MICRO-AIR SCA Series User manual

Installation and Operation Manual

Important:

This manual contains specific cautionary statements relative to worker safety. Read this manual thoroughly and follow

as directed. It is impossible to list all the hazards of dust control equipment. All persons involved with the equipment or

systems should be instructed how to operate in a safe manner.

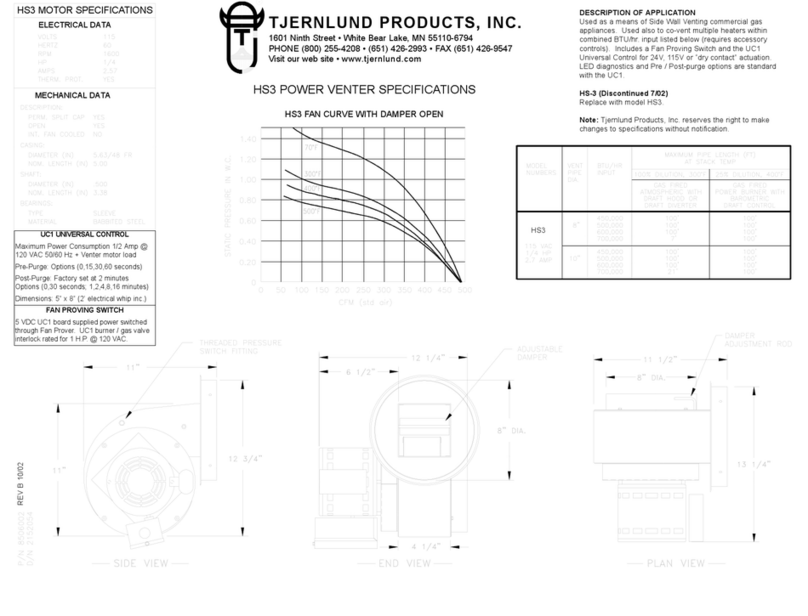

MODEL SCA

MODEL SCA SPECIFICATIONS

INPUT VOLTAGE:

120V 60Hz 1 Phase

230V 60Hz 1 Phase

208-230V / 460V 60Hz 3 Phase

EXHAUSTER BLOWER/MOTOR:

TEFC 1 HP, 1 Phase - 12.0Amps @ 120 VAC

TEFC 1 HP, 3 Phase - 3.2Amps @ 230 VAC

TEFC 1 HP, 3 Phase - 1.6Amps @ 460 VAC

TEFC 3 HP, 3 Phase - 8.0Amps @ 230 VAC

TEFC 3 HP, 3 Phase - 4.0Amps @ 460 VAC

AIR FLOW:

SCA400: 4” Dia. Arms - 1275 CFM, 1HP exhauster

SCA600: 6” Dia. Arms - 1825 CFM, 1HP exhauster

SCA600: 6” Dia. Arms - 2000 CFM, 3HP exhauster

SCA800: 8” Dia. Arms - 2000 CFM, 3HP exhauster

ARM LENGTH:

5’- 4” Diameter

7’- 4”, 6” & 8” Diameters

9’- 6” & 8” Diameters

12’- 6” & 8” Diameters

HOOD LAMP:

12 V. Halogen @ 4 Amps (standard)

WEIGHT:

4” Dia. - 5’= 21 lbs.

4” Dia. - 7’= 23 lbs.

6” Dia. - 7’= 48 lbs.

6” Dia. - 9’= 51 lbs.

6” Dia. - 12’= 59 lbs.

8” Dia. - 7’= 59 lbs.

8” Dia. - 9’= 64 lbs.

8” Dia. - 12’= 67 lbs.

1 HP Motor/Blower Assembly = 45 lbs.

3 HP Motor/Blower Assembly = 70 lbs.

RANGE OF MOTION:

See Figure 1. Factory set for “A” at 10 Deg. Moving the

adjustment collar closer to the socket end of the pipe will

reduce the amount of upward motion.

Caution:

All electrical work must be done by a

qualified electrician according to local, state

and national codes.

Typical installations require that the

blower or gusset assembly be mounted to

a wall. Be sure that the wall is structurally

sufficient to support the arm assembly

being installed.

