SSI30 Wood Insert

463D4004

Read all instructions and warnings carefully before starting installation. Failure to

follow these instructions may result in a possible fire hazard and will void the warranty.

MHSC inserts and component parts have been tested to

operate safely when installed in accordance with instruc-

tions provided in this manual. Carefully read and under-

stand all instructions before beginning installation.

If you notice any damage to insert or component parts,

immediately report damage to your MHSC dealer.

Only use MHSC components or the warranty will be voided

and a fire hazard may be created.

MHSC warranty will be voided by and MHSC disclaims any

responsibility for the following actions:

•

•

(except for chase flash-

ings as detailed in MHSC Chimney Top installation

instructions).

• MHSC

•

MHSC

MHSC

Consult local building codes to ensure that you are in

compliance installing the insert.

This insert and chimney system must be vented out-

doors.

1. Check with the building inspector’s office for compliance

with local codes; a permit may be required.

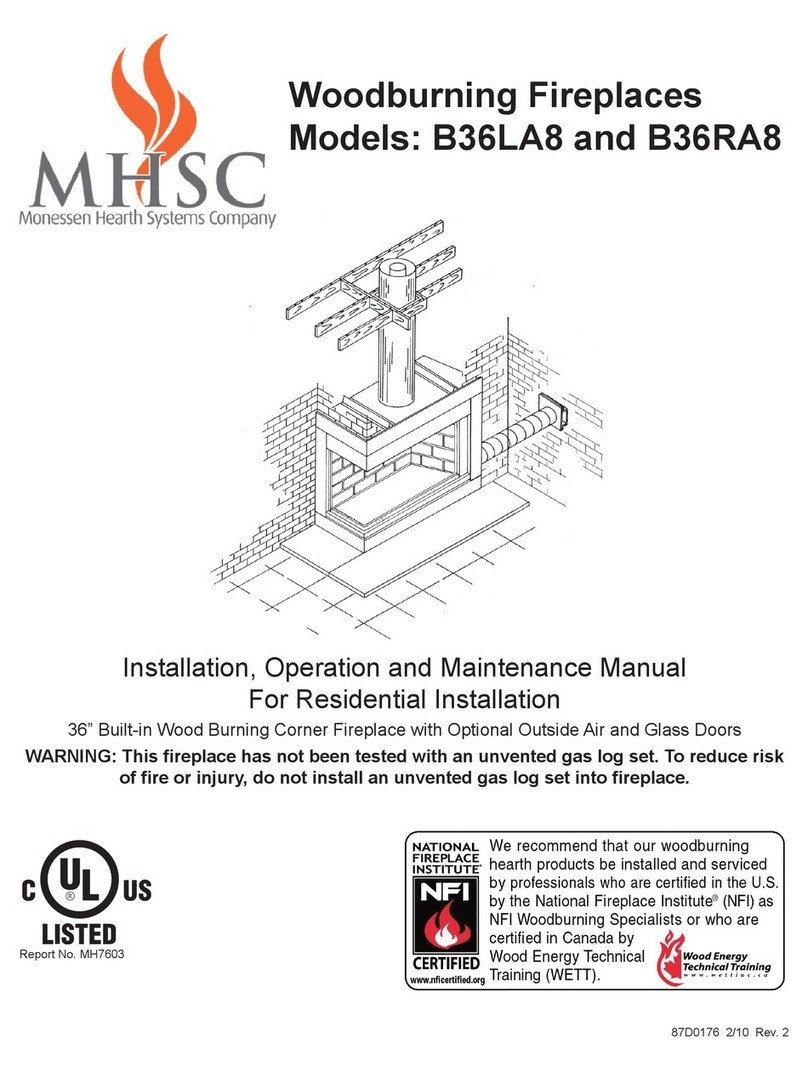

2. This appliance requires a masonry or prefabricated

chimney listed to ULC S629 (Canada) and UL 103HT

(U.S.) sized correctly.

3. A 6" (152 mm) diameter flue is required for proper

performance.

4. Always connect this unit to a chimney and VENT

TO ANOTHER ROOM OR INSIDE A BUILDING.

connect this unit to any duct work to which

another appliance is connected such as a furnace.

connect this unit to a chimney flue serving

another appliance.

The connector pipe and chimney should be inspected

periodically and cleaned if necessary.

8. Remember the clearance distances when you place

furniture or other objects within the area. store

wood, flammable liquids or other combustible materials

too close to the unit.

9. Contact your local municipal or provincial fire authority

for information on how to handle a chimney fire. Have

a clearly understood plan to handle a chimney fire. In

the event of a chimney fire, turn air control to closed

position and

tamper with combustion air control beyond

normal adjustment.