Michigan Pneumatic Tool MP-HS-1SC User manual

Industrial Air Tools

MP-HS-1SC

1-800-521-8104 •www.michiganpneumatic.com

Manual

Single Piston Heavy

Duty Scabbler

2

Table of ContentsTable of Contents

Features

Table of Contents � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 2

Features � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 2

Safety � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 3

Maintenance � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

MP-HS-1SC Specications � � � � � � � � � � � � � � � � � � � � � � � � � � � 11

MP-HS-1SC Parts Print � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 12

Troubleshooting � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 13

Limited Warranty � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 14

Notes � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 15

The MP-HS-1SC is a single piston hand held scabbler with

carbide tipped piston. The unit is designed for close quarter

applications, vertical surfaces and other areas that standard

scabblers cannot reach.

Piston Diameter ............................... 2"

Blows Per Minute ........................2000 bpm

Height ....................................9-1/2"

Length ......................................8.5"

Weight....................................10 lbs.

Air Inlet Thread ...............................3/8"

Avg. Air Consumption .......................15 cfm

3

Safety

General Product Safety

Information

• Failure to observe the following

warnings and failure to avoid

these potentially hazardous

situations could result in death or

serious injury.

• Read and understand this

and all other supplied manuals

before installing, operating

repairing, maintaining, changing

accessories or working near

this product.

• Only qualied and trained

operators should install, adjust

or use the tool.

• It is your responsibility to

make this safety information

available to others that will

operate this product.

• The warnings given in this and

all other supplied manuals are for

identifying hazards that are fore-

seeable in the general use of

this tool. However, specic

applications may create other

hazards that must be identied

and reduced before using the tool.

• Always install, operate, inspect

and maintain this product in

accordance with all applicable

standards and regulations (local,

state, country, federal, etc.)

Operate and maintain this tool

as recommended in this manual

to prevent an unnecessary

increase in noise, vibration, dust

and fume hazards.

WARNING

Product Safety

Information – When

Placing the Tool in

Service

• Before beginning a job the

operator or their employer must

assess all potential risks of

using this product to do the job.

These risks must be eliminated

or appropriate controls must be

implemented to reduce the risk

to a safe level.

• Always use clean, dry air at 90

psig (6.2 bar/620 kPa) maximum

air pressure at the inlet, unless a

higher pressure rating is specied

on the tool. Exceeding the

maximum rated pressure (PMAX)

shown on the tool may result in

hazardous situations including

excessive speed, rupture, or

incorrect output torque or force.

• Ensure an accessible

emergency shut off valve has

been installed in the air supply

line, and make others aware of

its location.

• Install a properly sized Safety

Air Fuse upstream of hose and

use an anti-whip device across

any hose coupling without

Safety

4

Safety

internal shut-off to prevent

hose whipping if a hose fails or

coupling disconnects.

• Whenever universal twist

couplings (claw couplings)

are used, lock pins should be

installed to prevent connection

failure. Whip hoses can cause

severe injury. Do not use

damaged, frayed or deteriorated

air hoses and ttings. Check

that all ttings are tight before

applying air pressure.

WARNING

Product Safety

Information – General

Hazards While Tool

In Use

• Always use Personal Protective

Equipment appropriate to the

tool used and material worked.

This may include dust masks

or other breathing apparatus,

safety glasses, ear plugs, gloves,

apron, safety shoes, hard hat

and other equipment.

• Air under pressure can cause

severe injury. Never direct air at

yourself or anyone else.

• Always turn off the air supply.

Bleed the air pressure and

disconnect the air supply

hose when not in use before

performing any maintenance on

this tool or any accessory.

• Keep clear of whipping air

hoses. Shut off the compressed

air before approaching a

whipping hose.

• Do not use power tools when

tired or under the inuence of

medication, drugs or alcohol.

• Never use a damaged or

malfunctioning tool or accessory.

• Do not modify the tool,

safety devices or accessories.

Modications can reduce the

effectiveness of safety measures;

increase the risks to the operator,

and void the warranty.

• Do not use this tool for

purposes other than

recommended.

• Exposed throttles shall not

be used where obstructions

can hold the throttle in the

“on” position.

