MGF 930456 User manual

This manual is the translation of the original, written in Italian language

1

MGF

MGF srl –– Via Chico Mendes, 8 – 43058 orbolo Mezzani (PR) Italy – Tel. +39 0521-818301 Fax: +39 0521-818202

e-mail: [email protected] – www.mgftools.com – www.nebulife.it – www.nebulizzare.com

Art. 930456 - 930457

930487- 930488

Dual tage Vacuum

Pump

User Manual

Rev. 2 dated 07/03/2022

CAUTION

CAUTION

CAUTION !

It is recommended to carefully read the instructions for use described in this manual before using the instrument.

Keep this manual near the instrument for any quick consultation by the operators!

The Manufacturer declines all responsibility for malfunctions and/or consequences arising from incorrect operations by the User.

Even partial reproduction of this manual in any form is prohibited without the written authorization of the Manufacturer.

The Manufacturer reserves the right to make improvements or changes to its instruments at any time and without notice.

Introduction

Introduction

Congratulations on purchasing this machine.

This manual supplied with the machine and the remaining installation material, which varies according to the configuration of the kit or the

estimate prepared, provides important instructions for the construction of a properly functioning system, for its operation and maintenance.

We remind you that this manual is an integral part of the instrument and contains the indications for a correct use of the same.

We therefore invite you to carefully read the instructions for use before using the instrument, to properly instruct the operators and to keep

it carefully for any future consultation.

These good standards will be the guarantee to obtain excellent performance and reliability from the instrument over time.

IMPORTANT: use MGF

MGF pump oil; the use of different lubricants could reduce the performance of the pump or damage it, even irreversibly.

NEVER U E THE PUMP WITHOUT OIL !!!!

General informations

General informations

ERVICE

For any form of technical assistance you can contact us in one of the following ways:

telephone: +39 0521 818301

fax: +39 0521 818202

email: [email protected]

We will serve you as soon as possible.

The shipment of material under repair must be previously authorized by means of the RMA form (binding condition for the collection of any

goods under repair).

WARRANTY TERM

The product warranty covers any manufacturing defect for a period of time equal to one (1) year from the date of manufacture for

products purchased with invoice, 2 years for products purchased by private individuals.

The following clauses expressly exclude the product from guarantee:

•Consumables insofar as the malfunction is caused by normal wear of the parts

•Damage caused by improper operation

•Bad maintenance

•Machine tampering or modification

The company excludes from its responsibility any indirect damage, damage caused to people and things by defects and machine downtime,

incorrect use, lack of maintenance.

2

MGF

MGF srl –– Via Chico Mendes, 8 – 43058 orbolo Mezzani (PR) Italy – Tel. +39 0521-818301 Fax: +39 0521-818202

e-mail: [email protected] – www.mgftools.com – www.nebulife.it – www.nebulizzare.com

Safety Instructions

Safety Instructions

GENERAL AFETY WARNING

•Observe the general safety regulations for electrical appliances: only carry out maintenance and inspection operations when the

machine is disconnected from the electricity mains. Do not put the power cable under tension, replace it if damaged. Avoid getting

the electrical contacts wet.

•Make sure that the high pressure hoses are not damaged. If necessary, replace them with original tubes. Carry out the

maintenance and disassembly operations of the accessories with the pump off, after having discharged the residual pressure.

•trictly respect the instructions in this manual and work using the general precautions dictated by safety regulations and common

sense.

•Find out in advance about refrigeration systems, refrigerant gases and the risks associated with pressurized equipment used in

conjunction with this station.

•Wear PPE: gloves, eye protection goggles and cold burns caused by refrigerants.

•Consult the technical data sheet of the refrigerant used. Avoid contact with skin and inhalations.

•Avoid working in the presence of water, open flames and hot surfaces: electrical and chemical risks deriving from the

decomposition of the refrigerant.

