Completed by ________________________________ Date ________________________________

Miele

•

9

Independence

W

ay

•

Princeton,

NJ

08540

•

800-991-9380

•

F

ax

609-419-4241

•

[email protected]14. Programming the water hardness and acvate soener if necessary (connued)

A. Filling the salt reservoir

• Remove the bottom basket from the machine.

• Unscrew the salt reservoir cap.

Before lling the salt reservoir with reactivation salt for

the rst time, ll it with water till water spills out.

• Place the funnel provided in place (see illustration).

• Carefully ll the reservoir with 1 bag of ProCare Universal

61 salt. Displaced water will run out as it is being lled.

• Wipe any residual salt o the screw threads on the socket.

• Screw the cap on rmly.

• Immediately after this step: Run the “Rinse” program

to remove any traces of salt from the cabinet.

Note: There may be a delay before the “Rinse” program

starts due to the reactivation of the water softener.

B. Setting the water softener

• Turn o the machine with the “On/O” button.

• Turn the program selector to the “Stop” position.

• Press and hold the “Display” and “Start” buttons at the same time.

Simultaneously turn the machine on with the “On/O” button. The current program

status “P...” will appear in the display and the “Fill/Drain” indicator will illuminate.

• Press the “Drying” button once.“E01” (programming level 1) will appear in the display.

• Turn the program selector one switch position clockwise (1 o’clock position).

The number “19” will appear in the display (this indicates the factory water hardness

setting in gr/gal, equivalent to 340 ppm).

• Press the “Display” button as many times as necessary or hold it in until the

required value (hardness level in gr/gal) appears in the display. Once the number “60”

has been reached the counter will begin again at “0.

• Press the “Start” button. “SP” will appear in the display.

• Press the “Start” button again.

The setting will now be stored in memory. The display will go out. For future servicing, it is

useful to make a note of your water hardness level.

• Document the water hardness level here and on page 14 the operating manual:

__________ gr/gal or __________ ppm

Please reference page 14 of the operating manual for setting the water softener hardess.

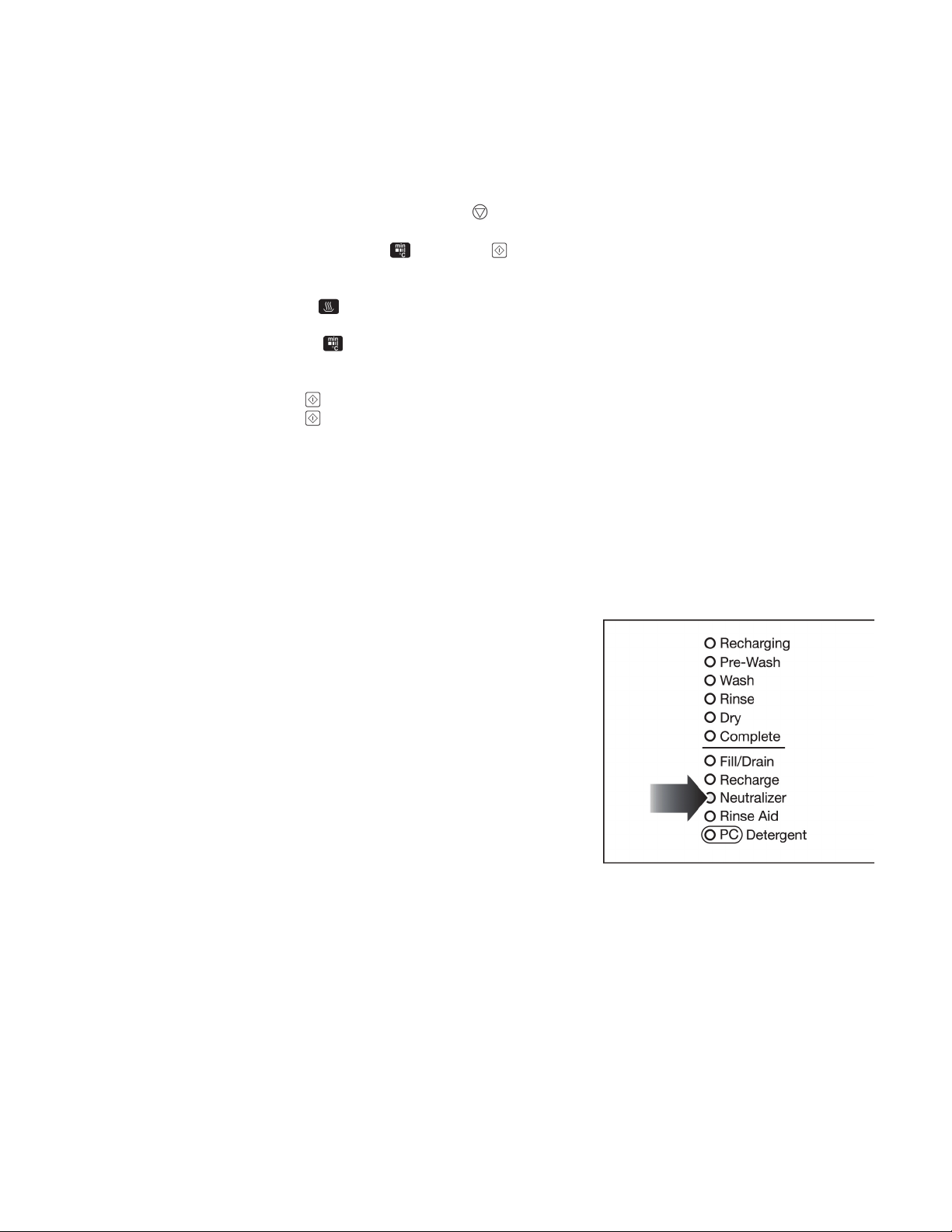

C. Salt Indicator (see illustration)

Reactivation takes place automatically during a program.

The “Recharging”indicator (#1 in illustration) illuminates.

When the salt reservoir is empty, the “Recharge”

indicator (#2 in illustration) illuminates to remind the end user

to ll the reservoir.