• When a secondary handle

is supplied ensure it is properly

installed and use two hands to

maintain control when operating

the tool.

Safety

5

Safety

Workplace Hazards

• Slips, trips and falls are major

causes of workplace injury. Keep

work area clean, uncluttered,

ventilated, and illuminated.

• Be aware of slippery surfaces

caused by the use of the tool and

also of trip hazards caused by

the air line.

• For overhead work, safety

helmets must be worn. The

increased risks to the operator

and others must be assessed

and reduced to a safe level.

• Keep others at a safe distance

from your work area or ensure

they use appropriate Personal

Protective Equipment.

• This tool is not designed for

use in potentially explosive

atmospheres including those

caused by fumes, dust or near

ammable materials.

• This tool is not insulated

against electric shock.

Be aware of buried, hidden

or other hazards in your work

environment. Do not contact

damage cords, conduits, pipes or

hoses that may contain electrical

wires, explosive gases or

harmful liquids.

Projectile Hazards

• Always wear eye protection

when operating or performing

maintenance on this tool. The

grade of protection required

should be assessed for each use

and may include impact-resistant

glasses with side shields,

goggles, or a full face shield over

those glasses.

• Ensure work pieces are secure.

Use clamps or vises to hold work

piece whenever possible.

• Failure of the work piece or

accessories can generate high-

velocity projectiles.

Noise Hazards

• Always wear hearing protection

when operating this tool.

• Exposure to high noise levels

can cause permanent, disabling

hearing loss and other problems

such as tinnitus (ringing, buzzing,

whistling or humming in the

ears). Therefore, risk assessment

and the implementation of

appropriate controls for these

hazards are essential.

Safety

6

• Appropriate controls to reduce

the risk from noise hazards may

include actions such as damping

materials to prevent work pieces

from “ringing.”

• If the tool has a silencer, always

ensure it is in place and in good

working order when the tool is

being operated.

Operating Hazards

• Operators and maintenance

personnel must be physically

able to handle the bulk, weight

and power of the tool.

• Keep body stance balanced

and rm. Do not overreach when

operating this tool. Anticipate

and be alert for sudden changes

in motion or forces during start

up and operation. The operator

should change posture during

extended tasks, which can help

avoid discomfort and fatigue.

• Use of the tool can expose

the operator’s hands to hazards,

including crushing, impacts,

cuts, abrasions and heat. Wear

suitable gloves to protect hands.

However, ensure that the gloves

do not restrict your ability to

release throttle mechanism.

• To avoid accidental starting –

ensure the tool is in the “off”

position before applying air

pressure, avoid the throttle when

carrying, and release the throttle

with loss of air.

• Do not lubricate tool with

ammable or volatile liquids

such as kerosene, diesel or jet

fuel. Use only recommended

lubricants.

• Do not carry or drag the tool by

the hose.

• Tool and/or accessories may

briey continue their motion after

throttle is released.

Accessory Hazards

• Use only sizes and types of

accessories and consumables

that are recommended by

the tool manufacturer; do not

use other types or sizes of

accessories or consumables.

Safety

7

Dust and Fume Hazards

• Wear appropriate respiratory

protection if dust or fumes are

present in the work area.

• Dust and fumes generated

when using power tools, and

existing dust disturbed by their

use can cause ill health (for

example, cancer, birth defects,

asthma and/or dermatitis,). Risk

assessment and implementation

of appropriate controls for these

hazards are essential. The priority

shall be to control them at the

source.

• Direct the exhaust so as to

minimize disturbance of dust in a

dust-lled environment.

• All integral features or

accessories for the collection,

extraction or suppression of

airborne dust or fumes should be

correctly used and maintained

in accordance with the

manufacturer’s instructions.

Prevent exposure and inhalation

of harmful dust and particles

created by power tool use.

• Some dust created by power

sanding, sawing, grinding, drilling

and other construction activities

contain chemicals known to

cause cancer, birth defects, or

other reproductive harm. Some

examples of these chemicals are:

• Lead from lead based paints

• Crystalline silica from bricks

and cement and other

masonry products

• Arsenic and chromium from

chemically treated lumber

• Your risk from these exposures

varies, depending on how often

you do this type of work.

• To reduce your exposure to

these chemicals: work in a well

ventilated area and work with

approved safety equipment

such as dust masks that are

specially designed to lter out

microscopic particles.

Entanglement Hazards

• Entanglement of loose clothing,

personal jewelry, neckwear, hair,

gloves or other items can occur if

not kept away from the working

end of the tool. Entanglement

can result in choking, scalping,

lacerations, broken bones and/or

severed extremities.

Safety

8

Vibration Hazards

• Power tools can vibrate in

use. Exposure to vibration can

cause disabling damage to

the nerves and blood supply

of the hands and arms. If you

experience numbness, tingling,

pain or whitening of the skin in

your ngers or hands, stop using

the tool and seek advice from

a qualied health professional

before resuming use.

• Hold the tool with a light but

safe grip, taking account of the

required hand reaction forces

because the risk arising from

vibration is generally greater

where the grip force is higher.

• Wear warm clothing when

working in cold conditions and

keep your hands warm and dry.

Repetitive Motion

Hazards

• Repetitive motions or

uncomfortable positions may

be harmful to your hands, arms,

shoulders, neck or other parts

of the body. Stop using any tool

if symptoms such as persistent

or recurring discomfort, pain

throbbing, aching, tingling,

numbness, burning sensations

or stiffness occur. These warning

signs should not be ignored.

Seek advice from a qualied

health professional before

resuming use.

WARNING

Product Safety

information – When

Maintaining the Tool

• Keep the tool operating safely

through regular preventative

maintenance including regular

checks of speed and vibration.

• When maintaining the tool,

avoid exposure or breathing

of hazardous dust and other

substances deposited on the tool

during use.

• Use only proper cleaning

solvents to clean parts. Use

only cleaning solvents which

meet current safety and health

standards. Use cleaning solvents

in a well ventilated area.

Safety

9

• Do not remove any labels.

• Replace any damaged label.

Using The Scaler

Remember that it is always the

tool that must do the work. There

is no need for the operator to

apply extra pressure on the tool

when it is working.

Maintain the contact with the

work surface by applying enough

pressure to stop the tool from

bouncing.

Maintenance

1. To obtain maximum efciency

from the pneumatic tool, preserve

its features and avoid repeated

repairs, a routine inspection

and repair programme are

recommended at least every

1000 hours, the intervals

between the various inspections

depending on the amount of

exertion on the power tool.

2. Disassemble the tool, clean

the parts with an appropriate

solvent and check them carefully.

3. Lubricate and reassemble

the unit.

