MGF 904 Series User manual

The present manual has been realised, where possible, in accordance with Rule 98/37/CE "Direttiva

acchine", 2006/42/CE "Nuova Direttiva acchine" UNI Rule 10893 "User instruction - “order of contents”.

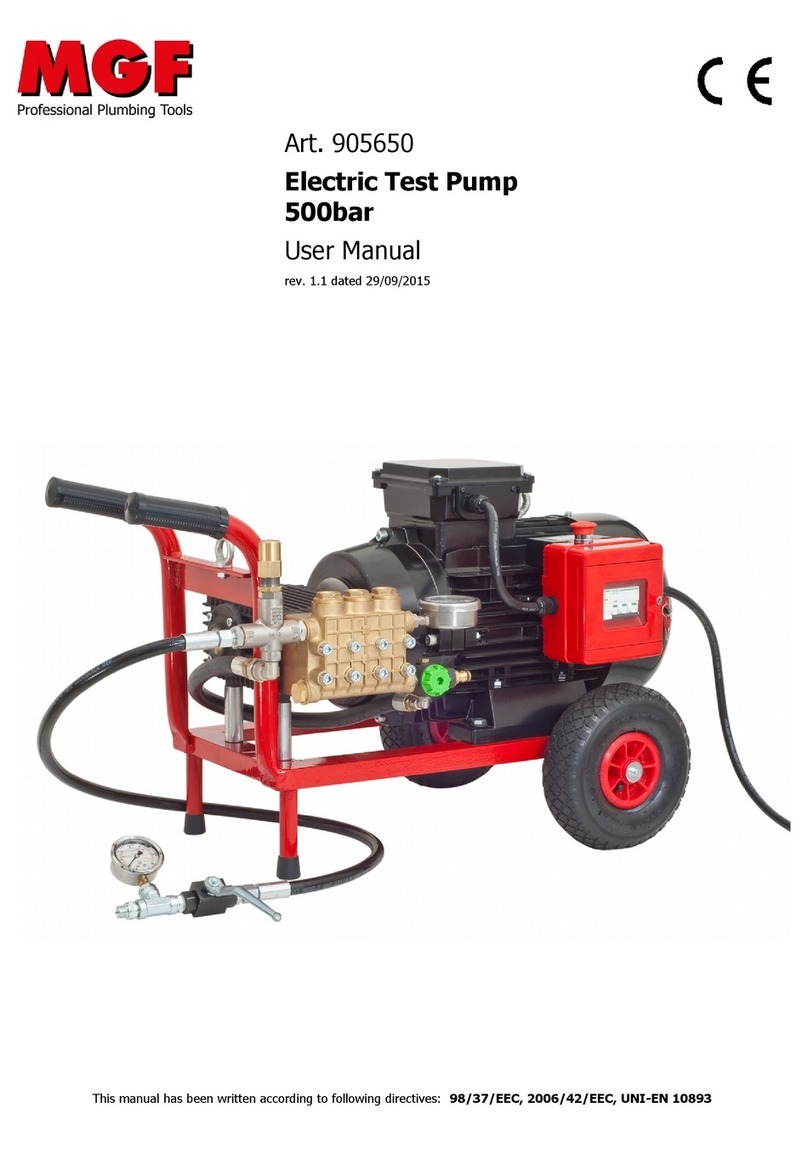

Art. 904XXX

High Pressure

Test Pump

User Manual

rev. 1.0 del 12/02/2014

Introduction

Introduction

This manual, supplied with the pump and remaining installation material pipes, nozzles, fittings, electronics,

tools...) provides important informations about the correct installation, use and maintenance.

Read this manual carefully to respect all the directives provided, are important conditions for

warranty validity and correct use and functioning of the whole system.

The installer must inform the end user about the correct use of the system.

The manufacturer declines every responsibility for damages caused by wrong installation, or misuse

of the system.

