2

www.micronfilter.it

ENGLISH

This manual contains all the information necessary for the proper use of the machine. The

user is kindly requested to take careful heed of the warnings and to read it thoroughly. It is

also requested that this manual be conserved in a suitable place so that it remains legible

and unaltered. The contents of this manual may be changed without notice for the purpose

of including variations or improvements to the units already shipped.

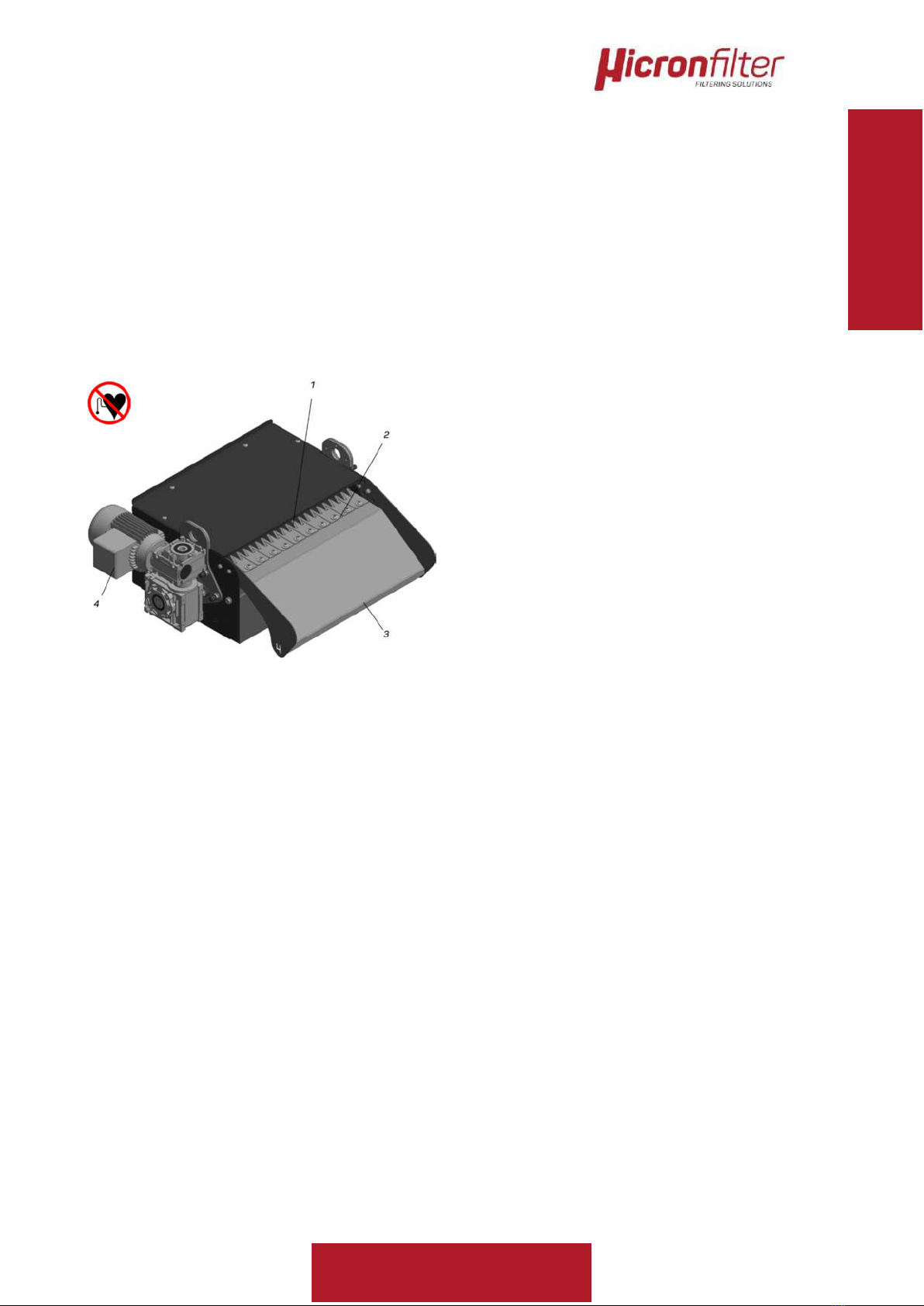

2.0 FUNCTIONAL DESCRIPTION

The Kalamit series of magnetic cleaners for cutting fluids is indicated for all machine tools

used to work metal, to separate magnetic particles from emulsions and whole oils with

maximum viscosity of 20° cSt at 40° C.

The cleaner works in a simple and effective

manner, clearly illustrated in the diagram.

The soiled fluid is conveyed by gravity or

pressure to the inside of the cleaner. The

rotating magnets (1) retain the magnetic

particles, which are then removed by a comb

blade (2) that sends the mud to the

adjustable chute (3). The cleaned fluid flows

through the containment tank (if requested)

and then, according to the use, is relaunched

by the machine tool via an electric pump (if

requested). The magnetic disk cleaner does

not use disposable filters. The recovered mud is easily disposed of as differentiated waste.

The Kalamit series of magnetic cleaners for cutting fluids is indicated for all machine tools

used to work metal, to separate metal particles from emulsions and whole oils with

maximum viscosity of 20° cSt at 40° C, for a capacity ranging from 50 to 700 l/min. The

cleaners are all made of sturdy zinc-coated sheet metal, bent and welded by a fully

automated process and finished with powder coating. They consist of a support frame where

the group of permanent magnets are installed, connected to a motor reducer through a

command shaft. The groups are factory-supplied with a mud-scraping blade and a chute with

adjustable inclination. There are also covers and flow-breaker pre-chambers, containment

tanks for the filtered fluid, and many other optionals. The soiled fluid is conveyed by gravity

or pressure to the inside of the cleaner. The rotating magnets retain the magnetic particles,

which are then removed by a comb blade that sends the mud to the adjustable chute. The

filtered fluid flows into the containment tank. The magnetic disk cleaner does not use

disposable filters. The recovered mud is easily disposed of as differentiated waste.