

MGF srl –– Via Chico Mendes, 8 – 43058 Sorbolo Mezzani (PR) I aly – Tel. +39 0521-818301 Fax: +39 0521-818202

e-mail: info@mgf ools.com – www.mgf ools.com – www.nebulizzare.com

The de ec or could no respond o a

confirmed leak Sensor ip is aged Please change a new sensor as soon as

possible.

The de ec or gives false alarm when

here is no halogen presen A mospheric composi ion has changed

Please press RESET key o se he

background o “zero” level, ry o avoid

he change of air empera ure or

humidi y

Conformity Declaration

Conformity Declaration

MGF

MGF srl - Via Chico Mendes, 8 - 43058 Sorbolo Mezzani (PR) - I aly declares under i s own responsibili y ha he FGAS

Leak De ec or ar . 932299 is in conformi y wi h he following s andards or s andardized documen s:

Safe y S andards

•EN 61326-1: 2013 (Elec romagne ic Compa ibili y 2014/30/EU)

MGF

MGF srl

Ing. Maioli Francesco

7

MGF

MGF srl –– Via Chico Mendes, 8 – 43058 Sorbolo Mezzani (PR) I aly – Tel. +39 0521-818301 Fax: +39 0521-818202

e-mail: info@mgf ools.com – www.mgf ools.com – www.nebulizzare.com

Control Certification

Control Certification

Pursuan o curren legisla ion, i is cer ified ha he ins rumen has been checked before shipmen and ha he minimum

guaran eed sensi ivi y is respec ed.

This es is carried ou by means of a sample leak calibra ed according o he specifica ions of he EN14624/2012 s andard.

Da e:

Signa ure:

8

MGF

MGF srl –– Via Chico Mendes, 8 – 43058 Sorbolo Mezzani (PR) I aly – Tel. +39 0521-818301 Fax: +39 0521-818202