General Informations

General Informations

ACHINE TECHNICAL DATA

Find out the label on the machine providing the informations about technical data

TECHNICAL ASSISTANCE

call number: +39521818301 4 lines)

fax: +39521818202

email: [email protected]

Shipment of defective parts must be authorized by MGF RMA module. Otherwise we cannot accept arriving

goods.

WARRANTY TER S

Warranty on these machines is on every manufacturing defect for a time of 2 years from manufacturing.

Manufacturing time is indicated on label on the pump.

The warranty doesn't cover:

–Consumable parts: nozzles, gaskets, orings after first run installation and test.

–Problems caused by misuse

–Bad maintenance

–Machines or parts modified or changed

MGF is not responsible besides for damages caused by: system stop lost of productivity, plant stops...), misting

of dangerous liquids or polluted water, vandalisms.

The warranty doesn't cover substitution damages, since MGF is not the installation maker.

High pressure pipe available on demand

904900

904800

904700

Art.

CARATTERISTICHE TECNICHE COMUNI

1000 bar

500 bar

300 bar

Pressure

1/2” GAS

A

800mm

B

800mm

C

400mm

D

500mm

E

400mm

F

50Kg

weight

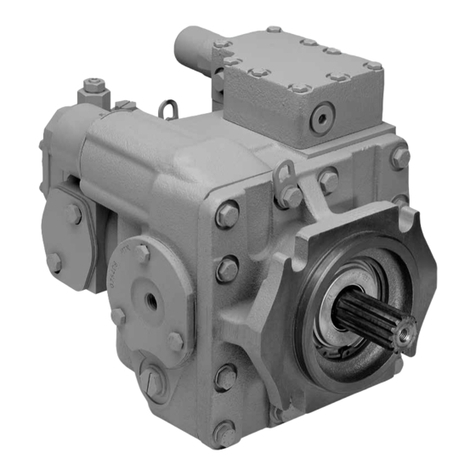

RELEASE LEVER 1° / 2° STAGE

Assembly and Operating Instructions

Assembly and Operating Instructions

High pressure test pumps are easy to use and can be used by anyone without undue fatigue.

Pumps should be assembled as follows, using PTFE tape on all threads to ensure air tight connections.

1. Screw suction pipe into the base of the pump.

2. Mount the pump on the bridge of the tank.

3. Screw in the valve unit, ensuring the connection hole for the gauge tube is opposite the outlet and is

vertical.

4. Screw the gauge tube.

5. Mount gauge.

6. Connect hose.

7. Check all connections are tight.

8. Fill tank with enough water, or oil mixed with water, to cover suction pipe inlet and check pump operation.

9. Connect the pump to the appliance.

10. If necessary re-seal any threads which show signs of leakage.

11. If pump refuses to prime, pour liquid into the outlet to wet the valve area.

12. To start test, close the discharge valve and open the flow-valve. There are two handwheels on the control

valve block for these two valve. A light alternating movement of the handle creates a steady flow of liquid

after a few initial priming strokes; keep up the movement which gradually becomes stiffer until the desired

pressure is read on the gauge.

13. Next close the discharge valve, isolating the appliance being tested. To end the operation, open both

valves and surplus liquid will run back into the tank via the drain hole in the valve control block.

Instructions for Use

Instructions for Use

Manual hydraulic high pressure test pump are piston type, two-stage high and low pressure), self-priming and

double acting.

ASSE BLY

Before you start any operation of pump, make sure that all the accessories has been fitted correctly: suction tube

with nut and filter, manual lever, pressure gauge and pressure gauge supply, delivery hose for high pressure

usually not included).

In order to favour the immediate reading during the test, orient the pressure gauge in the direction of the

operator. Remember to apply the seals necessary to all components.

Since there are threads, it will be necessary to interpose those products that prevent any leakage: PTFE Teflon)

tape or in liquid or fillets paste.

