2

Safety Instructions P 2

Cautions P 4

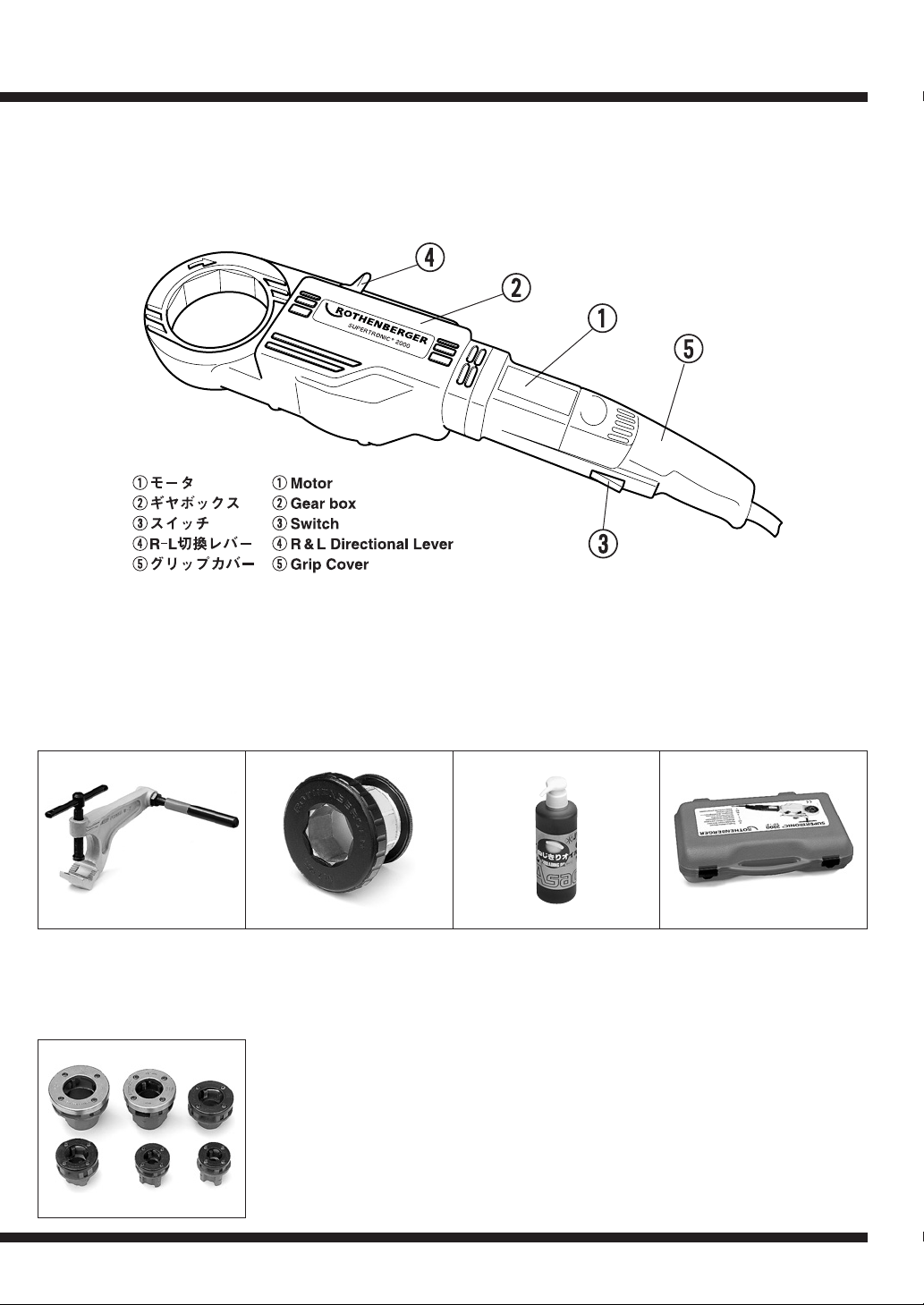

Main Parts P 5

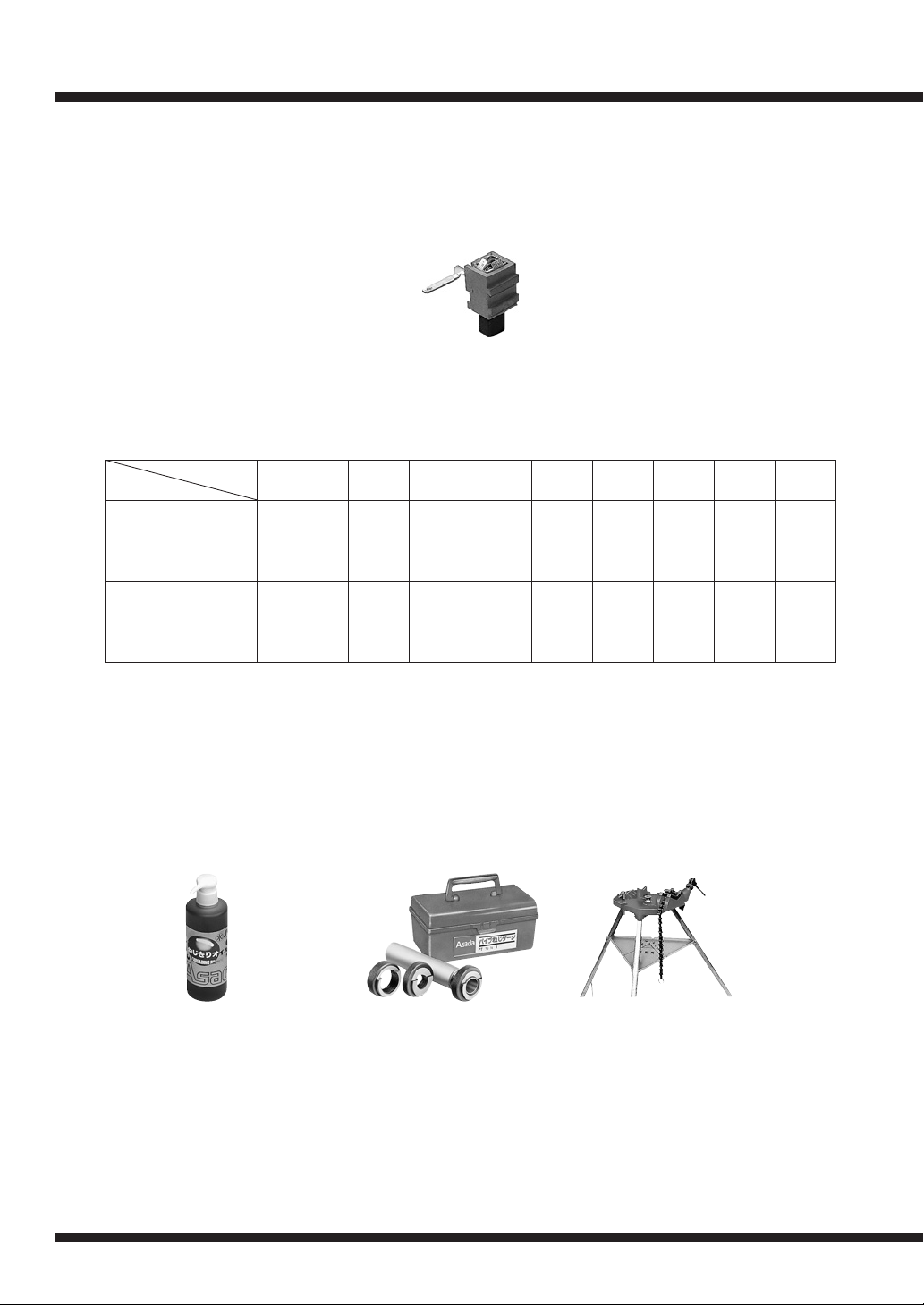

Standard Accessories P 5

Optional Accessories P 6

Specifications P 7

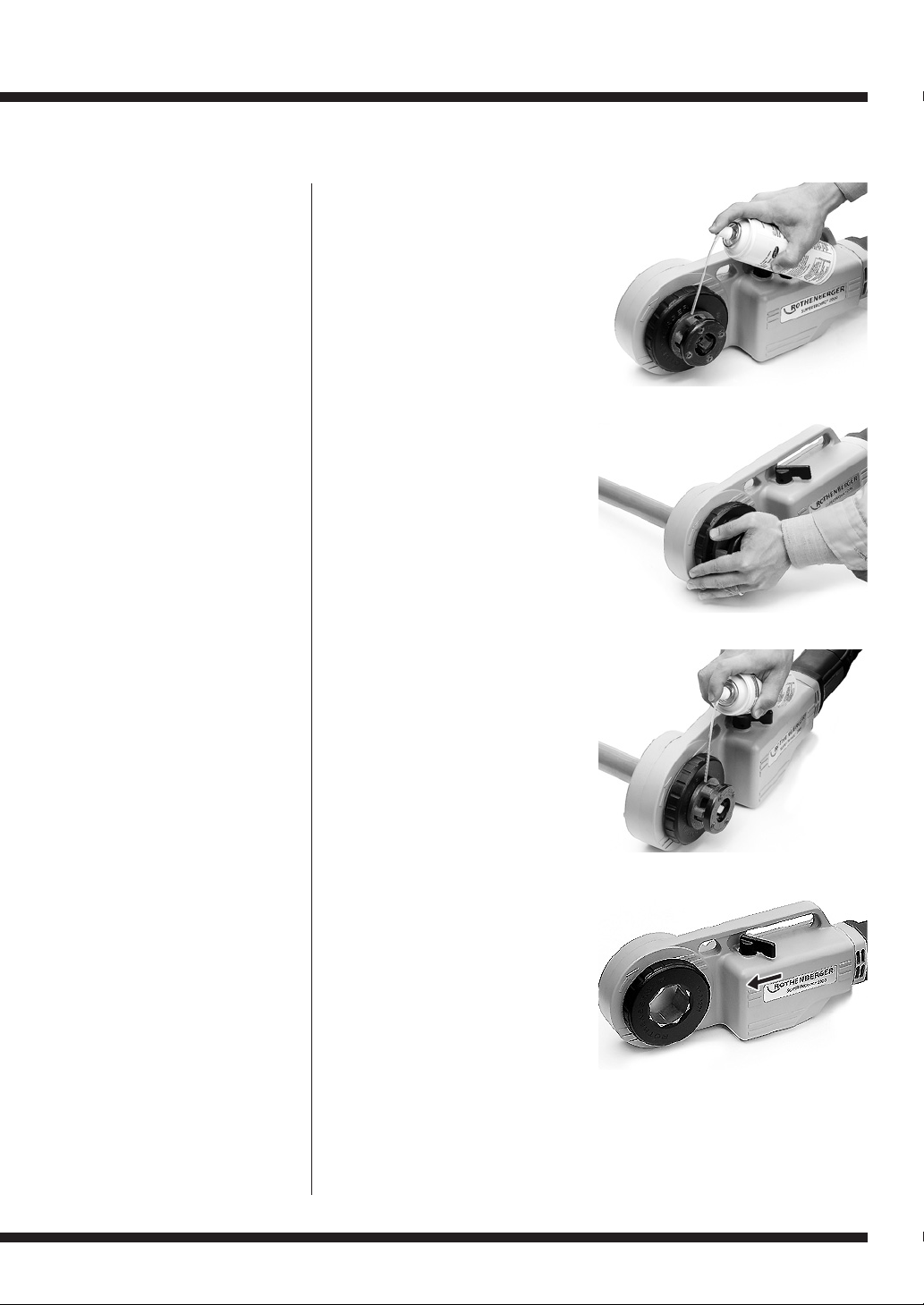

How to Operate-Machine P 8

Maintenance Instructions P 10

Parts Replacement Instructions P 11

Wiring Diagram P 11

機械を正しく

SafetyInstructions

CONTENTS

正しい服装で安全作業

Wearproperclothing

Loose clothing can get easily

tangled in moving parts. When

operating machine, do not wear

unbottoned jackets, loose sleeve

cuffs, neckties, etc.

Wear safety shoes, hard hat and

safety glasses depending on the

working circumstances.

安全作業は安全姿勢から

Securemachineand

footing

Make sure that machine is stable

and keep proper footing and

balance.