e-mail: info@mgf ools.com – www.mgf ools.com – www.nebulizzare.com

Table of contents

Popular Security Sensor manuals by other brands

Ceasefire

Ceasefire PRO-SENSE TI-002267 installation guide

Timeguard

Timeguard TG135A Installation & operating instructions

Tinker & Rasor

Tinker & Rasor AP instructions

wattstopper

wattstopper CX-105 installation instructions

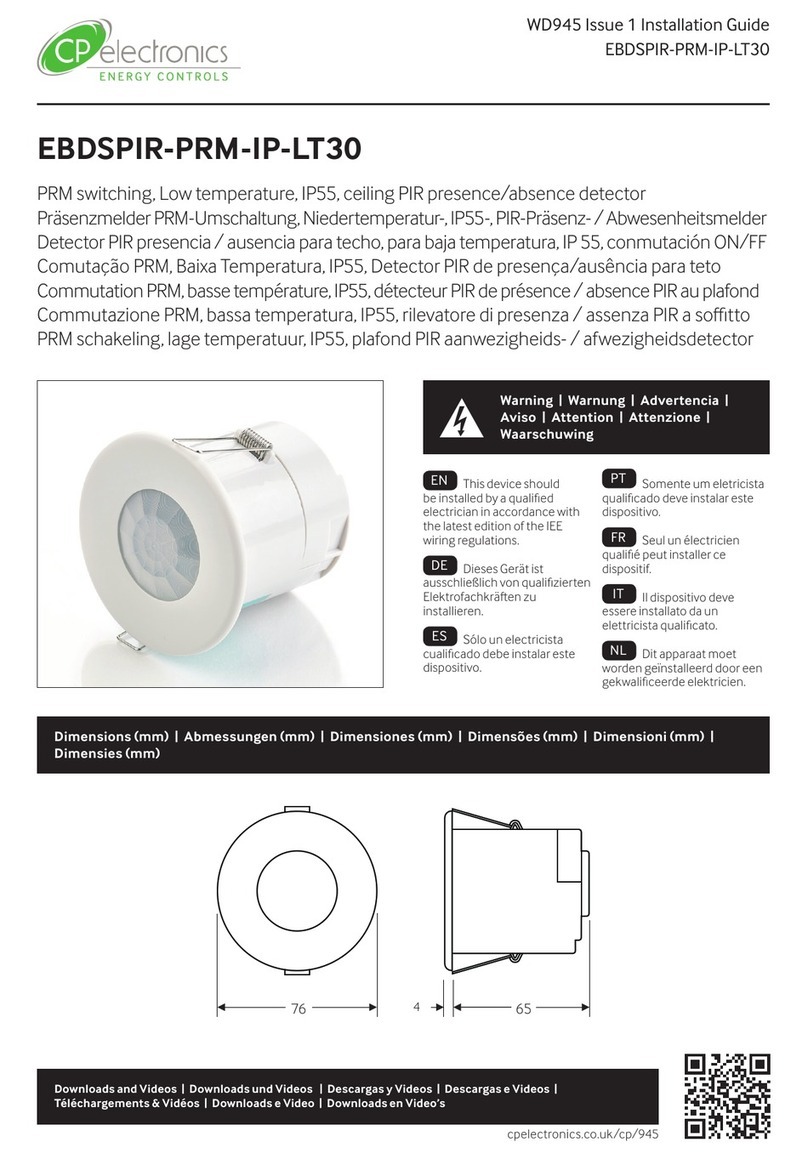

C.P. Electronics

C.P. Electronics EBDSPIR-PRM-IP-LT30 installation guide

C.P. Electronics

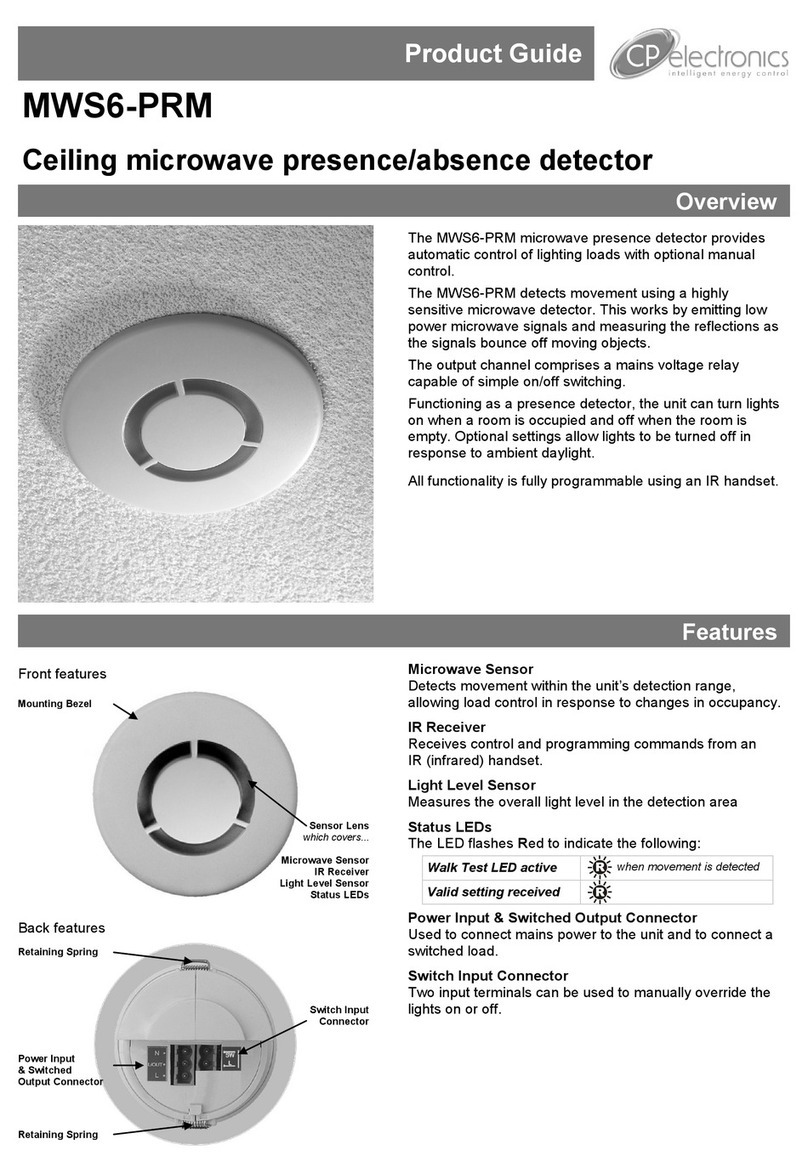

C.P. Electronics MWS6-PRM Product guide