CONNECTION TO THE APPLIANCE TO BE TESTED

After screwing the delivery hose to the pump, connect the same to the appliance to test pipe, tank, valve, etc..),

paying attention to the "hydraulic seal".

FILL UP THE APPLIANCE TO BE TESTED

Whatever is the appliance to test, it has to be filled up in advance with the same liquid that will be used for the

test.

FILLING THE TANK

The pump has a tank with a capacity of 100 liters. Fill up the tank making sure the suction tube is completely

submerged. Use a mixture of water and emulsifiable oil in order to prevent oxide formation inside the machine.

If you can not find the liquid, use water or common oil.

SAFETY

Before shipment, all the pumps are tested in firm, are tough and very robust and therefore very safe.

The operator should wear gloves and protective screen, and people not involved with the testing should leave test

bench.

FIRST STAGE

The machine has two coaxial pistons. The first piston in action is the brass one, with a larger diameter. For this

purpose, verify that the release lever is adjacent to the pump body.

Check that the drain flyer is tight, otherwise close it turning in a clockwise way.

Pumping moving the lever from the bottom on the top. Due to the low flow rate, the pressure gauge will not

begin to rise immediately, but after a few cycles.

The pump is self - priming, so it will come into operation by taking the fluid from the tank below and sending it in

the appliance to be tested.

When you reached 100/120 bar, skip to second stage.

SECOND STAGE

Place the release lever in opening position at 90° respect the pump body), to position the brass piston with

greater diameter and to free the steel piston with smaller diameter. This piston allows the attainment of high

pressures.

Pumping regularly and quickly, moving the lever from the bottom on the top.

Check the pressure shown in the gauge, and do not exceed the maximum pressure.

DISCHARGE THE PRESSURE

At the end of the test, you will have to relieve the pressure acting on the flyer's tap that is on the side of the

pump body. Turning in anticlockwise way the faucet opens the valve by draining the emulsifiable oil or water)

through the drain hole, located under this tap.

From this hole ejects the liquid to the tank below.

Maintenance

Maintenance

Periodically lubricate the piston, clean the suction filter and valves.

Periodically check the pipe.

Use original parts and accessories and make do the repair by qualified personnel.

If you decide not to use the machine, it is recommended to keep it in any case out of the reach of children.

In case of scrapping, disassemble the machine and collect the homogeneous parts for disposal in accordance with

local regulations.

Do not use the parts scrapped as spare parts.

Warnings

Warnings

•Use the pump only for the purpose for which it is intended and in full compliance with the general safety

regulations. Be sure that the machine and all its parts are placed out of reach of children. Keep clean and

well lit work area.

•Position the pump so that the filling of the system can be in operated safety. Do not use the pump resting

on uneven surfaces or horizontal. Avoid working in hazardous environments eg, in the presence of

flammable liquids or gases).

•Use a clothing appropriate to the work to be performed. Do not use loose clothing, long hair pick, remove

rings and necklaces.

•Ensure that there is an optimal grip of the handle. Do not work with greasy hands, if necessary, clean the

handle before using the pump.

•Noise level during use is less than 80dbA

The manufacturer declines all responsibility for any damage that may arise from non-compliance

with the intended use, the instructions and warnings contained in this document.