Arm Size “A” “B”

SCA405 40 Deg. 90 Deg.

SCA407 50 Deg. 90 Deg.

SCA607 38 Deg. 90 Deg.

SCA609 60 Deg. 90 Deg.

SCA612 60 Deg. 90 Deg.

SCA807 45 Deg. 90 Deg.

SCA809 70 Deg. 90 Deg.

SCA 812 68 Deg. 60 Deg.

PRE-OPERATING INSTRUCTIONS:

1. Open cardboard carton(s) and remove unit. Remove

packaging supports from arm assembly. Be careful not

to dent the steel tubes on the arm during unpacking.

2. Inspect the unit for damage that may have been caused

during shipping. Immediately report any such damage

to the shipping carrier.

3. Examine the unpacked unit and compare it to the

parts list description to verify that all components are

received. If a component is missing from the assembly,

contact your Micro Air representative.

Fig. 1

MICRO AIR®SCA

CLEAN AIR SYSTEMS

!

2

!

INSTALLATION:

NOTE: Due to the numerous system combinations

available, some of the following installation steps

may not be applicable. Follow steps that directly

address the specific system being installed.

1. Determine the location where the arm assembly will be

installed (typically at a 10’height).

2. Drill holes into wall or support that align with the

gusset or blower mount assembly. Attach the assembly

to the wall using hardware provided (Fig. 2).

3. Attach the arm sub-assembly to the motor/blower or

gusset assembly as shown (Fig. 3). It is recommended

that two (2) people perform this step; one to support

the arm assembly, while the other attaches hardware

to clamp the arm assembly onto the motor/blower or

gusset assembly.

4. Secure the control cable to the arm base using hose

clamp. Allow enough slack so arm can move freely

(Fig. 4).

SCA MICRO AIR®

CLEAN AIR SYSTEMS

3/8 Hex Bolt X 1

3/8 Plain Washer X 2

3/8 Lock Washer X 1

3/8 Hex Nut X 1

3

Fig. 2

Fig. 4

Fig. 3

Hose Clamp

1/4” Washer

1/4” Washer

1/4” Washer

1/4-20 Nylock Nut

1/4-20 Hex Bolt

1/4” Lock Washer

1/4-20 Hex Bolt

1/4” Lock Washer

4

MICRO AIR®SCA

CLEAN AIR SYSTEMS

ELECTRICAL INSTALLATION:

Caution:

Installation can cause exposure to live

parts. Disconnect electrical power before

proceeding with installation.

1. An electrical control box is included to house

appropriate control transformers, relays, and motor

starters. Locate the electrical control box and mount

to wall or support, anywhere within reach of the arm

control cable connector.

2. Connect the motor/blower power cord to the electrical

control box (Fig. 5). The power cord is pre-wired to

the motor blower.

3. Confirm that the motor wiring matches the supply

voltage.

4. Confirm that the blower impeller wheel is rotating in

the correct direction when energized (Fig. 6).

5. Connect the arm control cable to the electrical control

box (Fig. 5). The arm control cable is pre-wired for

turning the lamp on and/or the motor/blower on.

6. Connect input power to the electrical box at the labeled

terminal strip. Refer to specific wiring diagrams

and Fig. 5 for details. Be sure to ground input to the

electrical control box per local electrical codes.

OPERATION:

1. Upon completion of installation, the SCA should

appear similar to the system shown in Fig. 7.

2. Grasp the hood handle and lift the lower arm section

up and down. If the middle joint seems to tight, loosen

the two nylock hex nuts that hold the joint together

in 1/4-1/2 turn increments. If the arm has trouble

maintaining a position, tighten the nuts.

3. The hood joint section can be manipulated up and

down as well as right and left. If the joints are too

loose or too tight, simply adjust the nylock hex nuts as

needed.

4. To operate the blower, depress the fan switch located

on the remote switch control box to ON. The blower

motor will activate via a motor relay located inside the

electrical control box.

5. Activate the lamp located inside the hood by depressing

the lamp switch located on the remote switch control

box.

6. The damper lever near the hood can be rotated 90

degrees to adjust the inlet air velocity.

Input Power

120V 1-Ph.