Safety

Wear Respiratory

Protection

Wear Eye

Protection

Wear Hearing

Protection

Read Manuals

Before Operating

Product

10

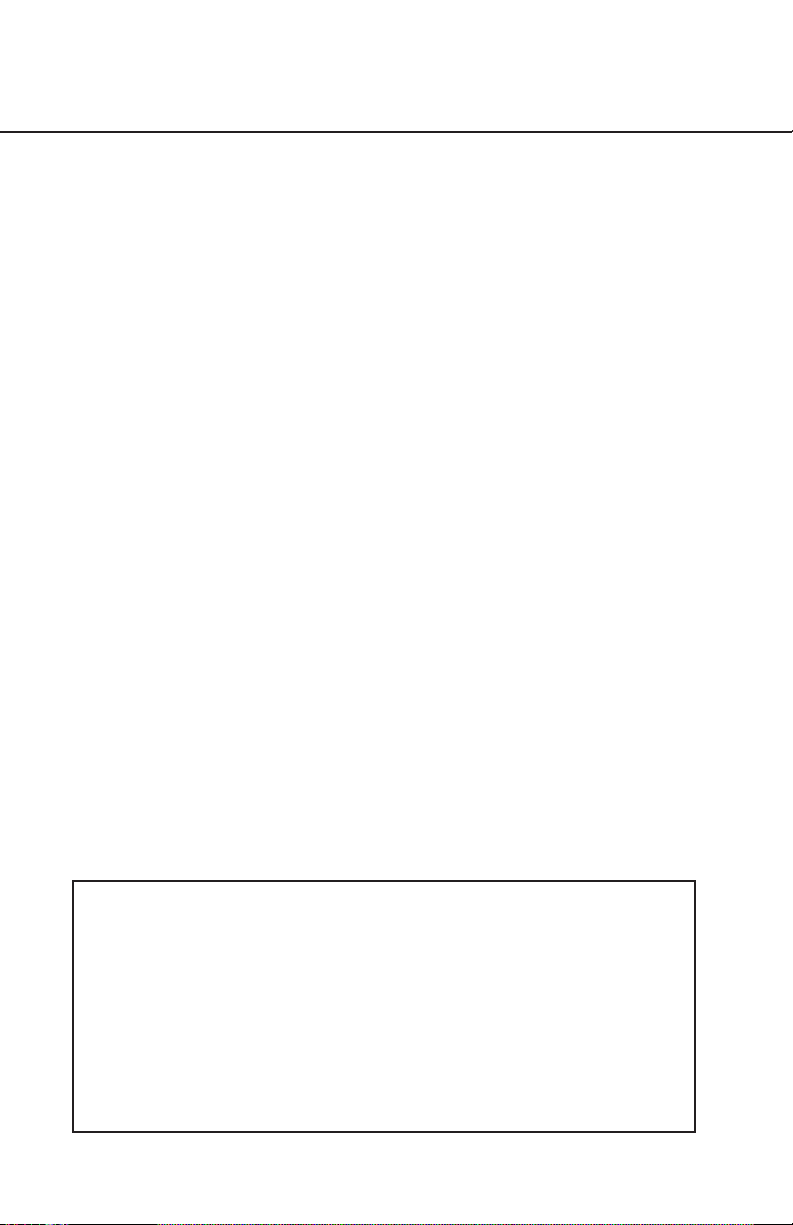

Lubrication

1. Each time a tool is dis-

assembled for maintenance

or repair, the tool must be

lubricated.

2. Apply 6-8 drops of air tool oil

into the inlet prior to and after

each use (see gure 10.2).

