If your track switch has not yet been installed, follow these instructions:

As shown in Figure 2, create a slot through the roadbed and/or track support board under the hole in

the throwbar of the track switch. Do this by drilling two 1/8" diameter holes about 3/16" apart (for HO

gauge track), then cut and file out the space between them. Be careful to leave the hole smooth and

splinter-free. Note: For scales larger than HO, make the slot correspondingly longer.

Figure 3 shows the track switch installed with the hole in the throwbar positioned above the slot. Be

sure the slot is wide enough to clear the throwbar hole when the track switch is completely thrown in

either direction.

On the underside of the track support board, drill a 1/8" diameter x 1/2" deep hole at a distance 1-1/2"

to 1-3/4" from the slot. Remove the mounting bracket clamping screw and install the mounting bracket

with the mounting screw provided in the kit as shown in Figure 4.

Install the brass wire through the hole in the motor shaft as shown in Figure 5. Place the end of the

wire through the hole, then tightly wrap it around the motor shaft as shown. It will stay in an upright

position with just a small amount of wobble (which is just what we would like to have) and act as the

throw rod for the track switch.

Spread the gap in the mounting bracket, then snap the motor into place in the bracket as shown in

Figure 6. At the same time, guide the throw rod wire up through the hole in the track switch throw bar

as shown in Figure 7. Reinstall the clamping screw and adjust the motor position so that the throw rod

wire clears all edges of the slot. Trim off excess throw rod wire as shown in Figure 8 (be careful to

leave a little extra so it doesn't slip out of the hole when the switch is thrown).

Skip the next part of the instructions and proceed to: Electrical Hook-Up and Final Adjustment

The Switch Tender is a stall-motor switch machine. That means that the motor runs until it throws

the track switch; then, it simply stalls, holding the points tightly against the stock rails. A resistor

(provided), installed in either one of the motor lead wires, prevents the motor from overheating in

the stalled position, even though the electrical power to the motor remains on. To throw the points

in the other direction, simply reverse the polarity of the motor connections using an electrical toggle

switch (not included...we recommend the Micro-Mark #83257 3PDT Toggle Switch, which will also

route power of the proper polarity to the frog of the track switch). Installation of the Switch Tender

requires ordinary hand tools, such as a flat tip screwdriver, needle-nose plier, small file, wire nipper

and wire stripper; an electric drill with 1/8" and 1/16" diameter bits will make things easy. After you

gain a little experience with installation, you should be able to install a Switch Tender in about 5

minutes (It takes longer to read the detailed instructions below than to install the Switch Tender).

Note: Dimensions given in the instructions are intended for HO gauge switches.

Adjust them accordingly for your track gauge.

The Switch Tender can be mounted either before (quite simple) or after (a little more work)

installation of your track switch. Instructions for both situations follow...

Figure 1

Figure 2

Figure 3

Figure 4

Figure 5

Figure 6 Figure 7 Figure 8

1-5/8”

MM040405

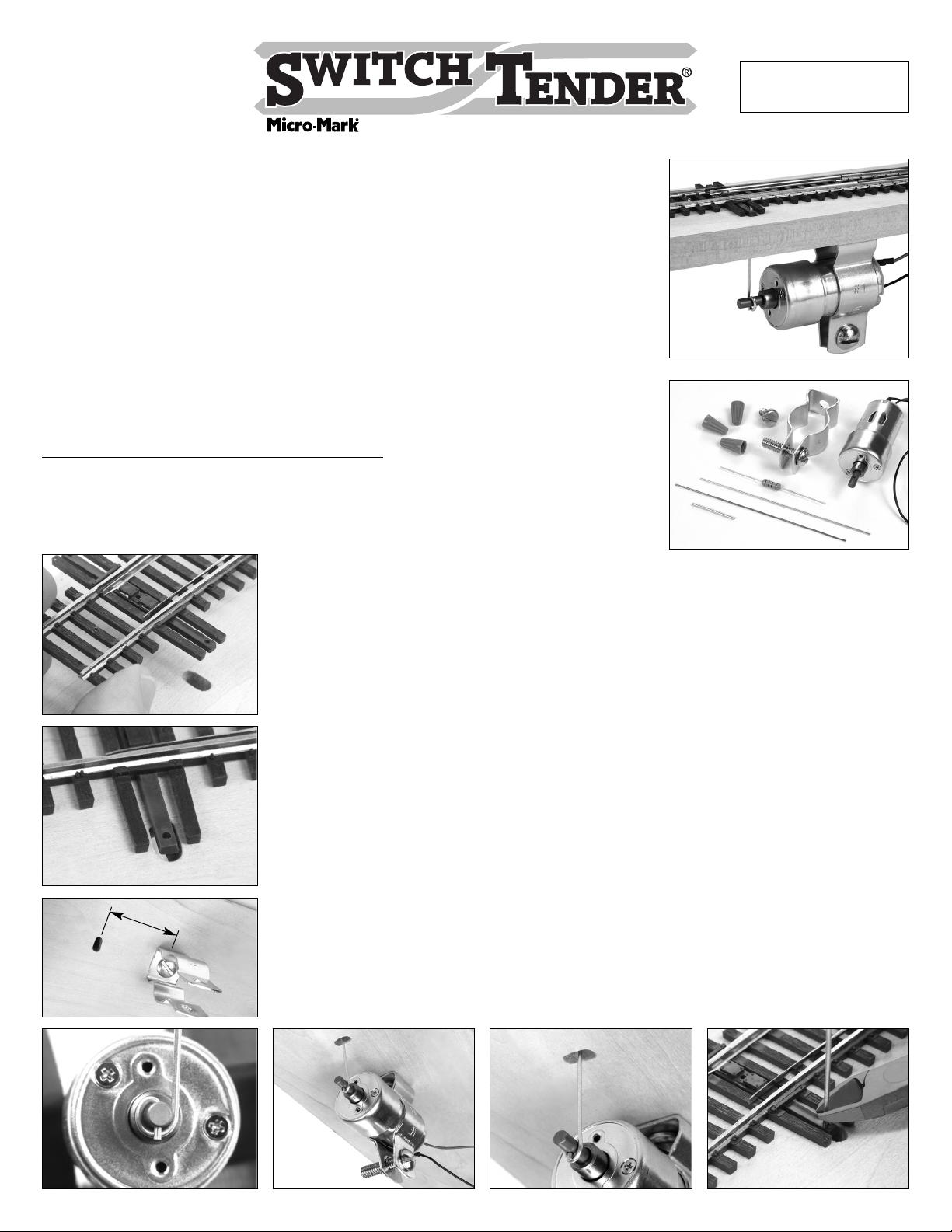

Figure 1 shows the contents of your Switch Tender kit:

1 premium quality motor with integral slow-motion gearhead

1 mounting bracket with clamping screw

1 mounting screw

1 resistor (150 ohm, 1 watt)

1 brass tube

1 steel wire

1 brass wire

3 wire nuts

This product contains lead, a chemical

known to the State of California to

cause cancer and birth defects or

other reproductive harm.

340 SNYDER AVENUE, BERKELEY HEIGHTS, NJ 07922