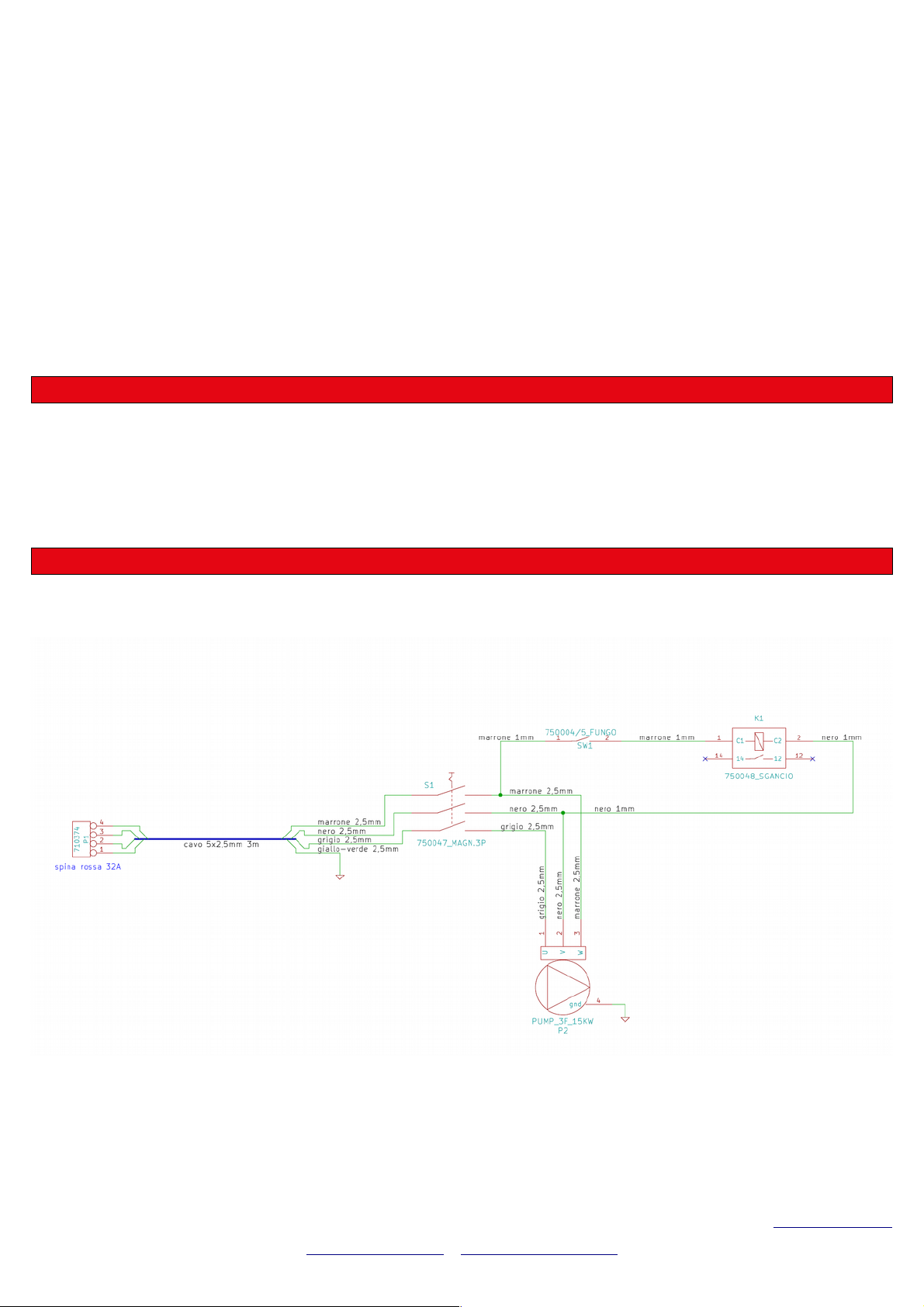

Hose connection: screw the high pressure hose and the suction hose (through quick connector or 1/ ” F thread) without using too

high torque.

Water plant connection: incoming water must be clean, without corrosives and, if possible, without limestone. Maximum allowed

temperature for water is 60 °C. Connection requires a hose of at least ½” (Ø 13 mm internal) and 15 bar. Shorten if possible the

connection hose and eliminate every bottleneck on the hose. Minimum flow rate is 0 L/min.

Power connection: before connecting, check if the electric plant respects safety requirements and if it is able output required power.

The plant must have safety switch and earth grounding. Before connecting, turn off the pump. Don’t connect other loads on the same

point. Using long power cords, be sure that section of every cable is right for the current flow, to avoid high temperatures and

dissipations.

Air lowing: to avoid pressure oscillation due to air inside plant, it’s due eliminating all air inside plant to allow complete water plant

filling.

Working suggestions and Warnings

Working suggestions and Warnings

Pressure regulation device w/dou le valve allows working at desired pressure efore filling the system.

•Close the tap on the high pressure hose: read pressure = 0 on the test gauge

•Turn fully counterclockwise the the pressure regulator

•Start the motor switching the main switch

•Turn the pressure regulator clockwise, until you reach the desired working pressure on the gauge on the pump (setting gauge)

•Open the tap on the pressure hose

•Fill the system

•Close the tap and stop the pump

Close “TEST” valve, as the desired pressure has een reached. In this way you’ll cut off from test the pump and all the input

plant, while you can continue checking pressure on gauge. For long time tests, you can disconnect HELP instrument from the pump and

leave only it on the building site.

Don’t leave the pump “ON” with “TEST” valve closed. After a few minutes the bypass water increases temperature and this could

damages gaskets.

Water temperature and air u les: Water temperature and air bubbles can change pressure inside plant. Consider these factors

while testing big plants with big temperature differences.

High pressure water jets can cause damages if used improperly. Avoid starting pump without connecting it to the plant.

High pressures can ring to explosions: always consider your working pressure range before starting the test on the system:

otherwise you may damage things and persons

Work always in a safe way: respect general safety instructions, don’t let that water flows inside pump, use safety shoes and glasses.

Respect electrical safety instructions: maintenance and inspections are allowed only with the pump disconnected from power net.

Don’t stress the power cord, change it if damaged. Keep dry every electric part.

Check if high pressure hoses aren’t een damaged. If necessary, change them with original spare parts. Work on them only with

the motor turned off and with pressure discharged.

Ensure always motor ventilation. Verify that motor can have right air flow from the chassis.

Check inlet filter before every test.

Change oil after 50 hours and then after 100 hours. Use MGF

MGF mineral oil (see below). This maintenance timing can change with harder

working conditions.

Art. Description

790051 Oil for MGF

MGF Pumps 5 L tank

790050 Oil for MGF

MGF Pumps 0,5 L bottle

If you don’t use the pump for a long time, and / or in low temperature countries, pump a little amount of no frost solution inside the

pump. This will ensure long life to gaskets. Before restarting pump, turn the shaft from the hole on the chassis to unblock, if necessary,

valves.

Before starting, turn manually the shaft if necessary (gaskets glued).

Troubleshooting

Troubleshooting

The pump doesn’t reach the pressure: check in order: inlet filter, air inside pump, valves, inlet connection, gaskets.