9

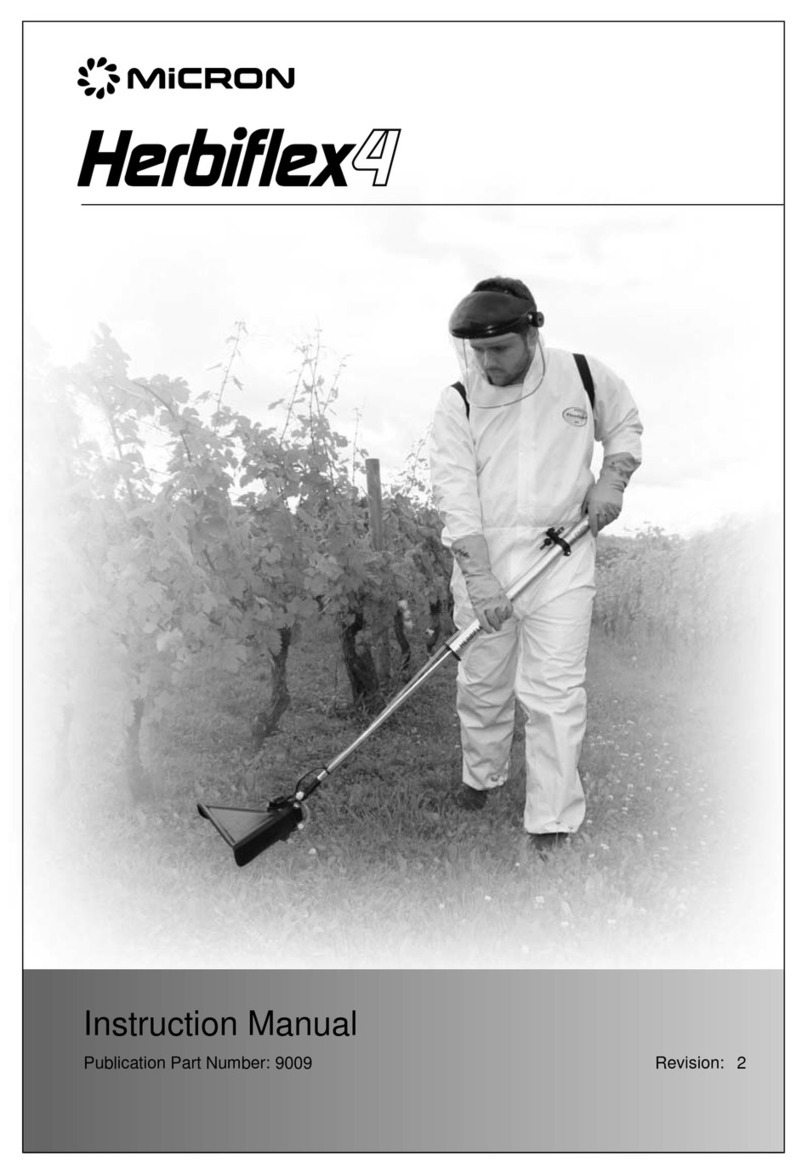

The formula below gives the relationship between swath width, flow rate, walking

speed and total spray volume:

Flow rate (ml/min) = 6 x total spray volume (l/ha) x walking speed (m/s) x band width (m)

The table below gives examples of feed nozzle selection and walking speed to

achieve desired total volume application rates.

These values have been measured using water only. Actual flow rates will depend on

the viscosity of the spray liquid used and the angle at which the operator holds the

sprayer. Before spraying, therefore, the HANDY should be calibrated by the operator

for the spray mix being used.