•Before disconnecting a pipe, check that all the valves are closed: this will prevent the refrigerant from being dispersed into the

atmosphere and avoid dangerous gas leaks. In any case, avoid to disperse the refrigerant in the environment. This practice, in

addition to reducing refrigerant pollution, facilitates the search for any gas leaks.

•Do not fill containers beyond 75% of their maximum capacity.

•Always ensure good ventilation to the pump. In particular, leave the air vents on the rear fan cover free.

•In case of scrapping, collect the homogeneous parts of the machine, accessories and packaging and dispose of them in

accordance with current legislation.

Product Specifications

Product Specifications

3

MGF

MGF srl –– Via Chico Mendes, 8 – 43058 orbolo Mezzani (PR) Italy – Tel. +39 0521-818301 Fax: +39 0521-818202

e-mail: [email protected] – www.mgftools.com – www.nebulife.it – www.nebulizzare.com

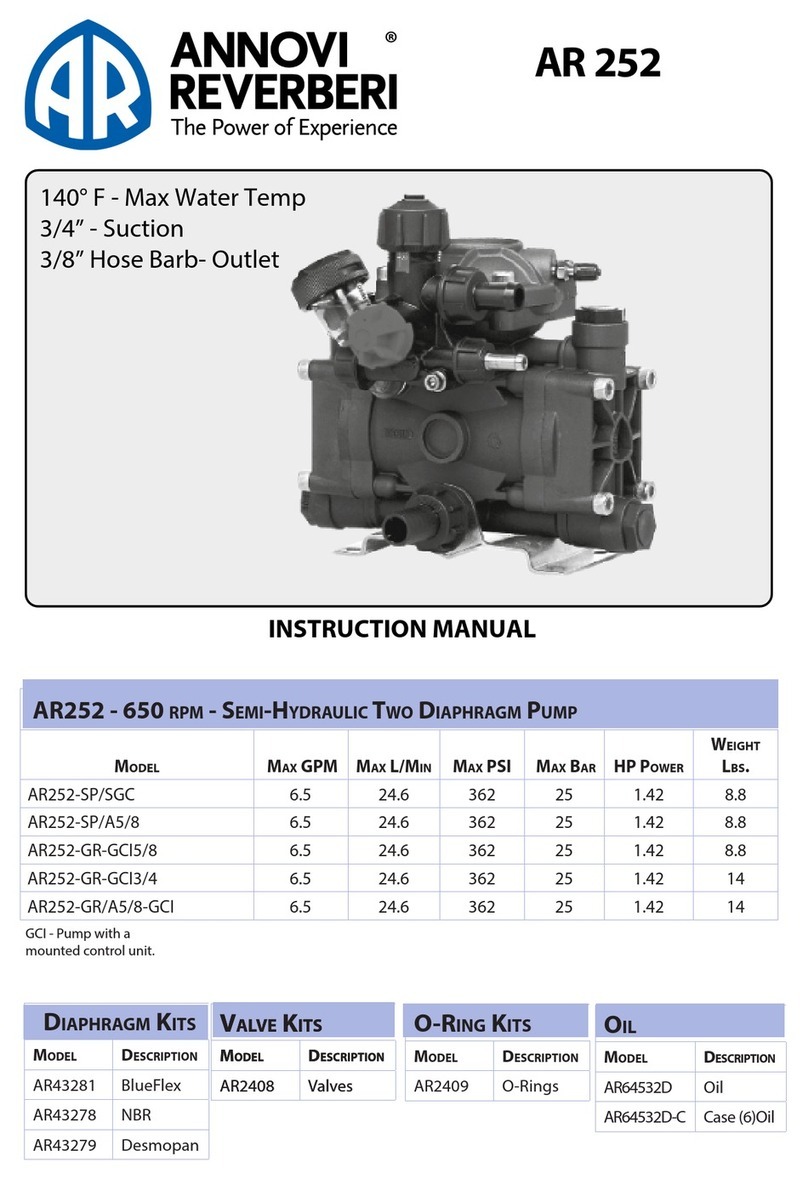

Free air displecement 42 L/min 85L/min 170L/min 283L/min

Art. 930456 930457 930488 930487

Pumping stages 2 2 2 2

olenoid valve i i i i

Vacuum gauge i i i i

Final Vacuum 200 mTorr 200 mTorr 200 mTorr 200 mTorr

Power supply 230V~50/60Hz 230V~50/60Hz 230V~50/60Hz 230V~50/60Hz

Motor power 190 W 250 W 560 W 750 W

Connection 1/4” AE 1/4” AE 1/4” AE 1/4” AE

Oil tank 180mL 330mL 330mL 600mL

Vacuum gauge 50mm 50mm 50mm 50mm

Weight (Kg) 6 7 15 16

ize (mm) 270 x 119 x 216 278 x 119 x 216 370 x 140 x 250 390 x 140 x 250

Function instruction

Function instruction

In all cases, the motors are designed for operating voltages above or below 10% of the normal rating.

FUNCTION IN TRUCTION

Verify that the voltage and frequency at the output match the specifications on the pump motor label.

All installation operations must be carried out before starting and with the pump strictly stopped. Check the ON-OFF switch to make sure it

is in the OFF position before plugging the pump into an outlet. While no special precautions are necessary for normal commissioning, a

series of operations must be carried out prior to initial commissioning.

1. Oil loading/unloading

Remove the drain plug from the end of the pump handle. The vacuum pump was originally tested and shipped without oil in the tank. OIL

MU T BE ADDED BEFORE U ING THE MACHINE. Failure to introduce oil seriously damages the machine and voids the warranty.

All installation operations must be carried out before starting and with the pump strictly switched off.

•Make sure the oil drain valve located under the reservoir is closed before adding oil.

•Remove the oil cap located on the top of the tank and insert the oil bottle.