Spare Parts

Spare Parts

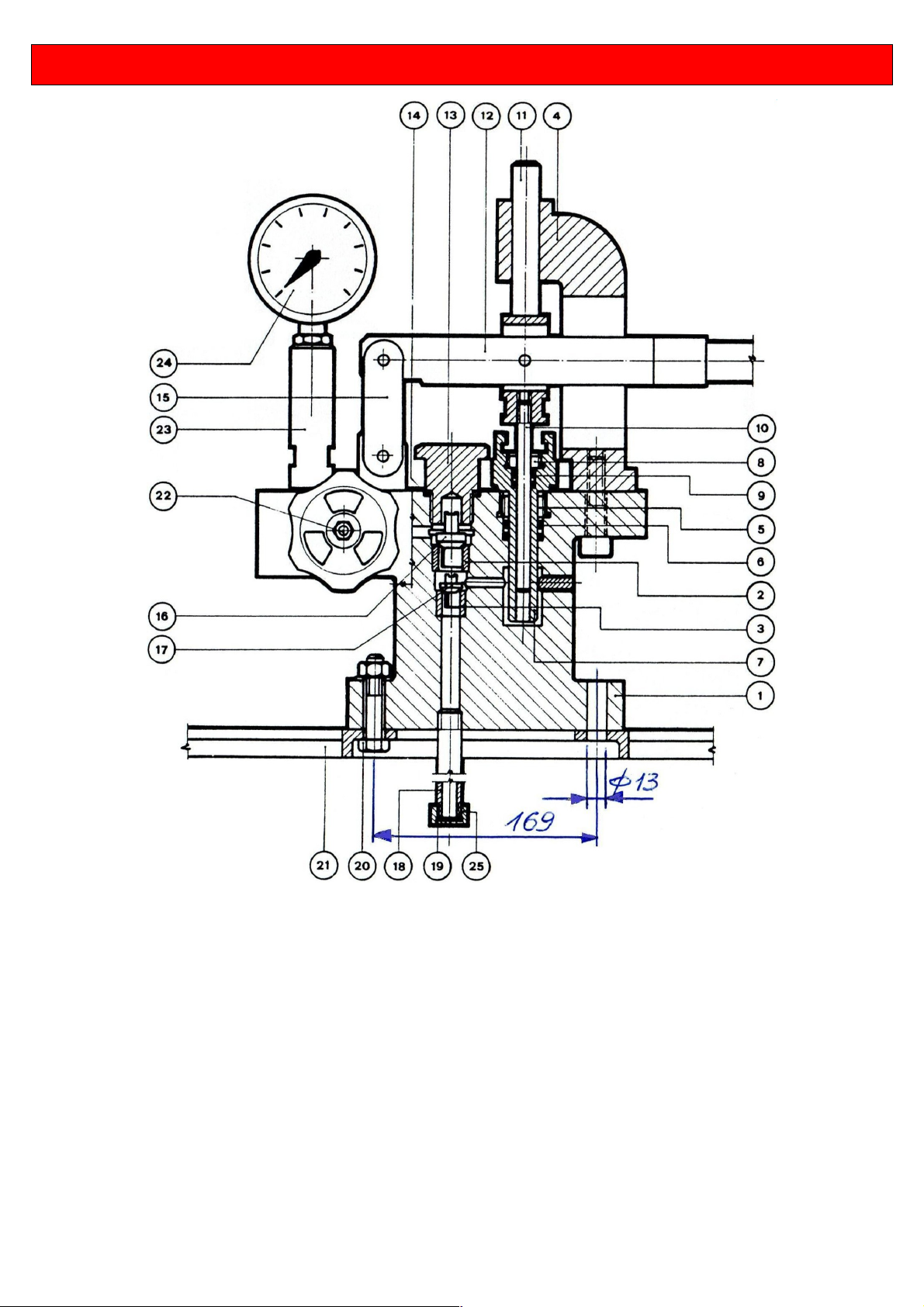

Pos. Description Pos. Description

1 Body pump 14 Seal cap

2 Seat upper shutter 15 Joint

3Seat lower shutter 16 Higher shutter

4 Support 17 Lower shutter

5 Large packing gasket 18 Suction tube

6 Seal for large piston 19 Stainless steel filter

7 Large piston 20 Bolt

8 Small packing gasket 21 Tank

9 Seal for small piston 22 Faucet

10 Small piston 23 Gauge holder

11 Guide for piston 24 Pressure Gauge

12 Lever with handle 25 Filter cap

13 Plug

Table of contents

Other MGF Water Pump manuals