Mielta Fantom FLS-3304-11-10 Manual instruction

FUEL LEVEL SENSOR

Fantom

FLS –3304-11-10

FLS –3304-11-15

FLS –3304-11-20

FLS –3304-11-25

FLS –3304-11-30

Setup and operation Manual

Firmware version 1.3.36

Configuration program version 3.6

Document edition from 20.01.2022

Tambov 2022

MIELTA Fantom

2

CONTENTS

1. Description................................................................................................... 3

2. Specification................................................................................................. 3

2.1 Power supply........................................................................................ 4

2.2 Measurer part ......................................................................................4

2.3 Radio communication........................................................................... 4

2.4 Active protection.................................................................................. 5

3Installation and connection..........................................................................5

4Sensor setup................................................................................................. 8

4.1 Calibration............................................................................................ 9

4.2 Anti-aliasing.......................................................................................... 9

4.3 Measurement and transmission......................................................... 10

4.4 Data transmission format and power................................................. 11

5. Transportation and storage........................................................................ 11

6. Warranty condition .................................................................................... 11

7. Package Contents....................................................................................... 11

MIELTA Fantom

3

1. Description

Wireless Fuel level sensor (FLS) Fantom MIELTA is designed to measure the level

of light oil hydrocarbons (diesel, fuel, gasoline, kerosene and etc.) in various purposes

containers. Sensor can be installed both on stationary objects and on automobile and

railway transport.

Sensor uses the linear capacitor capacitance measuring method. The capacitance

value depends on sensor immersion level in the dielectric liquid.

The sensor is made in a strong plastic case with IP67 protection class, it has a steel

flange with holes for mounting. Sensor`s tube and electrode is made of stainless steel and

it has oil-resistant dielectric coating. Radio communication antenna is Bluetooth Low

Energy (BLE) and the battery is inbuilt.

2. Specification

CHART 1.

POWER SUPPLY

Battery Li-SOCL2

3.6 V, 2.7 А*h

MEASUREMENT PERIOD

from 1 to 10 sec

THE PERIOD OF SENDING DATA

from 1 to 10 sec

AVERAGING INTERVAL

from 1 to 60

RELATIVE MEASUREMENT ERROR

No more than 1%

DATA TRANSFER FORMAT

0 –Mielta

1 –analog №1

WIRELESS TRANSMITTER

Bluetooth Low Energy 5.0, 2.4 GHz

FREQUENCY RANGE

2400-2483,5 mHz

TRANSMITTER POWER

Adjustable, <11 dBm EIRP

TILT ANGLE MEASURER

Inbuilt accelerometer, +/- 1G

α°=arcsin(Z/127)

TEMPERATURE MEASURER

inbuilt, +/- 2°С

INBUILT MEMORY

4 Mb

WIRELESS SOFTWARE UPDATE AND

CONFIGURATION

YES

DEGREE OF PROTECTION

IP67

EXPLOSION PROTECTION MARKING

0ExiaIIBT6X

OPERATING TEMPERATURE

from - 40 to +85 °C

OPERATING PERIOD

7 years

THE LENGTH OF THE MEASURING PART

*990 (1490, 1990, 2490, 2990) mm

DIMENSIONS OF HOUSING

80х80х25 mm

MIELTA Fantom

4

DIMENSIONS OF SENSOR

80х80х1015 (1515, 2015, 2515, 3015)

mm

*When mounting sensors with a length of more than 990 mm on moving objects, additional fastening of the sensor tube is

required

Mielta hereby declares that the type of radio equipment the FANTOM fuel level

sensor complies with Directive 2014/53 / EU.

2.1 Power supply

FLS Fantom has a lithium-thionyl chloride battery, a voltage of 3.6 V and a nominal

capacity of 2.7 А*h., which is designed for the entire service life in accordance with the

manufacturer's recommendations for setting the frequency of measurement and sending data.

After a malfunction, the battery can be replaced in the Mielta production laboratory, for this

you need to contact the technical support service.

The sensor detects its position in real time and when it deviates from the vertical by an

angle of more than 60 degrees, the power saving mode will be activated. The FLS switches

off the measuring device and continues sending the last recorded value, while still being able

to connect and configure. Therefore, the sensor can be stored in the warehouse in a horizontal

position. In this case, the power consumption is reduced to 30% from the rated one. The

sensor operation is guaranteed in the battery voltage range from 3.0V to 3.6V.

2.2 Measurer part

FLS Fantom is equipped with a unique integrated measuring device that converts the

capacity of a linear sensor element into a digital value used in fuel level calculations. A

essentially different method of measuring capacitance from the competitors allows you to

make measurements with high resolution and stability.

