Mid-West Instrument 130 Series User manual

Mid-West

®

Instrument

Installation and Operating Instructions

-

Model

130

B

ulletin No: IM

130

/

18

Supersedes IM130/02

6 5 0 0 d o b r y d r s t e r l i n g h e i g h t s , m i 4 8 3 1 4

1. Safety

Before installing verify compatibility to the process

media and temperature in contact with the wetted

parts. Incompatible media and / or operation at

temperature extremes can cause premature

degradation of materials which could result in

safety risk to personnel.

Verify the selected pressure range (differential

pressure and working pressure) and the switch

ratings are within specification for your application.

arning! Remaining media may result in a

risk to personnel, environment etc. Use

sufficient precautionary measures when

removing and transporting the product.

1.1

Intended use: The indicating / non-indicating

differential pressure s itches are used for

monitoring differential pressures in industrial

applications. The manufacturer shall not be liable for

any claims if the product is used in applications

contrary to the intended use.

1.2

Personnel: Personnel installing and putting this

instrumentation into service shall be suitably trained

and qualified in accordance ith local codes,

practices and regulations.

PROD CT DESCRIPTION

The Model 130 is a differential pressure instrument

available as a s itch, gauge, or both. A flexible elastomer

diaphragm and calibrated range spring are moved by

differential pressure. A magnet, coupled ith the

diaphragm, transmits motion through the all of the

pressure housing to a follo er magnet attached to an

indicating pointer. The rotation of the follo er magnet

causes the pointer to track movement of internal driver

magnet and indicate differential on the dial scale.

When equipped ith s itches for Aluminum, Brass or

316SS bodies only, a contact is made or broken by the

magnetic field of the internal magnet. See Bulletin

ELECIM130/latest for gauges ith s itches.

The diaphragm is totally supported upon reaching full

travel in either direction, providing full over-range

protection to rated orking pressure.

INSPECTION

Before installation check the product label on each

instrument against the receiving paper ork and the

intended application for correct part number, materials

of construction, orking pressure, dial range, etc. If

equipped ith s itches, check electrical rating, type of

enclosure, etc. Inspect for shipping damage and, report it

immediately.

Installation and Operating Instructions

-

Model

130

Series

NOTE - Before attempting repairs contact your local

Mid-West Representative or our factory. Failure to do

so will void any warranty.

INSTALLATION

Model 130 is calibrated and tested prior to shipment and

is ready for immediate installation. Use of the follo ing

installation procedures should eliminate potential

damage and provide optimum trouble-free operation.

1. CONNECTIONS

Model 130 P is provided ith ¼” compression tube

fittings, one lo and one high, on the top and bottom of

gauge body.

Model 130 A, B, S, is provided ith dual ¼” FNPT

connections top and bottom as standard. One pair of

high and lo pressure ports is for process connections.

Ports are identified for high and lo pressure. Be sure to

plumb to proper connections and system. Improper

connection ill not damage instrument but it ill not

function properly.

Flexible tubing is recommended to minimize effect of any

vibration that may exist.

When attaching connections to the 130 P, care must be

taken to prevent over-tightening hich may result in

stripping threads and/or cracking ports. In order to

prevent this, use a suitable rench to hold the factory

supplied fitting in place hile tightening, sometimes

called “double renching”.

2. INSTR MENT LOCATION

It is recommended that installation is no closer than one

inch of a steel surface other ise accuracy ill be

affected. On liquid service, the instrument should be

mounted below the process connections to facilitate self

bleeding. On gas service, it should be located above the

process fluid. If the process contains particulates, a

“pigtail” loop or drop leg (manometer “U-tube”

configuration) in the tubing ill minimize the possibility

of it migrating into the instrument.

NOTE – On liquid applications, unequal liquid heads on

high or low side will result in an inaccurate differential

pressure indication.

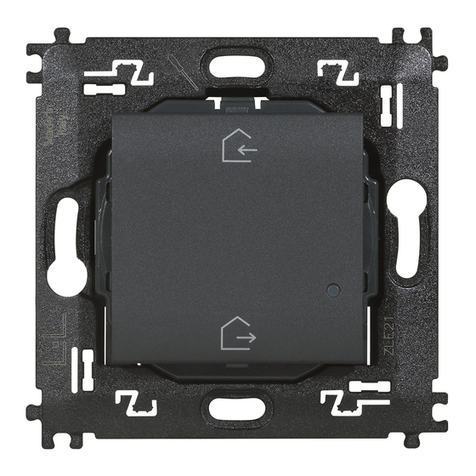

3. PANEL MO NTING

The Model 130 is designed for mounting through the

front of the instrument panel and is provided ith a

panel mount kit, consisting of four panel mounting

studs/nuts.

Make cutouts as indicated in figure sho n. Insert panel

mounting studs, finger tight, into metal inserts located in

the rear of the bezel.

Insert gauge through the panel, aligning panel mounting

studs ith holes in the panel. Install #8-32 nuts onto

studs and tighten securely.

4. PIPE MO NTING

If specified, your Model 130 ill have a pipe mount kit

installed. This provides for mounting on a 2” vertical or

horizontal pipe.

TRO BLE

SHOOTING

1. Gauge does not indicate differential

A. Check for proper hook up, high to “HI” and lo

to “LO”

B. Make certain block valves are open and, if using

a 3-valve manifold, that the equalizer (balance)

valve is closed.

C. If A & B check out correctly, loosen or

disconnect the high pressure line to determine if

there is pressure to the instrument.

D. If there is pressure to the instrument, check to

determine that there is differential across the

unit being monitored. If so, contact the factory

for assistance and/or an “RGA” (return goods

authorization) number to return the instrument

for repair or replacement.

4-1/2 in. DIAL PANEL CUT-OUT

MODEL 130 POLY