CALIBRATION

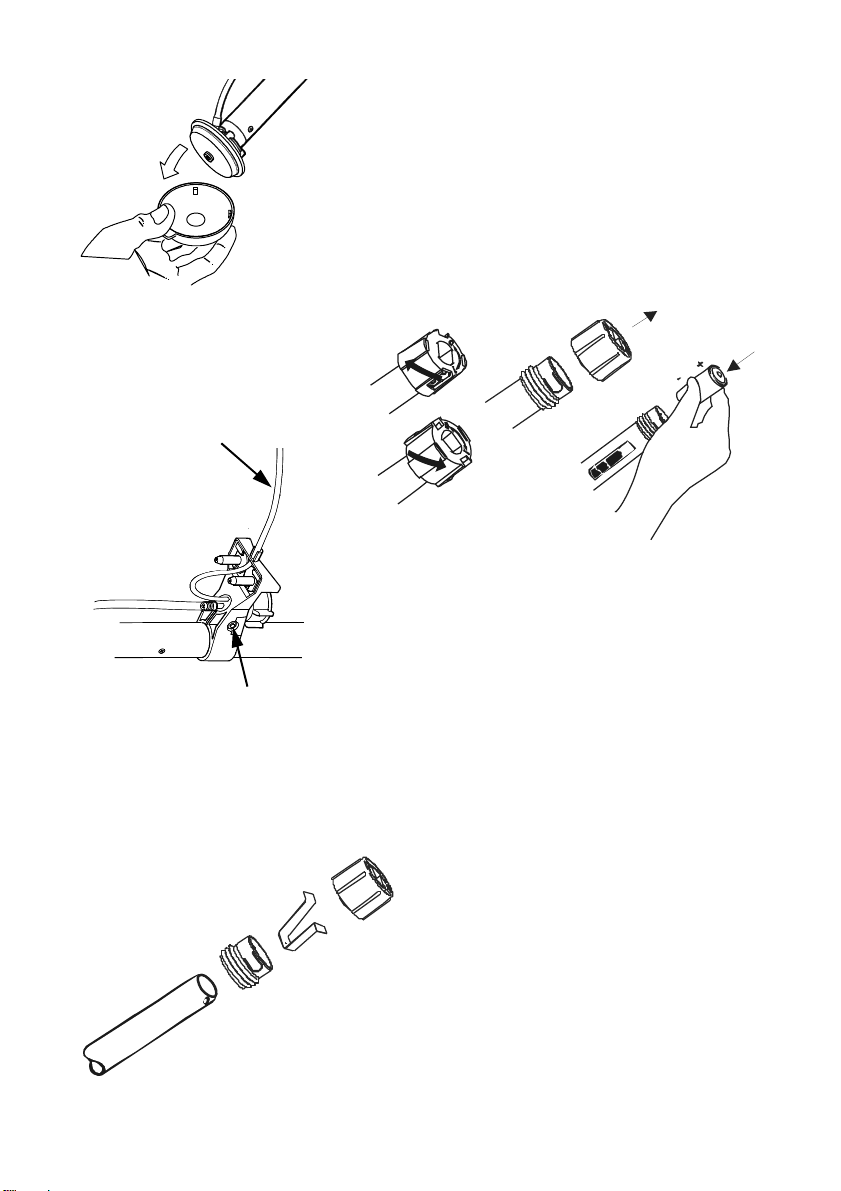

To calibrate the HANDY remove the atomiser disc (see ‘AFTER SPRAYING’) and

collect and measure the volume of spray liquid dispensed in one minute with the

sprayer held in the normal “head down” spraying position (see ‘TO START SPRAY-

ING’). As the balance of the machine and hence angle at which it is held will vary as

the spray bottle empties, an average flow rate will be obtained if measured with the

bottle half full.

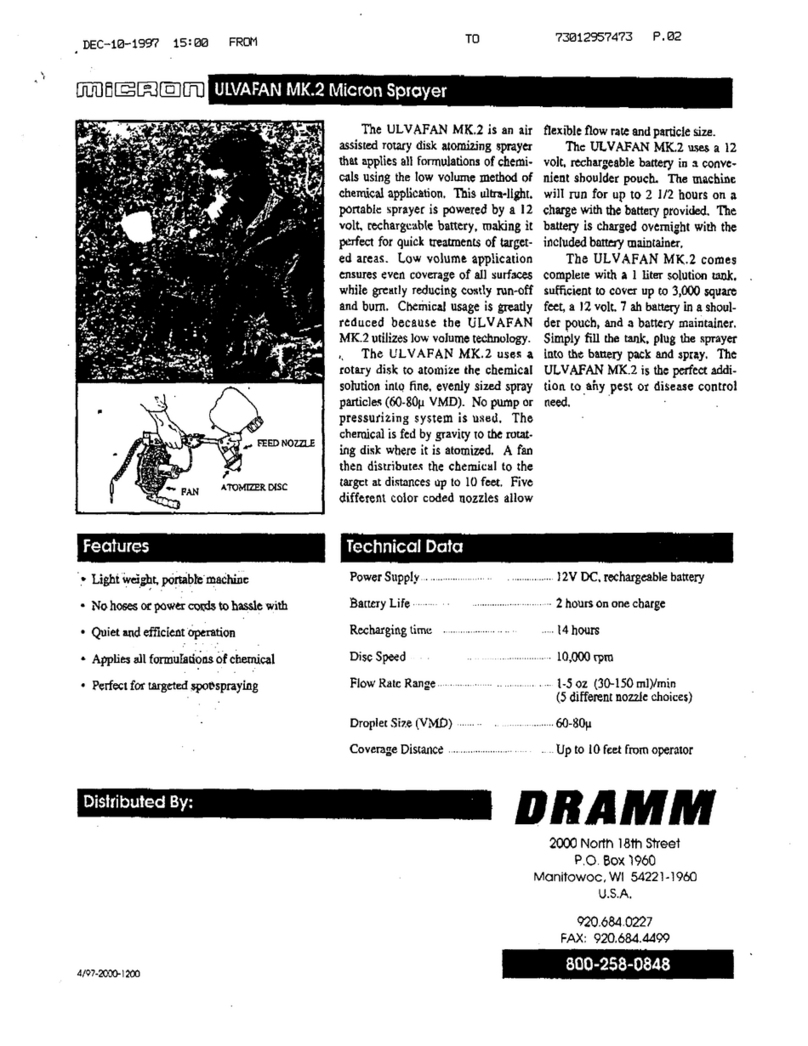

It may be necessary to fit a different feed

nozzle to obtain the desired flow rate. To

change the nozzle, pull off the feed tube and

remove the two screws which hold the nozzle

in position. Alternative nozzles are located in

slots in the battery case clamp. These are

colour coded according to flow rate. Select

the colour needed and screw into place.

Blue Yellow Red

Orange

Increasing flow rate

Once the flow rate for a particular feed nozzle has been determined, walking speed

should be adjusted to achieve the required spray volume.

In general it is preferable to walk more slowly to achieve the required spray volume

than to use higher flow rates.

Total spray volume

(l/ha)

Band width

(m)

Feed nozzle

Flow rate

(ml/min)

Walking speed

(m/sec)

10 (i.e. glyphosate)

1

Blue

70

1.2

20 (i.e. other herbicides)

1

Orange

180

1.5

Example: required spray volume rate = 20 l/ha Flow rate measured = 150 ml/min

Walking speed (m/s) = Flow rate (ml/min) = 150 = 1.25

6 x 1 x total spray volume (l/ha) 6 x 20