•lowly add oil until the oil is just visible at the bottom of the sight glass. The approximate oil capacity of the pump is 180-600ml (refer

to technical data). Avoid overfilling the reservoir which would cause the pump to overheat

•Replace the oil plug and remove the plug from one of the inlet ports. Turn the engine switch to ON. When the pump runs smoothly,

replace the plug on the inlet port. This can take from two to 30 seconds depending on the ambient temperature. After the pump has

run for about one minute, check the oil level in the sight glass. The level should be at the same level as the oil level line on the sight

glass. Add oil if necessary.

Note: When the pump is running, the oil level should be at the same level as the line on the sight glass. Insufficient filling will result in poor

vacuum performance. Overfilling can cause oil to leak out of the drain.

2. uction tube

Connect the suction pipe to the pump and to the manometric group. Reduce, if possible, curves, throttling and pressure drops in general, in

order to improve the final vacuum degree and evacuation speed

3. Electrical connection

Check that the characteristics of the electrical power supply network are compatible, that the electrical network complies with Community

legislation, is equipped with a differential thermal breaker and earth connection. When using extension cables, make sure that they have an

adequate section for the electrical load to be supported.

4. Ventilation

The MGF

MGF vacuum pump has been designed to work in optimal temperature conditions (40-50 °), thanks to the forced ventilation and the

efficiency of the exchange surfaces. Although it is equipped with a thermal protection device, it is good to make sure that there are no

obstacles to the air flow generated by the fan.

5. First start-up

Each pump undergoes a rigorous running-in cycle, however, before starting work, it is advisable to leave the pump running for 10 minutes

with the suction port closed.

6. hutdown

To help extend the life of the pump and promote easy start-up. Follow these procedures for shutdown.

•Close the manifold valve between the pump and the system.

•Remove the tubing from the pump inlet.

•Plug the inlet port to prevent contamination or loose particles from entering the pump.

4

MGF

MGF srl –– Via Chico Mendes, 8 – 43058 orbolo Mezzani (PR) Italy – Tel. +39 0521-818301 Fax: +39 0521-818202

e-mail: [email protected] – www.mgftools.com – www.nebulife.it – www.nebulizzare.com

Tips for Use

Tips for Use

tart-up: excluding the first start-up, they are not particular demands attention, if not control the oil level. The pump must be used on a

stable and horizontal surface.

