Mooney 30, 30A, 30S Filter Instruction Manual | 1

© 2023 Baker Hughes Company. All rights reserved.

Product Description

The Type 30/30A/30S/ Mooney Filter is designed

to remove dirt and other particulates in the pilot

supply that could affect the resrictor or variable

orifice in the pilot.

The Filter can be used in a variety of other gas and

liquid applications.

Installation

The following instructions apply to mounting the Type

30/30A/30S/ Mooney Filter on the Flowgrid regulator,

FlowMax regulator and connecting to the pilot system.

Refer to the Flowgrid regulator, FlowMax regulator,

and Pilot IOM manuals for installation instructions and

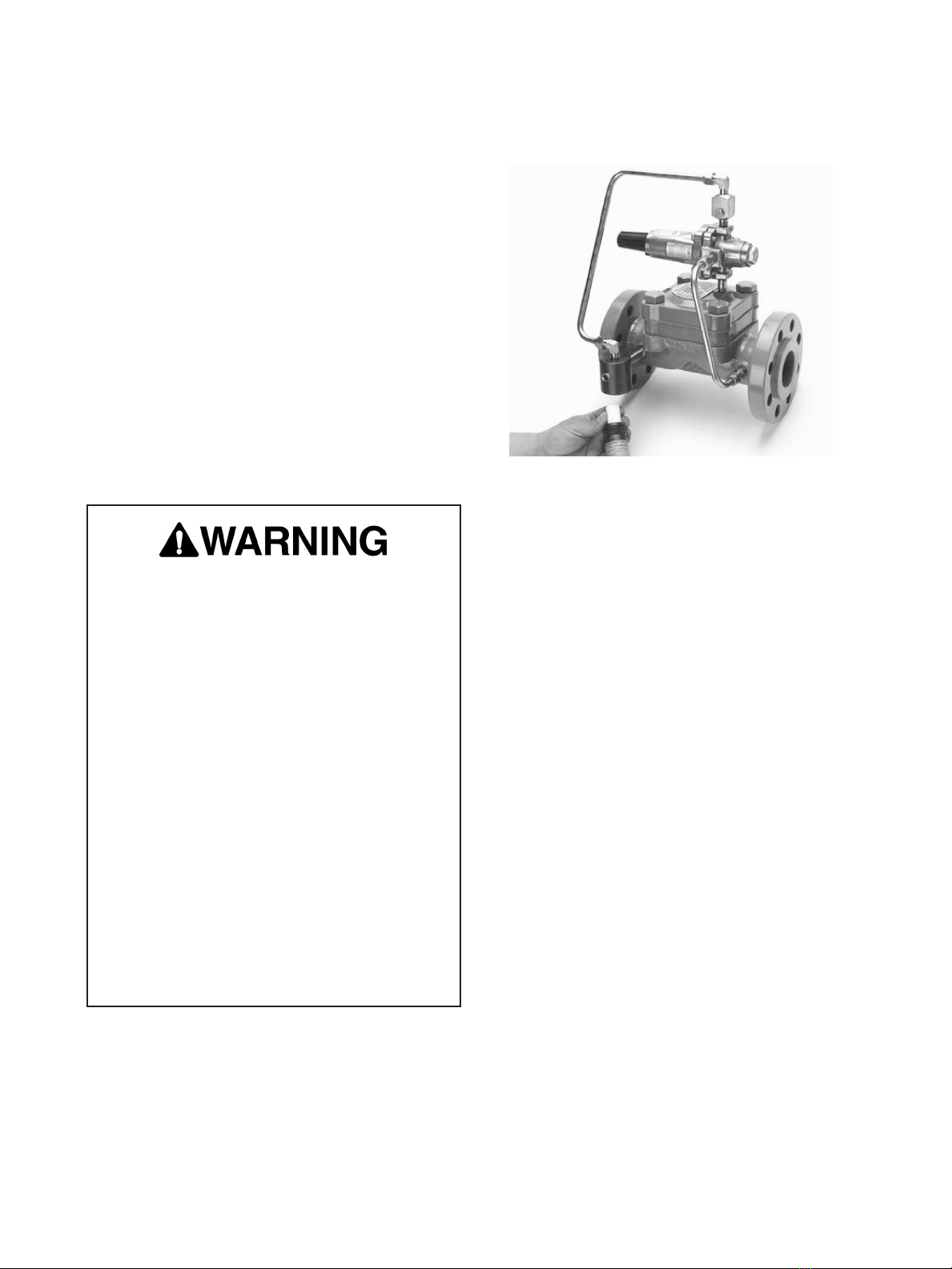

start-up procedures. Figure 1 - The Type 30A Mooney Filter with Filter

Housing removed allowing easy inspection of the

element. Mounted on a 2” large single Port Flowgrid

Regulator with Series 20 Pilot and Type 24 Restrictor.

1. Personnel: Installation of the Filter should be

made by qualified personnel familiar with high

pressure piping and pilot operated regulators.

2. Prior Inspection: Inspect the Filter for any damage

that might have occurred in shipping. Make sure

the body ports are clear of foreign material.

3. Orientation: The Type 30/30A/30S/ Mooney Filter

should be installed with the Drain Plug down to

allow drainage of liquids that may accumulate in

the Filter Housing (Refer to Figure 2, page 2).

4. Filter Mounting: Apply pipe dope a 1/4 inch NPT

schedule 80 seamless pipe nipple and mount filter

by connecting the INLET connection on the filter to

the body tap on the valve.

5. Filter Outlet: Run 3/8 inch tubing or 1/4 inch pipe

from the filter OUTLET port to the INLET side of the

restrictor in the pilot system of the regulator. The

Type 30/30A/30S/ Mooney Filter has tow OUTLET

ports for ease of tubing. Block the other port with

the plug provided.

Note: To avoid galling when stainless steel

to stainless steel connections are made, use

a lubricant (such as NEVER SEEZ by Bostik).

For best results, LIGHTLY lubricate the female

threads. Mixing the lubricant with pipe dope is

also acceptable. Do not exceed more than 1/4 turn

past the point the threads start to bind.

Scope

This manual provides installation, operation and maintenance instructions for the Type 30/30A/30S/ Mooney™

Filters. Instructions for the Flowgrid™regulator, FlowMax™ regulator, and Pilot will be found in separate manuals.

Personal injury, equipment damage, or

leakage due to explosion of accumulated

gas or bursting of pressure containing parts,

may result if this FILTER is overpressured, or

is installed where service conditions could

exceed the limits given in the specification of

this manual, or on the nameplate, or where

conditions exceed any ratings of the adjacent

piping or piping connections. Verify the

limitations of both valve and pilot to ensure

neither device is overpressured. To avoid

such injury or damage, provide pressure

relieving or pressure limiting devices (as

required by the Title 49, Part 192, of the U.S.

code of Federal Regulations, by the National

Fire Codes of the National Fire Protection

Association, or by other applicable codes),

to prevent service conditions from exceeding

those limits. Additionally, physical damage

to the valve/regulator, codes break the pilot

or filter off the main valve, causing personal

injury and/or property damage due to

explosion of accumulated gas. To avoid injury

and damage, install the filter in a safe location.