208-460V 3-Ph.

Motor/Blower

Cord Set

Arm Control

Cable

Fig. 5

Fig. 6

!

Fig. 7

5

SCA MICRO AIR®

CLEAN AIR SYSTEMS

TROUBLE SHOOTING CHART

CAUTION: BEFORE DISASSEMBLING THE UNIT OR DOING ANY INSPECTING OF THE PARTS, MAKE

CERTAIN THAT THE POWER HAS BEEN CUT OFF AND THE BLOWER HAS COME TO A COMPLETE STOP.

PROBLEM POSSIBLE CAUSE REMEDY

Blower fails to

start No incoming power

Blown breaker or fuse

Primary voltage to motor contactor is below 10%

tolerance

Burned out motor

Check line voltage

Replace fuse or throw breaker

Take steps to increase voltage to primary

Replace motor

Unit runs slowly or

inadequate capture

velocity

Wired for wrong voltage or improper rotation

Internal obstruction

Check input voltage

Check wiring diagram

Switch L1 & L2 (3-phase only)

Check if damper is open

Check inlet for blockage

Check hoses for proper connection

Check hoses for holes

Vibration Loose motor mount bolts

Foreign objects in blower

Tighten bolts

Remove debris from blower

Stronger resistance

during rotation of

the arm

Lack of grease in the rotating socket Grease the rotating socket

Arm will not stay

where it is placed The joints are loose Tighten the joints

GENERAL MAINTENANCE:

Daily

• Clean out any debris from the inner surface of the hood.

• Adjust any loose joints.

Once per month

• Grease the rotating socket with bearing grease listed to not react with Aluminum.

Once per 3 months

• Inspect the condition of the flexible hose for any opening that will allow air to flow through.

• Check the blower motor for bearing noise and impeller wheel for debris and dirt. No lubrication is required for the

motor since it is a totally enclosed, fan cooled type, with permanently lubricated bearings.

• Inspect hardware for loose nuts and bolts around the swivel base area. Tighten as needed.

• Inspect all wiring for loose connections and cracked or cut insulation. Replace as needed.