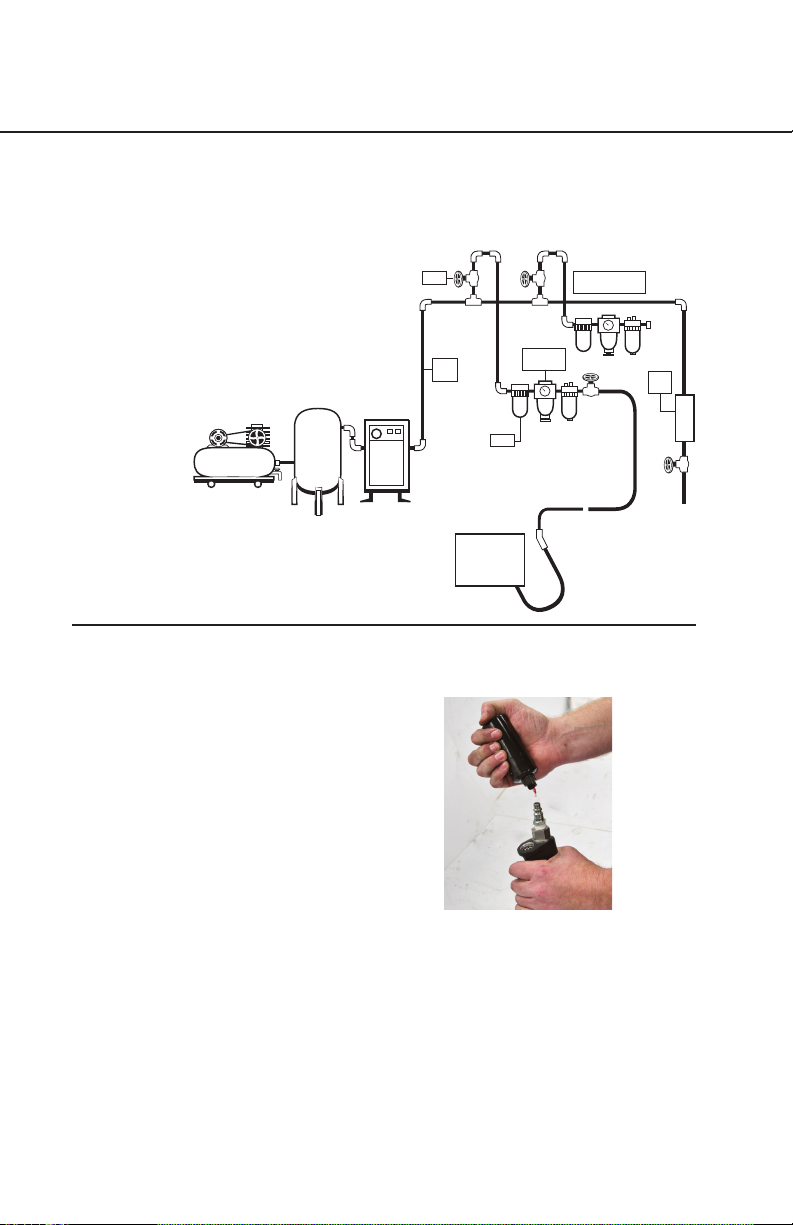

Air Supply

1. Always use clean, dry air

at 90 psig (6.2 bar/620kPa)

maximum air pressure.

2. Be sure all hoses and ttings

are the correct size and are

secured tightly.

3. Always use a Filter, Regulator,

Lubricator (see gure 10.1).

Maintenance

Compressor

Air Tank

Air

Dryer

Main

Pipe

Valve Higher than

1/100 inclination

Pressure

Regulator

Drain

Tank

Filter

Bigger Hose Better

Tool

Figure 10.1

Figure 10.2

11

Model

MP-HS-1SC

Single Piston Heavy Duty Scabbler

The MP-HS-1SC is a single piston hand held scabbler with carbide tipped

piston. The unit is designed for close quarter applications, vertical surfaces

and other areas that standard scabblers cannot reach.

Piston Diameter ............................... 2"

Blows Per Minute ........................ 2000 bpm

Height ....................................9-1/2"

Length ...................................... 8.5"

Weight....................................10 lbs.

Air Inlet Thread ............................... 3/8"

Avg. Air Consumption .......................15 cfm

04022015Rev5 PFT | NP

Specication Sheet

04022015Rev4 PFT | NP

12

Michigan Pneumatic Tool, inc.

MP-HS-1SC Single Piston HD Scabbler

6850 Middlebelt Rd. • Romulus, MI 48174 • 1-800-521-8104 • Ph: (313) 933-5890 • Fax: (313) 933-0440

Michigan Pneumatic Tool, inc.

10042018Rev1MME | MF

1

2

3

4

5

6

7

8

9

10

11

1R

2R 3R

4R

5R

6R

7R

8R

9R

10R

11R

12R

13R

Index Part No. Description Qty.

1 HS-BCAP Back Cap 1

2 HS-PISTON Piston 1

3 568-132BN70 O-Ring 1

4

R147915

Handle Assembly

Includes; see *R147915- Handle

Assembly

1

5 834-48 Dead Handle 1

6 HS-EXHCVR Exhaust Cover 1

7 PWB-11 Seal 1

8 810019 Bit Scabbler 9-Point 1

9 SNP-9.857 Pin Spring Lock (incl. SNP-528) 1

10 HS-CYLASM Complete Cylinder Assembly

Includes (HS-Bush) 1

11 HS-BUSH Scabbler Bushing 1

MP-HS-1SC Single Piston HD Scabbler

*R147915 - Handle Assembly

Index Part No. Description Qty.

1R R147620 Pivot Screw Nut 1

2R R147617 Pivot Screw 1

3R R147612 Throttle Lever 1

4R R147617 Pivot Screw 1

5R R147621 Operating Stud 1

6R R147620 Pivot Screw Nut 1

7R R147613 Body End 1

8R R147607 Snap Handle Body 1

9R R147609 Snap Handle Valve 1

10R A043001 Valve Ring Seal 2

11R R147618 Nylon Washer 1

12R R147619 Washer Retaining Ring 1

13R R147615 Valve Spring 1

R147915- Handle Assembly

6850 Middlebelt Rd. • Romulus, MI 48174 • 1-800-521-8104 • Ph: (313) 933-5890 • Fax: (313) 933-0440

Michigan Pneumatic Tool, inc.

