Electro-Pneumatic Phoenix

OPERATING MANUAL

Description

The Phoenix filter is a fully automatic backwashing filter, comprising six patented filter

elements in separate pods surrounding a central inlet chamber. The discharge from each

pod is collected in a common area under the “doughnut” shaped filter cover before leaving

via a common discharge port. The central inlet chamber contains a proprietary indexing

valve, which operates the filter’s backwash. Backwash is controlled by the circuit board

situated inside the filter cover, which in turn powers a 24 VDC electric motor and gearbox

assembly. The motor/gearbox rotates the Indexing Valve while sequentially backwashing

each pod. A pneumatic backwash valve opens and closes with each indexing position.

Operating Parameters

Power Supply: 24 VDC, 1 Amp supply

Minimum Operating Pressure: 40 psi

Maximum Operating Pressure: 100 psi

Maximum Differential Pressure: 40 psi

Static Test Pressure: 230 psi

Maximum Operating Temperature: 135º F (higher temperature ratings available)

Flow Rate: see flow chart (Exhibit 1)

Micron Ratings: 25, 50, 75, 125, 200 and 400 micron.

Minimum Air Pressure: 60 psi

Maximum Air Pressure: 100 psi

Materials Composition

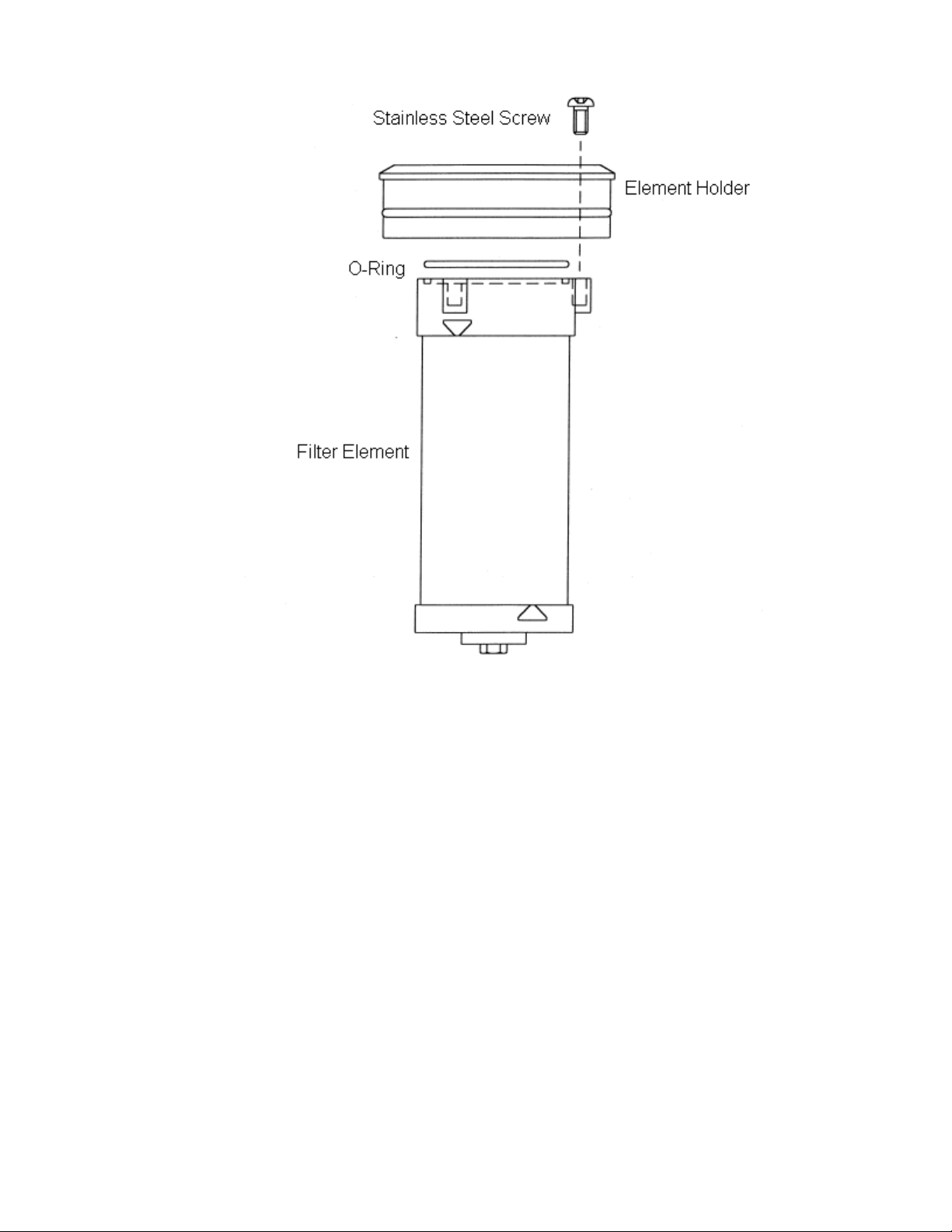

Filter Material

Filter Housing: Stainless steel 304L

Control Cover: Aluminum (non-wetted part)

Filter Elements: Stainless steel 316.

Element Holders: Glass filled polypropylene (stainless steel available), stainless

steel screws

Indexing Valve: Stainless steel 304 with Buna, EPDM, or Viton ‘O’ rings and

polyacetal shoe.

Backwash Valve: Chrome plated, brass body, stainless steel 316 ball with PTFE

seats and double acting actuator. Stainless steel wetted parts

available.

DP Switch: One micro switch, brass wetted parts, fitted with visual indicator

and nitrile seals. Upgrades include an additional micro switch,

stainless steel wetted parts, and Viton seals.

‘O’ Rings: Viton standard throughout, Buna and EPDM available.