MICRO AIR®SCA

CLEAN AIR SYSTEMS

6

120 Volt Light Only Wiring Diagram

SCA MICRO AIR®

CLEAN AIR SYSTEMS

120 Volt Light and Blower Wiring Diagram

7

MICRO AIR®SCA

CLEAN AIR SYSTEMS

8

208/230/460 Volt Light and Blower Wiring Diagram

SCA MICRO AIR®

CLEAN AIR SYSTEMS

9

SCA400 ARM ASSEMBLY PARTS LIST

ITEM PART NO. DESCRIPTION

1. 37107-01 Lamp Plate

2. P2170 Lamp

3. P2168 Lamp Socket

4. P2463 Hood Assembly

5. 37106-01 Switch Box

6. P2219 Rocker Switch

7. P2483 1/4-20 x 1” Hex Head Bolt

8. P246 1/4 Flat Washer

9. P2482 Hood Disc Pad

10. P2485 1/4-20 Nylock Hex Nut

11. P2490 1/4-20 x 1” Carriage Bolt

ITEM PART NO. DESCRIPTION

12. P2484 5/16” Nylock Hex Nut

13. P2465 Cup Washer

14. P2464 Friction Pad

15. P2614 5/16-18 x 1” Hex Head Bolt

16. P164 1/4-20 x 3/4” Hex Head Bolt

17. P2457 4” Arm Spring Shock

18. P2470 4” Dia. Flex Hose

19. P2232 Hose Clamp

20. P2312 Micro Air Decal

N/S P2471 4 Conductor Cable - 9’ long

N/S P2472 4 Conductor Cable - 15’ long

MICRO AIR®SCA

CLEAN AIR SYSTEMS

10

SCA600 & SCA800 ARMASSEMBLY PARTS LIST

ITEM PART NO. DESCRIPTION

1. 37107-01 Lamp Plate

2. P2170 Lamp

3. P2168 Lamp Socket

4. P2466 6” Hood Assembly

P2469 8” Hood Assembly

5. 37106-01 Switch Box

6. P2219 Rocker Switch

7. P164 1/4-20 x 3/4” Hex Head Bolt

8. P246 1/4 Flat Washer

9. P2482 Hood Disc Pad

10. P2485 1/4-20 Nylock Hex Nut

11. 37104-01 Damper Handle Stop Plate

12. P2206 5/16” Flat Washer

13. P2484 5/16” Nylock Hex Nut

14. 37103-01 Damper Handle

15. P2478 1/2-13 x 2.25” Hex Head Bolt

16. P2468 Cup Washer

17. P2467 Friction Pad

ITEM PART NO. DESCRIPTION

18. P2479 1/2-13 Nylock Hex Nut

19. P141 3/8-16 Hex Nut

20. P142 3/8 Lock Washer

21. P2206 Flat Washer

22. P2481 3/8-16 x 1.25” Carriage Bolt

23. P2458 7’& 9’Arm Spring Shock

P2459 12’Arm Spring Shock

24. P2483 1/4-20 x 1” Hex Bolt

25. P2312 Micro Air Decal

26. P2232 Hose Clamp

27. P2616 6” Dia. Flex Hose

P2617 8” Dia. Flex Hose

N/S P2471 4 Conductor Cable - 9’ long

N/S P2472 4 Conductor Cable - 15’ long

N/S P2473 4 Conductor Cable - 18’ long

SCA MICRO AIR®

CLEAN AIR SYSTEMS

11

SCA ELECTRICAL CONTROL BOX PARTS LIST

ITEM PART NO. DESCRIPTION

1. P7318 Nema 4 Control Box

2. P445 3 Conn. Terminal Strip

3. P3246 8 Conn. Terminal Strip

P3252 Terminal Strip Label

4. P2534 Transformer

5. P2474 Arm Control Wiring Harness

N/S P2475 Arm Control wiring Harness Hex Nut

6. P2477 Motor Control Wiring Harness

7. P2078 Relay

8. P3909 Contactor

9. P3914 Overload (1HP)

P3915 Overload (3HP)

SINGLE PHASE CONTROL BOX 3-PHASE CONTROL BOX

MICRO AIR®SCA

CLEAN AIR SYSTEMS

12

1 HP. BLOWER ASSEMBLY

ITEM PART NO. DESCRIPTION

1. P2473 Motor Cable

2. P386 Strain Relief

3. P2729 #12 x 3/4” Drive Screw

4. 37111-02 Motor Mount Plate (1-Phase)

37111-05 Motor Mount Plate (3-Phase)

5. P2761 Blower

6. 37111-01 4” Swivel Plate

37111-03 6” Swivel Plate

7. P2077 1 HP. Single Phase Motor

P2249 1 HP. 3-Phase Motor

3 HP. BLOWER ASSEMBLY

ITEM PART NO. DESCRIPTION

1. P2473 Motor Cable

2. P386 Strain Relief

3. P2729 #12 x 3/4” Drive Screw

4. 37111-05 Motor Mount Plate (3-Phase)

5. P2715 Blower

6. 37111-06 6” Swivel Plate

37111-04 8” Swivel Plate

7. P2716 3 HP. 3-Phase Motor

BLOWER ASSEMBLY PARTS LIST

L1170

07/13

13

SCA MICRO AIR®

CLEAN AIR SYSTEMS

Serial Number:

Supply Voltage:

Date Installed:

Installed By:

Notes:

This manual suits for next models

11

Table of contents

Popular Fan manuals by other brands

Lifebreath

Lifebreath ERV series installation guide

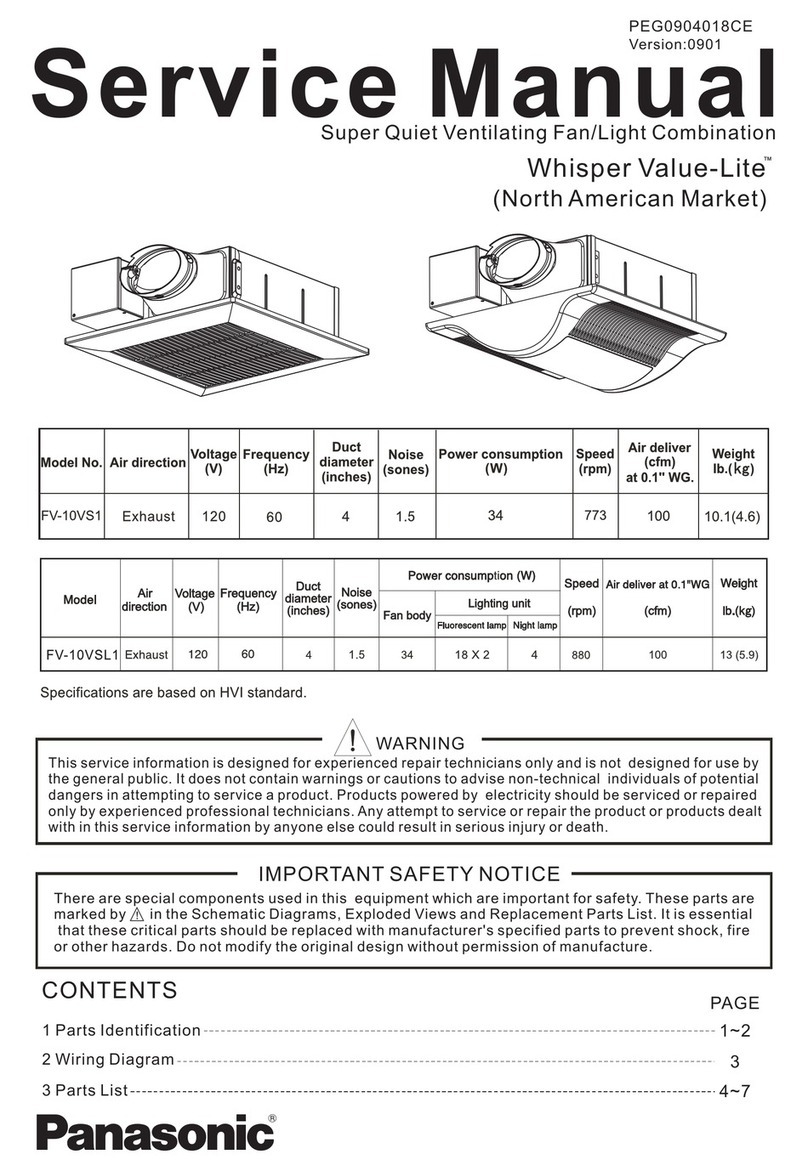

Panasonic

Panasonic Whisper Value-Lite FV-10VS1 Service manual

Soleus Air

Soleus Air FSM-40 operating instructions

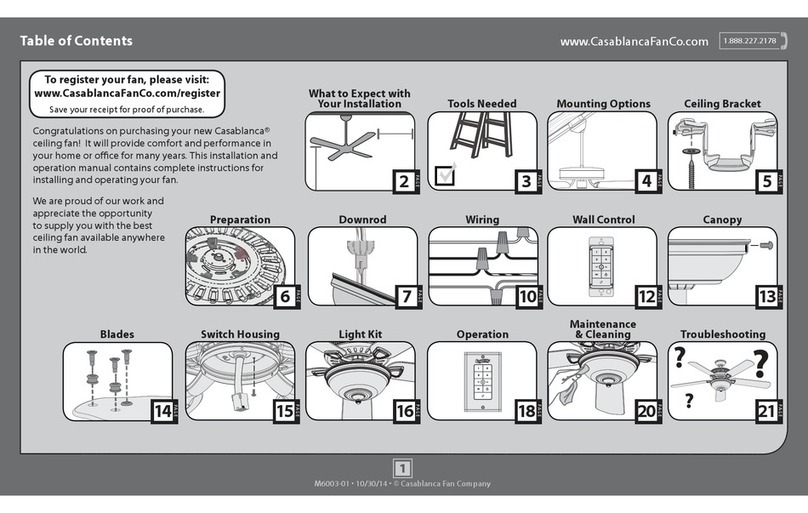

Casablanca

Casablanca Ainsworth 55005 user manual

Mitsubishi Electric

Mitsubishi Electric Lossnay VL-220CZGV-EB instruction manual

VonHaus

VonHaus 2500460 manual