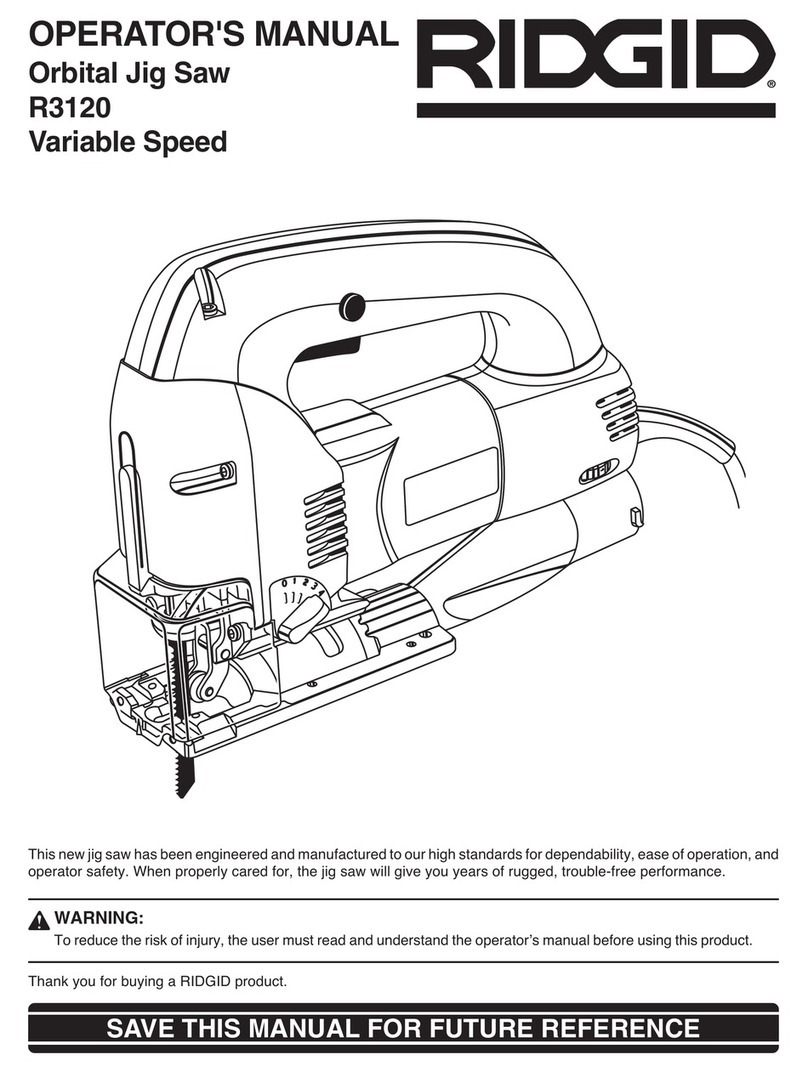

moving the handle down in order to start the threader

(Figure 3).

Make sure the handle is clean and free from

oil and grease. This allows for better control of the tool.

Figure 3 – SlidingThreader On Pipe

5. Before applying force to the handle, ensure that the

ratchet pawl is engaged.

Pawl may fail to engage if pushed against

the side of the die head. Specific care should be taken

when threading pipe that is vertical.

6. When hand threading, your weight should be above the

handle ensuring maximum leverage. If possible, do not

do all the work with your arms, use your weight. Do not

overreach. Keep proper footing and balance to main-

tain better control.

Do not slide a pipe or “cheater” over the

handle to gain extra leverage. This practice can result in

serious injury.

7. Apply a generous quantity of RIDGID Thread Cutting Oil

when threading (Figure 4). Use of a lubricating oil or a

poor thread cutting oil can result in a poor quality cut

thread, leaky joints, short die life and high handle forces.

Figure 4 – ApplyingThread Cutter Oil

8. Stop threading when the end of the dies are flush with

the end of the pipe. At this point, the correct size has

been reached to produce the proper joint. To continue

8/03

Manual PipeThreader Instructions

Printed in U.S.A. 999-997-601.10

RIDGID 00-R, 12-R and 11-R Threaders are designed to

thread pipe or conduit using individual die heads for each

size of pipe and a manually operated ratchet.

Warning! Read these instructions carefully before

using this tool. Failure to follow all instructions may

result in property damage and/or serious injury.

1. Inspect the threader before use. Replace dies or any

other part that shows damage or wear. To ensure a

high quality thread, only use RIDGID replacement dies.

Worn dies can result in poor thread quality

and high handle forces.

2. Mount the pipe firmly in a pipe vise. When threading

an existing pipe, make sure it is secure and will not

move. Cut the end of the pipe cleanly and squarely

using a pipe cutter (Figure 1).

When working on a scaffold or lift, the oper-

ator should be properly secured to prevent injury in the

event of a fall.

Figure 1 – Cutting End of Pipe

3. Ream the end of the pipe to remove any burrs that

may have been produced during the cutting of the pipe

(Figure 2).

Figure 2 – Reaming End of Pipe

4. Select the correct die head for the size and type of

pipe to be threaded and the thread form you require.

Insert die head into the ratchet. Slip the pipe guide at

the rear of the threader over the pipe and gently apply

pressure to the front of the die head at the same time

WARNING

WARNING

WARNING

WARNING

WARNING