LX23224IDB Evaluation Board

U

Us

se

er

r

G

Gu

ui

id

de

e

Copyright © 2011 Microsemi 8

Rev. 0.2, 10-04-2011 Analog Mixed Signal Group

2381 Morse Avenue, Irvine, CA 92614, USA; Within the USA: (800) 713-4113, Outside the USA: (949) 221-7100 Fax: (949) 756-0308

4 Installation

The following chapter describes the steps required for installing and operating the Evaluation Board.

4.1 Preliminary Steps and Safety Precautions

Connect all required peripherals prior to powering the board. (LED’s, digital dimming generator)

Do not perform a hot-swap!

Verify board is properly configured prior to turning on power supply. (LED’s per srting. SW1 at BL

OFF state)

4.2 LED Demo Panel Configuration

Do not look directly at the LED panel when system is operating and LED panels are illuminating.

The following paragraph describes the steps required for LED panel configuration.

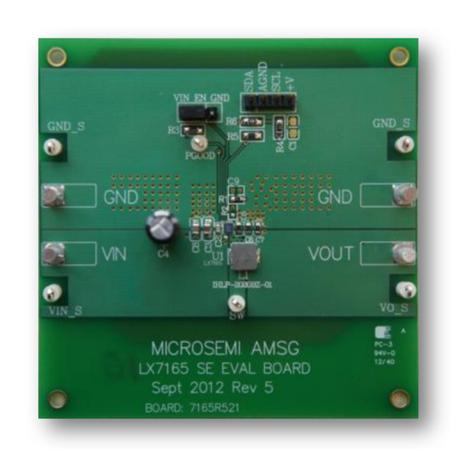

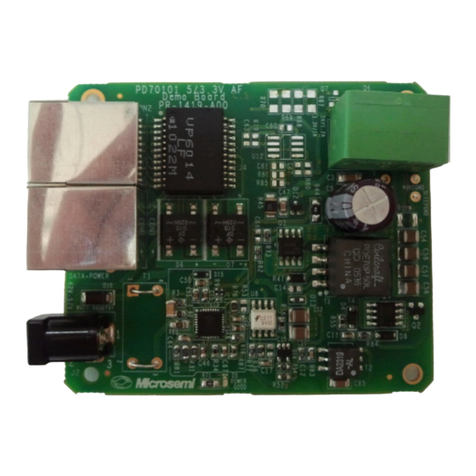

The panel contains 48 high-power white LEDs connected in series as one string and 10 configuration switches (see

Figure 4). Users can configure the LED string LED count to any LED number they need.

Single LED forward voltage is 3V@125mA, therefore for 120V output-voltage 40 LEDs are needed.

LED OFF

LED ON

510 20 143 3 2 ALL

W/O

WITH

CHAIN

SW1 SW2

Figure 4: LED Number Configuration Switches and PCB Silk

•W/O WITH switch – LED string chaining switch. For applications with output-voltage lower than 150V

this switch should be moved to W/O.

•5, 10, 20, 1, 4, 3, 3, 2 switches – LED number configuration switches.

For example:

•ALL switch – LED string short circuit switch. To short circuit entire string, move switch to LED OFF. To

release the short, move switch to LED ON.

4.2.1 Fault simulation using the LED Demo Panel

During normal system operation users can perform various fault conditions using the LED Demo panel

switches.

•Open string – By moving “W/O WITH” switch to WITH

•Short entire string – By moving “ALL” switch to LED OFF

•LED short – Users should choose LED number to be shorted and move suitable switch to LED OFF.