2 of 17

All data can be subject to change without advanced notice. Version: December 6, 2018. © Micronel AG

Contents

1 Important Information ......................................................................................................... 3

1.1 About This Manual....................................................................................................... 3

1.2 Depiction of Warning Notices....................................................................................... 3

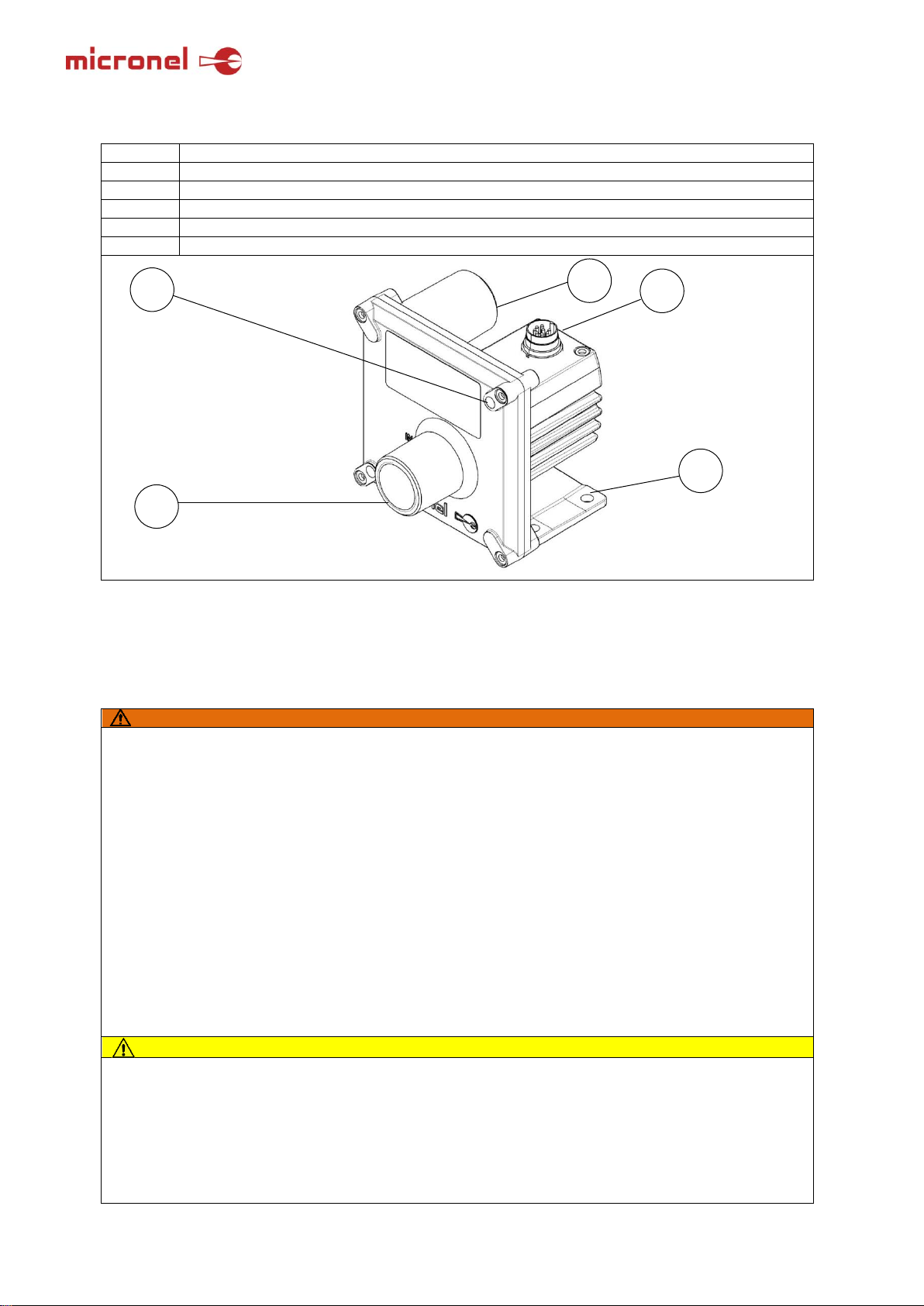

2 Overview of U100HL-024KA-4 ........................................................................................... 4

3 Basic Safety Information..................................................................................................... 4

4 Intended Use...................................................................................................................... 5

4.1 Improper Use............................................................................................................... 6