It has been implemented a new algorithm for self-diagnosis in emergency. If the

measurement range specified during calibration is exceeded with error code, the sensor shows

the deviation amount. Analysis of the error value may indicate the cause of the fault: incorrect

calibration, changes in fuel quality, or water and dirt is in the fuel.

2.3 Radio communication

The sensor is equipped with a modern integrated Bluetooth 5.0 Low Energy radio

transmitter and a built-in high-performance antenna, which allows providing high-quality

radio communication with minimal power consumption.

The parameters measured by the sensor are transmitted in a BLE standard broadcast

packet (chart 2).

MIELTA Fantom

5

CHART 2.

Parameter

Valid values

Description

Level

from 0 to 10000

The value of the fuel level.

The range is configurable, by default 30 - 4095

2xххх

Error, level is below the minimum, where xxxx is value of the

level decrease as a percentage of the operating range

3xххх

Error, level is above the maximum, where xxxx is the value of

exceeding the level as a percentage of the operating range

40000

No Calibration (required a calibration)

Temperature

from -50 to

+100

Temperature of the housing FLS, °С

-127

Error, temperature below -50 °С

+127

Error, temperature above +100 °С

Battery voltage

from 10 to 40

Battery voltage in volts, multiplied by 10

0

Error, voltage is below 1.0 V

255

Error, voltage is above 4.0 V

Acceleration

along the

longitudinal axis

of the sensor

from -127 to

+127

The angle of inclination of the sensor relative to the horizontal

position is calculated by the formula α°=arcsin(Z/127).

The value of the parameter: 0 –horizontal position;

+127 –vertical position, housing is up;

-127 –vertical position, housing is down;

To monitor and change the sensor settings, its calibration and taring, you must use any

mobile device with Bluetooth version 4.2 or later, as well as the program-Configurator for

mobile devices Mielta Device Manager (Mielta DM) for the relevant operating system

(Android, iOS). The program is available for free in the Google Play and App Store.

2.4 Active protection

Fantom has a built-in sensor that can detect attempts to cover it with any conductive

material (metal) in order to destabilize or disrupt data transmission over the radio channel.

The sensor will analyze data, will store in memory and will transmit this data into the terminal

via a special Protocol.

Even if the user succeeded in blocking radio communication for some time, data on

the fact of sabotage will be transmitted immediately as soon as the connection is resumed.

3Installation and connection

The sensor is mounted at the top of the fuel tank and opposite to the lowest point of

the bottom of the tank. Preference is given to an layout that provides minimal overlaps of the

space around the sensor housing with metal structures and has open access to the surrounding

space. Around its axis, the sensor must be oriented in such a way that the priority direction of

the antenna radiation (Pic. 1) is directed as much as possible in the maximum opposite

direction to the metallic construction.

MIELTA Fantom

6

Picture 1. The installation dimensions of the FLS.

Picture 2. Sensor connecting dimension.

The surface for mounting the sensor must be horizontal and selected with regard to the

availability and ease of installation. The central hole has a Ø20 mm. diameter (Pic. 2). The

mounting holes diameter is chosen based on the material of the fuel tank and the attachment

method. It is used self-tapping screws to fix the sensor. When mounted on a metal tank, 4

holes with a diameter of 4-4.5 mm are drilled or screws with a drill are used. When mounted

in a plastic tank, 4 holes with a diameter of 3 mm are drilled and self-tapping screws without

a drill are used.

Priority direction of radiation of

the antenna

MIELTA Fantom

7

Mounting procedure:

1. Select a location for installation, clean it of contamination.

2. Mark the holes according to the template, drill and remove the sawdust.

3. Measure the depth of the fuel tank from the bottom to the mounting surface.

4. Measure the sensor length from the mounting flange 20 mm shorter than the

measured depth of the fuel tank.

5. Saw off the tube and the central electrode, deburr, insert the insulator into the end

of the measuring tube.

6. Calibrate the sensor FLS.

7. Clean and degrease the mounting surface of the fuel tank. Apply a sealant to the

surface, glue the rubber seal. Apply the sealant to the gasket and install the sensor.

8. Secure the sensor with screws.

9. Seal the mounting screws with a wire seal.

If necessary, to bypass obstacles in fuel tanks with complex shape, the measuring tube

of the sensor can be bent. Bending is performed using specialized pipe benders with a bend

radius of at least 250 mm. The bend angle should not exceed 15 degrees (Pic. 3).

Bending sensor tube procedure:

1. Calculate the location of the fold, mark it on

the sensor tube;

2. Place the sensor tube in the pipe bender with

the label in the middle;

3. Open the FLS connection in the mobile APP

Configurator and monitor the value Level

row;

4. Bend the tube until the required angle is

reached, preventing the closure of the central

electrode and tube.

