4

Micron® 1300W Hot Air SMD Rework Station

SAFETY PRECAUTIONS RECOMMENDED FOR OPERATION

1. Ensure the voltage rating of the unit and your power supply is identical prior to use.

2. Check carefully for any damage that may have occurred during transportation.

3. Put the product on a safe and stable working table. The surface should be made of fire and heat resist-

ant material, because the unit can reach very high temperatures and is potentially dangerous.

4. During the operation, the metal heater and nozzle is extremely hot, and will cause serious burns

if they make contact with exposed skin. Use gloves and/or any other heat resistant tools to pick

up the PCB assembly to eliminate the possibility of accidental burns.

5. Do not touch the unit or allow it to touch anything when in operation. Keep the nozzle and

heating element away from the body, clothes and flammable material when in operation.

6. Do not use the product near combustible gases or flammable materials that may ignite. Be sure

the work area is well ventilated.

7. Turn the power switch OFF and allow the heater to cool before checking or replacing the heater and

other parts, or prior to storing the unit. Do not modify the unit.

8. Do not block the air outlet of the nozzle, as this may damage the heating element.

9. This unit is designed for SMD rework and should not be used for any other purpose without first con-

sulting the manufacturer or its authorized agent. Suitable for SOIC, CHIP, QFP, PLCC, BGA etc.

10. To improve the operating life of the heating element, it is recommended that the unit not be used con-

tinuously at high temperature with a low air flow level. Let the heating element cool for up to 20 minutes

after using.

11. When the power is switched off, the unit will briefly continue to blow cooling air through the pipe. Do

not disconnect the plug during this cooling process. Ensure that it is placed back on its cradle to cool

down between rework operations. Also, do not press the green button on the hand tool while it is in the

cooling stand. Failure to comply with these instructions may result in damage to the hand tool.

12. Do not leave the machine unattended while switched on and operating. Turn off the machine

and unplug the power cord when you are leaving. Always place the hand tool in its holder when

not being used. The nozzle and the heating element remain hot after being switched off.

13. Do not use if damaged: If the pump stops working or the rework station becomes faulty,

immediately discontinue using the unit. Only authorized technicians are able to safely repair the

unit or replace parts.

14. Do not disassemble the pump. Please return to your vendor or its authorized repairers for

proper servicing.

TO PREVENT ELECTRICAL SHOCK, TAKE THESE PRECAUTIONS

1. Death or serious injury may result from electric shock. It is therefore essential to isolate the equipment

from the mains before commencing maintenance or repairs. Remember to unplug in the power cord.

2. Always connect the unit to a grounded power socket.

3. Do not pour water/liquids or subject the heating surface to physical shock. This may damage the heat-

er. Avoid contact with moisture.

4. The station must be switched off and the power cord must be unplugged before replacing the

fuse in the AC socket at the rear of the machine.

5. Turn the power switch off and remove the AC power cord by pulling the plug (not the cable) when the

unit will remain unused for a long period of time.

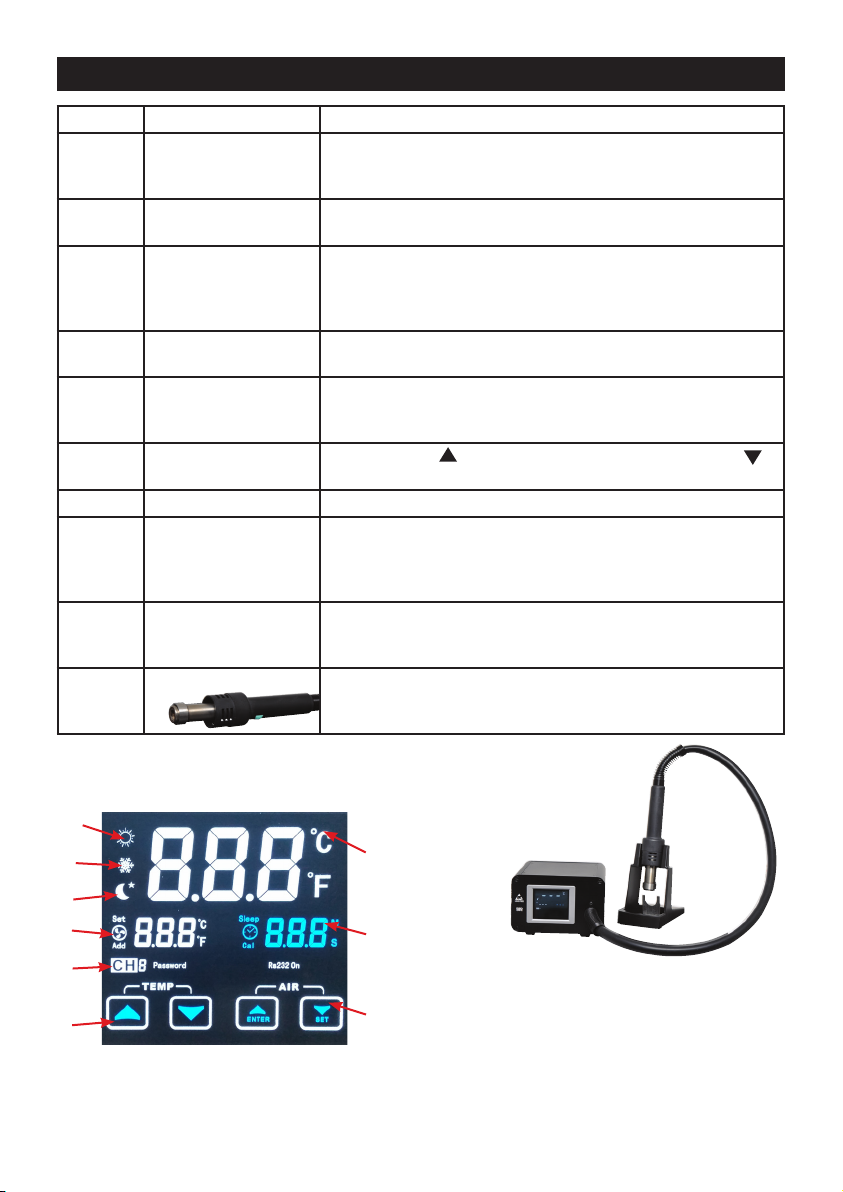

BOOTING UP

Plug the power cord connector into the AC socket on the back of the machine, and plug the power cord

into a mains power outlet. Boot is executed with CH0 program. You can adjust the temperature and air

volume. If you want to use CH1-CH3 program, please press the green button on the handle to scroll

through to start the CH1/CH2/CH3 setting. Each CH program in the loop is slightly different – see below.