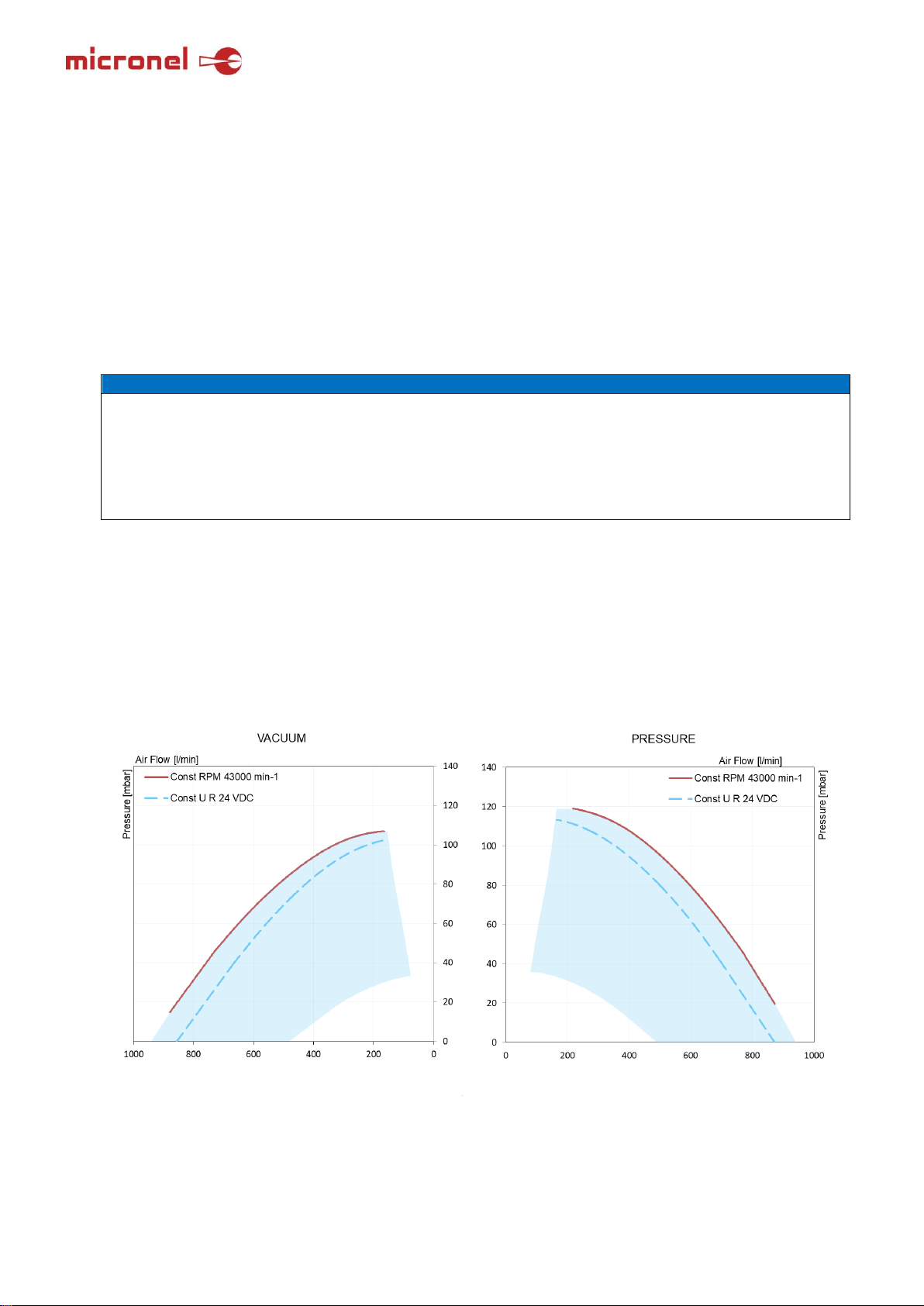

5 Technical Specifications..................................................................................................... 6

5.1 Performance Fields...................................................................................................... 6

5.2 Mechanical Nominal and Threshold Values of the Blower............................................ 7

5.3.1 Dimensions............................................................................................................ 7

5.3.2 Nominal and Threshold Values of the Blower........................................................ 8

5.4.1 Materials................................................................................................................ 8

5.5.1 Mounting .............................................................................................................. 9

5.5.2 Sound and Vibration Dampening........................................................................... 9

6 Connections....................................................................................................................... 9

6.1.1 Structure of the Internal Electronics......................................................................10

6.1.2 Pin Assignment ....................................................................................................11

6.1.3 Electronic Functions.............................................................................................11

6.2. Pipe and Hose Connections.......................................................................................12

7 Initial Commissioning.........................................................................................................13

9 Cleaning Maintenance.......................................................................................................15

9.1 Inspection................................................................................................................16

9.2 Lubrication..................................................................................................................16

9.3 Troubleshooting..........................................................................................................16

10 Transport.........................................................................................................................17

11 Storage............................................................................................................................17

12 Disposal ..........................................................................................................................17