5. If there is an electrical short circuit of the

central electrode and tube, it is necessary to

reduce the angle of the bend by applying force

to the folding position on the reverse side,

until the guaranteed isolation of the electrode

from the tube is achieved.

6. Saw the measuring tube to the required

length.

7. Calibrate, install and do taring the sensor.

If necessary, the sensor tube can be bent in

two or more places to give it a complex shape.

Please, note that the bent measuring tube loses its symmetry and linearity, which

directly affects the values of the sensor. A bent sensor without taring can have non-linear

Picture 3. Sensor tube bending.

MIELTA Fantom

8

distortions in the readings at different levels. During taring of the sensor, it is recommended

to do more number of measuring points (30-50 points per meter) to compensate nonlinearity.

4Sensor setup

To configure the sensor, use The Mielta Device Manager Configurator program, it is

available for free in the Google Play and App Store app stores. For full operation, you must

confirm all the permissions requested by the program.

After installing and running the program, the "Connection" tab will show a search for

BLE devices (Pic. 4). Swipe down activates the next search. Found a FLS Fantom device in

the list will have a name, it contains the prefix "MD" and last 4 digital serial number of the

sensor. When you select one sensor from the list, the parameters window will be open (Pic.5)

which will show all the data transmitted by the sensor in common mode with a specified

interval.

To configure the sensor, you must activate the two-way connection. In this mode, the

sensor will show an expanded list of parameters in real time (Pic. 6).

The value of fuel level is set to the value 2048, if there is no calibration parameters, a

calibration must be made.

There is a data reception indicator “Link” in the upper right corner of the window.

When the data packet comes from the sensor, the indicator flashes green every time. When

the sensor is in the “Connection” mode, the data transmits faster and the indicator lights up

constantly.

Picture 4. Search window.

Picture 5. Parameters window

Picture 6. Connecting

MIELTA Fantom

9

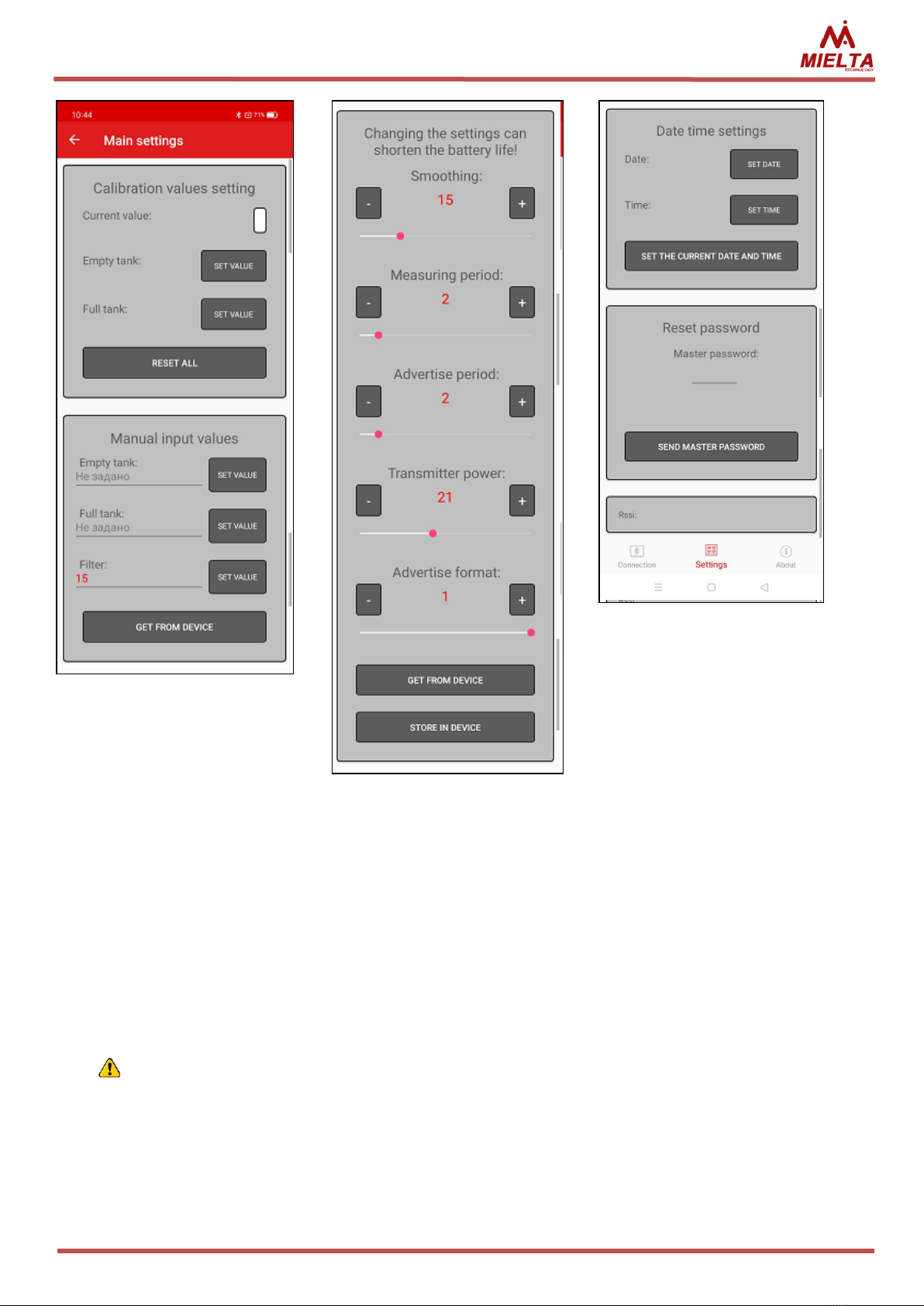

“Settings” tab shows list of settings (Pic. 7).

The Main settings include calibration of the fuel level sensor, parameters os the sensor

and settings of the date and time.

4.1 Calibration

The “empty tank” and “full tank” calibration values

set the measurement range in conventional units which

measures within the specified range of output values.

Calibration must be done after cutting the measuring tube

to the required depth and installing the insulator-plug.

First step is the "full tank" calibration. It must be

performed by dipping the sensor into the fuel tank till to

the level of the drain hole. After the current value from the

sensor is stabilized, you can write this value into

parameters. (Pic. 8).

The second step is the "empty tank" calibration. For

this, remove the FLS from the fuel and let the remaining

fuel flow out of the tube for 5 minutes. After stabilization,

you can write the value from the sensor for the empty tank

in the relevant parameter.

If you do first "empty tank" calibration,

without wetting the sensor (before “full tank”

calibration), it will cause the operating range to

be set incorrectly.

If necessary, the calibration values can be written manually in the relevant section of

the window (Pic. 8)

4.2 Anti-aliasing

The sensor has “anti-aliasing” parameter, to reduce fluctuations in the level value. This

parameter sets the number of recent measurements value and calculate the average value.

(Pic. 8). The parameter has a range of acceptable values from 1 to 60. The value 12 is set by

default. This parameter may have a value of more than 30 for some types of equipment or

tanks without partitions.

Picture 7. Settings list

MIELTA Fantom

10

4.3 Measurement and transmission

The values of the measurement period and the transmission period (advertising)

directly affect the speed of the sensor's response to changes in the level and its power

consumption. These parameters should be in the range from 1 to 10.

By default, the following values are set: the measurement period is 5 seconds, and the

transmission period is 2 seconds. These values are used in calculating the guaranteed period

of operation on a single battery.

Changing the parameters, the frequency of measurement and transmission to

less multiplies the consumption and reduces the life of the sensor. The

manufacturer does not guarantee the service life in case of changes of these

parameters.

Picture 8. Main settings

MIELTA Fantom

11

4.4 Data transmission format and power

The transmitter power parameter can be in the range from 0 to 49. The default value is

24. Increasing the power of the transmitter in some situations can improve the quality of

signal. However, the location of the FLS and receiving tracker and shielding metallic

constructions has a much bigger effect to the quality of the signal.

An increased transmission power also leads to increased power consumption.

FLS Fantom supports two formats:

Option 0 (by default) –format Mielta;

Option 1 - similar sensor from other manufacturers.

5. Transportation and storage

The fuel level sensor should be stored in warehouse conditions at a temperature of

20°C to + 50°C аnd a relative humidity of not more than 85°C. Contact with conductive dust,

water and technical liquids is eliminated. Sensor is transported in the original packing, by any

kind of transport.

6. Warranty condition

The manufacturer guarantees the operation of the fuel level sensor within 3 years from

the date of sale, in case that the consumer complies with the conditions and rules of

transportation, storage, installation and operation. The average service life is 7 years.

Warranty does not apply:

- for the sensors with mechanical damages and defects (cracks, chips, dents, traces of

impacts, thermal, electrical and chemical effects) caused by the fault of the consumer or third

parties due to violation of operating, storage or transportation conditions;

- for the sensors with traces of repair outside the manufacturer's service center;

- for the sensors which failed due to incorrect software update.

7. Package Contents

Name

Quantity

FLS Mielta Fantom (FLS-3304-11)

1

Mounting kit:

- gasket

- insulator-plug

- self tapping screw

- self-tapping screw for sealing

- seal

- wire for sealing

1

1

2

2

1

1

Passport

1

Packaging

1

MIELTATECH.COM

sales@mielta.ru

This manual suits for next models

4

Table of contents

Other Mielta Accessories manuals