Technical Information

2

KM 34xx Gas Cookto

s

Table of Contents

AWarning and Safety Instructions ............................................................4

1General Information......................................................................................... 4

2Touch Current Measurement ..........................................................................4

3Gas..................................................................................................................5

BModification History.................................................................................5

CTechnical Data..........................................................................................6

DLayout of Electrical Components ...........................................................8

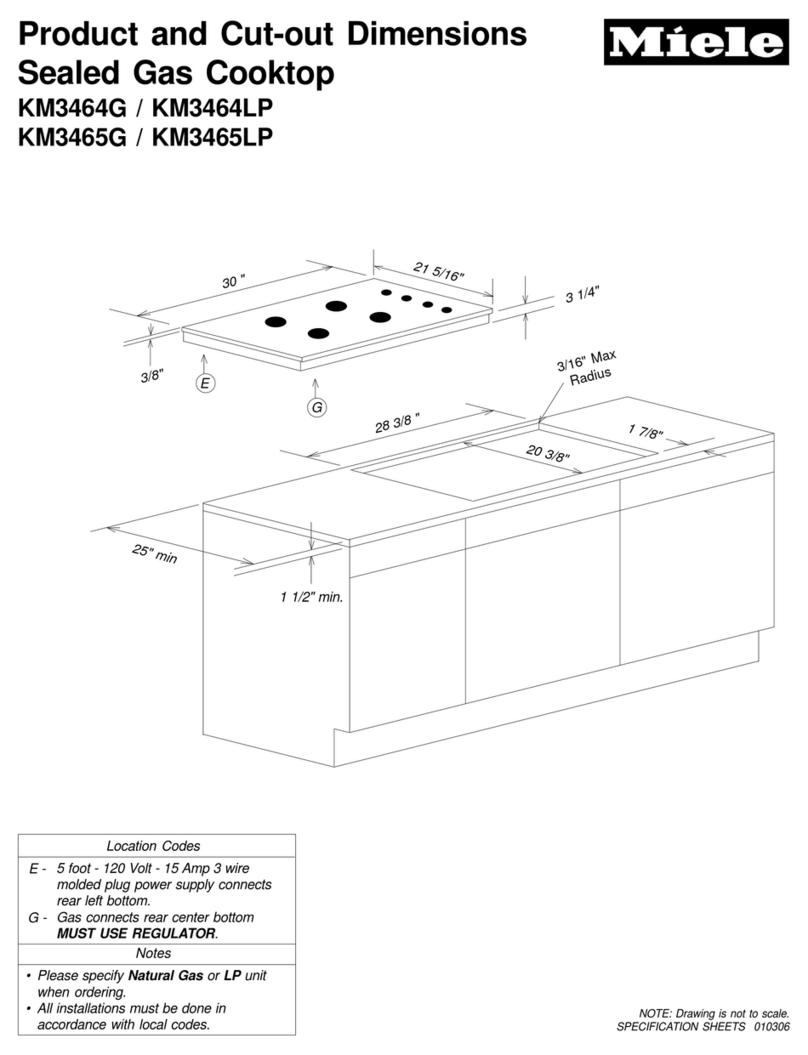

010Cooktop.....................................................................................................9

1Technical Data ..............................................................................................10

2Function.........................................................................................................10

2.1Rapid Ignition..................................................................................... 10

2.2Thermocouple....................................................................................10

2.3 Automatic Re-Ignition ........................................................................10

3Fault Repair................................................................................................... 11

3.1Flame Does Not Ignite.......................................................................11

3.2Burners Do Not Light .........................................................................11

3.3Burners Do Not Light - No Gas Supply..............................................11

3.4Flame Goes Out at the Minimum Setting...........................................11

3.5Burner Ignites Automatically During Use ...........................................12

4Service ..........................................................................................................13

4.1Cooktop Surface Removal.................................................................13

4.3Gas Type (Jet) Conversion................................................................14

4.4Main Jet Replacement.......................................................................15

4.5Thermocouple (Flame-Monitoring Electrode) Removal .....................17

4.5.1Normal/Fast Burners..............................................................17

4.5.2Wok Burners ..........................................................................17

4.6Ignition Electrode Removal................................................................18

4.6.1Normal/Fast Burners..............................................................18

4.6.2Wok Burners ..........................................................................18

4.7Burning Properties Test.....................................................................19

4.7.1Normal/Fast Burners..............................................................19

4.7.2Wok Burners ..........................................................................19

4.8 Thermocouple Test............................................................................20

4.9Automatic Re-Ignition Test ................................................................20

020Burner Tap..............................................................................................21

4Service ..........................................................................................................22

4.1Switch Removal.................................................................................22

4.2Simmer Adjustment Jet Replacement ...............................................22

4.3Solenoid Removal..............................................................................23

4.5 Electronics Removal ..........................................................................23

4.6Transformer Removal ........................................................................ 24

4.7Terminal Block Removal....................................................................24

4.8Leakage Test.....................................................................................25

4.9Solenoid Continuity Check.................................................................25