8. Comply with all applicable safety regulations and workplace safety regulations, especially when you feel more

practical in using the instrument. Negligence or omissions can cause serious injury and permanent damage.

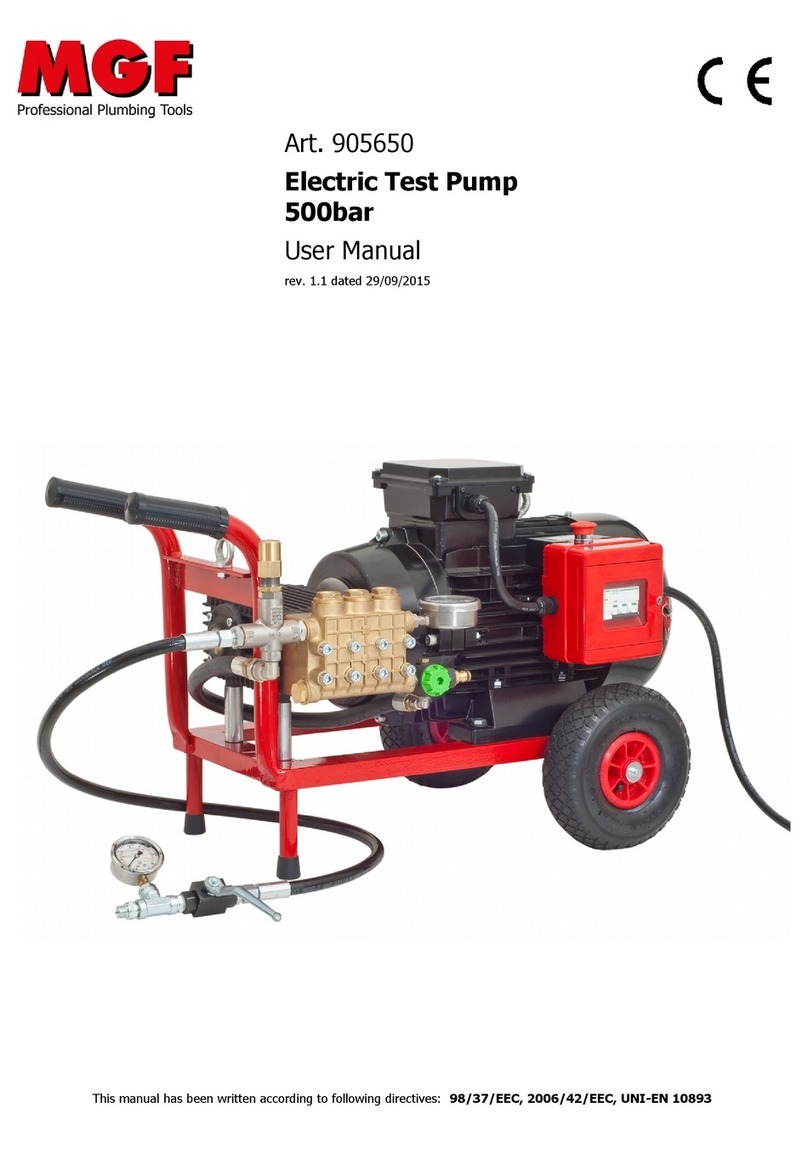

4. Use of the machine

1. Do not overload the machine. Do not exceed the indicated rating values. Use the machine only according to its

intended use.

2. Do not use machines with a defective switch. A machine with a faulty operating system must be repaired

immediately.

3. Unplug from the socket before making adjustments, changing accessories, carrying out maintenance or storing

the appliance. This safety measure prevents accidental starting of the machine.

4. Do not leave the machine connected to the power supply unattended. Keep the machine out of reach of children,

unskilled, untrained and untrained people about the use and maintenance of the machine. Use by experienced

people is very dangerous.

5. Carefully maintain the machine and its accessories. Check that the moving parts work properly, are not blocked

or damaged. All active and passive protection devices must be checked periodically and before each use. Before

using the appliance, have the damaged parts repaired. Incorrect or unintended maintenance of the machine can

cause serious damage and injury.

6. Use the machine and accessories in accordance with these instructions. Keep in mind the working conditions and

the type of work to be performed. Using the machine for purposes other than those intended may lead to

dangerous situations and damage.

7. Keep the handles and operating and control parts dry, clean and free of oil and grease. This is a necessary

condition for safe use and a better reaction in case of unforeseen situations.

5. Service

1. Have the machine repaired only by specialized and qualified personnel and only with original spare parts. This

ensures product safety even after repair.

2. Keep the machine in a correct state of maintenance, carrying out and carrying out calibrations and maintenance

according to the scheduled maintenance plan. A non-maintained machine is more dangerous and is not protected

by warranty.

Warnings for the use of the machine

1. Hold or tighten the hoses firmly before operating the machine. The pressure waves inside the tube can create whip

effects and hit people or things.

2. Make sure that the hoses are not subject to rubbing against abrasive, sharp or damaged surfaces. They could in fact

explode if subjected to pressure.

3. The machine works at very high pressures up to 60 bar. Pay particular attention.

4. Before making connections or disconnecting the pipes, make sure that there is no pressure inside. At the end of the

work, disconnect all the hoses from the water system.

5. Before each use, check that the high-pressure hoses are not damaged. A damaged high-pressure hose can burst and

cause injury.

6. Use only high-pressure hoses, valves and original couplings. This ensures the safety of the appliance even after the

replacement of damaged components.

7. Only operate the machine if it is resting on a horizontal, stable, robust and dry surface. An inadequate support plan

can result in damage and injury of various kinds.

8. Never use the machine on networks without a differential safety switch. Before use, make sure that the differential

switch (circuit breaker) operates correctly. The use of a residual current safety circuit breaker reduces the risk of

electric shock.

9. Do not direct jets of liquid onto the machine, not even to clean it. The infiltration of water into an electrical device

increases the risk of electrocution.

5

MGF

MGF

srl –– Via Chico Mendes, 8 – 43055 Mezzani (PR) ITALY – Tel. +39 0521-818301 – Fax +39 0521-818202