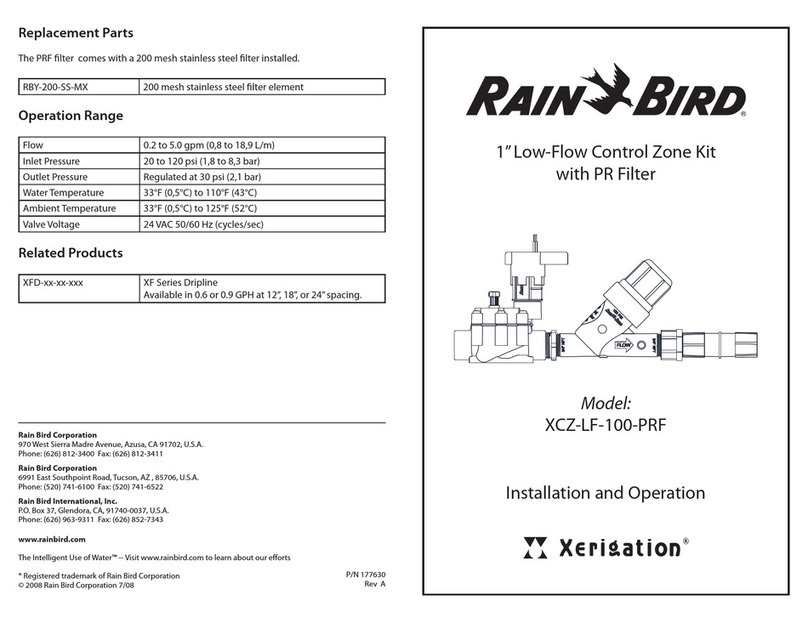

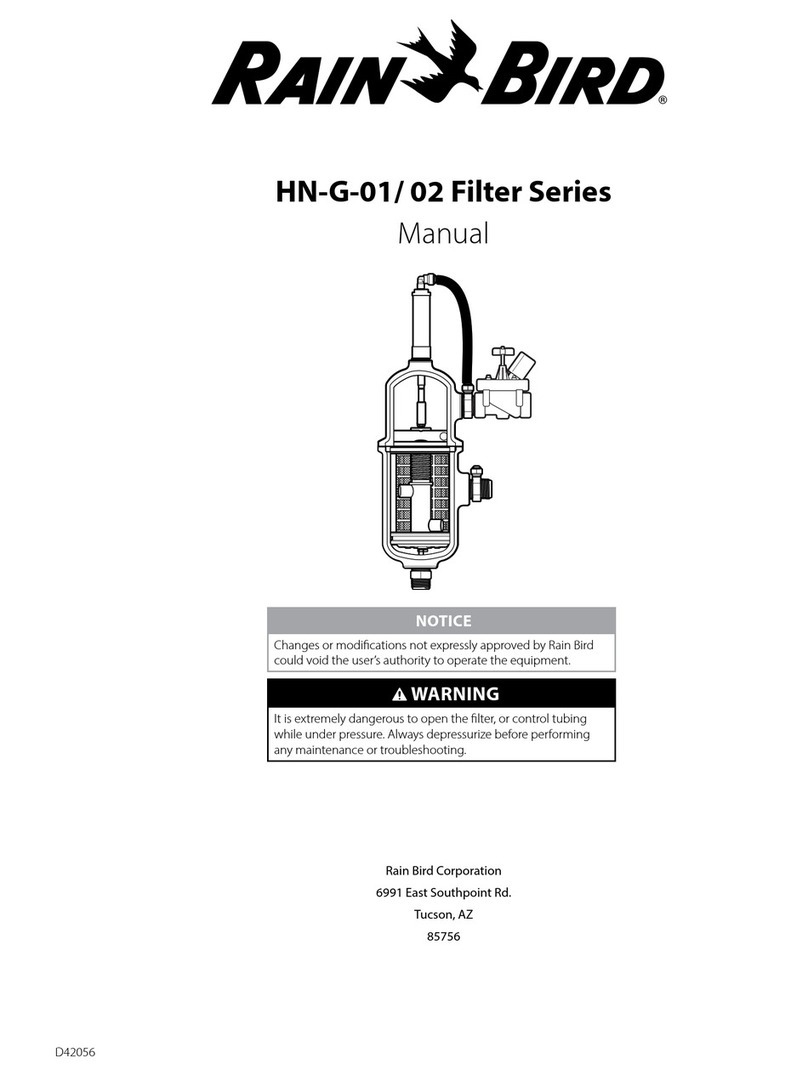

3. Installation Example

How your lter is installed will depend on how your system is structured and the specic requirements of your site. This example illustrates a

stand-alone lter installation with minimal added components in discharge plumbing like what is located on a municipal feed water source

(or pumped water where the pump is located remotely).

* User to supply

Union tting*

1/4” Connection

1/4”Tubing

Piston

1” Hydraulic drain valve

Union tting*

Union tting*

Outlet (to irrigation)Inlet (from pump)

Drain (to drain)

Unions are required for ease of maintenance and in order to make installation easier. With unions, at all recommended spots, the

lter may be removed for service and any threaded connections can also be easily accessed if any of these need to be tightened up

or resealed due to movement during shipping or installation. The drain will be a 1” union. The inlet and outlet will be either 1” or 2”

unions depending on the model ordered. Unions will make servicing and winterizing the lter much easier. A bypass loop with

bypass valve is also recommended so that the lter can be bypassed during service if required.

Drain should not discharge

under water level, or in any

way that would provide

back pressure, as this will

impede performance

The discharge needs to be

unobstructed and if longer

than 20 feet the discharge

line should be up-sized to

1.25” or 1.5” PVC.

Gauges on the inlet

and outlet are highly

recommended to be able to

monitor pressure dierential

visually.

The drain line can be swivelled 360

degrees to any discharge direction by

loosening the band clamp (remembering

to tighten it afterward).

Follow standard PVC solvent welding procedure to plumb the lter into the irrigation line.

The Inlet, Outlet and Drain line pipes need to be supported so that no stress is transferred to

the lter. Pipe support is attached to pipe with a pipe attachment. Can take various forms like

this: