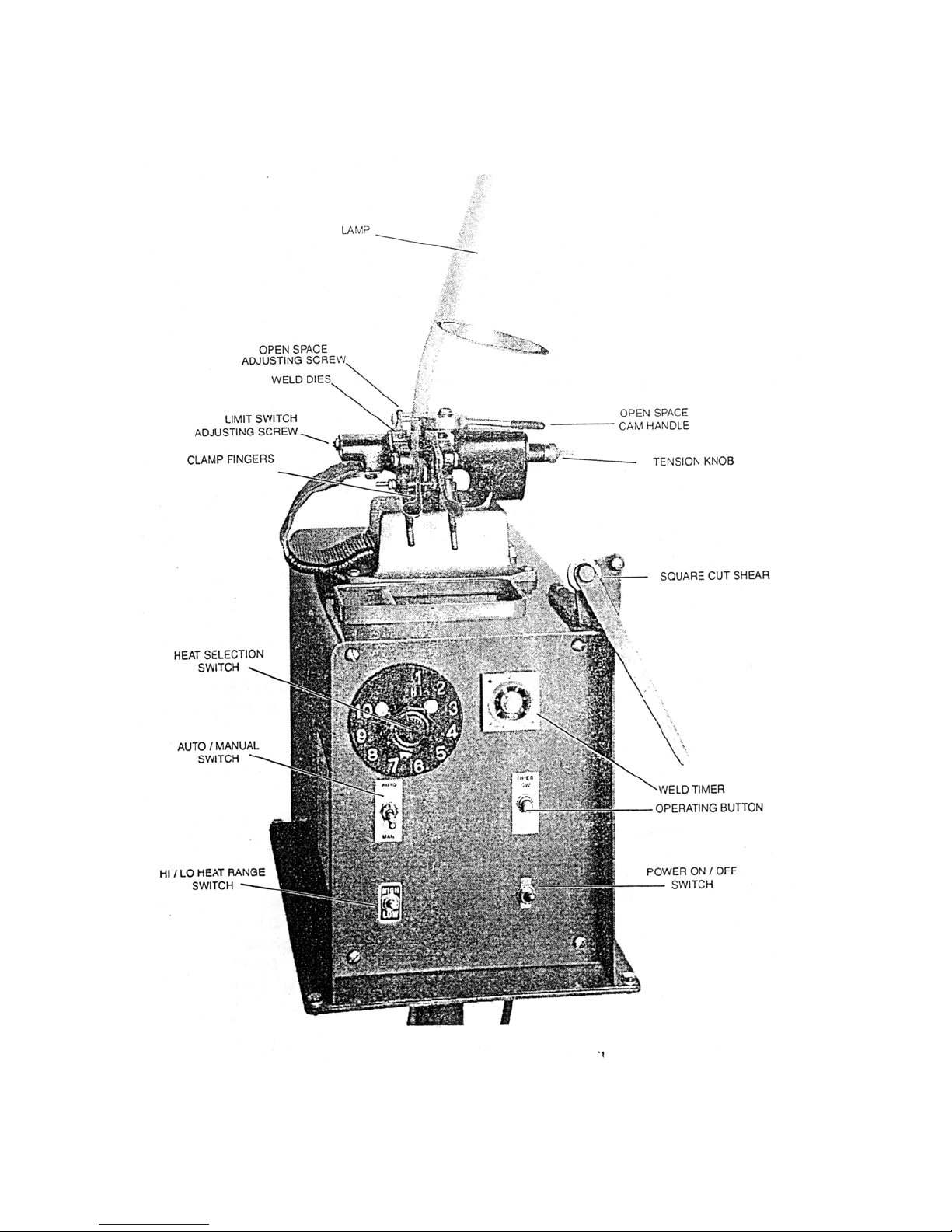

5.0 TYPICAL OPERATING SEQUENCE

5.1 Wire must be clean and free of dirt and oil.

5.2 Set weld heat switch to recommended setting (Ref 8.0)

5.3 Set hi-low range switch (Ref 8.0)

5.4 Set upset pressure (Ref 8.0)

5.5 Rotate space cam to open stop (1/4” between dies)

5.6 Twist conductor end in direction of natural lay.

5.7 Carefully square cut conductor ends so no individual wires

extend beyond cut.

5.8 Select correct size of ceramic sleeve.

5.9 Thread conductor end into ceramic sleeve so as wire ends

are midway through sleeve. Rotating ceramic in direction of

wire lay will assist threading procedure.

5.10 Clamp preset conductor and sleeve into welding die set, so

as ceramic sleeve is centered between open welding dies.

5.11 Thread other prepared conductor into sleeve and allow the

conductor to gently but firmly contact first conductor.

Positive contact to wire ends is important for good weld.

Clamp that conductor into welding dies.

5.12 Rotate and center ceramic sleeve to assure free movement of

conductors during weld process.

5.13 Rotate spacing lever to 0.

5.14 Depress the operation switch, hold for 1 to 3 seconds to

assure a complete weld cycle.

5.15 Unclamp welded conductor and remove ceramic sleeve.

Fracture expendable type sleeve.

5.16 The inside diameter of ceramic sleeve slightly exceeds the

nominal conductor size, therefore the weld zone is slightly

larger than conductor diameter.

5.17 An additional sizing operation, swaging, may be required

should weld zone exceed tolerances on subsequent processing

operations. Micro Products has a special swage tool with

exchangeable tooling available to assist with this sizing

operation.

5.18 The above operation applies to either auto or manual. When

the auto manual switch is in auto, the weld time will be

limited to that selected on the timer.

6