TABLE OF CONTENTS

1. INTRODUCTION.....................................................................................1

2. SPECIFICATION.....................................................................................2

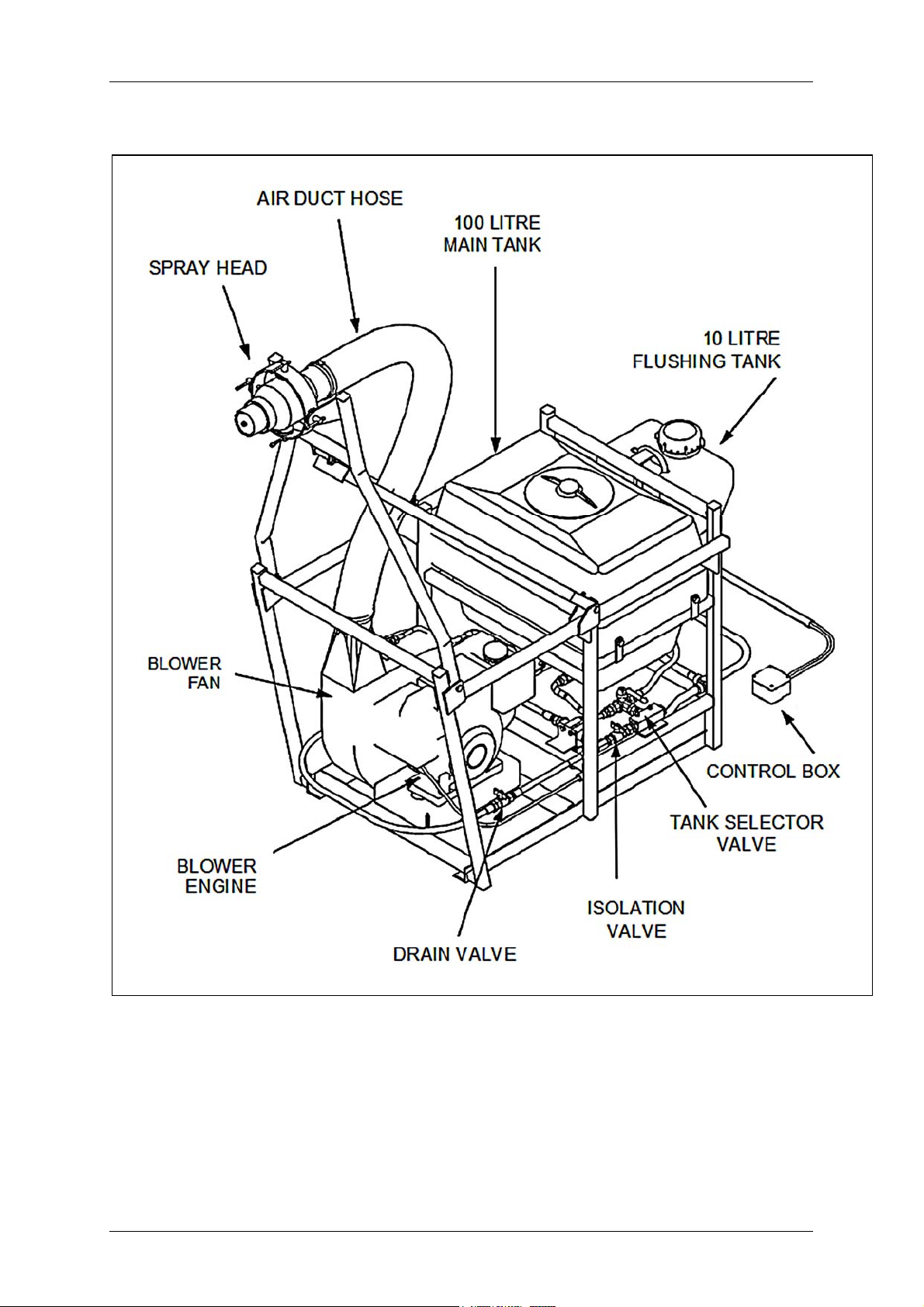

3. INSTALLATION.......................................................................................4

3.1 Installation on Vehicle...................................................................4

3.2 Assembly of Sprayer.....................................................................4

3.3 Electrical Installation and Test......................................................5

4 CONTROLS.............................................................................................5

4.1 Pump and Valves..........................................................................6

4.2 Engine ..........................................................................................6

4.2.1 Engine Controls.................................................................7

4.2.2 Engine Start/Stop Preocedure...........................................8

4.2.3 Using Remote Starter........................................................8

4.2.4 Using Engine Key Switch..................................................9

4.2.5 Using Manual Engine Starter ............................................9

4.2.6 Engine Stop.....................................................................10

5 SAFETY.................................................................................................10

5.1 Using Pesticides.........................................................................10

5.2 Engine Safety .............................................................................11

6 CALIBRATION .......................................................................................12

6.1 Measure the Forward Speed of the Vehicle................................12

6.2 Select a Suitable Track Spacing.................................................12

6.3 Calculate required Flow Rate from the Sprayerr.........................13

6.4 Set the Flow Rate.......................................................................14

6.5 Select the Correct Droplet Size...................................................16

7 SPRAYING PROCEDURE.....................................................................17

7.1 After Use.....................................................................................17

7.2 Cleaning .....................................................................................18

7.3 Additional Applications................................................................18

8 MAINTENANCE.....................................................................................18

8.1 Engine ........................................................................................18

8.1.1 Oil .................................................................................18

8.2 Fan .........................................................................................19

8.3 Pump .........................................................................................19

8.4 Atomiser .....................................................................................20

9 FAULT FINDING....................................................................................22

10 PARTS.................................................................................................24

10.1 AU8115MS Main Components .................................................24

10.2 AU8115MS Pipework Components ..........................................28

10.3 AU8115MS Sprayhead Components........................................32

10.4 AU8115MS Atomiser Components...........................................33

10.5 EX7008 Pump Components .....................................................34

10.6 5881A Filter Components.........................................................35

10.7 EX7463 Electric Throttle Actuator Components........................36

11 ELECTRICAL SCHEMATIC.................................................................36