Vacuum pump oil: The condition and type of oil used in any high vacuum pump are extremely important in determining the maximum

achievable vacuum. The use of high vacuum pump oil is recommended. This oil has been specially blended to maintain maximum viscosity

at normal operating temperatures and to improve starts at low temperatures. Uses 0,5L MGF

MGF Mineral Oil for vacuum pumps

Art. 790100

.

Maintenance

Maintenance

Periodically check the condition of the pump and the electrical components (cable and electrical box). Replace the damaged parts with

original MGF

MGF spare parts.

Lubrication: the first oil charge must be replaced after approximately 150/200 hours of operation. ubsequent changes must be made

every 400/500 hours or every 3/4 months.

The oil must be replaced even in the presence of humidity or dirt, which can damage the pump and affect its performance. It is essential to

use MGF

MGF pump oil, which is optimal for ensuring correct pump operation (

Art. 790100

).

Oil change procedure

1. Be sure the pump is warmed up.

2. Remove the oil drain cap. Drain contaminated oil into a suitable container and dispose of properly. Oil can be forced from the

pump by opening the inlet and partially blocking the exhaust with a cloth while the pump is running. Do not operate the pump for

more than 20 seconds using this method.

3. When the flow of oil has stopped, tilt the pump forward to drain the residual oil.

4. Replace the OIL DRAIN cap. Remove the exhaust fitting and fill the reservoir with new vacuum pump oil until the oil just shows at

the bottom of the sight glass. The approximate oil capacity of the pump is 180-800ml (reference the technical data).

5. Be sure the inlet ports are capped, then turn on the pump. Allow it to run for one minute, then check the oil level space. If the oil

is below the sight glass OIL LEVEL line add oil slowly (with the pump running) until the oil reaches the OIL LEVEL line. Replace the

exhaust fitting, making sure the inlet is capped and the drain cap is tight.

6. If the oil is badly contaminated with sludge that forms when water is allowed to collect in the oil, you may need to remove the oil

reservoir cover and wipe it out.

◦Another method of dealing with heavily contaminated oil is to force oil from the pump reservoir. To do this, allow the

pump to run until it it is warmed up. While the pump is still running, remove the oil drain plug. lightly restrict the

exhaust. This will back-pressure the oil reservoir and force the oil from it, carrying more contamination.

When the oil ceases to flow, turn off the pump.

Repeat this procedure as required until the contamination is removed. Replace the OIL DRAIN cap and refill the reservoir

to the proper level with fresh vacuum pump oil.

5

MGF

MGF srl –– Via Chico Mendes, 8 – 43058 orbolo Mezzani (PR) Italy – Tel. +39 0521-818301 Fax: +39 0521-818202

e-mail: [email protected] – www.mgftools.com – www.nebulife.it – www.nebulizzare.com

Spare Parts

Spare Parts

ERVICE

For any form of technical assistance you can contact us in one of the following ways:

telephone: +39 0521 818301

fax: +39 0521 818202

email: [email protected]

N° Descripton N° Descripton

1Fan cover 14 Inlet fitting

2Cross screw 15 Trestle

3Fan 16 crew

4Motor cover 17 Rotary-vane

5Cross screw 18 Cap board

6Bearing 19 Exhaust fitting

6

MGF

MGF srl –– Via Chico Mendes, 8 – 43058 orbolo Mezzani (PR) Italy – Tel. +39 0521-818301 Fax: +39 0521-818202

e-mail: [email protected] – www.mgftools.com – www.nebulife.it – www.nebulizzare.com

7Motor rotor 20 Die cast alumiun housing

8Power supply cords 21 ight glass

9Power switch 22 Oil drain cap

10 Centrifugal switch 23 crew

11 Motor stator 24 eal

12 Capacitor 25 crew

13 Handle 26 Rubber foot

14 Inlet fitting 27 Base

Common problems

Common problems

Your pump has been for dependable use and long life. If something should go wrong, the following guide will help you get the pump back

into service as quickly as possible.