10042018Rev1MME | MF

1

2

3

4

5

6

7

8

9

10

11

1R

2R 3R

4R

5R

6R

7R

8R

9R

10R

11R

12R

13R

Index Part No. Description Qty.

1 HS-BCAP Back Cap 1

2 HS-PISTON Piston 1

3 568-132BN70 O-Ring 1

4

R147915

Handle Assembly

Includes; see *R147915- Handle

Assembly

1

5 834-48 Dead Handle 1

6 HS-EXHCVR Exhaust Cover 1

7 PWB-11 Seal 1

8 810019 Bit Scabbler 9-Point 1

9 SNP-9.857 Pin Spring Lock (incl. SNP-528) 1

10 HS-CYLASM Complete Cylinder Assembly

Includes (HS-Bush) 1

11 HS-BUSH Scabbler Bushing 1

MP-HS-1SC Single Piston HD Scabbler

*R147915 - Handle Assembly

Index Part No. Description Qty.

1R R147620 Pivot Screw Nut 1

2R R147617 Pivot Screw 1

3R R147612 Throttle Lever 1

4R R147617 Pivot Screw 1

5R R147621 Operating Stud 1

6R R147620 Pivot Screw Nut 1

7R R147613 Body End 1

8R R147607 Snap Handle Body 1

9R R147609 Snap Handle Valve 1

10R A043001 Valve Ring Seal 2

11R R147618 Nylon Washer 1

12R R147619 Washer Retaining Ring 1

13R R147615 Valve Spring 1

R147915- Handle Assembly

13

MP-HS-1SC Single Piston HD Scabbler Troubleshooting

Trouble Possible Cause Solution

Low Power Restriction in Air Strainer

Screen/Mufer

Remove Inlet Bushing, Air Stainer Screen, and

Mufer. Clean with a suitable solvent in a well

ventilated work space. Replace Inlet Bushing, and

Air Stainer Screen.

Low Power Worn and/or Broken

Pistons

Replace Piston

Low Power Worn/Damaged Cylinders Replace Body

Low Power Debris in Completely disassemble tool. Clean all parts with a

suitable solvent in a well ventilated work space.

Runs without

actuating Trigger

Worn/Damaged Valve

Stem O-Ring and/or

Valve Spring

Replace the Throttle Vave Seat and Throttle Valve

(see page 12).

14

Limited Warranty

For Your Records:

Dealer Contact Name _______________________________________

Dealer Contact Phone ______________________________________

Date of Purchase ___________________________________________

Serial Number _____________________________________________

MP-HS-1SC 1-YEAR LIMITED

EXPRESS WARRANTY

Michigan Pneumatic Tool, Inc.

makes every effort to ensure that

its MP-HS-1SC scabblers are

of high quality, and warrants all

new MP-HS-1SC scabblers it

sells to be free from defects in

materials and workmanship for

a period of three hundred sixty

ve (365) days from the date of

original purchase. This warranty

shall not apply to defects due,

directly or indirectly, to abuse,

misuse, negligence, normal

wear and tear or improper

maintenance, nor shall it apply

to any product which has been

repaired or altered outside of our

facilities. Should any product fail

to provide satisfactory service,

return the complete product

requiring warranty service to

Michigan Pneumatic Tool for

examination, with transportation

charges prepaid, together with

an explanation of the complaint

and proof of purchase. Michigan

Pneumatic Tool guarantees to

repair or replace any product

found upon our inspection

to be so defective. Michigan

Pneumatic Tool makes no

other warranty expressed or

implied and expressly disclaims

any implied warranty of

merchantability or tness for a

particular purpose. There are

no warranties which extend

beyond the description contained

herein. Michigan Pneumatic

Tool shall in no event be liable

for death, injuries to persons

or property, or for incidental,

consequential, indirect or special

damages of any nature arising

from the sale or use of the MP-

HS-1SC, excepting only the

cost or expense of repair and

replacement as described above.

This warranty gives the customer

specic legal rights. Other legal

rights may vary from state to

state.

15

Notes

Industrial Air Tools

6850 Middlebelt Rd. • P.O. Box 906

Romulus, MI 48174-7406

© 2018 Michigan Pneumatic®Tool, Inc.

10052018Rev3MME | MF

Table of contents