If disassembly of the pump is required, please check your warranty. The warranty may be voided by misuse or customer tampering wich

results in the pump being inoperable.

•Failure to start: Check the line voltage. The pump ned to start at ± 10% line voltage (loaded) at 32°F. At extremes, switching

between the startand run windings may occur.

•Oil leakage:

1. Be sure the oil is not a residual accumulation from spillage, etc.

2. If leakage exists the module cover gasket or the shaft seal may need replacing.

If leakage exists in the area of the oil drain plug, you may need to reseal the plug using a commercial pipe thread sealer.

•Failure to pull a good vacuum:

1. Be sure the vacuum gauge and all connections are in good condition and leak free. You can confirm leakage by

monitoring the vacuum with a thermistor gauge while applying vacuum pump oil at connections or suspected leak points.

The vacuum will improve briefly while the oil is sealing the leak.

2. Be sure the pump oil is clean. A badly contaminated pump may require several oil flushes.

3. Be sure the oil is at the proper level. For maximum pump operation, the oil must be even with OIL LEVEL line on the

sight glass when the pump is running. Do not overfill---- operating temperatures will cause oil to expand, so it will appear

at a higher level than when the pump is not running. To check the oil level, start the pump with the inlet capped. Check

the oil level in the sight glass. Add oil if necessary.

Storage

Storage

•When not in use, store the machine in a cool place. To protect against dirt and dust, use the original packaging

•Follow the maintenance instructions

isposal

isposal

Do not dispose of power tools with household waste!

•In compliance with the European Directive 2002/96/EC on Waste Electrical and Electronic Equipment and its

transposition into national law, used power tools must be collected separately and recycled in an environmentally

sustainable manner.

7

MGF

MGF srl –– Via Chico Mendes, 8 – 43058 orbolo Mezzani (PR) Italy – Tel. +39 0521-818301 Fax: +39 0521-818202

e-mail: [email protected] – www.mgftools.com – www.nebulife.it – www.nebulizzare.com

Conformity eclaration

Conformity eclaration

MGF

MGF srl - Via Chico Mendes, 8 - 43058 orbolo Mezzani (PR) - Italy declares under its own responsibility that the Dual tage Vacuum

Pump art. 930456, 930457, 930487 and 930488 are comply with the requirements of directive 2006/42/EC; with regard to electromagnetic

compatibility, to directive 2004/108/EC; as regards the safety of electrical equipment, the directive 2006/95/EC; as far as hazardous

materials are concerned, they comply with the 2011/65/EC standard; as regards electrical waste, they comply with the 2012/19/EC

standard; as regards pressure vessels, it complies with standard 97/23/EC

MGF

MGF srl

8

MGF

MGF srl –– Via Chico Mendes, 8 – 43058 orbolo Mezzani (PR) Italy – Tel. +39 0521-818301 Fax: +39 0521-818202

e-mail: [email protected] – www.mgftools.com – www.nebulife.it – www.nebulizzare.com

This manual suits for next models

3

Table of contents

Other MGF Water Pump manuals

Popular Water Pump manuals by other brands

Makita

Makita DVP181ZK instruction manual

salmson

salmson MULTI-VE Series Installation and starting instructions

Storch

Storch WAMAB installation instructions

Pentair

Pentair MYERS C40-20 Installation and service manual

Carbest

Carbest 4-KAMMER DRUCKPUMPE User instruction

Zipper Mowers

Zipper Mowers ZI-DWP900 Operation manual

DEMA

DEMA MixRite TF-25 quick start guide

Kessel

Kessel SECOH SLL Series instruction manual

VEVOR

VEVOR Q1CZ-800C1 user manual

Ingersoll-Rand

Ingersoll-Rand PD10E-X-X user manual

Annovi Reverberi

Annovi Reverberi BHS 90 instruction manual

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS T6A61S-B Installation, operation and maintenance manual